10 ENGLISH

ENGLISH (Original instructions)

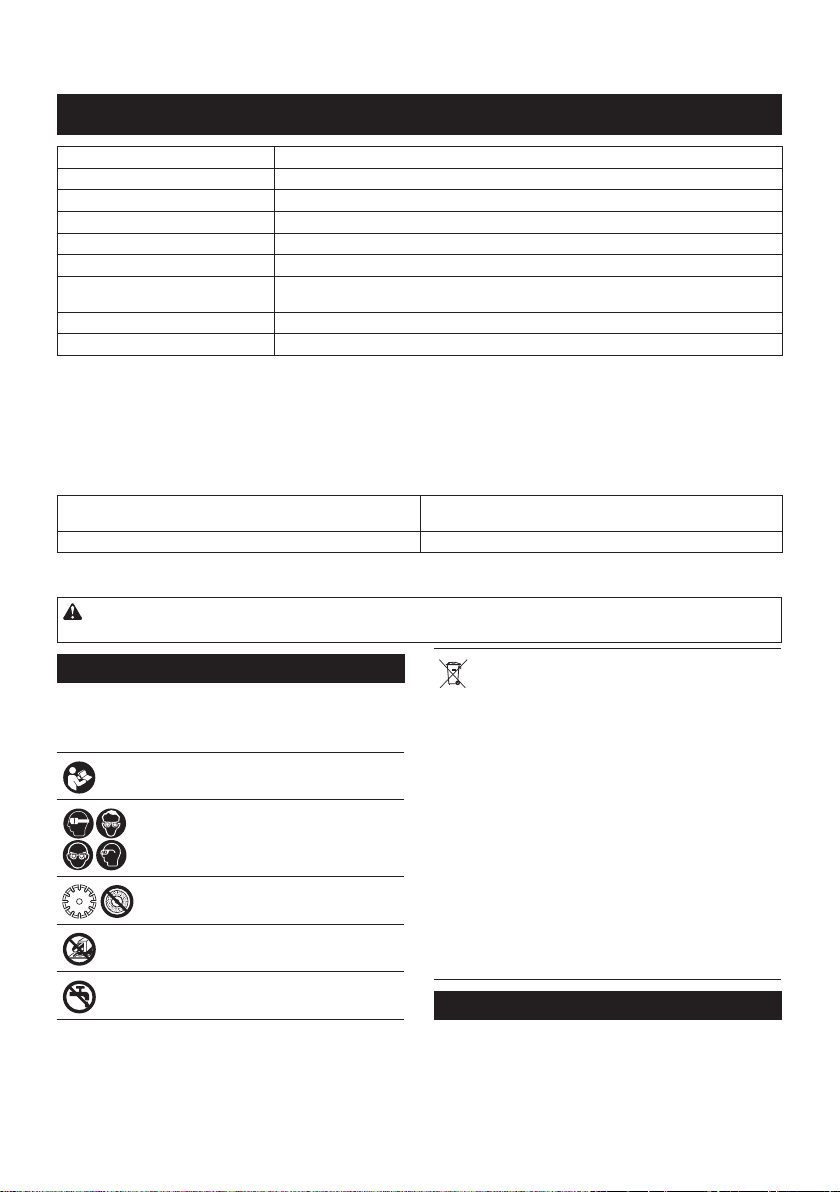

SPECIFICATIONS

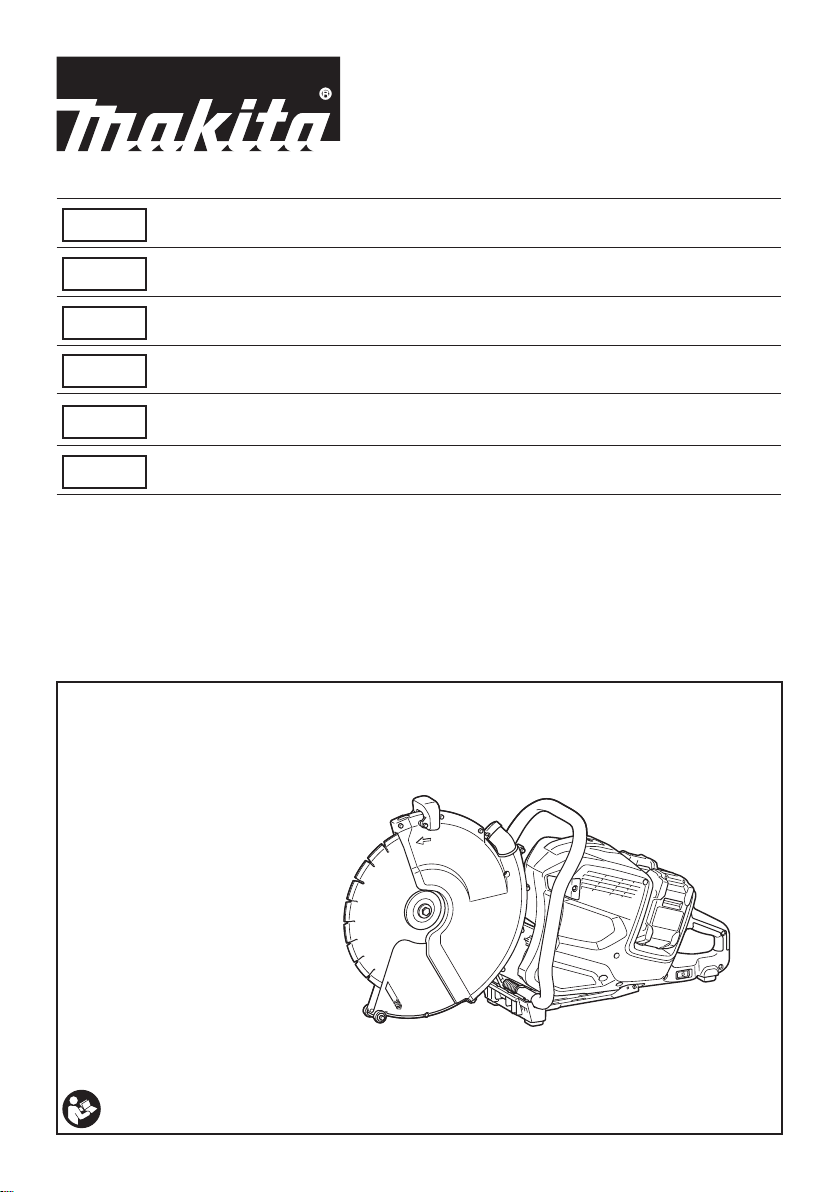

Model: CE002G

Wheel diameter 350 - 355 mm

Max. wheel thickness 4.0 mm

Max. cutting depth 127 mm

Rated speed 4,200 min-1

Rated voltage D.C. 72 V - 80 V max

Recommended air volume of the

vacuum cleaner

Equal to or more than 1.8 m3/min

Overall length 825 mm

Net weight 13.1 - 15.1 kg

• Duetoourcontinuingprogramofresearchanddevelopment,thespecicationshereinaresubjecttochange

without notice.

• Specicationsmaydierfromcountrytocountry.

• Theweightmaydierdependingontheattachment(s),includingthebatterycartridge.Thelightestandheavi-

estcombinations,accordingtoEPTA-Procedure01/2014,areshowninthetable.

Applicable battery cartridge and charger

Batterycartridge BL4040 / BL4050F* / BL4080F*

*:Recommendedbattery

Charger DC40RA/DC40RB/DC40RC

• Someofthebatterycartridgesandchargerslistedabovemaynotbeavailabledependingonyourregionof

residence.

WARNING: Only use the battery cartridges and chargers listed above.Useofanyotherbatterycartridges

andchargersmaycauseinjuryand/orre.

Symbols

Thefollowingsshowthesymbolswhichmaybeused

fortheequipment.Besurethatyouunderstandtheir

meaningbeforeuse.

Read instruction manual.

Wearsafetyglasses.

Donotuseabrasivecut-owheel.

Onlydiamondwheelisapplicable.

Do not cut metal.

Do not feed water.

Li-ion

OnlyforEUcountries

Due to the presence of hazardous com-

ponents in the equipment, waste electrical

and electronic equipment, accumulators

andbatteriesmayhaveanegativeimpact

on the environment and human health.

Do not dispose of electrical and electronic

appliancesorbatterieswithhousehold

waste!

In accordance with the European Directive

on waste electrical and electronic equip-

mentandonaccumulatorsandbatteries

andwasteaccumulatorsandbatteries,

as well as their adaptation to national law,

wasteelectricalequipment,batteriesand

accumulatorsshouldbestoredseparately

and delivered to a separate collection point

for municipal waste, operating in accor-

dance with the regulations on environmen-

tal protection.

Thisisindicatedbythesymbolofthe

crossed-outwheeledbinplacedonthe

equipment.

Intended use

Thetoolisintendedforcuttinginmasonrymaterials

with a diamond wheel.