自動化產品(繁體中文)

–

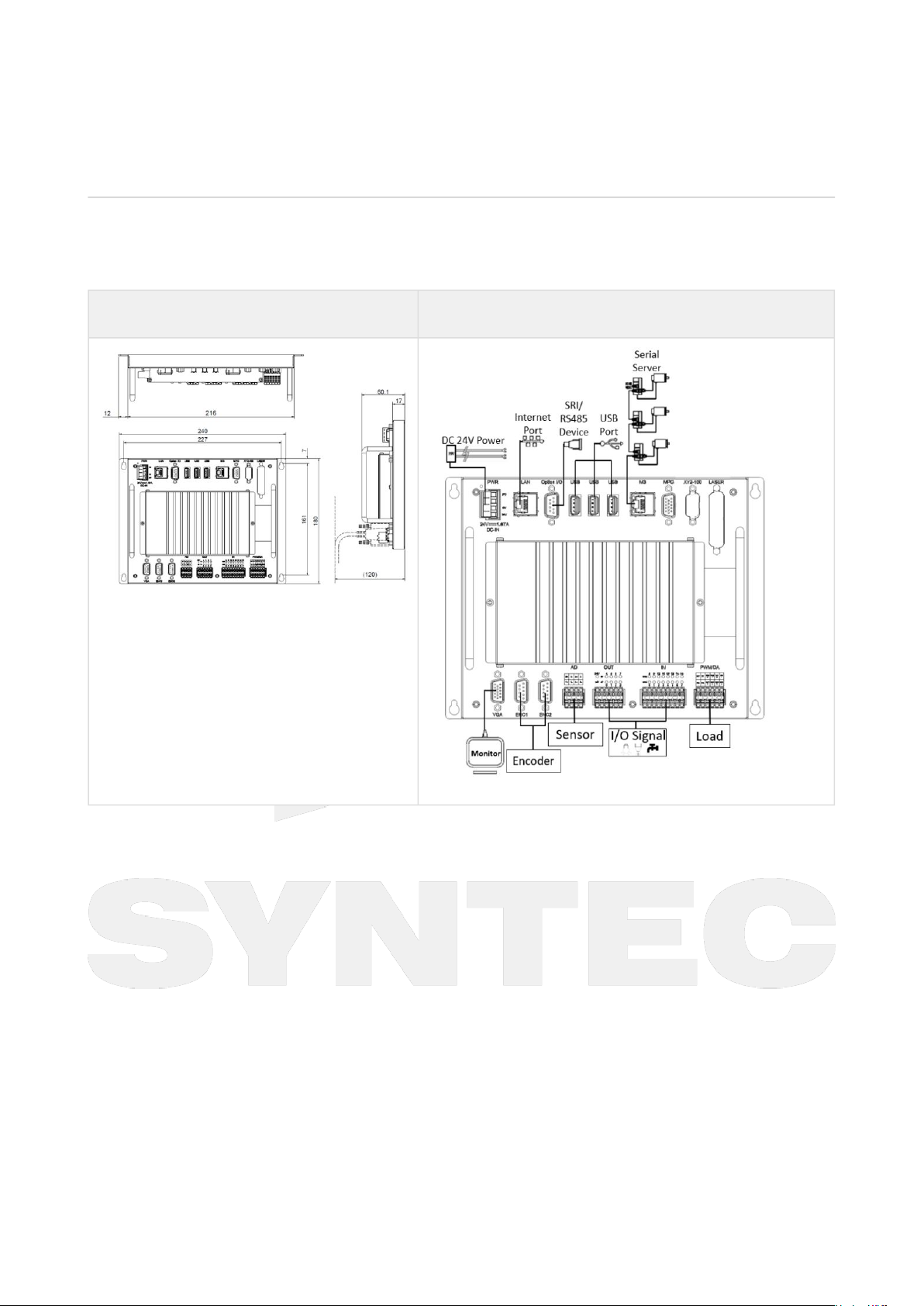

720CA Laser Cutting Machine Assembly Manual - Pulse Driver

Basic Machine Configuration–4

2 Basic Machine Configuration

The laser cutting system includes a controller, laser source, keyboard and mouse interface. This manual will guide

users through the installation process, starting with the mechanical setup, step by step.

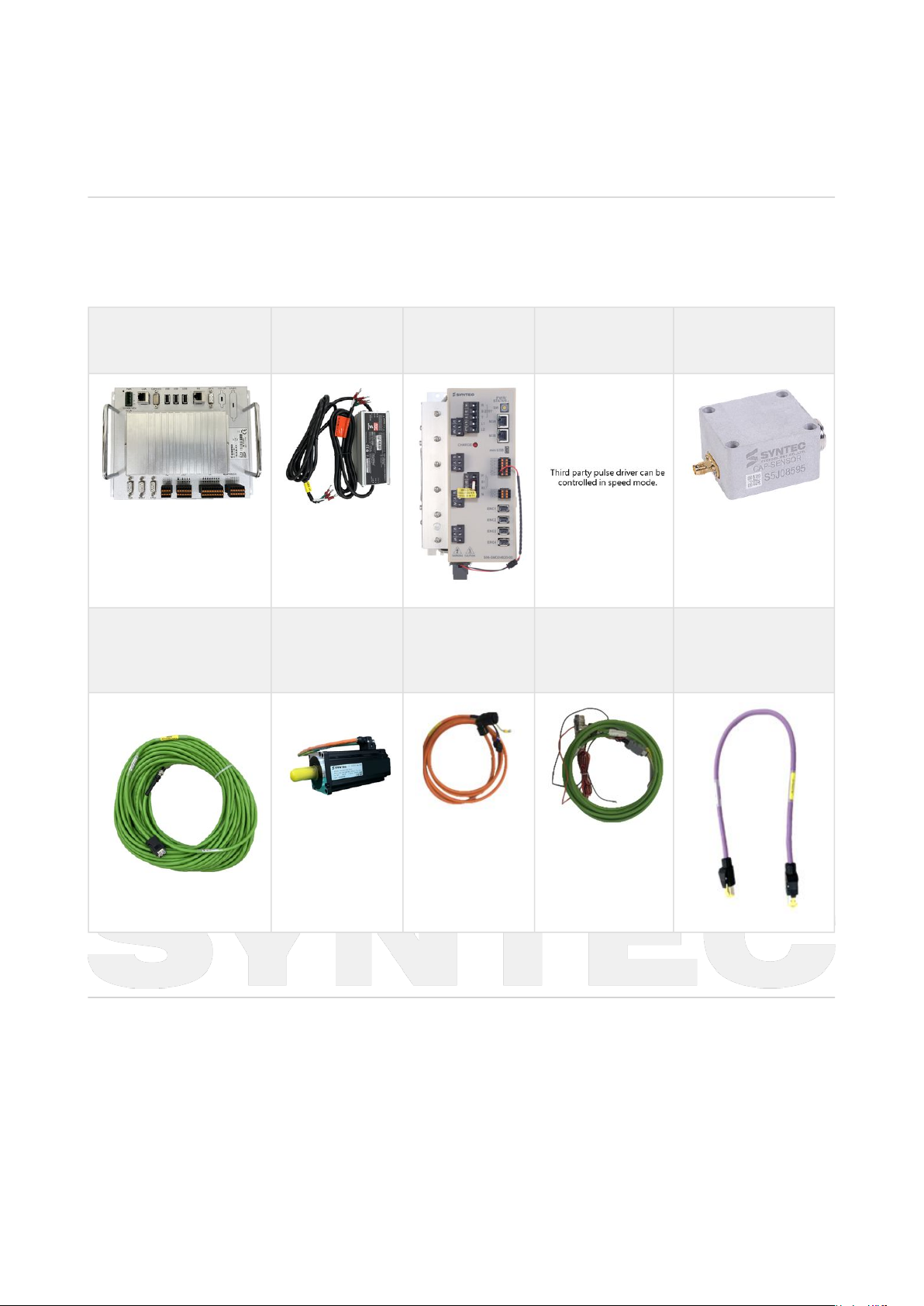

2.1 Hardware Introduction

720CA Controller 24V Power

Adapter

Serial Driver Pulse Driver Capacitive Sensor

Amplifier Module

Capacitive Sensor

Amplifier Module

Communication Cable

Motor Motor Power

Cable

Motor Encoder

Cable

M3 Communication

Cable

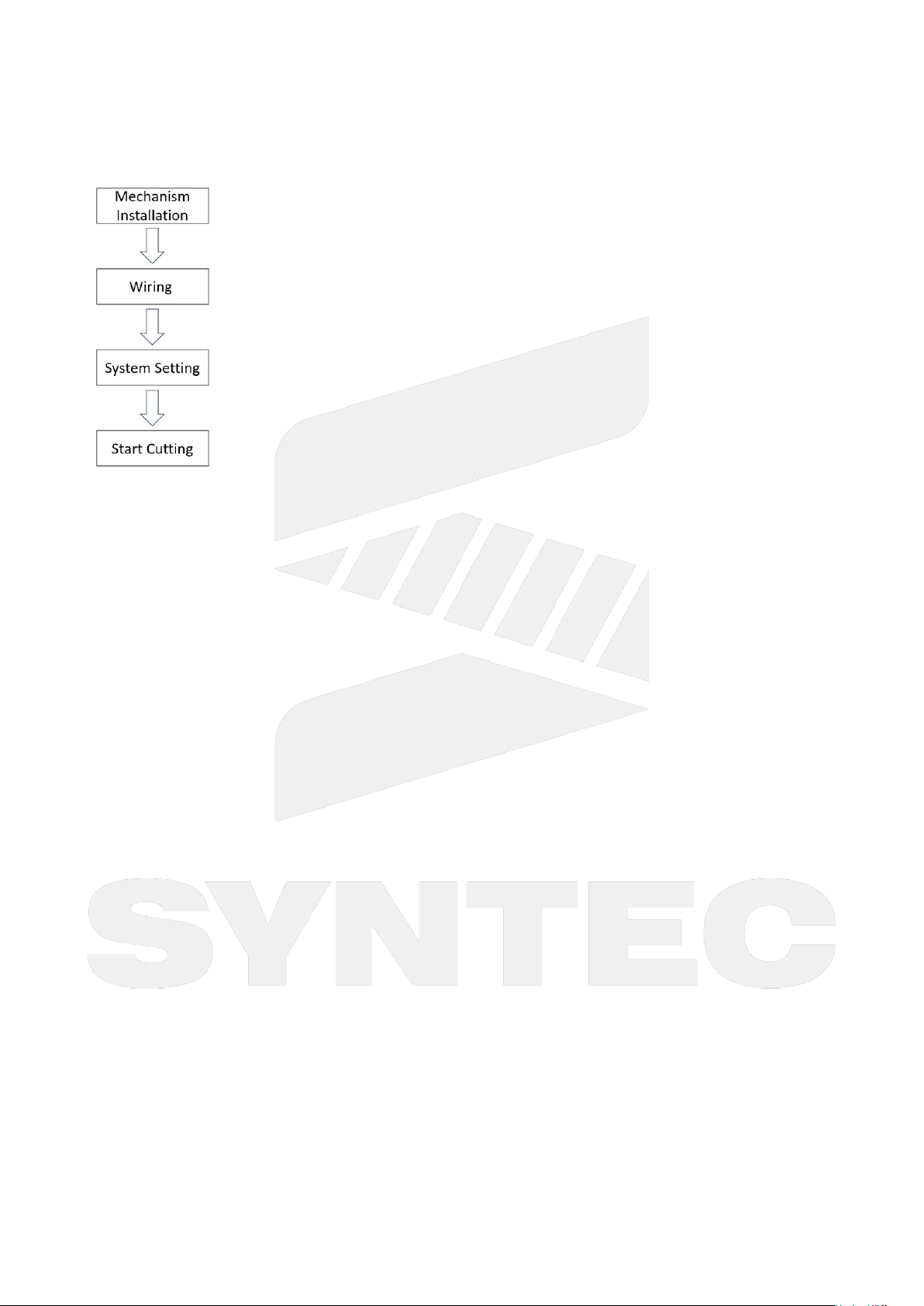

2.2 Installation Process

Mechanical Installation: Complete the installation of the mechanics, including motors, drivers, controller, and

laser source.

Wiring: Connect the wiring between the motors, drivers, controller, and laser source. Once this step is completed,

you can power up the system.

System Setting: This step involves software operations, including parameter settings, I/O configurations. Once the

system is configured, you will be able to precisely control the laser cutting controller.