Blue Diamond 91566-99427 User manual

Operation and Maintenance Manual

Multi-Purpose Cutter

888-376-7027 | BlueDiamondAttachments.com

Register your

WARRANTY

within 30 days

of purchase

91566 – 99427

Blue Diamond® Attachments2

Thank you for your decision to purchase a Blue Di-

amond® Multi-Purpose Cutter. To ensure maximum

performance of your equipment, it is mandatory that you

thoroughly study the Operator’s manual and follow the

recommendations. Proper operation and maintenance

are essential to maximize equipment life and prevent

personal injury.

Operate and maintain this equipment in a safe man-

ner and in accordance with all applicable local, state,

and federal codes, regulations and /or laws. Follow all

on-product labeling and instructions.

Make sure that all personnel have read this Operator’s

Manual and thoroughly understand safe and correct

operating, installation and maintenance procedures.

Blue Diamond is continually working to improve its

products. Blue Diamond reserves the right to make any

improvements or changes as deemed practical and pos-

sible without incurring any responsibility or obligation

to make any changes or additions to equipment sold

previously.

Although great care has been taken to ensure the

accuracy of this publication, Blue Diamond makes no

warranty or guarantee of any kind, written or expressed,

implied or otherwise with regard to the information

contained within this manual. Blue Diamond assumes

no responsibility for any errors that may appear in this

manual and shall not be liable under any circumstances

for incidental, consequential or punitive damages in con-

nection with, or arising from the use of this manual.

Keep this manual available for frequent reference. All

new operators or owners must review the manual before

using the equipment and annually thereafter. Contact

your Blue Diamond Attachments Dealer for assistance,

information, or additional copies of the manual. Contact

www.bluediamondattachments.com or call 888-376-

7027 for a complete list of dealers in your area.

Serial Number Location:

Please record attachment information in the space pro-

vided for future reference.

Model Number:_____________________________

Serial Number: _____________________________

Dealer Name: ______________________________

Dealer Number:_____________________________

Date of Purchase:___________________________

The serial number plate is located on the left side, just

forward of the attachment mounting plate.

Always use your serial number when requesting infor-

mation or when ordering parts.

NOTE: The directions left, right, front and rear, as

mentioned throughout this manual, are as viewed from

the operator’s position.

Introduction: Owner Information

Revision Date: 07.19.2023

3Blue Diamond® Attachments

Table of Contents

1. Introduction..................................................................................4-6

1.1 General Safety Information......................................................4

1.2 Qualified Operators................................................................. 5

1.3 Attachment Information.......................................................... 6

2. Safety ...........................................................................................7-9

2.1 General Safety Information.....................................................7

2.2 Qualified Operators................................................................ 8

3. Operation .................................................................................10-19

3.1 Work Area Safety ....................................................................10

3.2 Tractor Requirements............................................................10

3.3 Attachment Installation..........................................................11

3.4 Operation................................................................................. 17

3.5 Right of Way or Roadway Mowing ..................................... 18

3.6 Transporting Safety ...............................................................18

3.7 Storage .....................................................................................19

4. Maintenance ..........................................................................20-22

4.1 Maintenance Safety...............................................................20

4.2 Greasing..................................................................................20

4.3 Blade Servicing......................................................................20

4.4 Service Schedule ..................................................................22

5. Parts.........................................................................................23-32

5.1 Main Frame Components – 44” Deck............................... 23

5.2 Main Frame Components – 32” Deck..............................25

5.3 Motor Assembly ....................................................................26

5.4 Safety Decals.........................................................................30

6. Warranty ....................................................................................... 33

Blue Diamond® Attachments4

1.1 General Safety Information

Blue Diamond® Attachments cannot anticipate

every possible circumstance that might involve

a potential hazard. The warnings in this manual

and on the unit are, therefore, not all-inclusive. If

a method of assembly, operation, or maintenance

not specifically recommended by us is used, you

must satisfy yourself that it is safe for you and for

others. You should also ensure that the unit will not

be damaged or be made unsafe by the methods

that you choose.

The information, specifications, and illustrations in

this manual are based on the information that was

available at the time this material was written and

can change at any time without notice.

• Read and follow instructions in this manual

and the machine’s Operators Manual before

operating.

• The manual must always remain with the

machine and be available for operators. In case

of loss or damage, request a new copy from

your dealer or from Blue Diamond.

• Strictly follow all rules prescribed by the safety

pictograms/decals applied to the machine.

Ensure that all safety pictograms/decals are

legible. If pictograms/decals are worn, they

must be replaced with new ones obtained

from Blue Diamond and placed in the position

indicated by this manual.

1. Introduction

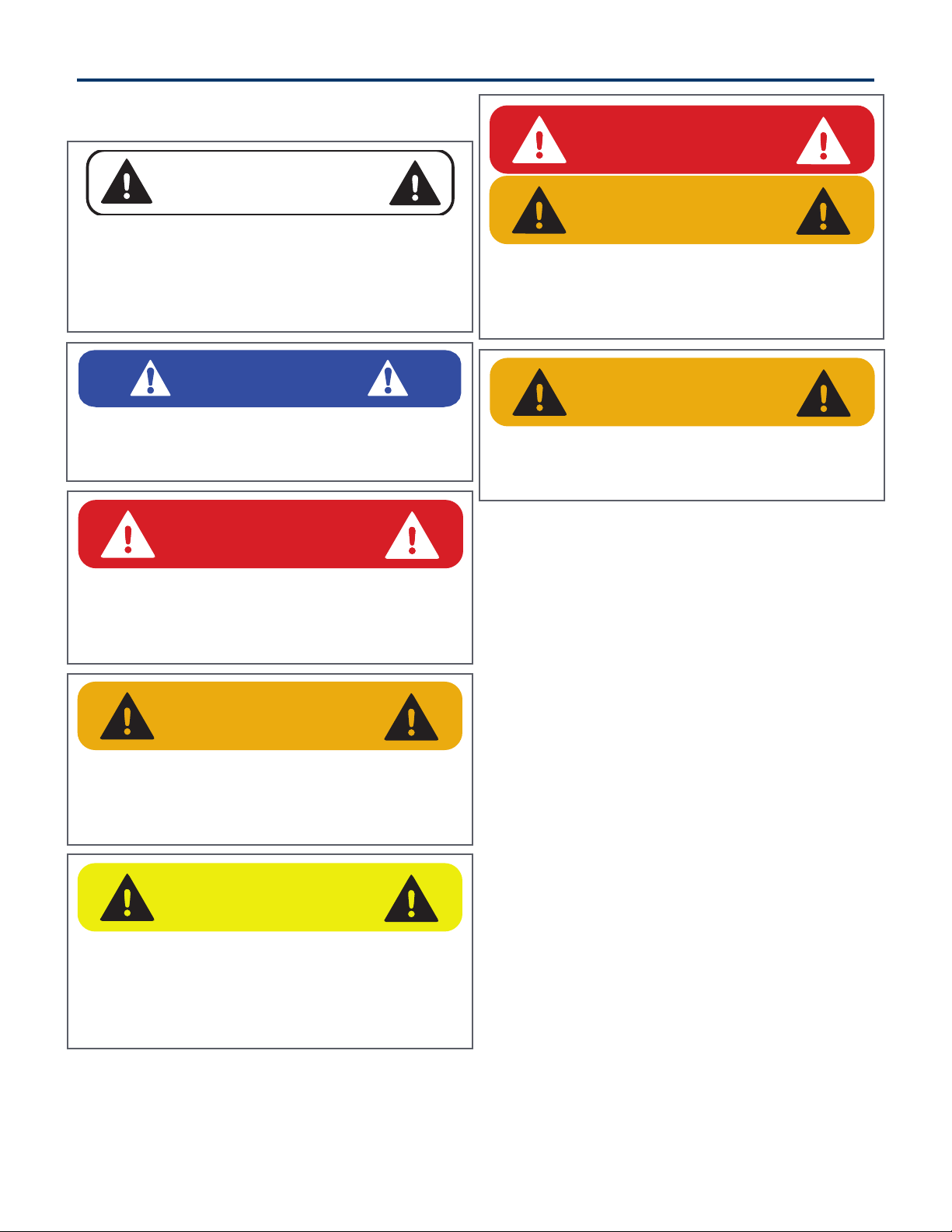

DANGER

Failure to comply with the following safety

instructions can and will result in serious injury and

possibly even death if they are not understood and

followed.

WARNING

CAUTION

The signal word CAUTION on the machine and

in the manuals indicates a potentially hazardous

situation which, if not avoided, may result in minor

or moderate injury. It may also be used to alert

against unsafe practices.

WARNING

The signal word WARNING on the machine and

in the manuals indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

DANGER

The signal word DANGER on the machine and

in the manuals indicates a hazardous situation

which, if not avoided, will result in death or serious

injury.

SAFETY ALERT SYMBOL

This SAFETY ALERT SYMBOL identifies important

safety messages on the equipment and in the

owner’s manual. When you see this symbol, be

alert to the possibility of personal injury and

carefully read the message that follows.

IMPORTANT

The signal word IMPORTANT identifies

procedures which must be followed to avoid

damage to the machine.

WARNING

DO NOT assemble, operate, or maintain the unit

until you read and understand the information

contained in this manual.

5Blue Diamond® Attachments

• Before using the machine, make sure that

all safety devices are installed and in good

working conditions. In case of damage or

shields, replace them immediately. A cutter

maintained or operated improperly can be

dangerous to the user and bystanders causing

serious injury or death.

• It is absolutely forbidden to remove or alter

safety devices.

• Do not modify the cutter or safety devices in

any way. Do not weld the unit. Unauthorized

modifications may impair its function and

safety. Personal injury or death can result from

unauthorized modifications.

If the cutter has been altered in any way from

the original design, Blue Diamond® does not

accept any liability for injury or warranty.

• Before starting, and during operation of the

attachment, make sure there are no people

or animals in the operation area; the machine

can project material from the back with risks of

serious injury or death.

• Never allow riders on the tractor, cutter, or

hitch at any time. Falling or crushing hazards

can result in severe injuries or death.

• Pay maximum attention to avoid any accidental

contact with rotating parts of the machine.

• During operation, adjustment, maintenance,

repairing, or transportation of the machine, the

operator must always use appropriate Personal

Protective Equipment (PPE) including but not

limited to safety glasses, gloves, and hearing

protection.

• Do not operate the attachment or machine

while wearing loose fitting clothing that can be

entangled or caught in parts of the machine.

• Do not operate the implement when tired, not

in good condition, or under the influence of

alcohol or drugs.

• If the use of the machine is required at night

or in conditions of reduced visibility, use the

lighting system of the tractor and possibly an

auxiliary lighting system.

1.2 Qualified Operators

Safe Operation Needs a Qualified

Operator

Operator Training

• Anyone who is using and/or maintaining the

cutter must read, clearly understand, and

follow ALL safety, operation, and maintenane

information presented i this manual, other

related OEM manuals, and the safety signs.

• Check the rules and regulations at your

location. The rules may include an employer’s

work safety requirements. Regulations may

apply to local driving requirements or use

of a Slow Moving Vehicle (SMV) emblem.

Regulations may identify a hazard such as a

utility line.

• The new operator must start in an area without

bystanders and use all the controls until he or

she can operate the machine safely under all

conditions of the work area.

1. Introduction

AVOID SERIOUS INJURY OR DEATH

Operators must receive instructions before

operating the machine. Untrained operators can

cause serious injury or death.

For an operator to be qualified, he or she must

not use drugs or alcoholic drinks which impair

alertness or coordination while working. An

operator who is taking prescription drugs must

get medical advice to determine if he or she can

safely operate a machine and the equipment.

For an operator to be qualified, he or she must

have read and understood the instructions of

this manual, he or she must make adequate

preparation for the proper use of the machine,

and he or she must hold a driving license.

In case of doubt regarding the use of the machine

and/or the interpretation of this manual, the

operator must contact either their dealer or Blue

Diamond.

DANGER

Blue Diamond® Attachments6

1.3 Attachment Information

Congratulations on your choice of a Blue

Diamond® Attachments cutter. This equipment

has been designed and manufactured to meet the

needs of discerning users.

The Blue Diamond® multi purpose cutter is

designed to cut grass, weeds, and light brush.

Many features incorporated into this cutter are

the result of suggestions made by customers like

you. Read this manual carefully to learn how to

operate the oset mower safely and how to set it

to provide maximum cutting eciency.

The multi purpose cutter are designed for light-

duty applications such as weed, grass, and light

brush up to 3” diameter. The cutters can be used

to mow under a fence line or it can be turned

vertically to mow the sides of hedgerows and tree

lines.

The cutter uses a single spindle with two

free-swinging blades, which reduce the shock of

impact when a stationary object is contacted. A

shear key in the input shaft protects the motor

from damage.

Intended Use

Do not use this cutter for any other purpose than

its intended use; cutting grass, weeds, and light

brush in an in-line or oset application.

The multi-purpose cutter can also be used in a

vertical configuration for mowing along hedge

rows and tree lines.

Disposal of Equipment at End of Useful

Life

The Blue Diamond® Attachments cutter has been

designed for the specific purpose of cutting grass,

weeds, and light brush. When this unit is no longer

capable of doing its designed purpose, it should

be dismantled and scrapped. Do not use any

materials or components from this unit for any

other purpose.

Unanswered Questions

If you have any questions not answered in this

manual or if you require additional copies or if the

manual is damaged, please contact your dealer.

1. Introduction

7Blue Diamond® Attachments

2.1 Safety Guidelines

Operating Safety

• Read and follow instructions in this manual

and the machine’s Operator’s Manual before

operating.

• Under no circumstances should young children

be allowed to work with this equipment.

• This equipment is dangerous to persons

unfamiliar with its operation.

• Do not use the cutter if any parts are damaged.

If the oset mower has a defect, immediately

stop using it and remedy the problem before

continuing.

• The safety shield found on the multipurpose

cutter is designed to reduce the risk of

throwin objects; however, the cutter deck

and safety shield cannot prevent all objects

from escaping theblade enclosure in every

mowing configuration, especially when cutting

vertically.

• The cutter can throw objects up to 300 feet. To

avoid serious injury or death, keep all thrown

object shielding in place. Inspect area for

potential thrown objects before cutting.

• DO NOT operate in a work area that has

not been inspected for foreign debris and

obstacles.

• Remove any foreign objects and clearly mark

any objects that cannot be removed.

• Check for overhead and / or underground lines

before operating equipment (if applicable).

• In addition to the design and configuration

of equipment, hazard control and accident

prevention are dependent upon the

awareness, concern, prudence and proper

training of personnel involved in the operation,

transport, maintenance and storage of

equipment.

• Check that the attachment is securely fastened

to the machine.

• Make sure all the machine controls are in the

NEUTRAL before starting the machine.

• Operate the equipment only from the

operator’s position.

• When learning to operate the equipment, do it

at a slow rate in an area clear of bystanders.

• The equipment must be used ONLY on

approved machines.

• DO NOT make any adjustments or repairs on

the equipment while the machine is running.

• DO NOT operate equipment in poor visibility

conditions such as fog, darkness, or any

conditions that limit clear visibility less than

300 feet (100 m) in front of and to the sides of

the equipment.

• When conditions make it necessary to slow

ground speed, shift to a lower gear rather

than reducing engine speed. The engine will

maintain rated speed and keep cutter running

at optimum cutting speed.

• Wear safety glasses, gloves, hearing protection

and other protective clothing when required.

2. Safety

WARNING

Safety precautions and warnings are provided

in this manual and on the unit. If these hazard

warnings are not heeded, bodily injury, or death

could occur to you or to other persons.

Blue Diamond® Attachments8

Personal Protection Equipment

When using this cutter, wear appropriate personal

protective equipment (PPE). This list may include,

but is not limited to:

• Ear Protection

• Hearing Protection

• Protective shoes with slip resistant soles

• Protective goggles, glasses, or face shield

• Protective clothing and gloves

• Safety vest (when operating near roads)

Machine Requirements and Capabilities

• The machine’s operator’s cab should be

equipped with a thermoplastic polycarbonate

or similar material front window, and similar

protection on the sides of the operator’s cab

before operating the equipment.

• The tractor should be equipped with a Roll

Over Protective Structure (ROPS) and a seat

belt. A crushing hazard can ocur if the driver

is ejected from the seat while the tractor is

in motion. Fasten the seat belt whenever the

tractor is moving.

• Keep bystanders clear of moving parts and the

work area. Keep children away.

• Use caution on slopes and near banks and

ditches to prevent overturn.

Fire Prevention Safety

• Flamable debris (leaves, grass, etc.) must

be removed regularly. If flammable debris

is allowed to accumulate, it can cause a fire

hazard. Clean often to avoid this accumulation.

• Carry a fire extinguisher on the tractor at all

times to extinguish possible fires encountered.

• The equipment’s hydraulic motor compartment

must be inspected every day and cleaned

if necessary to prevent fire hazards and

overheating.

• All fuels, most lubricants, and some coolant

mixtures are flammable. Flammable fluids that

are leaking or spilled onto hot surfaces or onto

electrical components can cause a fire.

Hydraulic System

• Check hydraulic tubes, hoses and fittings for

damage and leakage. Never use open flame

or bare skin to check for leaks. Hydraulic tubes

and hoses must be properly routed and have

adequate support and secure clamps. Tighten

or replace any parts that show leakage.

• Always clean fluid spills. Do not use gasoline or

diesel fuel for cleaning parts. Use commercial

nonflammable solvents.

2. Safety

9Blue Diamond® Attachments

2.2 Safety Decals

General Safety Decal Information

Good safety practices require that you familiarize

yourself with the various safety signs, the type

of warning, and the area or particular operation

related to that area that requires your Safety

Awareness.

Pay close attention to the safety signs and

instructional labels attached to the machine and

the cutter. If the cutter is missing a label or a label

has become unreadable, replace the label before

operating the cutter.

Safety Instructions and Instructional

Labels

1. Keep safety signs or instructional labels clean

and legible at all times. Use a clean, damp

cloth to clean safety labels.

2. Replace any missing or hard-to-read safety

signs or instructional labels.

3. Use care when washing or cleaning the

equipment not to remove or damage the

labels. When using a pressure washer to clean

the cutter avoid spraying too close to decals;

high-pressure water can enter through very

small scratches or under edges of decals

causing them to peel or come o.

4. Locations for the labels and replacement part

numbers are shown in the parts section on

page 29.

5. Replacement parts must have replacement

labels attached during installation and/or

before the oset mower is used.

6. Labels are available from your authorized

dealer at no charge.

How to Install Replacement Safey

Decals

1. Clean and dry the installation area.

NOTE: Do not install the signs if the temperature is

below 50°F (10°C).

2. Determine the exact position before you

remove the backing paper.

3. Remove the backing paper.

4. Align the sign over the specified area and

carefully press the sign to the part/frame.

NOTE: Small air pockets can be pierced with a

pin and smoothed out using the piece of backing

paper.

2. Safety

Blue Diamond® Attachments10

3.1 Work Area Safety

• Never operate the cutter in darkness or foggy

conditions where you cannot clearly see at

least 300 feet in front and to the sides of the

tractor and oset mower.

• Make sure that you can clearly see and identify

passersby, steep slopes, ditches, drop-os,

overhead obstructions, power lines, debris,

and foreign objects. If you are unable to clearly

see these type of items, stop operating the

oset mower.

• Do not operate the multi purpose cutter, or

drive the tractor into material that is burning,

or areas that recently burnt and may contain

hot embers. Burning material, sparks, and

coals could be thrown from the oset mower to

areas of vegetation that might ignite.

• Carry a fire extinguisher on the tractor at all

times to extinguish possible fires encountered.

• Do not operate the multi purpose cutter on a

tractor with an under-frame exhaust.

• Before turning, slightly raise the cutter o the

ground.

• After the cutter is hydraulically disengaged, the

motor can free-wheel for several minutes. Stay

clear of the blades until they come to complete

stop.

• Large, dense, or wet vegetation may need

to be cut in two or more passes to achieve a

uniform cut.

• Stay alert and watch for trees, low hanging

limbs, power lines, and other overhead

obstacles as well as solid ground objects.

• Avoid cutting in reverse.

3.2 Tractor Requirements

The tractor used to operate the oset mower

must have the power capacity to lift, push, and

hydraulically operate the oset mower.

Depending on the model the tractor will need

either:

9 – 14 GPM or oil flow

15 – 20 GPM or oil flow

The recommended tractor is a 3000 pound

tractor with rear ballast (such as a mower deck) to

oset the weight on the front of the tractor. Also

recommended are tractor tires that are “filled” or

solid to prevent puncture from the brush.

This unit WILL NOT work on a skid steer machine.

Operating the multi purpose cutter with a tractor

that does not meet the following requirements

may cause tractor or oset mower damage and be

a potential danger to the operator and passersby.

Always review the “controls” section of the tractor

operator’s manual to be familiar with the location,

settings, and function of the tractor controls.

Be familiar with all controls before using this

equipment.

• Approved Roll–Over Protective Structure

(ROPS) or ROPS cab and seat belt.

• Tractor Safety Devices; Slow Moving Vehicle

(SMV) emblem, lighting.

3. Operation

WARNING

Always refer to the tractor owner’s manual to

ensure compatibility and maximum safety.

WARNING

Using the cutter on a skid steer will void the

warranty and have potential for serious injury to

the user or bystanders.

11Blue Diamond® Attachments

3.3 Attachment Installation

Entering The Operator’s Position

Use the attachment safety treads, handles and

steps (on the machine) to enter the operator’s

position.

When in the operator’s position, lower safety seat

bar, start the engine and release the parking brake.

Leaving The Operator’s Position

Park the machine/attachment on a flat level

surface.

Place all controls in neutral, engage the park

brake, stop the engine and wait for all moving

parts to stop. Leave the operator’s position.

Connecting Attachment To The Machine

Use caution when connecting the cutter to the

tractor. The multi-purpose cutter should be

securely resting at ground level or setting on

blocks. Keep hands and feet from under the deck

and clear of pinch points between the tractor hitch

arms and tractor hitch pins.

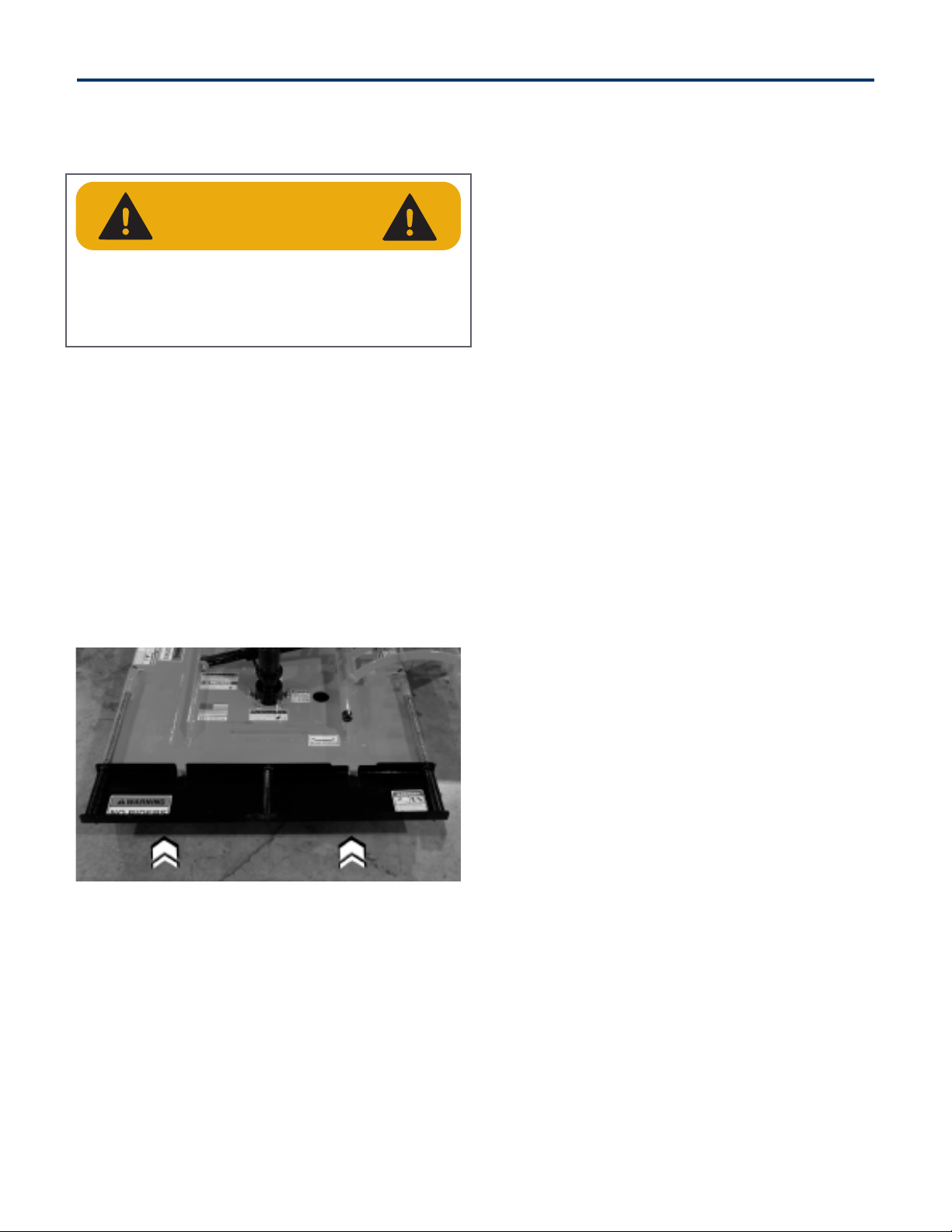

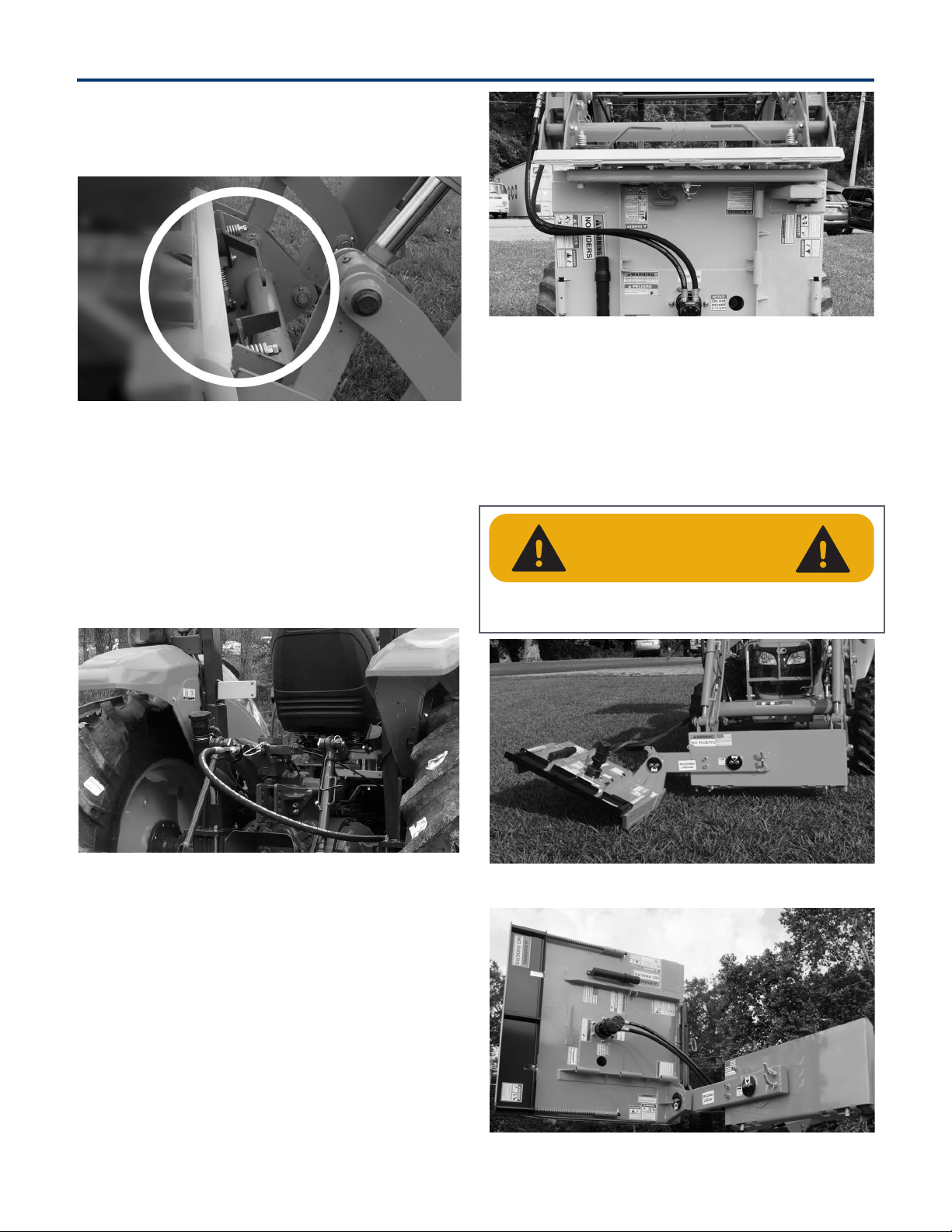

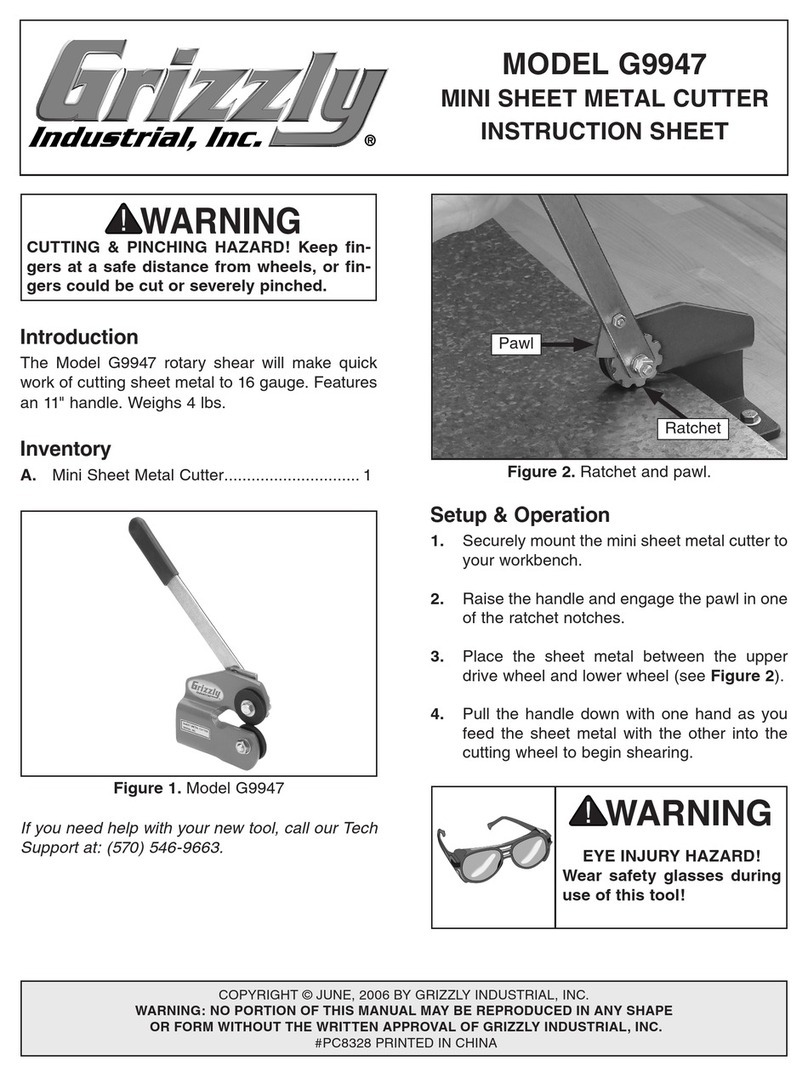

1. Connect the mower to the loader arms [Figures

1& 2].

Figure 1

Figure 2

3. Operation

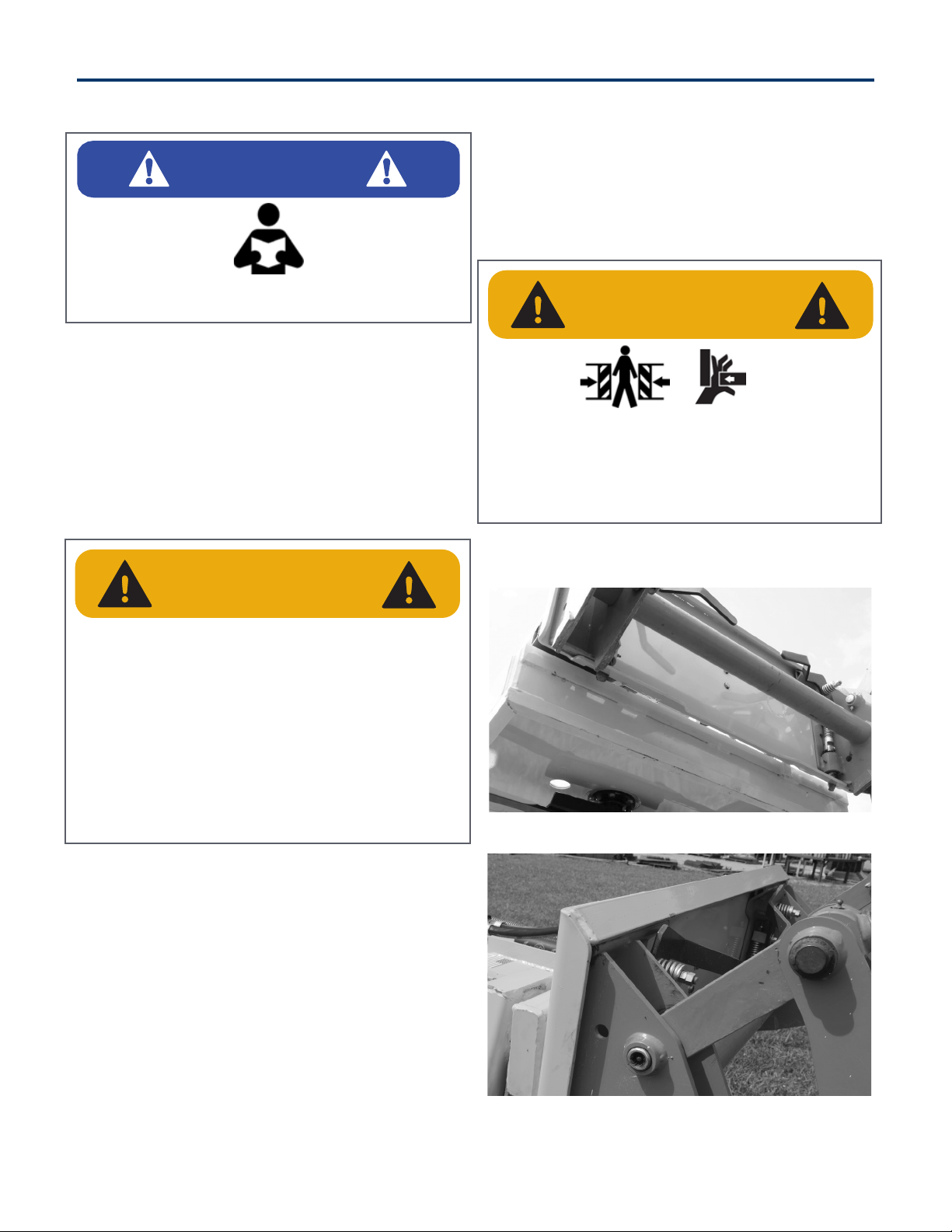

WARNING

AVOID SERIOUS INJURY OR DEATH

• Always park on a flat level surface.

• Lower lift arms and place attachment flat on

the ground.

• Place all controls in NEUTRAL.

• Engage the park brake.

• Stop the engine and remove the key.

• Wait for all moving parts to stop.

SEE MACHINE’S OPERATOR’S MANUAL FOR

ADDITIONAL INFORMATION.

IMPORTANT

See the machine’s Operator’s Manual for detailed

information on operating the loader. WARNING

CRUSH HAZARD

Crush hazard between loader’s quick attachment

plate and mower. Do not allow anyone to stand

between the loader and implement during

connecting operations.

Blue Diamond® Attachments12

Connecting Attachment to the Machine

Cont’d

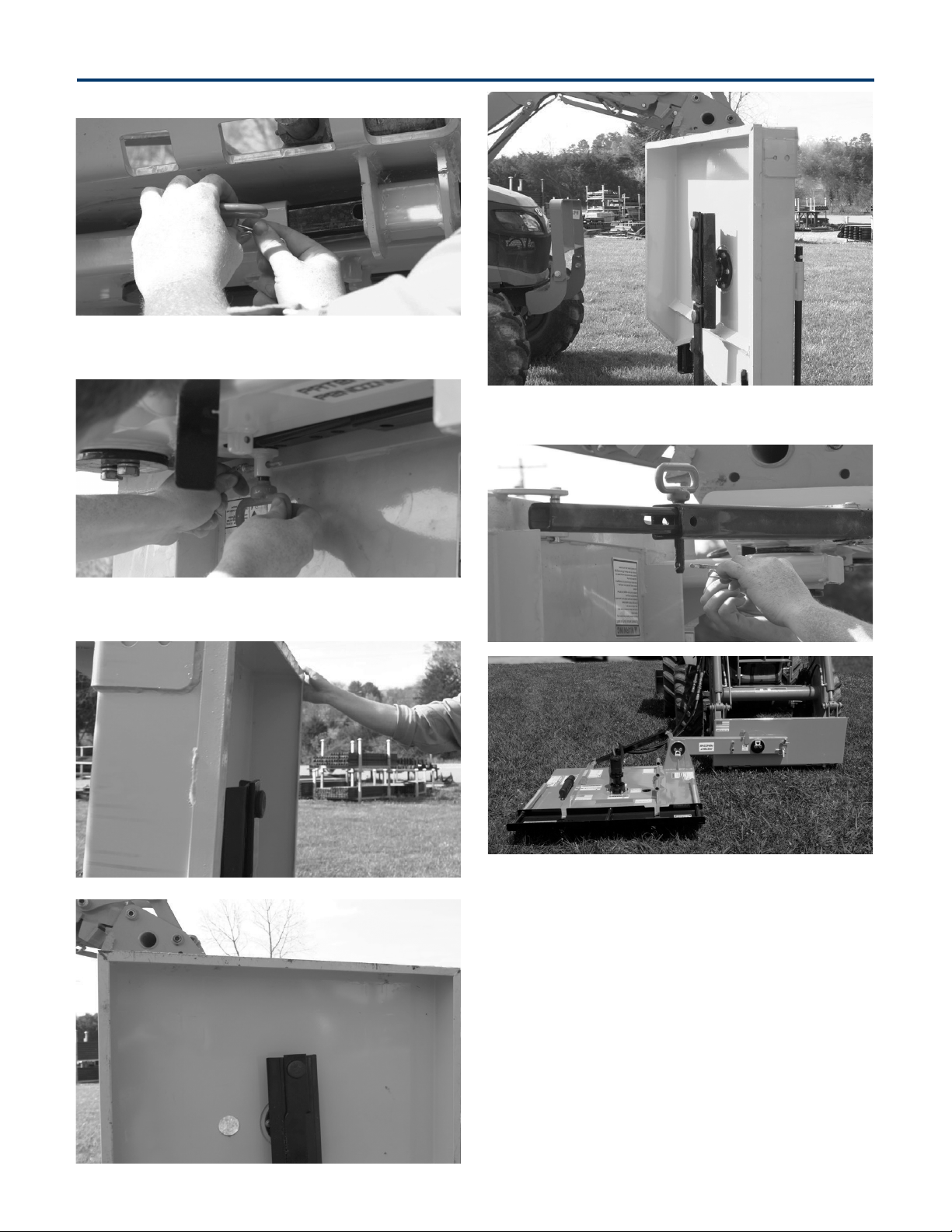

2. Lock the mower to the lift arms.

Figure 3

3. Turn OFF the tractor engine and dismount.

4. Connect a user-supplied hydraulic supply hose

from the tractor supply manifold valve to the

hose routed to the right port of the hydraulic

motor. The pump port configuration is from the

tractor’s viewpoint.

NOTE: The hose MUST be 5/8 inch diameter. DO

NOT use smaller or larger diameter hoses.

Figure 4

5. Connect the left return port on the motor to a

user supplied hose (5/8 inch diameter) routed

to the tractor’s reservoir.

The return hose must have free–flow back into

the pump reservoir and not be ported through

the tractor’s manifold valve. DO NOT connect

into the tractor’s rear remote return valve.

NOTE: An optional Hose Kit is available consisting

of two male QD couplings, two female QD

couplings, two 5/8” diameter hoses, and two pump

fittings.

Figure 5

6. Start the mower and check for rotation.

Make sure the pump is turning in the correct

direction. Hooking up the hoses to the wrong

port will make the cutters operate in a reverse

direction.

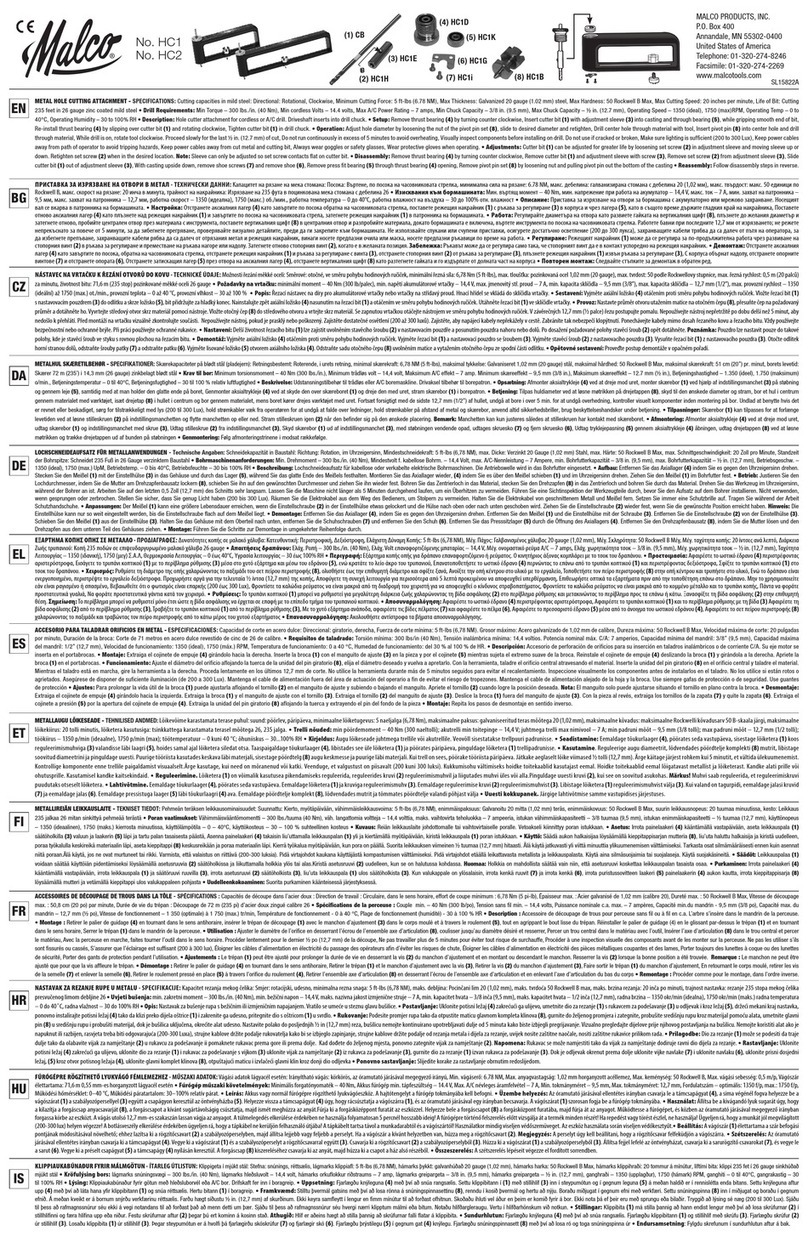

7. Place the mower in the desired cutting

configurations.

Figure 6: Horizontal oset mowing configuration

Figure 7: Vertical mowing configuration

3. Operation

WARNING

DO NOT put hands or feet under the oset mower

deck while the blades are rotating.

13Blue Diamond® Attachments

3.3 Attachment Installation

Cont’d

Horizontal Oset Mowing Configuration

1. Disconnect the supply hose from the tractor’s

manifold valve.

2. Disconnect both the supply and return hoses

to the mower.

3. Place the ends of the hoses in a place they will

not be contaminated by dirt.

4. Remove the red-handled t-pin from the

outermost side of the cutter deck.

5. Slide the locking tupe out of the mounting

plate and rotate the cutter deck around to the

oset position.

6. Replace locking tube in the hole it was

previously in.

3. Operation

Blue Diamond® Attachments14

7. Replace the red-handled t-pin.

8. Remove the second red-handled t-pin from the

cutter deck and float arm.

9. Take the outside edge of the deck and

reposition it into the oset position.

10. Select the proper hole for the desired cutting

position. Replace the red-handled t-pin.

11. Reconnect supply hoses to the mower and the

tractor.

3. Operation

15Blue Diamond® Attachments

3.3 Attachment Installation

Cont’d

Vertical Mowing Configuration

1. Begin by following Steps 1 – 9 of the Horizontal

Oset Mowing Configuration on pages 13 – 14.

2. Position the mower deck 90 degrees to the

front of the tractor. Replace the red-handled

t-pin into the fixed 90 degrees position hole.

3. Reconnect supply hoses to the mower and to

the tractor.

Other Mowing Configurations

NOTE: Use the top hold of the float bar to utilize

the “floating” position seen below.

3. Operation

Blue Diamond® Attachments16

Disconnecting Attachment from the

Machine

1. Place the mower flat on the ground. If a

perpendicular configuration was used, place

the mower in a flat configuration before

disconnecting it.

2. Shut o the tractor, set the parking brake, and

remove the key.

3. Operate the tractor’s hydraulic levers to

release all pressure.

4. Unhook the supply (pressure) hose from the

rear of the tractor (manifold valve).

5. Unhook both hose quick disconnect fittings at

the front of the tractor. Make sure the fittings

are kept clean.

6. Lower parking stand (when applicable).

7. Release from the mower.

Mower Checklist

Ecient and safe operation of the oset mower

requires that every user read and understand

the operational instructions and all related safety

instructions outlined in this manual.

This Initial Setup Checklist is provided for the user/

owner. It is important for both personal safetyand

to maintain the mechanical condition of the multi-

purpose cutter that this checklist is followed.

Althouth there are no operational restrictions

on the multi-purpose cutter when used for the

first time, it is recommended that the following

mechanical items be checked.

1. After 1/2 hour of operation: Tighten all

fasteners if necessary. Lubricate all grease

fittings.

2. After 10 hours of operation, go to the normal

servicing and maintenance schedule in section

4.1 on page 22.

Inspection Checklist before Use

3. Operation

ITEMS

P

Initially, retighten the tapered roller

bearing in the pivot arm after 15 minutes

of initial use and again at 30 minutes.

Recheck again before the next use.

PMake sure the cutter is securely attached

to the tractor.

P

Use only an appropriately sized tractor.

See Section 3.2 Tractor Requirements on

page 10.

PMake sure the hydraulic hose is properly

attached to the tractor.

PMake sure all safety shields and guards

are properly installed.

PCheck the blade bolts and blade carrier

nut.

PCheck the condition of the blades.

P

Inspect the overall oset mower for

potential problems or damage. Do not

use the oset mower if it needs repairs of

any type.

17Blue Diamond® Attachments

3.4 Operation Checklist

Although the oset mower is easy to use, each

operation should review this section to familiarize

themselves with the detailed safety and operating

procedures. When using this machine, follow this

procedure before beginning operation:

3.5 Right of Way or Roadway

Mowing

Use all safety shields for highway, right-of-way,

parks, greenbelt mowing, or all other mowing

where human dwellings, vehicles, or livestock

could be within 300 feet of the multi-purpose

cutter.

No shielding is 100% eective in preventing

thrown objects. In order to reduce the possibility

of injury from thrown objects:

1. Maintain multi-purpose cutter shielding in good

operational condition.

2. Inspect the condition of the throw object

guards, oset mower side skirts, and skid

shoes daily. Replace or repair worn or

damaged guards.

3. Inspect the condition of the blades and blade

bolts daily. Replace any cracked, worn, bent, or

damaged blades. Always replace blade bolts

and lock washers when replacing blades. Make

sure the blade bolts are properly tightened.

Multi-purpose Cutters can throw objects 300 feet

or more under adverse conditions.

1. To avoid serious injury or death from thrown

objects, inspect the area thoroughly for

potential throw objects and remove them

before cutting.

2. Remove debris, rocks, wire, cable, metal

objects, and other foreign material from

mowing area.

3. Wire, cable, rope, chains, and metal objects

can be thrown or swung outside the deck with

great velocity.

4. Mark the location of objects that cannot be

removed.

3. Operation

ITEMS

PClear an area of at least 300 feet on all

sides of bystanders, especially children.

POperate the oset mower only in

conditions where there is clear visibility.

P

Inspect and clear the area to be cut of

stones, branches, debris, and any hard

objects that may be thrown.

PMark the location of objects that cannot

be removed.

PMake sure all safety shields and guards

are properly installed.

PCheck the blade bolts and blade carrier

nut.

PCheck the conditions of the blades.

P

Begin cutting at a slow speed, then

increase to a speed that gives a clean

cut without lugging the engine. Do not

operate above 5 MPH

P

Never allow blades to contact solid

objects like rocks, posts, wire, curbs,

guardrails, or the ground while mowing.

P

Avoid operating the oset mower

in reverse direction when possible.

Check to make sure that there are no

persons behind the oset mower, and

use extreme care when maneuvering in

reverse.

Blue Diamond® Attachments18

Stop mowing if passersby are within 300 feet

unless:

1. All thrown object shielding, including front and

rear deflectors, chain guards, steel guards,

bands, side skirts, and skid shoes are in place

and in good condition when mowing.

2. Mower sections or wings are adjusted to

be close and parallel to the ground without

exposing the blades.

3. Mowing area has been inspected and foreign

materials and debris have been removed.

4. Passersby are inside an enclosed vehicle.

3.6 Transporting Safety

Tractor Owner/Operator Manual: Always refer

to the tractor owner’s manual to determine its

compatibility and maximum safety.

Tractor Operation: Before attaching the cutter to

the tractor, be familiar with its controls and how to

stop it quickly in the event of an emergency. Read

and understand this manual and the one provided

with your tractor before transporting the multi-

purpose cutter.

Fall and Crush Hazard: Do not allow riders on the

multi-purpose cutter or tractor.

Maximum Transporting Speed: Do not exceed 20

MPH when transporting the oset mower. Slow

down for corners and rough terrain.

Visibility: Clean reflectors, SMV or SIS sign, and

lights before towing. Make sure all the lights and

reflectors required by highway and transport

authorities are in place and can be seen clearly by

all overtaking and oncoming trac.

Regulations: Make sure all local, state, and federal

regulations regarding the transport of equipment

on public roads and highways are met. Check

with the local authorities regarding transporting

the oset mower on public roads. Obey all

applicablelaws and regulations.

Rollover Protection: The tractor should be

equipped with a Roll Over Protective Structure

(ROPS) and a seat belt.

Drive Safely: Be a safe and courteous driver.

Anticipate what other drivers will do and drive

accordingly.

Allow Extra Distance: Apply brakes early. Leave

extra distance between your vehicle and the one(s)

ahead to provide adequate stopping space. Extra

distance will be required to stop the vehicle.

Clear Vision: Remove all objects from the area that

would prevent clear vision of the complete work

area of would present an obstacle when moving

the multi-purpose cutter.

Hitch Attachment: Be sure the cutter is securely

attached to the tractor and in good operating

condition before use.

Working Taillights: Make sure lights on the tractor

are working properly.

Additional Lighting: For cutters without lights,

install additional lights on the rear of the tractor to

safeguard against rear-end collisions. Daybreak

and dusk are particularly dangerous and rear pilot

vehicles are recommended. Cutters without lights

should be transported on public roads only during

daylight hours.

Hazard Flashers: Use hazard flashers on the

tractor when transporting unless prohibited by law.

Right-of-way: When traveling below the posted

speed limit, keep to the right and yield the right-of-

way to allow faster trac to pass.

3. Operation

DANGER

The following safety instructions can and will

result in serious injury and possibly even death if

they are not understood and followed.

WARNING

19Blue Diamond® Attachments

3.7 Storage

Storage Safety

At the end of the season, the multi-purpose cutter

should be thoroughly inspected and prepared

for storage. Repair or replace any worn or

damaged components to prevent any unnecessary

downtime at the beginning of the next season.

Placing In Storage

1. Remove all entangled vegetation.

2. Thoroughly wash the multi-purpose cutter with

a pressure washer or water hose to remove all

clippings, dirt, mud, or debris.

3. Select an area that is dry, level, and free debris

(inside a building is ideal). Move the multi-

purpose cutter to its storage area.

4. Lubricate all grease points. Make sure all

grease cavities have been filled with grease to

remove any water residue from washing.

5. Touch up all paint nicks and scratches to

prevent rusting.

Storage Safety

When removing the multi-purpose cutter from

storage, follow this procedure:

1. Attach the multi purpose cutter to the tractor

lift arms

2. Raise the multi-purpose cutter up o the

blocks.

3. Before placing the cutter back into service,

replace any worn or defective parts and

perform the Pre-Operation Checklist on page

17.

3. Operation

CAUTION

PERSONAL INJURY HAZARD

Store the multi-purpose cutter in an area away

from human activity. To prevent the possibility of

serious injury, donot permit children to play on or

around the stored multi-purpose cutter.

IMPORTANT

To prevent damage to the multi-purpose cutter,

store it in a dry, level area.

CAUTION

CRUSH HAZARD

Always set the multi-purpose cutter on safety

stands or on blocks for storage.

Blue Diamond® Attachments20

4.1 Maintenance Safety

Personal Protection Equipment: Wear close fitting

and belted clothing to avoid getting caught in

moving parts. Wear personal protection equipment

(PPE), which may include hard hat, safety glasses,

safety shoes, gloves, etc. appropriate for the work

site and the working conditions.

Damaged Parts Hazard: Do not use the multi-

purpose cutter if any parts are damaged. If

the multi-purpose cutter is believed to have a

defect which could cause it to work improperly,

immediately stop using it and remedy the problem

before continuing.

No Unauthorized Modifications: Do not modify

the cutter or safety devices. Do not weld on the

unit. Unauthorized modifications may impair its

function and safety and will void the warranty. If

the oset mower has been altered in any way

from the original design, the manufacturer does

not accept any liability for injury or warranty.

Crush Hazard: Always set the oset mower on

safety stands or on the ground when performing

maintenance.

Good Working Condition: Keep all parts in good

condition and properly installed. Fix damage

immediately. Replace worn or broken parts.

Replacement Parts: If replacement parts are

necessary, genuine factory replacement parts

must be used to restore the unit to its original

specifications. Blue Diamond® will not accept

responsibility for damage as a result of the use of

unapproved parts.

Safety Shields and Devices: When completing

a maintenance or service function, make sure all

safety shields and devices are installed before

placing the multi-purpose cutter in service.

4.2 Greasing

Grease all zerks according to the Service

Schedule on page 22. Use an SAE multiporpose

high-temperature grease with extreme pressure

(EP) performance. Also acceptable is an SAE

multipurpose lithium base grease.

1. Always use a handheld grease gun for all

greasing.

2. Wipe grease zerks with a clean cloth before

greasing to avoid injecting dirt and grit.

3. Apply grease until new grease can be seen

coming out of the joint.

4. Do not let excess grease collect on or around

parts, particularly when operating in sandy

areas.

5. Replace and repair broken grease zerks

immediately.

6. If any grease zerk will not take grease,

remove and clean it thoroughly. Also, clean

the lubricant passageway. Replace the zerk if

necessary.

4.3 Blade Servicing

Inspect blades before each use to determind that

they are properly installed and in good condition. If

any blade is bent, excessively nicked, worn, or has

any other damage, replace both blades. Do not

sharpen the blades. The blades have two cutting

edges and should be flipped when the first edge is

dull or damaged.

Manually wiggle the blade carrier to check for

any looseness. Recheck torque every fifty hours.

Retighten any loose parts.

4. Maintenance

DANGER

Failure to comply with the following safety

instructions can and will result in serious injury

and possibly even death.

WARNING

Table of contents

Other Blue Diamond Cutter manuals

Popular Cutter manuals by other brands

Scheppach

Scheppach FS3600 Translation of original instruction manual

Husqvarna

Husqvarna K 770 Vac Operator's manual

Malco

Malco HC1 Installation instruction

Wolfcraft

Wolfcraft VNC 250 operating instructions

Phoenix Contact

Phoenix Contact CUTFOX 10 Original operating instructions

Summa

Summa S 75 user manual

ES manufacturing

ES manufacturing MB110 Series OPERATING INSTRUCTIONS, MAINTENANCE & SAFETY

D-CUT

D-CUT LU-215 Operation manual

REMS

REMS Nano operating instructions

Modern

Modern RAPTOR Operator's manual

Grizzly

Grizzly MINI SHEET METAL CUTTER INSTRUCTION SHEET... instruction sheet

Gerber

Gerber GSx Plus user manual