Blue Giant STRONGARM HVR303 User manual

OWNER’S MANUAL

STRONGARM™ HVR303 VEHICLE RESTRAINT

WITH BLUE GENIUS™TOUCH CONTROL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

WARNING

Do not operate or service this product unless you have

read and fully understand the entire contents of this

manual. Failure to do so may result in property damage,

bodily injury or death.

ACTUAL PRODUCT MAY NOT APPEAR EXACTLY AS SHOWN

STARTING FROM APRIL, 2017 / SERIAL #418567

2

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

1.0 ABOUT THE STRONGARM™ HVR303 WITH BLUE GENIUS™ TOUCH CONTROL 3

1.1 OWNER’S PURCHASE RECORD 3

2.0 INTRODUCTION 4

2.1 WARRANTY INFORMATION 4

2.2 EXCLUSION OF LIABILITY 4

2.3 MANUFACTURER’S NOTE 4

2.4 OWNER’S RESPONSIBILITY 5

3.0 SAFETY MESSAGE COLOR IDENTIFICATION 6

3.1 OPERATIONAL SAFETY WARNINGS 6

4.0 LOCKOUT / TAGOUT PROCEDURE AND RULES 7

5.0 EMERGENCY VEHICLE RESTRAINT LOWERING PROCEDURE 7

6.0 CONTROL PANEL OPERATION 8

6.1 BUTTON FUNCTION 8

7.0 OPERATING INSTRUCTIONS 9

7.1 FUNCTIONAL DESCRIPTION 9

7.2 STOP BUTTON FUNCTION 10

7.3 PRIOR TO USE-EQUIPMENT IN STORED POSITION 10

7.4 TRAILER AT BAY 11

7.5 ENGAGING RESTRAINT 11

7.6 DEPLOYING THE DOCK LEVELER 12

7.7 RELEASING THE RESTRAINT ARM 12

8.0 ENGAGING THE OVERRIDE FEATURE 13

8.1 RELEASING THE OVERRIDE FEATURE 14

9.0 MAINTENANCE 15

9.1 PLANNED MAINTENANCE PROGRAM (PMP) 15

9.2 OPERATOR INSPECTION 15

9.3 ROUTINE SERVICING AND MAINTENANCE 15

9.4 PLANNED MAINTENANCE PROGRAM INTERVALS 15

9.5 MAINTENANCE SEQUENCE 15

9.6 PMP CHECKLIST - STRONGARM™ HVR303 VEHICLE RESTRAINT 16

10.0 RECOMMENDED SPARE PARTS 17

10.1 STANDARD OPERATIONAL COMPONENTS 17

10.2 OPTIONAL SUPPORT COMPONENTS 18

11.0 DECAL IDENTIFICATION AND LOCATION 19

12.0 EQUIPMENT COMPONENT ILLUSTRATIONS 20

12.1 COMPONENTS AS SHIPPED CHECKLIST 20

12.2 MECHANICAL ASSEMBLY - 56-010200 21

12.3 GENERAL DIMENSIONS 22

12.4 GEARMOTOR ASSEMBLY - 1005462 23

12.5 CONTROLS 24

12.6 JUNCTION BOX W/REMOTE I/O 25

12.7 JUNCTION BOX ASSEMBLY 25

12.8 DOCK INTERLOCK SENSOR 26

12.9 EXTERIOR TRAFFIC LIGHT / MIRROR IMAGE SIGN 26

13.0 VEHICLE RESTRAINT TROUBLESHOOTING 27

14.0 BLUE GENIUS™ LCD MESSAGES 28

15.0 WIRING DIAGRAM 28

15.1 WIRING DIAGRAM—115V SINGLE PHASE 29

TABLE OF CONTENTS

3

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

1.1 OWNER’S PURCHASE RECORD

OWNER’S PURCHASE RECORD

Please record information for future inquiries and to validate warranty. (See Section 2.1 for warranty validation)

Dealer: Date in Service:

Number of Units:

Serial Number: Door #:

Serial Number: Door #:

Serial Number: Door #:

Serial Number: Door #:

Serial Number: Door #:

Serial Number: Door #:

Serial Number: Door #:

Serial Number: Door #:

Serial Number: Door #:

1.0 ABOUT THE STRONGARM™ HVR303 WITH BLUE GENIUS™ TOUCH CONTROL

NOTICE

See section 11.0 "Decal Identification and Location," item #7 for serial number location.

The manufacturer offers a full line of dock levelers, dock safety equipment, accessories, ergonomic and scissor lift equipment, and

industrial trucks. Concurrent with a continuing product improvement program, specifications are subject to change without notice.

Please contact the manufacturer for latest information. Some features illustrated may be optional in certain market areas.

With a restraining force of 32,000 lb (14,500 kg), the StrongArm™ HVR303 electric lock vehicle restraint counteracts the dangers

associated with unexpected horizontal or vertical trailer movement. Its vertical restraining range of 9" to 25" (227 – 635 mm) and instant

compensation float of 16" (406 mm) enable it to match active trailer movement, making the HVR303 work well with air-ride suspension

systems and minimizing the risk of accidental separation and worker injury.

The Blue Genius™ Gold Series II Touch Control Panel’s features include an LCD menu screen, function (ENGAGE, RELEASE, STOP)

buttons and a flat-surface keypad with unique touch sensors.

An interior and exterior lights communication system keeps truck drivers and warehouse personnel advised of safety conditions during

dock operations.

4

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

DEALER INFORMATION

Name:

Contact:

Telephone:

2.1 WARRANTY INFORMATION

Thank you for purchasing Blue Giant products. We appreciate

your business, and are confident that our product will serve

you for many years to come. In the event that you experience a

problem with our product, our Warranty Center is here to support

the Blue Giant Product(s) that you have purchased.

To validate warranty on recently purchased equipment,

please complete and submit your information with our

on-line Warranty Registration at www.BlueGiant.com.

For more information about Blue Giant Warranty Support, please

contact your local Blue Giant Equipment dealer, representative or

authorized partner near you. You may also visit www.BlueGiant.

com or phone 1.905.457.3900.

* NOTE that failure to validate warranty at the time of receipt can

seriously affect the outcome of any claim.

2.2 EXCLUSION OF LIABILITY

The manufacturer assumes no liability for damage or injury to

persons or property which occur as a result of defects or faults in

or incorrect use of the Vehicle Restraint System. The manufacturer

also assumes no liability for lost profits, operating downtimes, or

similar indirect losses incurred by the purchaser. Injury to third

parties, irrespective of its nature, is not subject to compensation.

The manufacturer reserves the right to make changes at any time

to the modules, components, and accessories, concurrent with

its continuing product improvements and development program.

Specifications, operating instructions, and illustrations included in

this manual are subject to change without notice. Please contact

manufacturer for the latest information.

2.3 MANUFACTURER’S NOTE

The Vehicle Restraint has been carefully inspected and tested at

the manufacturer’s plant prior to shipment, but should be checked

upon receipt for transport damage. Any observed transport

damage is to be listed on the signed copy of the freight document.

Notify the freight forwarder of any damage WITHIN 48 HOURS.

2.0 INTRODUCTION

The following is a quick reference to important procedures that

must be followed while using the Vehicle Restraint System. It is

not intended to cover, or suggest that it does cover, all procedures

necessary to ensure safe operation. All operators should be aware

of and abide by all workplace safety regulations applicable to

the operation of the Vehicle Restraint System. These laws and

regulations include but are not limited to:

• The Occupational Safety and Health Act

• Canada Occupational Health and Safety Regulations

• Occupational Safety and Health Acts for Individual States

(USA)

For additional information on these regulations as well as industry

standards that may apply to this product, please contact:

American National Standards Institute (ANSI)

1430 Broadway

New York, NY 10018

Telephone: 212.642.4900

www.ansi.org

Also a member of:

Loading Dock Equipment Manufacturers

A Product Section of Material Handling Industry of America

A Division of Material Handling Industry

8720 Red Oak Blvd, Suite 201

Charlotte, NC, 28217-3992

Telephone: 704.676.1190

www.mhi.org/lodem

5

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

2.4 OWNER’S RESPONSIBILITY

1. The owner should recognize the inherent danger of the

interface between the dock and the freight carrier. The owner

should, therefore, train and instruct operators in the safe use

of the dock equipment and accessories in accordance with the

manufacturer’s recommendations.

2. The owner should thoroughly familiarize themselves with

the following procedures and specifications, and request

immediate replacement of all manufacturer-supplied

documents that are missing, damaged, or otherwise illegible.

• Installation instructions

• Operating instructions

• Planned maintenance procedures

• Inspections procedures

• Replacement parts lists

Upon receipt of any newly purchased dock equipment, the

owner shall verify the presence of owner’s manuals, operating

placards, and any other documentation necessary for

training dock personnel how to use the equipment safely and

effectively.

3. Manufacturer’s recommended periodic maintenance and

inspection procedures shall be followed, and written records

of the performance of these procedures should be kept as per

warranty guidelines.

4. Dock equipment that is structurally damaged, experiencing

performance irregularities, or has been potentially

compromised (i.e. sudden loss of support due to premature

truck departure) shall be removed from service until a trained

and authorized manufacturer’s representative can conduct an

inspection and perform any necessary repairs.

5. As with any piece of machinery, dock equipment requires

routine maintenance, lubrication, and adjustments. Your

local Blue Giant®representative offers owners the option

of a Planned Maintenance Program (P.M.P.). As part of this

service, your local Blue Giant representative will do all routine

maintenance, lubrication, and adjustments.

6. The owner shall ensure that all nameplates, caution/

instruction markings or labels are in place and legible, and

that the appropriate operating/maintenance manuals are

provided to authorized users. Replacement name plates,

caution/instruction labels, and manuals containing operating

and maintenance instructions are available through the

Blue Giant Aftermarket Solutions Department. See Section

10.0 "Decal Identification and Location" for more information.

7. Modifications or alterations of dock equipment shall be made

only with written permission of the original manufacturer. These

changes shall also satisfy all safety recommendations of the

original equipment manufacturer for the particular application

of the dock equipment.

8. The owner or a trained and authorized representative shall

verify that all freight carrier brakes have been applied and a

vehicle restraint and/or wheel chocks properly engaged before

cross-docking procedures such as loading and unloading

begin.

9. Unless specifically agreed to in writing by Blue Giant

Equipment Corporation at the time of order (and prior to

manufacture), all Blue Giant Dock equipment is sold as a

complete offering, and must not be altered or added to in

any manner (which includes configuration and function)

without written permission from an authorized manufacturer’s

representative.

10. If, at the request of the owner, Blue Giant does not supply

all or some of the dock equipment power unit and/or control

panel components, the owner shall assume responsibility for

any and all operational and safety issues associated with the

resulting configuration.

6

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

Serious injury or death will likely occur if the

instructions are not followed.

Serious injury or death may occur if the

instructions are not followed.

Procedures marked important must be followed in

order to prevent damage to machinery.

Instructions marked caution concern safe operating procedure.

Failure to comply may result in personal injury.

3.1 OPERATIONAL SAFETY WARNINGS

DANGER

WARNING

NOTICE

CAUTION

1. Installation must be performed only by trained and authorized personnel.

2. Prior to installation, place adequate barriers to prevent vehicle traffic from entering the work area.

3. During installation, anchors must be properly torqued to achieve the necessary anchoring strength. DO NOT USE IMPACT DRIVERS.

4. Any electrical work must be performed by qualified personnel only.

5. Do not remove the wheel chocks until loading /unloading is finished and the truck is cleared for departure or the vehicle restraint has been

released and the lights have changed to RED inside and GREEN outside.

WARNING

1. Do not operate the dock equipment while anyone is standing in its path.

2. Lift the dock equipment with suitable hoisting equipment only. Do not

stand under the dock equipment or any heavy object while it is being

hoisted.

3. BEFORE BEGINNING ANY SERVICE PROCEDURES:

Disconnect the power and follow all lockout / tagout procedures outlined

in this manual.

Keep hands and feet away from operating space of the

restraint apparatus.

CRUSH

HAZARD

DANGER

1. Do not ground welding equipment to any electrical components.

2. Do not allow the drill to go too deeply into the control box, as damage may occur to the control systems.

3. Never use air to blow debris from the control box. Use a vacuum to perform any necessary cleaning.

4. Do not connect green ground lead into control box or junction box until all welding has been completed.

5. If an extension plate / box is required, securely mount it on the restraint with hardware provided before shimming and drilling.

6. Improper adjustments and / or lubrication may cause operational problems with equipment.

NOTICE

1. Only trained personnel should operate or service this equipment.

2. Do not operate the dock equipment until the transport vehicle is parked against the dock bumpers.

3. Always park the dock equipment after use.

4. Conduct routine inspections and maintenance. Failure to do so could cause equipment damage and or personal injury.

5. Always call your authorized service representative or manufacturer immediately if a malfunction occurs.

CAUTION

3.0 SAFETY MESSAGE COLOR IDENTIFICATION

This manual includes color-coded safety messages that clarify instructions and specify areas where potential hazard exists. To prevent

the possibility of equipment damage and serious injury or death, please observe strictly the instructions and warnings contained in

the messages. If warning decals become damaged or missing, replace them immediately. Avoid accidents by recognizing dangerous

procedures or situations before they occur.

XXXXXXXXXXXX

XXXXXXXXXXX

OPERATE

DO NOT

1 2

7

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

WARNING

Always lockout and tagout any power source before performing any

work on any electrical devices or electrical controls according to OSHA

regulations and approved local electrical codes.

Approved way to lockout / tagout.

Restraint unlocked and in the stored position.Restraint locked and in the deployed position.

Rotate bar away from the wall to unlock. Restraint hook can descend to the

stored position.

Insert unlocking bar (Part# 56-011930) into slot with pressure for leverage.

4.0 LOCKOUT / TAGOUT PROCEDURE AND RULES

In accordance with the rules and regulations of the Occupational

Safety and Health Administration (OSHA), all affected employees

must be notified that the machine or equipment will be shut down

and locked out to perform repair or maintenance work. The work

area must be checked to ensure that all personnel have been

removed or safely repositioned. The machine or equipment power

supply shall be locked in the OFF position or disconnected from

the energy source. Blue Giant strongly recommends that only

OSHA-approved lockout devices and procedures be utilized.

The energy isolating device must bear a prominent warning tag

indicating that work is being done on the equipment and the

name of the authorized employee responsible for the lockout. It is

mandatory that tagout notices not be susceptible to deterioration

or illegibility due to weather conditions or exposure to chemicals

and moisture.

5.0 EMERGENCY VEHICLE RESTRAINT LOWERING PROCEDURE

In the event of a power/malfunction failure to the control panel while the restraint arm is in the vertical locked position, the locking

mechanism can be released manually. The restraint hook can then be lowered to the stored position. In case of restraint or control

panel malfunction, see below.

NOTE: Turn-off power switch / disconnect before performing manual emergency procedure.

NOTE: Confirm that the trailer ICC bar is not applying pressure to the hook / lock mechanism before attempting to unlock. Otherwise,

manual release will not be possible.

READ AND FULLY

UNDERSTAND THE OWNER’S

MANUAL BEFORE OPERATING

THIS PRODUCT.

DISCONNECT POWER

BEFORE OPENING.

WARNING

www.BlueGiant.com

Gold Series

TM

enius

G

lue

B

Touch Control

R

R

E

S

T

R

A

I

N

T

ESC

SEL

ESC

SEL

Engage

Release

Do Not Enter

Caution

Enter on Green

7

123

456

789

0#

*

*

REST RAINT

Engage

Release

STOP

R

E

S

T

R

A

I

N

T

REST RAINT

Engage

Engager

Release

8

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

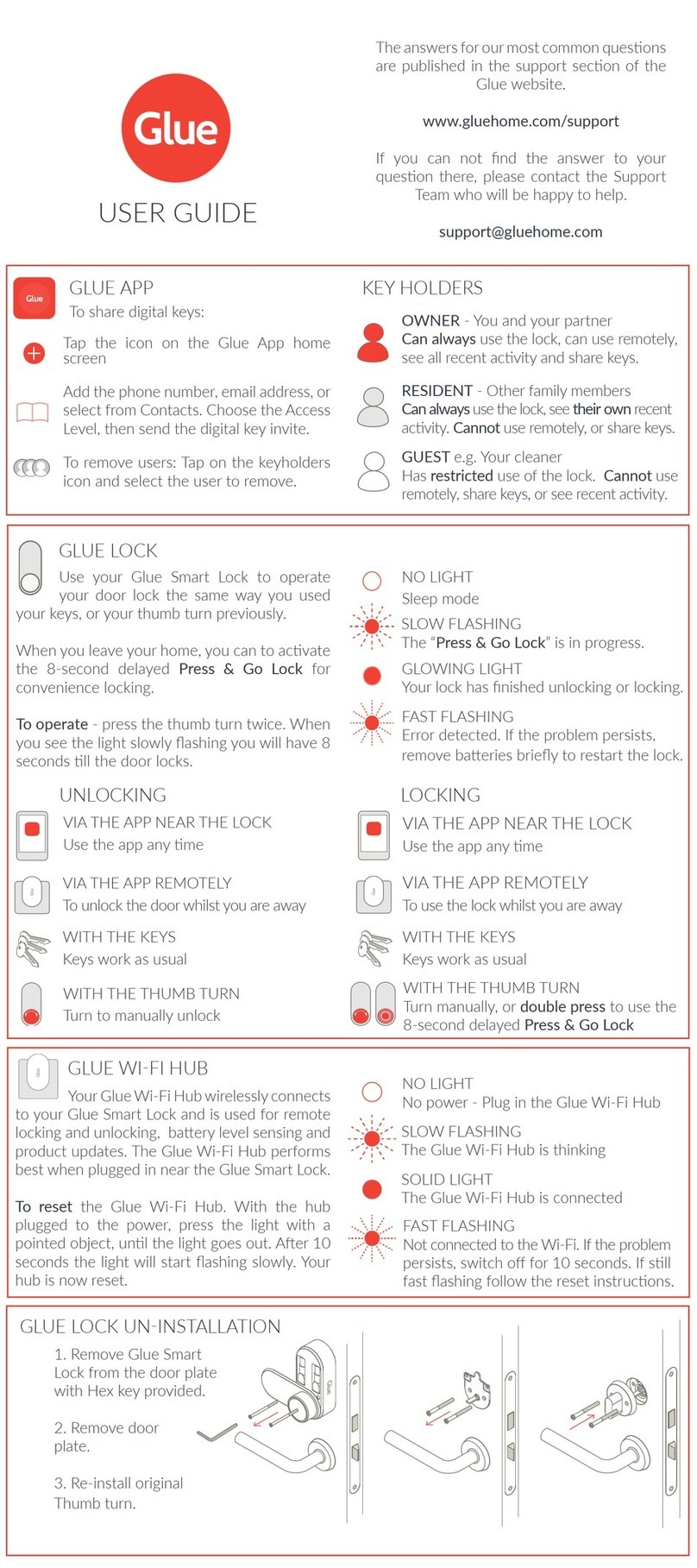

Controls combinations of all supported dock equipment: one individual vehicle restraint, one individual dock leveler, and controls for

a door. Also equipped with touch buttons, inside forklift operator traffic lights, operator menu screen, and keypad for coded features.

6.0 CONTROL PANEL OPERATION

Select

Escape

Restraint “ENGAGE”

(Raise / Lock Restraint)

Restraint “RELEASE”

(Lower / Unlock

Restraint) / Override

Release

“STOP”

Audible Speaker

Control Panel Keypad

(Override, Security,

Features)

Green Light

(Enter on Green)

Yellow Light

(Proceed with Caution)

Red Light

(Do Not Enter)

NOTE: Typical decal shown, actual decal is bilingual.

Menu Screen

(LCD Display)

Audible touch

6.1 BUTTON FUNCTION

When touching any of the function buttons or keypad, use the pad

of the finger. The control panel’s unique touch sensors detect the

proximity of the dock operator’s finger. Audible touch buttons and

keypad on the control panel provide instant sound feedback to

user input.

The 'Engage' and 'Release' buttons require only a single touch to

activate their respective functions. Do not apply constant pressure

Scroll "UP" / “DOWN”

www.BlueGiant.com

GoldSeries

TM

DISCONNECTPOWER

BEFOREOPENING.

READANDFULLYUNDERSTAND

THEOWNER’SMANUALBEFORE

OPERATINGTHISPRODUCT.

WARNING

R

#038-244E

STOP

R

E

S

T

R

A

I

N

T

0

ESC

SEL

8

9

5 6

2 3

1

4

7

EnterOnGreen

DoNotEnter

ProceedWithCaution

www.BlueGiant.com

GoldSeries

TM

DISCONNECTPOWER

BEFOREOPENING.

READANDFULLYUNDERSTAND

THEOWNER’SMANUALBEFORE

OPERATINGTHISPRODUCT.

WARNING

R

#038-244E

STOP

R

E

S

T

R

A

I

N

T

0

ESC

SEL

8

9

5 6

2 3

1

4

7

EnterOnGreen

DoNotEnter

ProceedWithCaution

www.BlueGiant.com

GoldSeries

DISCONNECTPOWER

BEFOREOPENING.

READANDFULLYUNDERSTAND

THEOWNER’SMANUALBEFORE

OPERATINGTHISPRODUCT.

WARNING

R

#038-244E

DoNot Enter

EnterOn Green

STOP

R

E

S

T

R

A

I

N

T

0

ESC

SEL

8 9

5 6

2 3

1

4

7

ProceedWithCaution

www.BlueGiant.com

GoldSeries

DISCONNECTPOWER

BEFOREOPENING.

READANDFULLYUNDERSTAND

THEOWNER’SMANUALBEFORE

OPERATINGTHISPRODUCT.

R

#038-244E

STOP

R

E

S

T

R

A

I

N

T

0

ESC

SEL

8

9

5 6

2 3

1

4

7

EnterOn Green

DoNotEnter

ProceedWithCaution

WARNING

www.BlueGiant.com

GoldSeries

DISCONNECTPOWER

BEFOREOPENING.

READANDFULLYUNDERSTAND

THEOWNER’SMANUALBEFORE

OPERATINGTHISPRODUCT.

R

#038-244E

STOP

R

E

S

T

R

A

I

N

T

0

ESC

SEL

8

9

5 6

2 3

1

4

7

EnterOn Green

DoNotEnter

ProceedWithCaution

WARNING

www.BlueGiant.com

GoldSeries

DISCONNECTPOWER

BEFOREOPENING.

READANDFULLYUNDERSTAND

THEOWNER’SMANUALBEFORE

OPERATINGTHISPRODUCT.

R

#038-244E

STOP

R

E

S

T

R

A

I

N

T

0

ESC

SEL

8

9

5 6

2 3

1

4

7

EnterOn Green

DoNotEnter

ProceedWithCaution

WARNING

ENGAGE RESTRAINT

1. Open the overhead door and visually conrm that the vehicle has

an ICC bar and that it is aligned and in range of the restraint arm.

The control panel light is RED and the trafc light is GREEN.

2. Touch the ‘Engage’ button. The arm will rotate from the home

position to secure the ICC bar and the LCD screen will read

“Restraint Engaging.” The trafc light will turn RED and the control

panel light will remain RED. When the ICC bar is secured, the LCD

screen will read “Restraint is Engaged,” followed by “Dock Leveler

Restored” and “Ready to Raise Deck.” After the deck is deployed

onto the truck bed, the control panel light will

turn GREEN.

OPERATING INSTRUCTIONS

Only for the StrongArm™HVR303 Vehicle Restraint

MENU DISPLAY

SCREEN

MENU DISPLAY

SCREEN DISENGAGE RESTRAINT

1. After the dock leveler is safely parked, touch the ‘Release’ button to

disengage the vehicle restraint. The control panel light will change

to RED and the LCD screen will read “Restraint Releasing.” When

the arm reaches the home position, the LCD screen will read “Blue

Genius Ready” and the trafc light will turn GREEN.

NOTE: If the restraint arm was not properly parked, the LCD screen

will read “Arm Blocked.” Consult the Troubleshooting section of the

manual.

VEHICLE RESTRAINT OVERRIDE

1. Touch the ‘Engage’ button. If a vehicle’s ICC bar is absent or cannot be

engaged, the LCD screen will read “ICC Bar Not in Range.” A visual

inspection is now necessary to determine whether the vehicle needs to

be realigned or if wheel chocks are necessary. The control panel light

and trafc light are both RED.

2. Press the * key on the keypad. The LCD screen will read “Enter Code

_ _ _.” Enter the factory set default supervisor code 247 (NOTE: this

code can be changed. Please call your Blue Giant distributor for further

information) the LCD screen will read “Dock Leveler Restored” and

then “Ready to Deploy Deck,” followed by “Restraint Is Bypassed.”

Once the deck is deployed and home sensor becomes inactive, the

control panel light will turn GREEN while ashing YELLOW.

3. When work has been completed, store the dock leveler. Then touch

the ‘Release’ button on the control panel. The control panel light will

turn RED, warning dock staff that the vehicle is no longer accessible.

The outside trafc light will turn GREEN, advising the truck driver that it

is safe to depart once the wheel chocks are removed.

MENU DISPLAY

SCREEN

THE INSIDE LIGHT WILL CHANGE TO SOLID

GREEN WHILE FLASHING YELLOW INDICATING TO

PROCEED WITH CAUTION AFTER THE OVERRIDE

CODE HAS BEEN ACCEPTED AND DOCK LEVELER

HAS BEEN DEPLOYED.

ENTER OVERRIDE CODE: * 247 (DEFAULT)

VISUALLY CHECK

TO ENSURE NO ICC

BAR IS PRESENT.

STOP PROCEDURE

1. Touching the ‘STOP’ button during operation will cut power to the

restraint. If the arm is in mid-travel, it will lower to a hard stop via

gravity. To exit the ‘STOP’ mode touch ‘ESC.’

038-847Ewww.BlueGiant.com

www.BlueGiant.com

GoldSeries

TM

T o u c h C o n t r o l

DISCONNECTPOWER

BEFORE OPENING.

READANDFULLY UNDERSTAND

THEOWNER’SMANUAL BEFORE

OPERATINGTHISPRODUCT.

WARNING

R

#038-244E

Do Not Enter

Proceed With Caution

Enter On Green

STOP

R

E

S

T

R

A

I

N

T

0

8 9

5 6

2 3

1

4

7

9

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

7.1 FUNCTIONAL DESCRIPTION

The vehicle restraint is used to restrain a trailer at the loading dock. When engaged, it secures a vehicle’s under ICC bar, restricting any

forward movement caused by vehicle creep or unscheduled departure. It is electrically operated via the Blue Genius™ Touch Control

Panel, and comes standard with an automatic lights communication package consisting of red/yellow/green control panel lights and

exterior red/green LED traffic lights.

7.0 OPERATING INSTRUCTIONS

WARNING

Exterior red / green traffic

lights advise the truck driver

when it is safe to depart.

Red / yellow / green control panel lights

keep forklift operators and warehouse

personnel advised of safety conditions

at the loading dock.

OUTSIDE TRAFFIC

LIGHT

INSIDE COMMUNICATION

LIGHTS & CONTROL PANEL

HVR303 operation placard—part # 038-847E.

Truck / Vehicle Dock Bumper Dock Leveler (Typical)

Vehicle

ICC Bar

Dock Interlock

(Lip Sensor)

Dock Face

Vehicle Restraint

(Hook Released)

Do not operate this vehicle restraint unless you have been trained and

authorized to do so, and have read and understood all of the safety

information and instructions contained in this manual.

Do not operate this restraint until you have checked its condition.

Report the need for repairs to your supervisor immediately and do not

operate the unit until repairs are made.

Never try to lift or move any part of the vehicle restraint manually.

Keep hands and feet clear of vehicle restraint pinch points.

It is the responsibility of the owner / operator of truck / vehicle to

(whenever possible) exhaust the air from air-ride suspension systems

prior to performing loading or unloading.

Because ICC bars differ in strength and construction, review the need

to use wheel chocks in conjunction with the vehicle restraint.

This vehicle restraint is designed for rear impact guards (RIG)

and rear impact protection (ICC Bar) that follow the Federal

Motor Carrier Safety Administration guidelines (FMCSA

section 571.223 and 571.224) + NHTSA (National Highway

Traffic Safety Administration) guidelines.

www.BlueGiant.com

GoldSeries

TM

DISCONNECTPOWER

BEFORE OPENING.

READANDFULLYUNDERSTAND

THEOWNER’SMANUAL BEFORE

OPERATINGTHISPRODUCT.

WARNING

R

#038-244E

STOP

R

E

S

T

R

A

I

N

T

0

ESC

SEL

8

9

5 6

2 3

1

4

7

Enter On Green

Do Not Enter

Proceed With Caution

www.BlueGiant.com

GoldSeries

TM

T o u c h C o n t r o l

DISCONNECTPOWER

BEFORE OPENING.

READANDFULLY UNDERSTAND

THEOWNER’SMANUAL BEFORE

OPERATINGTHISPRODUCT.

WARNING

R

#038-244E

Do Not Enter

Proceed With Caution

Enter On Green

STOP

R

E

S

T

R

A

I

N

T

0

8 9

5 6

2 3

1

4

7

10

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

ADVANCED SAFETY FEATURES

STANDARD OPERATION PROCEDURES

OUTSIDE TRAFFIC

LIGHT STATUS

INSIDE COMMUNICATION

LIGHTS & CONTROL PANEL

MENU DISPLAY

SCREEN

Typical

Image

OUTSIDE TRAFFIC

LIGHT STATUS

INSIDE COMMUNICATION

LIGHTS & CONTROL PANEL

MENU DISPLAY

SCREEN

Carriage raised

Hook Released

Leveler

parked w/dock

interlock

sensor

7.2 STOP BUTTON FUNCTION

Should an unexpected interference occur or potentially dangerous

situation arise, the Blue Genius™ control panel has a temporary

‘STOP’ button. Touching the ‘STOP’ button during operation will

cause the unit to stop in mid motion and the internal alarm will

beep until the stop function is exited. The control panel light will

flash RED and the exterior traffic light will be RED. To exit the

‘STOP’ mode touch the ‘ESC’ button.

7.3 PRIOR TO USE: EQUIPMENT IN STORED

POSITION

The Blue Genius™ control panel is powered on and ready for

use. The restraint apparatus is in the home position and the dock

leveler lip is parked safely in the lip keepers. The outside traffic

light is GREEN and the control panel light is RED.

-

INITIAL PRODUCTION

3/19/2012

REV

BY

REVISION DESCRIPTION

DATE

ECN NUMBER

BLUE GIANT EQUIPMENT CORP.

SCALE: 1:8

SIZE

DWG. NO.

A

MATERIAL

APPROX.

WEIGHT (lb.):

REF.

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL 1/32

ANGULAR: MACH .5 BEND 2

ONE PLACE DECIMAL 0.015

TWO PLACE DECIMAL 0.010

THREE PLACE DECIMAL 0.005

NAME

DATE

DRAWN

DESIGN

ENG APPR.

MFG APPR.

Q.A.

SHEET 3 OF 3

COATING:

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

BLUE GIANT EQUIPMENT CORPORATION.

ANY REPRODUCTION IN PART OR AS A

WHOLE WITHOUT THE WRITTEN PERMISSION

OF BLUE GIANT EQUIPMENT CORPORATION

IS PROHIBITED.

PROPRIETARY AND CONFIDENTIAL

DESCRIPTION

85 Heart Lake Road South

Brampton, Ontario, L6W 3K2

Tel: 905-457-3900

Fax: 905-457-5586

PART NUMBER:

FOR:

MATERIAL NO

PART NUMBER:

FINISH:

SIGNATURE

REVISION:

Created: Friday, January 06, 2012 2:11:11 PM / Printed: Tuesday, May 01, 2012

HOOK VEHICLE

RESTRAINT ASSY

56-010200

HVR303

453.273

56-010200

--01+WIP

56-010200

Dec 08, 2011

Dec 08, 2011

Dec 08, 2011

Dec 08, 2011

Dec 08, 2011

PC

PC

123456789

B

A

C

D

E

F

G

H

THIRD ANGLE

PROJECTION

www.BlueGiant.com

GoldSeries

TM

T o u c h C o n t r o l

DISCONNECTPOWER

BEFORE OPENING.

READANDFULLY UNDERSTAND

THEOWNER’SMANUAL BEFORE

OPERATINGTHISPRODUCT.

WARNING

R

#038-244E

Do Not Enter

Proceed With Caution

Enter On Green

STOP

R

E

S

T

R

A

I

N

T

0

8 9

5 6

2 3

1

4

7

www.BlueGiant.com

GoldSeries

DISCONNECTPOWER

BEFORE OPENING.

READANDFULLYUNDERSTAND

THEOWNER’SMANUAL BEFORE

OPERATINGTHISPRODUCT.

WARNING

R

#038-244E

STOP

R

E

S

T

R

A

I

N

T

0

ESC

SEL

8

9

5 6

2 3

1

4

7

Enter On Green

Do Not Enter

Proceed With Caution

11

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

OUTSIDE TRAFFIC

LIGHT STATUS

INSIDE COMMUNICATION

LIGHTS & CONTROL PANEL

INSIDE COMMUNICATION

LIGHTS & CONTROL PANEL

OUTSIDE TRAFFIC

LIGHT STATUS

MENU DISPLAY

SCREEN

MENU DISPLAY

SCREEN

Disengaged /

retracted

with trailer ICC in

contact with restraint

Engaged hook

with notch above

ICC bar

7.5 ENGAGING RESTRAINT

Touch the ‘Engage’ button on the control panel. The securing

apparatus will exit the stored position to secure the truck’s ICC bar.

The LCD screen will read ‘Engaging’. The traffic light will turn RED

and the control panel light will remain RED. When the ICC bar is

secured, the LCD screen will read ‘Restraint is Engaged’, followed

by ‘Dock Leveler Restored’ and ‘Ready to Raise Deck’.

NOTE: For vehicles without an ICC bar, or if the restraint apparatus

cannot successfully engage, please refer to the ‘Vehicle Restraint

Override Feature’ instructions in this section of the manual.

7.4 TRAILER AT BAY

The truck reverses into position against the dock leveler bumpers.

The outside traffic lights are GREEN and the control panel light is

RED.

REV

BY

REVISION DESCRIPTION

DATE

ECN NUMBER

BLUE GIANT EQUIPMENT CORP.

SCALE: 1:20

SIZE

DWG. NO.

A

MATERIAL

APPROX.

WEIGHT (lb.):

REF.

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL 1/32

ANGULAR: MACH .5 BEND 2

ONE PLACE DECIMAL 0.015

TWO PLACE DECIMAL 0.010

THREE PLACE DECIMAL 0.005

NAME

DATE

DRAWN

DESIGN

ENG APPR.

MFG APPR.

Q.A.

SHEET 1 OF 1

COATING:

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

BLUE GIANT EQUIPMENT CORPORATION.

ANY REPRODUCTION IN PART OR AS A

WHOLE WITHOUT THE WRITTEN PERMISSION

OF BLUE GIANT EQUIPMENT CORPORATION

IS PROHIBITED.

PROPRIETARY AND CONFIDENTIAL

DESCRIPTION

85 Heart Lake Road South

Brampton, Ontario, L6W 3K2

Tel: 905-457-3900

Fax: 905-457-5586

PART NUMBER:

FOR:

MATERIAL NO

PART NUMBER:

FINISH:

SIGNATURE

REVISION:

Created: Friday, April 13, 2012 11:16:50 AM / Printed: Tuesday, October 23, 2012

AP-00 - DOCK + TRUCK

+ TL

TRUCK AT BAY

941367.766

Indeterminate

Nov 25, 2009

Nov 25, 2009

Nov 25, 2009

Nov 25, 2009

Nov 25, 2009

123456789

B

A

C

D

E

F

G

H

THIRD ANGLE

PROJECTION

P

www.BlueGiant.com

GoldSeries

TM

enius

G

lue

B

T o u c h C o n t r o l

DISCONNECTPOWER

BEFORE OPENING.

READANDFULLY UNDERSTAND

THEOWNER’SMANUAL BEFORE

OPERATINGTHISPRODUCT.

R

#038-244E

Do Not Enter

Proceed With Caution

Enter On Green

STOP

R

E

S

T

R

A

I

N

T

0

ESC

SEL

8 9

5 6

2 3

1

4

7

www.BlueGiant.com

GoldSeries

TM

enius

G

lue

B

T o u c h C o n t r o l

DISCONNECTPOWER

BEFORE OPENING.

READANDFULLYUNDERSTAND

THEOWNER’SMANUAL BEFORE

OPERATINGTHISPRODUCT.

R

#038-244E

Do Not Enter

Proceed With Caution

Enter On Green

STOP

R

E

S

T

R

A

I

N

T

0

ESC

SEL

8

9

5 6

23

1

4

7

12

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

OUTSIDE TRAFFIC

LIGHT STATUS

INSIDE COMMUNICATION

LIGHTS & CONTROL PANEL

PERFORM LOADING AND UNLOADING

OUTSIDE TRAFFIC

LIGHT STATUS

INSIDE COMMUNICATION

LIGHTS & CONTROL PANEL

MENU DISPLAY

SCREEN

MENU DISPLAY

SCREEN

Leveler

parked w/

dock interlock

sensor

Engaged with

trailer ICC in

contact with

restraint

7.7 RELEASING THE RESTRAINT ARM

After the dock leveler is safely parked, the control station light

will turn RED while the outside traffic light remains RED. Touch

the 'Release' button to disengage the vehicle restraint. The

LCD screen will read 'Restraint Releasing.' When the restraint

hook reaches the home position, the LCD screen will read 'Blue

Genius Ready' and the outside traffic light will turn GREEN.

NOTE: If the securing apparatus was not properly parked, the

LCD screen will read ‘Arm Blocked’. Consult the Troubleshooting

section of the manual.

7.6 DEPLOYING THE DOCK LEVELER

Deploy the dock leveler (supplied by others) using controls

provided by original manufacturer. When the deck rises, the LCD

screen will read ‘Deck Deployed’. When the dock leveler deploys

onto the trailer bed, the outside traffic light will be RED, warning the

truck driver to stay in place. The control panel light will be GREEN,

advising dock staff that loading and unloading may safely begin.

7

123

456

789

0#

*

*

13

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

MENU DISPLAY

SCREEN

Should it be necessary to bypass the vehicle restraint function (i.e. the truck has an outdated, damaged, or missing ICC bar), a system-

approved override code may be entered via the Blue Genius™ touch keypad. This code can be used whether or not the dock leveler is

interlocked with the Blue Genius™. Ensure that the vehicle is manually chocked before loading and unloading begins.

NOTE: If a visual inspection confirms that the ICC bar is missing or too damaged to be secured, bypass Step 1 in the instructions below

and go directly to Step 2, which explains how to enter the Override Code.

1. During "Engaging Restraint" (Section 7.5), the LCD screen

may read "ICC Bar Not in Range." This message indicates that

a vehicle's ICC bar is absent or cannot be engaged.

Determine whether the vehicle needs to be realigned or if

wheel chocks are necessary.

2A. Press the * key on the keypad. The LCD screen will read

‘Enter Code *_ _ _’.

Enter the supervisor code (default factory set code is '247').

NOTE: The default code can be changed. Please call your

Blue Giant representative for further information.

Do Not Enter

Caution

Enter on Green

Wheel chock

8.0 ENGAGING THE OVERRIDE FEATURE

R

E

S

T

R

A

I

N

T

Engage

Release

Do Not Enter

Caution

Enter on Green

Dock Leveler

Restored

Ready to Deploy

Deck

Restraint is

Bypassed

R

E

S

T

R

A

I

N

T

14

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

8.0 ENGAGING THE OVERRIDE FEATURE CONT'D.

Continue operation of overhead door, dock leveler, and vehicle restraint as outlined in Section 7.5 "Engaging Restraint". The following

indicators will appear:

2B. The LCD screen will read ‘Dock Leveler Restored’ and then

"Ready to Deploy Deck," followed by "Restraint is Bypassed."

2C. Once the deck is deployed and the home/lip sensor becomes

inactive, the control panel light will turn GREEN while flashing

YELLOW. This indicates that the vehicle restraint is not

engaged.

8.1 RELEASING THE OVERRIDE FEATURE

1. Store the dock leveler. (NOTE: Override is still active when

dock leveler and vehicle restraint are in the parked position).

The control panel light will turn RED.

Touch the ‘Release’ button on the control panel to release the

override. The control panel will verify that the vehicle restraint

has been lowered to the home position. The LCD screen will

read "Blue Genius Ready."

The exterior traffic light will turn GREEN, advising the truck

driver that it is safe to depart once the wheel chocks are

removed. Light will only turn GREEN at the end of this step.

Do Not Enter

Caution

Enter on Green

Engage

Release

15

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

9.0 MAINTENANCE

WARNING

Do not operate and/or service this vehicle restraint until you have read and understood all of the safety information and instructions

contained herein and on the vehicle restraint.

Do not work under or around the vehicle restraint without first placing adequate barriers to positively prevent vehicle traffic from

entering the work area.

Follow proper lock-out/tag-out procedures.

Keep hands and feet clear of vehicle restraint pinch points and wear appropriate safety attire – glasses, gloves and work boots.

9.1 PLANNED MAINTENANCE PROGRAM (PMP)

In addition to the daily operator inspection, the manufacturer

recommends (and local government regulations may require)

that a planned maintenance program (PMP) and safety inspection

program be performed by a trained and authorized service

technician on a regular basis to maintain the equipment is in safe

operating condition. The PMP will provide an opportunity to make

a thorough inspection of the safety and operating condition of the

dock leveler. Necessary adjustments and repairs can be done

during the PMP, which will increase the life of components and

reduce unscheduled downtime.

Recommended procedures for a periodic planned maintenance

program that covers inspections, operational checks, cleaning,

lubrication, and minor adjustments are outlined in this manual.

An authorized dealer or distributor is prepared to assist with

a planned maintenance program by offering trained service

personnel with expertise in dock leveler maintenance requirements.

9.2 OPERATOR DAILY INSPECTION

The vehicle restraint should always be examined by the operator

PRIOR TO ANY USE to verify that it is safe to operate.

The manufacturer recommends making multiple photocopies of

the PMP Checklist (See Section 9.6 “PMP Checklist - StrongArm™

HVR303 Vehicle Restraint”). The operator should fill out this form to

keep a daily record of operation and maintenance issues.

9.3 ROUTINE SERVICING AND MAINTENANCE

Regular maintenance and care of the vehicle restraint is very

important for cost, operation efficiency, and operator safety. A faulty

vehicle restraint is a potential source of danger to the operator, and

to other personnel working near it. As with all quality equipment,

keep the vehicle restraint in good operating condition by following

the recommended schedule of maintenance.

Failure to properly maintain or operate the dock leveler within its

rated capacity can void the manufacturer warranty.

9.4 PLANNED MAINTENANCE PROGRAM INTERVALS

Arrange for a qualified vehicle restraint service technician to

perform regularly scheduled planned maintenance on your vehicle

restraint every three months for single shift operations or monthly

for multi-shift operations. Call your authorized manufacturer or

dealer for further details.

9.5 MAINTENANCE SEQUENCE

1. Cleaning, including pit area

2. Visual inspection of all components

3. Lubrication, as required (by a trained service

technician only)

4. Test operate all functions

5. Adjustments, if required (by a trained service

technician only)

6. Check for missing or damaged dock bumpers

7. Record inspection details and findings for owner's files

16

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

9.6 PMP CHECKLIST - STRONGARM™ HVR303 VEHICLE RESTRAINT

WARNING

DANGER

DANGER

Prior to installation, place adequate barriers to prevent

unauthorized personnel and vehicle traffic from entering

the work area.

All repairs and maintenance work are to be conducted by

trained and authorized personnel ONLY.

INSPECTED BY: DATE:

SERIAL #: DOOR #:

Forward this checklist to the person responsible for dock equipment maintenance. See Section 1.1 “Owner’s Purchase Record” for

Date in Service.

INSTRUCTIONS FOR USE: Indicate “OK for USE” with a check mark in the appropriate box of each inspection point.

EVERY DAY:

c Remove any debris that may have accumulated around the

dock equipment

c Check dock bumpers/extensions, wall cracks

c Check interior and exterior lights system

c Check exterior signage

c Check hydraulic hoses for leaks and/or damage

c Check safety warning decals and replace if necessary

c Verify complication-free operation of the Blue Genius™

Control Panel

c Verify complication-free operation of the dock equipment

EVERY 90 DAYS (30 DAYS FOR MULTI-SHIFT OPERATIONS)

c Perform all "every day" tasks

c Grease HVR303 rollers

c Check powerpack connections, motor and valves

c Inspect for damaged or missing parts, rust, corrosion, bent

parts, cracks, etc.

c Check anchors

When repairing or conducting maintenance procedures on electrical components, perform lockout / tagout steps

according to OSHA regulations and approved electrical codes.

EVERY 90 DAYS CONT'D.

c Check junction box and control panel for proper and secure

mounting. Verify that all electrical connections are firm

cCheck hydraulic oil level in powerpack

c Check condition and torque on securing anchors, concrete

conditions

c Verify that the proximity sensors are secure

ONCE A YEAR

c Drain, flush, and change the hydraulic reservoir

as site / oil type dictate

Explain faults briefly in the space provided below:

PHOTOCOPY THIS CHECKLIST AND FILL OUT

REGULARLY FOR YOUR RECORDS.

17

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

STANDARD OPERATIONAL COMPONENTS

ITEM PART NO. DESCRIPTION QTY

REQ’D

1 56-010295 Extension Spring 4

2 019-034 Carriage Roller Housing with Bearing 4

3 56-010332 Y Bearing Assembly with

Hardware 2

4 026-H19 Limit Switch with Connector 2

5 1005470 Roller Chain Assembly 1

STANDARD OPERATIONAL COMPONENTS

ITEM PART NO. DESCRIPTION QTY

REQ’D

6 023-048 Chain Sprocket 1

7 118-755 Key 1/4 Square 3

8 026-H18 Harness with Cable and

Connectors 1

9 026-G025M Remote I/O Board (Resistor) 1

7

7

2

4

8 9

5

31

6

10.0 RECOMMENDED SPARE PARTS

10.1 STANDARD OPERATIONAL COMPONENTS

18

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

10

10.2 OPTIONAL SUPPORT COMPONENTS

OPTIONAL SUPPORT COMPONENTS

ITEM PART NO. DESCRIPTION QTY

REQ’D

10 1005476 Gear Motor Assembly with Cable

and Connector 1

11 028-206 Proximity Sensor (30mm

Unshielded) Home/Lip Sensor 1

12 56-011930 Lock Manual Release Tool 1

11 12

STRONGARM HVR303

038-846E

DO NOT STEP

038-845E

WARNING

WARNING

DO NOT STEP

BLUE GIANT EQUIPMENT

CORPORATION

85 Heart Lake Road South

Brampton, Ontario, Canada

L6W 3K2

MODEL HVR303

MH30.3-2015

SERIAL NO.

ANSI CODE

CONST. MM / YYYY

TEST LOAD

“REFER TO SAFETY AND OPERATING

INSTRUCTIONS IN YOUR OWNERS

MANUAL”

32,000 lbs.

kg.

14,545

www.BlueGiant.com

MADE IN CANADA

FABRIQUE AU CANADA

038-299E

038-240

VehicleRestraint

•Spring Energy could result

in serious injury or death.

WARNING

P/N 038-048-2

Keep Hands and Feet away

from operating space of the

Restraint Arm. CRUSH HAZARD

038-243E

CAUTION

STRONGARM HVR303

038-846E

19

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

11.0 DECAL IDENTIFICATION AND LOCATION

ITEM QTY PART NO. DESCRIPTION

1 1 038-846E Decal - BG HVR303

2 1 038-240 Decal - StrongArm - Vehicle Restraint

3 1 038-243E Decal - Crush Hazard

4 1 038-048-2 Warning Decal - Springs Energy

5 1 038-845E Warning Decal - Do Not Step

6 1 038-084EFS Warning Decal - Hazardous Voltage

7 1

038-299E F

Decal - Serial Plate

038-299E S

12

3

4

1

4

6

5

2

7

3

5

6 7

20

STRONGARM™ HVR303 VEHICLE RESTRAINT WITH BLUE GENIUS™TOUCH CONTROL—OWNER’S MANUAL

ISSUE DATE: MAY 23, 2017 REV.6 (PART # 038-844E)

ITEM QTY PART NO. DESCRIPTION APPROX. WEIGHT

1 1 56-010199 Roller Track Assembly 62 lb 28 kg

2 1 56-010197 Carriage Assembly 125 lb 57 kg

3 4 019-034 Roller Assembly 3.2 lb 1.45 kg

4 1 56-010193 Spring Bar Weld 12 lb 5.44 kg

5 1 56-010306 L Spring Cover Weld 6 lb 2.72 kg

6 1 56-010304 R Spring Cover 5 lb 2.27 kg

7 4 56-010295 Extension Spring OD

1.875 x 10.75 long 2 lb 0.9 kg

8 1 56-010320 Extension Arm Assembly 10 lb 4.5 kg

9 1 56-010968 HVR J. Box Assembly 1 lb 0.45 kg

ITEM # 11 - CONTROL AND COMPONENTS INCLUDED:

QTY PART NO. DESCRIPTION APPROX. WEIGHT

1

BGG0H1115F Complete Control Assembly

English / French

6.2 lb 2.81 kg

BGG0H1115S Complete Control Assembly

English / Spanish

1032-461 Exterior Traffic Light 1.3 lb 0.6 kg

1038-225

E

Exterior Driver Warning Sign 0.7 lb 0.32 kgF

S

126-011290 Dock Interlock (Lip Sensor) 0.4 lb 0.18 kg

1038-847E Operation Placard — —

1038-844E Owner's Manual (this one) — —

ITEM # 10 - HARDWARE INCLUDED:

QTY PART NO. DESCRIPTION APPROX. WEIGHT

2010-232 Socket Cap Screw 7/16"-14 x 1 1-2" L

1 lb 0.45 kg

2011-863 Serrated-Flange HEX. Nut 7/16" - 14

4011-042 Cap Screw, HEX Socket F/H 5/16-18 x 1"

2010-037 Cap Screw 5/16-18 x 3/4 HH GR. 5 ZC

2012-200 Regular Spring Lock Washer 5/16"

15 010-239 Self Tapping Anchor 6 lb 2.72 kg

156-010950 Junction Box with Remote I/O 0.8 lb 0.36 kg

12.0 EQUIPMENT COMPONENT ILLUSTRATIONS

12.1 COMPONENTS AS SHIPPED CHECK LIST

NOTE: Some components shipped loose for assembly in the field.

10

HARDWARE

11

CONTROL AND

COMPONENTS

7 6 5

4

39

8

Table of contents