INDEX

USE OF THE MANUAL.......................................................................................................................1

TERMINOLOGY .................................................................................................................................2

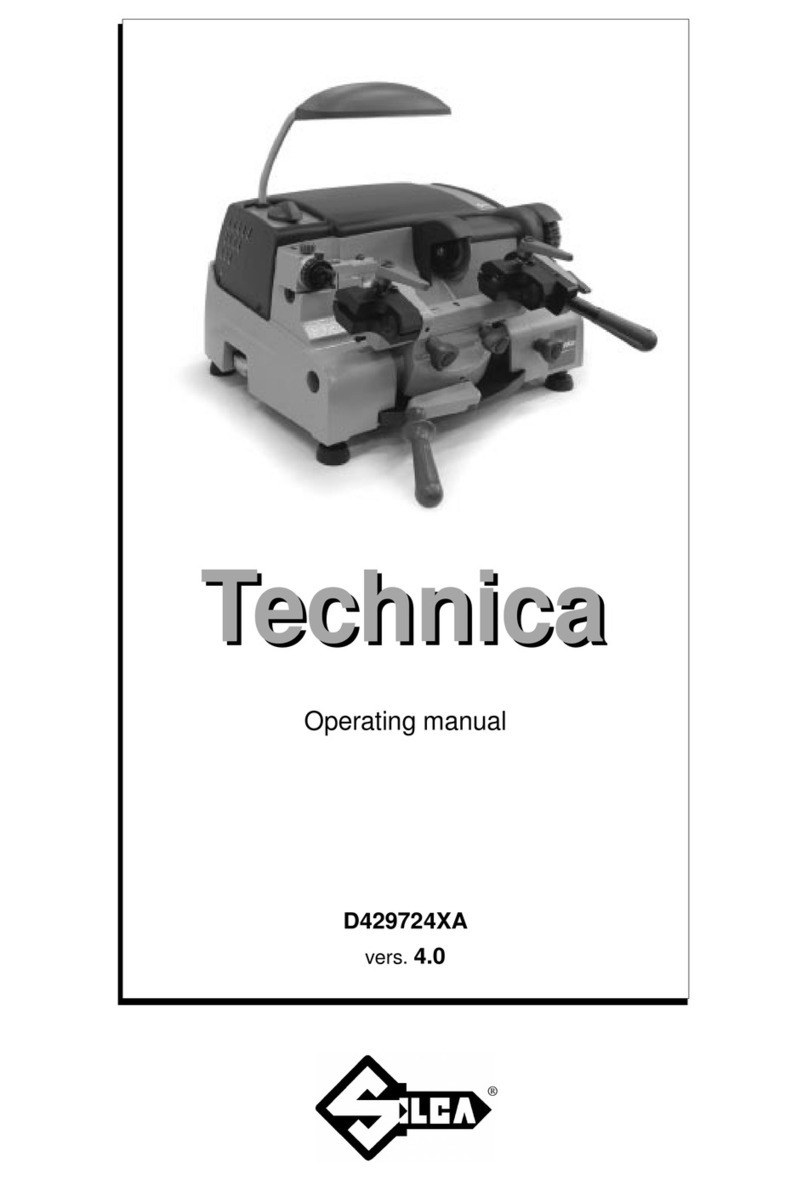

1 MACHINE DESCRIPTION....................................................................................................................5

1.1 WORKING PARTS......................................................................................................................6

1.2 ACCESSORIES PROVIDED .....................................................................................................7

1.3 TECHNICAL DATA .....................................................................................................................7

1.4 ELECTRIC DIAGRAM............................................................................................................8

2 HANDLING...........................................................................................................................................9

2.1 PACKING....................................................................................................................................9

2.2 TRANSPORT..............................................................................................................................9

2.3 UNPACKING...............................................................................................................................9

2.4 HANDLING THE MACHINE........................................................................................................9

3 MACHINE INSTALLATIONAND PREPARATION ..............................................................................10

3.1 CHECKING FOR DAMAGE......................................................................................................10

3.2 ENVIRONMENTAL CONDITIONS............................................................................................10

3.3 POSITIONING ..........................................................................................................................10

3.4 SAFETY DEVICES...................................................................................................................10

3.5 WORK STATION DESCRIPTION.............................................................................................11

3.6 STARTING THE KEY-CUTTING MACHINE.............................................................................12

3.6.1 STARTING THE MOTOR .....................................................................................................12

3.6.2 CUTTER MOTOR ON WARNING LIGHT.............................................................................12

3.6.3 LED LAMP ...........................................................................................................................12

4 MACHINE CALIBRATION AND REGULATION..................................................................................13

4.1 FITTING AND REMOVING TOOLS..........................................................................................13

4.2 MICROMETER GAUGE ...........................................................................................................14

4.3 CALIBRATION / TOOLALIGNMENT........................................................................................15

4.4 TRACER POINT SPRING........................................................................................................16

4.5 CLAMPS ..................................................................................................................................17

5 CUTTING............................................................................................................................................18

5.1 FITTING KEYS .........................................................................................................................18

5.2 KEY STOP................................................................................................................................18

5.3 CUTTING DIMPLE KEYS.........................................................................................................19

5.3.1 BACK CUTS.........................................................................................................................19

5.4 CUTTING LASER TYPE KEYS................................................................................................20

5.5 CUTTING LASER KEYS WITH NARROW STEMS (MERCEDES) .........................................21

5.6 CUTTING FICHET TYPE KEYS (H PROFILE) WITH OPTIONALADAPTER “F”....................21

6 MAINTENANCE..................................................................................................................................22

6.1 TIGHTENING AND REPLACING THE BELT............................................................................22

6.2 REMOVING THE UPPER FRONT UNIT..................................................................................23

6.3 REPLACING THE ROLLBAR...................................................................................................23

6.4 REPLACING THE TRANSPARENT SAFETY SHIELD.............................................................24