Blue Max Mini Modular Plus User manual

85

en

Operating manual

BlueMax Mini Modular Plus

86

en

86

1. Foreword

1. Introduction 89

2. Important notes 89

Revision service 89

Updating 89

3. Validity of this operating manual 89

Application 89

Copyright reserved 89

4. Owner‘s personal responsibility 89

5. Service 89

2. EC declaration and protocols

1. EC Declaration of Conformity 90

2. Important note 91

3. Verification of instruction 91

3. General safety rules

1. Information on signs, symbols and markings 92

2. General 93

3. Safety advice for the user company 94

4. Noise 94

5. Oils, greases and other chemical substances 94

6. Residual risk

94

7. Safety advice for operating personnel 95

8. Safety advice for operating the machine 95

9. Safety advice for carrying out maintenance work 95

10. Training / instruction 95

11. Personal protective equipment 96

4. Purpose / operating principle

1. General information 98

2. Intended use 98

3. Foreseeable incorrect use 98

4. Operating principle and description of the machine 99

5. Rating plate 99

6. Limit values 99

7. Liability 99

5. Technical information

1. Safety precautions 100

2. Attachment points 100

3. Technical Specifications 101

4. Equipment 102

Programming digital display 104

Setting 106

5. Guards 106

6. Noise mission 107

7. Aligning / fastening 107

General information 107

8. Connections required 107

Main power connection 107

Compressed air connection 108

9. Transportation 108

Transportation on fork lift truck or pallet jack 108

10. Internal handling 108

11. Checking delivery for missing items 108

12. Dealing with shipping damage 108

13. Measures on temporary storage 108

14. Site of installation 109

15. Safety guards to be provided by the owner 109

16. Permissible ambient conditions 109

17. Removing preservatives 109

18. Electrics 109

19. Compressed air connection 109

20. Suction extractor 109

6. Start up / trial run

1. General 111

2. Safety check 111

3. Malfunctions on start-up 111

4. Starting up for the first time 111

5. Machine versions supplied 112

6. Interchangeable drilling units 113

Interchangeable drilling unit, 3 spindles Selekta 113

Interchangeable drilling unit, System 32 hole line 113

Interchangeable drilling unit, System 32 hole line 90° 113

7. Other accessories 113

8. Assemblies 114

Press-in frame for the interchangeable drilling unit,

6 spindles 114

Centre stop 115

Continuation stops 115

Drilling depth settings 118

Drum stop 118

Hold-down clamp 118

Converting from manual operation to foot pedal 119

Connecting foot switch for a machine

with horizontal drilling unit 119

Connecting foot switch for a machine

without horizontal drilling unit 120

9. Carrying out trial run 121

10. Concluding start-up 121

7. Setting up

1. Preparing machine 122

Readiness for use 122

Connecting to extractor system 122

Connecting to compressed air supply 123

Connecting to power supply 123

Switching on 124

Operating 124

Drilling hole line, interchangeable drilling unit,

9 spindles 125

Inserting hinges 126

2. Setting up (preparing for work) 126

Tools used (drill bits) 126

Interchangeable drilling unit, 6 spindles,

Interchangeable drilling unit, 3 spindles (Selekta 22/9) 127

Interchangeable drilling unit, 9 spindles 127

Interchangeable drilling unit, 90°, 9 spindles 128

Changing interchangeable drilling units 128

Cleaning 128

Fitting drilling units 129

Checking switch for proper working order 129

Setting drilling depth, vertical drilling unit 130

Drilling with horizontal drilling unit 130

Settings on the back of the machine 131

Limiting drilling stroke for drilling hole lines 132

3. Hold-down clamp and centre stop 132

Hold-down clamp 132

Centre stop 133

Setting the drum stops 133

Pendulum stops 133

8. Operation

1. Safety check 134

General information 134

Readiness for use 134

Control panel 135

2. Switching on 136

Preparatory work 136

3. Operating 136

Hold-down clamp 137

Fitting Hettich hinges 137

Drilling 138

Pressing in 138

Contents

109

87

en

87

4. Malfunctions during operation 139

Troubleshooting 139

5. Checks during operations 139

Checks for proper working order 139

9. Servicing / care

1. General information 140

Working on electrical components 140

2. Instructing maintenance personnel 140

3. Making the machine safe on shutdown 141

4. Cleaning the machine 141

Electric motors 141

5. Servicing work 141

Servicing and maintenance 141

Servicing unit 142

6. Instructions on inspections 142

General 142

10. Malfunctions / troubleshooting

1. General information 143

2. Malfunctions caused by the owner 143

3. Troubleshooting 143

General causes of malfunction 143

Malfunctions while machine is operating 143

4. Reporting malfunctions 143

11. Dismantling / disposal

1. General information 144

Before dismantling 144

2. Taking out of service 144

3. Dismantling 145

General information 145

Dismantling the machine / system 145

4. Hazardous substances / disposal 145

Protecting the environment 145

Scrapping 145

Oil and oily wastes 145

12. Replacement parts lists

1. Base frame 147

2. Work surface 147

3. Eccentric tensioner 148

4. Guide frame 148

5. Foot extension 149

6. Suction extractor 149

7. Cable drag chain 150

8. Console 150

9. Lifting cylinder 151

10. Drill depth stop 152

11. Adjustable stop 152

12. Clamping element 153

13. Motor with support 154

14. Centre stop 154

15. Press-in frame 155

16. Hold-down clamp, rear 155

17. Hold-down clamp, front 155

18. Drum stop 156

19. Horizontal drilling unit 157

20. Interchangeable drilling unit, 90°, 9 spindles 158

21. Interchangeable drilling unit, 9 spindles 159

22. Interchangeable drilling unit, 6 spindles 159

23. Interchangeable drilling unit, 3 spindles,

Selekta (22/9) 159

24. Pneumatics diagram 160

25. Circuit diagram 161

13. Replacement part numbers

1. List of replacement part numbers with designation 162

14. Instructions for installing accessories

1. Press-in frame 164

2. Converting from pushbutton to foot switch 164

Connecting foot switch for a machine

with horizontal drilling unit 165

3. Installing laser 166

4. Installing support block 167

88

en

88

1. Foreword

1. Introduction 89

2. Important notes 89

Revision service 89

Updating 89

3. Validity of this operating manual 89

Application 89

Copyright reserved 89

4. Owner‘s personal responsibility 89

5. Service 89

Foreword

WARNING

Read these operating instructions carefully in order

to obtain a thorough understanding of the machine

and how to handle and maintain it. Operate the

machine in the proper manner as described in these

instructions so as to avoid injury and damage to the

system. Do not operate the machine on the basis of

suppositions. Keep these operating instructions to

hand and consult them if you are in any doubt as

to carrying out any particular procedure.

If any questions remain unanswered after reading

through the instructions, you must not put the

machine into operation.

Settle any unanswered questions first by consulting

Paul Hettich GmbH & Co. KG.

These operating instructions are intended to make it easier

for you to become familiarised with the machine and use its

capabilities in the proper manner.

The operating instructions contain important information on

operating the machine in a safe, proper and cost effective

manner. Following them will help to avoid hazards, repair

costs and down times, enhance reliability and prolong service

life.

Existing national regulations on preventing accidents and on

protecting the environment are also applicable.

The machine will only be assembled and

installed by persons instructed to do so by

Paul Hettich GmbH & Co. KG. This also applies in

particular to starting it up for the first time.

The operating instructions must be available at the machine

all the time. The operating instructions must be read and

applied by any person entrusted with working with / on the

machine, e.g.:

• Operation

• Including setting up, troubleshooting while working,

disposal of production waste, care, disposing of

consumables and auxiliary substances,

• Maintenance

• Servicing, inspection, repair

• Transportation

given the task.

89

en

89

1. Introduction

The main objective of this operating manual is to protect

“man and machine“ in accordance with the EC Machinery

Directives. It is intended for all persons involved in working

with and on this machine or system, in particular the

operating personnel.

• As operating / servicing personnel, first read this operating

manual and familiarise yourself with using the machine

and operating it safely as well as with how to perform

the necessary set-up, servicing and / or repair work in the

proper way while meeting the safety requirements.

• Your personal safety and that of your surroundings as

well as safe machine operation without risk to other

property or the environment will only be ensured if you

are familiar with and follow all of the information in this

operating manual as well as in pertinent health and safety

regulations.

• As customer and / or owner, make sure that this operating

manual is given to your operating / servicing personnel

before putting the machine / system into service for the

first time, that it remains available directly at the machine

at all times and that all persons concerned observe the

information and warnings provided in this operating

manual, the code of practice applicable to the site of

installation as well as the regulations on occupational

health and safety etc.

In other words, this operating manual does not release the

owner from the duty to devise his or her own health and

safety rules as well as safe work procedures tailored to his

or her production requirements / needs, to any specific

system / machine combination, to specific installation

conditions, to specific modes of connection and/or tool and

component properties etc., and to apply these, have them

applied and monitor their observance.

2. Important notes

Revision service

This operating manual is not subject to any revision service.

If changes / additions are made after the machine has been

delivered, it is the responsibility of the owner to update

this operating manual using his or her own addenda or any

addenda provided by Paul Hettich GmbH & Co. KG.

The right is at all times reserved to amend and improve

all technical specifications, details and illustrations in the

interest of technical progress.

Updating

The laws, provisions, regulations, directives, codes of practice

etc. specified in this operating manual as well as statements

derived from them were up to date at the time this manual

was compiled.

They must be heeded in their latest, applicable wording,

updated at the responsibility of the owner and always applied

in their more restrictive (stringent) wording.

We also point out that the content of this operating manual

is not part of any earlier agreement, assurance or legal

relationship or intended to amend such. All obligations on the

part of Paul Hettich GmbH & Co. KG arise from the pertinent

supply contract that also contains the complete and solely

applicable warranty arrangements or draws attention to

these. Statements made in this operating manual neither

extend nor restrict these warranty provisions.

3. Validity of this operating manual

• This operating manual only applies to this machine.

• Please always quote the machine no. in all queries and

orders for replacement parts.

Statements made in this operating manual in relation to

items of equipment not included with the machine are for

information only. They do not give rise to any legal claim to

the machine being equipped with these items.

Application

This operating manual has been produced in compliance

with EC directives, European (harmonised) standards etc.

References to occupational health and safety, environmental

protection and safety provisions may not yet conform

to harmonised accident prevention regulations (UVV) /

statutory accident insurance regulations (GUV) applicable

in Germany or to the DIN standards or technical regulations

stated in the appendix to the German Equipment Safety Act

(Gerätesicherheitsgesetz (GSG)).

The customer / owner is personally responsible for:

• regarding specified laws, regulations, directives etc., as the

basis for safe handling and maintenance practice,

• implementing and observing them in line with national /

regional / company-internal regulations,

• providing supplementary safety or protective equipment

prescribed by the responsible local, regional or national

authorities and for fitting them before using the machine /

system for the first time.

Operating instructions:

Paul Hettich GmbH & Co. KG

© 2017 by Paul Hettich GmbH & Co. KG

Copyright to the operating instructions

The copyright to this operating manual remains with

Paul Hettich GmbH & Co. KG.

These operating instructions are intended for the operating

personnel. They contain regulations and drawings of a

technical nature that must not be duplicated either in whole

or in part, distributed, used without permission for advertising

purposes or communicated to others.

Reproduction either in whole or in part is not permitted.

4. Owner‘s personal responsibility

The customer or owner is personally responsible for ensuring

that:

• provisions on occupational health and safety, environmental

protection and disposal are observed in relation to the

machine, handling it as well as in the course of inspections,

servicing and repair measures,

• no improper changes or modifications are made to the

machine and safety guards,

• the machine is not used in any inappropriate, improper or

non-intended manner.

5. Service

Customer Service

Paul Hettich GmbH & Co. KG

Vahrenkampstrasse 12 - 16

D-32278 Kirchlengern

90

en

90

en

2. EC declaration and protocols

1. EC Declaration of Conformity 90

2. Important note 91

3. Verification of instruction 91 1. EC Declaration of Conformity

EC declaration and protocols

EC Declaration of Conformity is enclosed loose.

91

en

91

2. Important note

Information for the owner

In addition to these operating instructions and the accident

prevention regulations in force in the country of use or at

the place of application, it is also necessary to follow the

recognised code of safe and proper working practice.

Without the consent of Paul Hettich GmbH & Co. KG, the

machine owner must not make any additions, alterations or

modifications to the machine that may affect safety.

Replacement parts used must meet the technical

requirements defined by Paul Hettich GmbH & Co. KG. This is

always ensured when using genuine replacement parts from

the applicable replacement parts list.

Only ever deploy trained or instructed personnel and clearly

define personnel responsibilities with regard to operating,

servicing and repair.

Use for other purposes and modifications

We expressly point out that the EC declaration shall become

null and void if modifications / changes etc. are made to the

machines listed above.

The company making the modification must amend the EC

declaration and extend or make out new documentation to

reflect the latest modification

(Art. 8 (6) of the EC Machinery Directive).

Name Date

from / to

Type of instruction received Signature of

the person

instructed

Instructor Person instructed Operation Safety rules Servicing

3. Verification of instruction

By signing this protocol the undersigned confirm that the

following details and specifications are correct.

Confirmation

I hereby confirm that I have read and understood the

operating manual for the machine:

Designation BlueMax Mini Modular Plus

Type Automatic drilling and insertion machine

Machine no.

have read and understood.

I furthermore undertake to observe and follow the general

safety precautions, the servicing and care instructions

as well as power-up and operating instructions and the

provisions relating to malfunctions. I am aware that any

failure to observe these instructions and provisions may lead

to accidents, put persons at risk and result in damage to

property and the machine.

92

en

General safety rules

3. General safety rules

1. Information on signs, symbols and markings 92

2. General 93

3. Safety advice for the user company 94

4. Noise 94

5. Oils, greases and other chemical substances 94

6. Residual risk 94

7. Safety advice for operating personnel 95

8. Safety advice for operating the machine 95

9. Safety advice for carrying out maintenance work 95

10. Training / instruction 95

11. Personal protective equipment 96

1. Information on signs, symbols and markings

The safety advice in the operating instructions is structured as

follows:

DANGER

This danger advice draws attention to an immediately

dangerous situation that will lead to death or serious

injuries if the safety measures are not followed.

WARNING

This danger note draws attention to a potentially

dangerous situation that may lead to death or serious

injuries if the safety measures are not followed.

CAUTION

This danger note draws attention to a potentially

dangerous situation that may lead to minor or slight

injuries if the safety measures are not followed.

NOTE

This advice draws attention to potential damage

to property or to a process of particular interest /

importance that may occur if the safety measures are not

followed.

In the operating instructions, hazard points are identified as

follows:

DANGER

Danger from electric shock!

Working on live components in the improper manner

presents a danger to life!

Work on electrical equipment must only be carried out

by authorised electricians!

WARNING

Hearing damage warning!

Some areas of the facility can reach noise levels of

over 80 dB (A).

Wear ear protectors when working in noisy areas!

WARNING

Danger from wood dust!

Wood dust can affect the respiratory tract. For this

reason, wear a dust protection mask.

93

en

WARNING

Fire risk!

Grinding and welding work must never be performed

on this machine.

Follow welding regulations and accident prevention

regulations.

WARNING

Explosion protection

Machine is not explosion-protected. Do not install

near paint shops.

WARNING

Warning - Hand injuries!

Hands could be crushed, drawn in or otherwise injured.

Never reach into the system‘s moving parts!

Wear hand protection!

WARNING

Warning - Hot surfaces / objects!

There is a risk of injury from touching hot surfaces

(e.g. electric motors).

Do not touch!

2. General

The machine described in the operating instructions is built to

the state of the art and safe to operate.

It complies with DIN EN 12100.

Hazard zones are made safe in compliance with the

regulations. However, the machine may present hazards if

it is used by untrained personnel improperly or not for the

intended purpose.

This may then result in risks to life and limb, jeopardise the

machine and prevent it from working efficiently.

Any person given the task of installing, starting, operating,

servicing or repairing the machine at the user‘s premises must

have read and understood these instructions, in particular the

section on “Safety precautions“.

In his or her own interest, the safety officer at the user

company should obtain written conformation from operating

personnel that they have received instruction and training

and are familiar with all safety precautions before they use

the machine for the first time.

The safety guards must never be removed or taken out of

operation.

If safety guards need removing for maintenance and repair

work, they must be refitted as soon as such work has been

completed.

The machine must only be used if it is in proper working order

and operated by trained, authorised personnel.

Work requiring specialised knowledge (e.g. electrical,

pneumatic system) must only be carried out by persons

specifically trained and suitable to do so.

Before attempting any work on the machine, turn the main

switch to the “0“ position (OFF), make the machine safe and

disconnect from the compressed air supply.

Switch off energy sources before carrying out repair, servicing,

installation or cleaning work.

Energy sources:

• Electrical energy

• Pneumatic energy

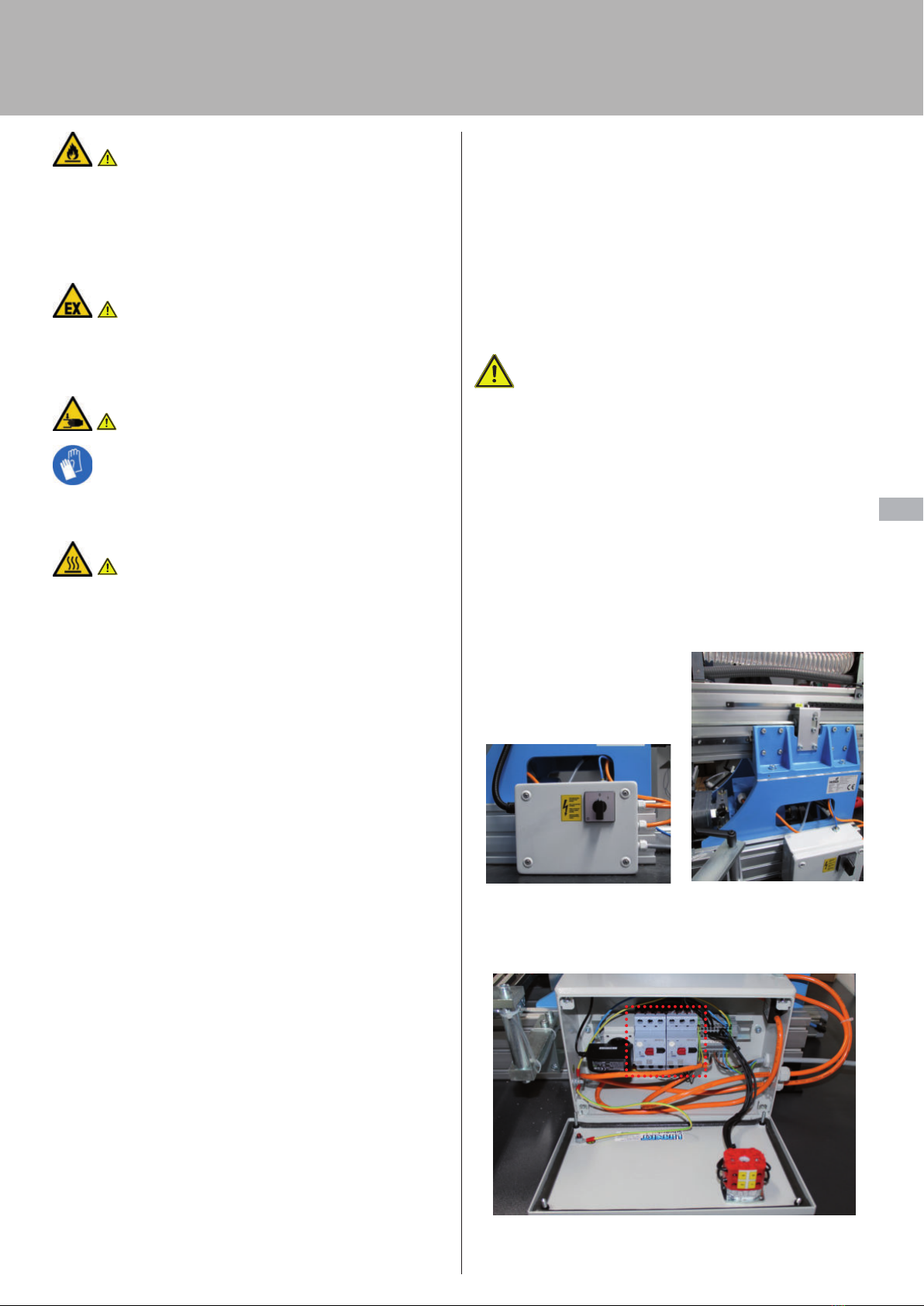

CAUTION

Danger from residual energy!

Stored energy will not be dissipated even after switching

the system off at the main switch.

Dissipate residual or stored energy!

Switch off / dissipate energy sources:

For safety regulations applicable to third party devices, refer

to the documentation from the third party manufacturers

(operating instructions for bought in units).

Electrical energy via the motor switch / machine‘s main

switch. Additionally attach a notice when servicing or other

work is being carried out on the machine.

Fig. 3: Main switch

(viewed by the operator, on the right hand side of the

machine frame)

Fig. 4: Motor protection circuit breaker

94

en

94

CAUTION

Warning - Hand injuries!

The main switch only shuts down the drive system, not

the pneumatic system!

The machine has no emergency stop button or

emergency stop facility. This means it is necessary to

take particular care when handling and working on

this machine.

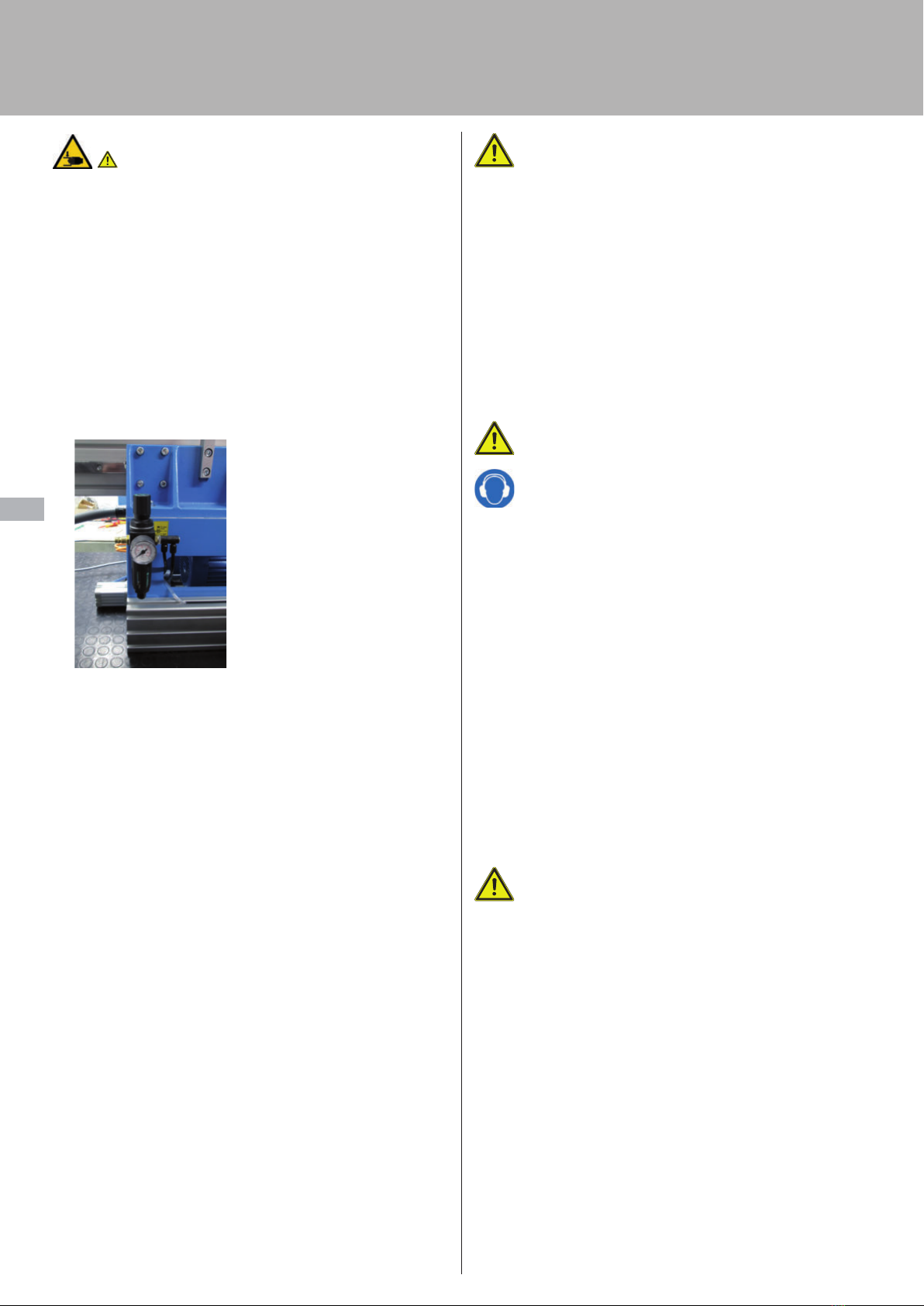

Pneumatic energy through the supply connection on the

machine frame. Make sure that all machine components are

depressurised and any stored energy is dissipated. As part of

the installation process, the owner will provide a mechanical

main cock at which the machine can be disconnected from

the compressed air supply.

Fig. 5: Pneumatic system servicing unit

(viewed by the operator, on the left hand rear side of the

machine frame)

3. Safety advice for the user company

All persons entrusted with operating the machine (including

line managers) must familiarise themselves with the section

on “Safety advice“.

The safety advice must be followed.

The machine must only be operated if it is in proper working

order. The user company will issue clear responsibilities, e.g.

for servicing, cleaning or repair, and ensure that the persons

carrying out this type of work have received the training

necessary for it.

The safety regulations applicable in the owner‘s country must

also be observed. Refrain from any work that adversely affects

operating safety.

The operating personnel will check the machine for changes

or malfunctions, report such to the safety officer responsible

and, if necessary, take the machine out of operation.

Only appropriate tools must be used for the work that needs

to be done; remove tools after completing work. The place at

which staff work must be selected in such a way as to ensure

that work operations can be viewed at all times, the machine

can always be stopped immediately and safety is never at risk.

General safety rules

WARNING

Never:

• reach into the machine when it is operating,

• remove covers and take safety guards out of operation,

• hinder unobstructed access to the controls,

• continue operating the machine if changes occur that

adversely affect safety and

• manipulate or circumvent safety guards.

4. Noise

The weighted equivalent continuous sound level

is > 80 dB (A).

WARNING

Hearing damage warning!

Local conditions may produce elevated sound pressure

and cause noise induced hearing loss!

Operating personnel must be provided with appropriate

protective equipment or be protected by other measures!

Wear ear protectors when working with the machine!

5. Oils, greases and other chemical substances

When handling oils, greases and other chemical substances,

you must observe and follow the applicable regulations and

safety data sheets of the manufacturers of these substances

with regard to storing, handling, using and disposing of them.

When working with caustic substances, you must wear

protective equipment of suitable material (safety goggles,

rubber gloves, rubber boots, protective clothing).

In the event of contact with the eyes or skin, immediately

rinse the area affected with copious quantities of water.

Appropriate facilities (eye wash bottle, wash basin, shower)

must be provided near the work area.

6. Residual risk

CAUTION

Residual hazards!

Handling the machine involves residual hazards that could

not be eliminated by design measures.

Pay attention to the residual risks in the Technical

Documentation!

The machine reflects the state of the art and is built in

accordance with recognised safety regulations. All the same,

the user or third parties may still be exposed to hazards.

The machine must be used

• for the intended purpose

• in an absolutely safe state.

95

en

95

WARNING

Risk of injury!

Never remove safety devices or render them ineffective by

making changes to the machine!

Malfunctions presenting a safety risk must be rectified

without delay!

Before attempting servicing and cleaning work, switch off

the entire machine and disconnect from the compressed

air supply!

7. Safety advice for operating personnel

• Work on the machine must only be carried out by

instructed, skilled personnel.

• Only skilled personnel who have received training or

instruction must be deployed.

• The generally recognised code of occupational health and

safety as well as accident prevention regulations must be

observed.

• Please keep first aid equipment (first aid kit etc.) in easy

reach.

• The owner must stipulate that operating personnel are

to wear personal protective equipment (safety shoes and

sturdy work clothing).

Work which may be done by the operating personnel

Work which may be done by the operating personnel:

• Activate, deactivate the machine

• Change drill bits

• Set the machine to component dimension

• Feed in individual parts (flat panels made of engineered

wood, hinges and connecting fittings)

• Start the drilling and inserting process

• Remove finished components

• Clean the machine

Requirements on operators

The operator must organise the work environment so as to

permit optimum, continuous production.

The operator must be receive instruction before commencing

work for the first time and every year thereafter.

Prior to commencing work, all persons working on or at the

system shall undertake to

• follow the basic regulations on health and safety at work

and on accident prevention

• wear personal / workplace related protective clothing and

equipment for the purpose of ensuring work safety and use

such while working if they are necessary for safety reasons

Work must only be performed for which authorisation has

been given.

For example:

• work on pneumatic equipment must only be carried out

by a specialist specifically trained to do so or by instructed

persons under the direction and supervision of such a

specialist in accordance with the applicable technical

regulations.

8. Safety advice for operating the machine

• The machine must only be put into operation in a fully

installed and operational state.

• The machine must only be operated if all protective guards

and safety related equipment, e.g. protective claddings or

enclosures, are in working order and undamaged.

• On putting the system into operation, the operator must

make sure that all safety equipment and protective guards

as well as the controls are in correct working order and free

of damage.

• The workplace environment must be kept clean and tidy at

all times. This must be ensured by internal checks.

• Immediately report any irregularities or malfunctions to the

department / person responsible. If necessary, the machine

must be shut down immediately and made safe.

9. Safety advice for carrying out maintenance work

• Maintenance work must only be performed by

the manufacturer‘s skilled personnel or under the

manufacturer‘s supervision.

• If the machine is completely shut down for servicing and

repair work, it must be prevented from switching back on

unexpectedly.

• If necessary, please cordon off the maintenance zone,

providing a wide safety margin!

• Attach a warning sign

•

For maintenance measures, use tools that are appropriate for

the work involved.

• Servicing and repair work must only be carried out by the

owner‘s qualified personnel.

• If safety devices need removing for servicing and repair

work, they must be refitted and checked as soon as the

work has been completed.

• Always tighten screw connections that have been loosened

during servicing and repair work.

• At the start of work, connections and screw connectors must

be cleaned of oil, operating consumables and dirt.

•

Make sure operating consumables and auxiliary substances

as well as replaced parts are disposed of safely and in an

environment friendly manner.

10. Training / instruction

• As owner, you are obliged to inform and instruct the

operating personnel in respect of applicable legal and

accident prevention regulations as well as the safety guards

fitted. In this context, bear in mind the varying specialised

qualifications of your staff.

• The operating personnel must understand the instruction

they are given, follow it as well as sign the documentation.

• This is the only way you can be sure that operating

personnel work in awareness of safety and of the hazards

that are involved. As owner, you should therefore obtain

written confirmation from all members of staff that they

have received training/instruction.

• Applying these safety measures will minimise potential

hazards to such an extent that the machine can be operated

safely.

96

en

96

NOTE

All of the safety guards in place must be checked at

least once before the start of each shift to make

sure that they are in place and undamaged (visual

inspection).

11. Personal protective equipment

The owner must provide the following personal protective

equipment:

• Safety shoes

• Ear protection

• Safety goggles

• Dust protection mask

• Safety gloves (as necessary)

General safety rules

97

en

97

98

en

98

Purpose / operating principle

4. Purpose / operating principle

1. General information 98

2. Intended use 98

3. Foreseeable incorrect use 98

4. Operating principle and description of the machine 99

5. Rating plate 99

6. Limit values 99

7. Liability 99

1. General information

This operating manual must be kept at the machine all

the time and be constantly available there. To ensure safe

operation and proper machine handling, it is important for

you to have read and understood the operating manual

and, in particular, the safety rules. The safety provisions and

operating instructions described in this operating manual

must be followed exactly.

Regularly check this machine‘s safety guards and work

sequences.

Danger!

Any person given the task of installing, servicing,

starting, operating or repairing the machine must have

read and, in particular, understood these instructions.

2. Intended use

WARNING

The machine must only be used for its intended

purpose and be in a perfectly safe condition!

Operating safety is only guaranteed if the machine is

used for its intended purpose!

The BlueMax Mini Modular Plus is a semi automatic drilling

and insertion machine for panel type workpieces and the

furniture fittings intended for them. This machine must only be

used for working on flat panels made of wood-based materials,

such as chipboard, blockboard panels, MDF, solid wood or

similar materials.

Any other use beyond this is deemed to be improper and non

intended use.

Intended use also includes following the operating, servicing

and maintenance conditions prescribed by the manufacturer.

Unauthorised changes to the machine will result in the loss of

product liability and liability on the part of the manufacturer

for resultant damage.

Any other use beyond this is deemed to be non intended use.

The manufacturer shall not be liable for any damage this

causes, with the risk involved being borne solely by the user.

3. Foreseeable incorrect use

WARNING

Hazards may occur if the system is used incorrectly!

The following situations in particular are deemed to be

foreseeable hazardous situations:

•

If the machine is used for any non-intended purpose,

treated improperly or operated by untrained or

unauthorised persons, it may present a risk of injury to

personnel and a risk of damage to the machine itself.

For this reason, only trained, instructed and authorised

persons must be allowed to operate this machine.

•

Improperly assembling, starting, operating and servicing

this machine

• Operating the machine with faulty safety guards

• Operating the machine with improperly fitted safety

guards

• Operating the machine with non-functioning safety

guards and protective equipment

99

en

99

• Failing to observe the information and instructions given

in the operating manual in relation to transporting,

storing, assembling, starting, operating, servicing and

setting up this machine

• Unauthorised structural changes

• Unauthorised changes to this machine‘s drive system

(power output, speed)

• Inadequate monitoring of machine parts subject to

particular wear

• Improperly performed repairs

• Disasters caused by the impact of foreign objects

or Acts of God

The situations above describe some of the residual hazards

which, despite being impermissible, may occur and harm the

health of staff.

The owner must observe the safety requirements defined

in the German Ordinance on Industrial Safety and Health

(Betriebssicherheitsverordnung).

4. Operating principle and description of the machine

The BlueMax Mini Modular Plus is a semi automatic drilling

and insertion machine for panel type workpieces. This

machine must only be used for working on flat panels made

of wood-based materials, such as chipboard, blockboard

panels, MDF, solid wood or similar materials.

All parts being worked on are fed into the machine by hand.

Flat panels made of wood-based materials, such as chipboard,

blockboard panels, MDF and solid wood are laid on the work

table and fixed into place with the clamping equipment. The

drilling process is initiated by pressing the start button / foot

switch (optional). The start button / foot switch (optional)

must remain pressed until the drilling process has been

completed. Using the integrated insertion facility (optional),

the furniture fittings are pressed into place by means of a

manually operated press-in frame (optional). This concludes

the machining process.

BlueMax Mini Modular Plus with accessories

5. Rating plate

Note!

The rating plate is located on the machine.

The rating plate shows the following information:

Manufacturer

Address

Type designation,

machine numbers

Year of manufacture

Technical specifications

(e.g. nominal pressure)

All country specific information, such as the depiction of the

CE or UKCA mark, can be found on the type plate attached to

the machine.

State all of the above details when requesting technical

information and ordering replacement parts.

6. Limit values

The following limit values apply to items of equipment

and accessories, such as drive motors, electric / electronic

operating equipment etc.:

• ambient temperature: 35 °C max.

• rel. air humidity: approx. 65 %

Space required by the machine

The space required for the BlueMax Mini Modular Plus is largely

determined by the dimensions of the machine base frame.

Machine life

The machine‘s life will depend on whether or not it is used

for its intended purpose, on adherence to regular servicing

intervals and on the regular replacement of expendable parts.

7. Liability

Defects must only be rectified by competent personnel.

Our liability is restricted to damage caused while using

the system in the intended manner. We shall not be liable

for safety defects not yet identifiable on the basis of the

current state of the art.

Failure to observe:

• safety advice for operating personnel

• advice on particular hazards

• the ban on unauthorised modifications and changes

• use replacement and expendable parts or auxiliary materials

approved by the manufacturer will rule out any liability on

our part for the consequences

100

en

100

Technical information

1. Safety advice

Observe the regulations, warnings and provisions on health,

safety and environmental protection for all of the work

described in this section.

2. Attachment points

Only use suitable and approved lifting gear (crane) for

unloading the machine, assemblies and components as well

as for lifting heavy loads; only use appropriate means of

transport for handling the machine internally.

Any unloading or internal transportation must not be done by

hand if such involves weights in excess of 25 kg.

When using industrial trucks to unload the machine and move

it internally, always take into account the machine‘s total

permissible weight (see Technical specifications).

Danger!

Never stand or work under loads suspended on lifting

gear. This presents the risk of fatal injury!

Observe the following when using lifting gear:

•

Only attach lifting gear at the points marked (lifting

eyebolts etc.) on the machine / assemblies / components.

•

Only use appropriate and tested load suspension devices

(lifting belts, ropes, chains, shackles etc.) with a sufficient

load carrying capacity.

•

Only give experienced, skilled personnel the task of

attaching the machine / assemblies / components.

•

Always ensure level standing for machine / assemblies, lift

vertically, never drag at an angle.

Protect projecting machine parts and equipment from

damage when using lifting gear and moving the machine

internally.

Set down loads gently with the usual care and take

immediate action to prevent them from falling over /

tipping, rolling away, suffering damage from external force,

e.g. colliding with industrial trucks and objects falling from

above.

5. Technical information

1. Safety precautions 100

2. Attachment points 100

3. Technical Specifications 101

4. Equipment 102

Programming digital display 104

Setting 106

5. Guards 106

6. Noise mission 107

7. Aligning / fastening 107

General information 107

8. Connections required 107

Main power connection 107

Compressed air connection 108

9. Transportation 108

Transportation on fork lift truck or pallet jack 108

10. Internal handling 108

11. Checking delivery for missing items 108

12. Dealing with shipping damage 108

13. Measures on temporary storage 108

14. Site of installation 109

15. Safety guards to be provided by the owner 109

16. Permissible ambient conditions 109

17. Removing preservatives 109

18. Electrics 109

19. Compressed air connection 109

20. Suction extractor 109

101

en

101

C D E F G H J , �i - =K Dm � .·c f� �> §"� L- m 1 2 3 4 1 2 3 4 1 ' +-+-5

5 -+ -+ 6 7 6 7 8 ---8 9 11

(m

•o o 0 9 10 11

12 13 15

16 A B C D E F G H J K -----------�-------

6 Gepr. 3 1 HE-020.1

15

16

-L

A1

862141

C D E F G H J , �i - =K Dm � .·c f� �> §"� L- m 1 2 3 4 1 2 3 4

1 ' +-+-

5

5

-+ -+

6 7 6 7 8 ---8 9 11 (m •o o 0 9 10 11 12 13 15

16 A B C D E F G H J K -----------�-------

6 Gepr. 3 1 HE-020.1

15

16

-L

A1

862141

C D E F G H J , �i - =K Dm � .·c f� �> §"� L- m 1 2 3 4 1 2 3 4 1 ' +-+-5

5 -+ -+ 6 7 6 7 8

---

8 9 11 (m

•o o 0

9 10 11 12 13 15

16 A B C D E F G H J K -----------�-------

6 Gepr. 3 1 HE-020.1

15

16

-L

A1

862141

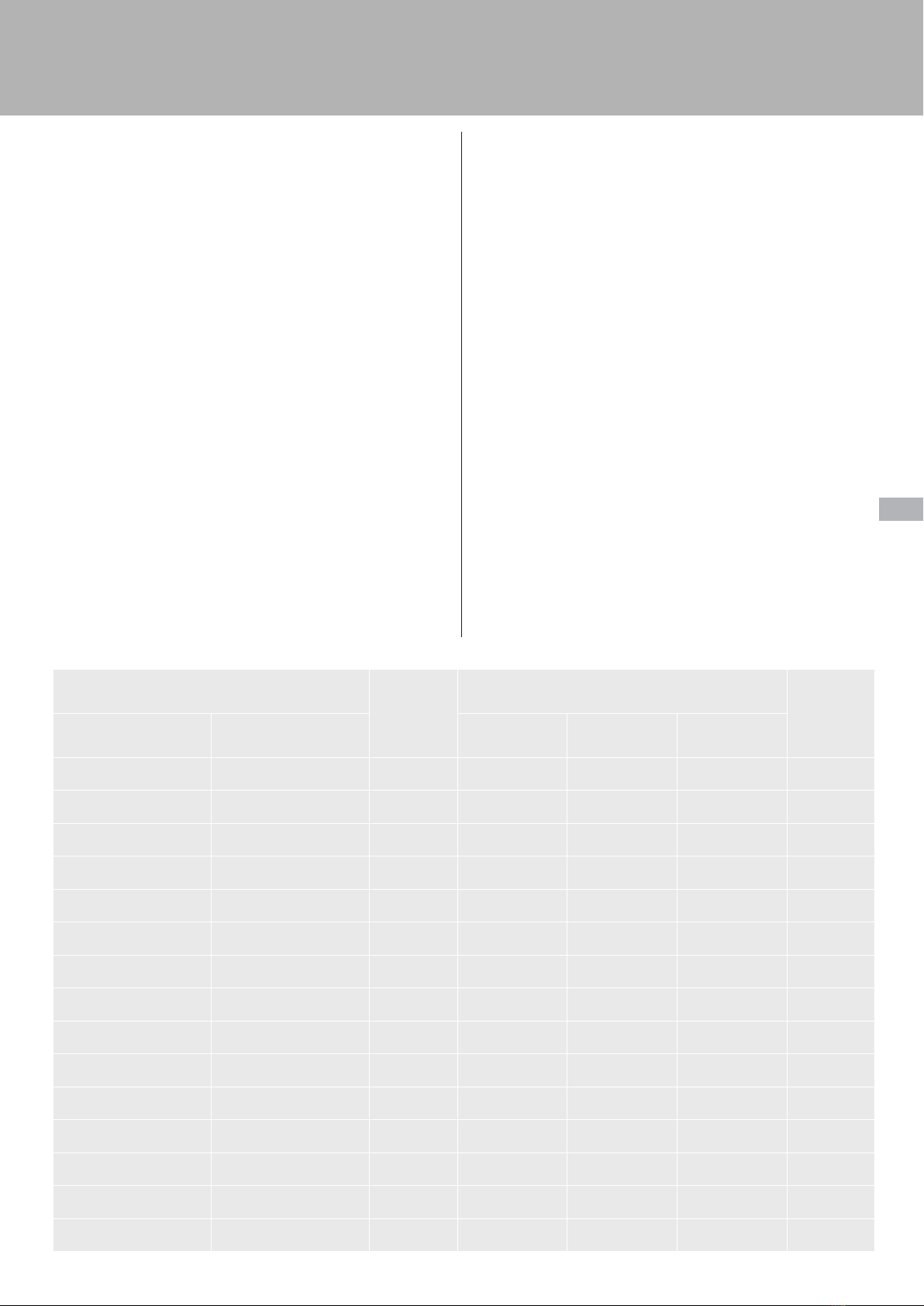

3. Technical specifications

Bezeichnung: Bohr- und Einpressautomat für plattenförmige Werkstücke

BlueMax Mini Modular Plus

H x W x D (mm) 862 x 800 x 1856

Weight approx. 145 kg

Power output data

Cycle time manual

Electrics

Operating voltage 400 V

Motor power 1.1 kW

HB unit power 0.55 kW

Rated current 2.65 A

Mains power fuse protection 6 A

Pneumatic system

Air pressure min. 6 bar, max. 7 bar

Noise Max. noise level: > 80 dB (A)

Temperature < 35°C

Working dimensions, vertical drilling unit

Max. workpiece thickness: 38 mm

Max. drill bit diameter: 35 mm

Max. drilling size: 30 mm

Max. pull out distance of drilling unit: 600 mm

Working dimensions, horizontal drilling unit

Max. workpiece thickness: 38 mm

Max. drill bit diameter: 8 mm

Max. drilling height: 5 – 20 mm

Max. drilling depth: 40 mm

Space required for machine

102

en

102102

1bis 5

1

2

3

4

5

61bis 5

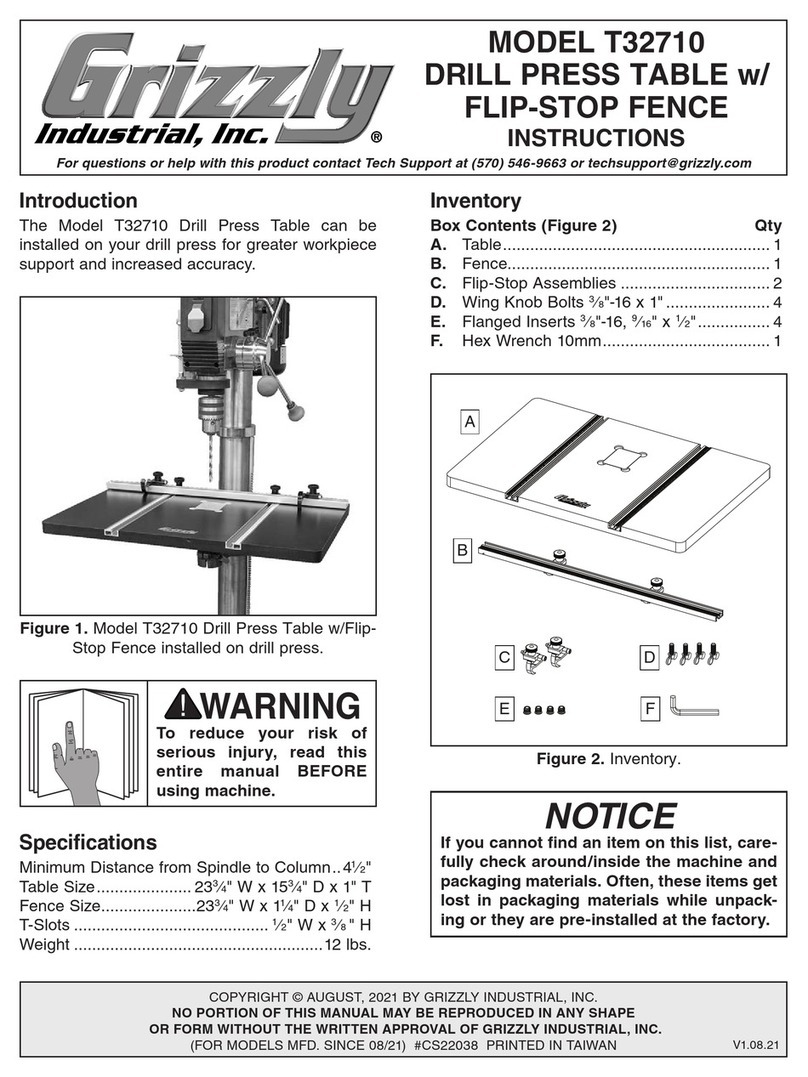

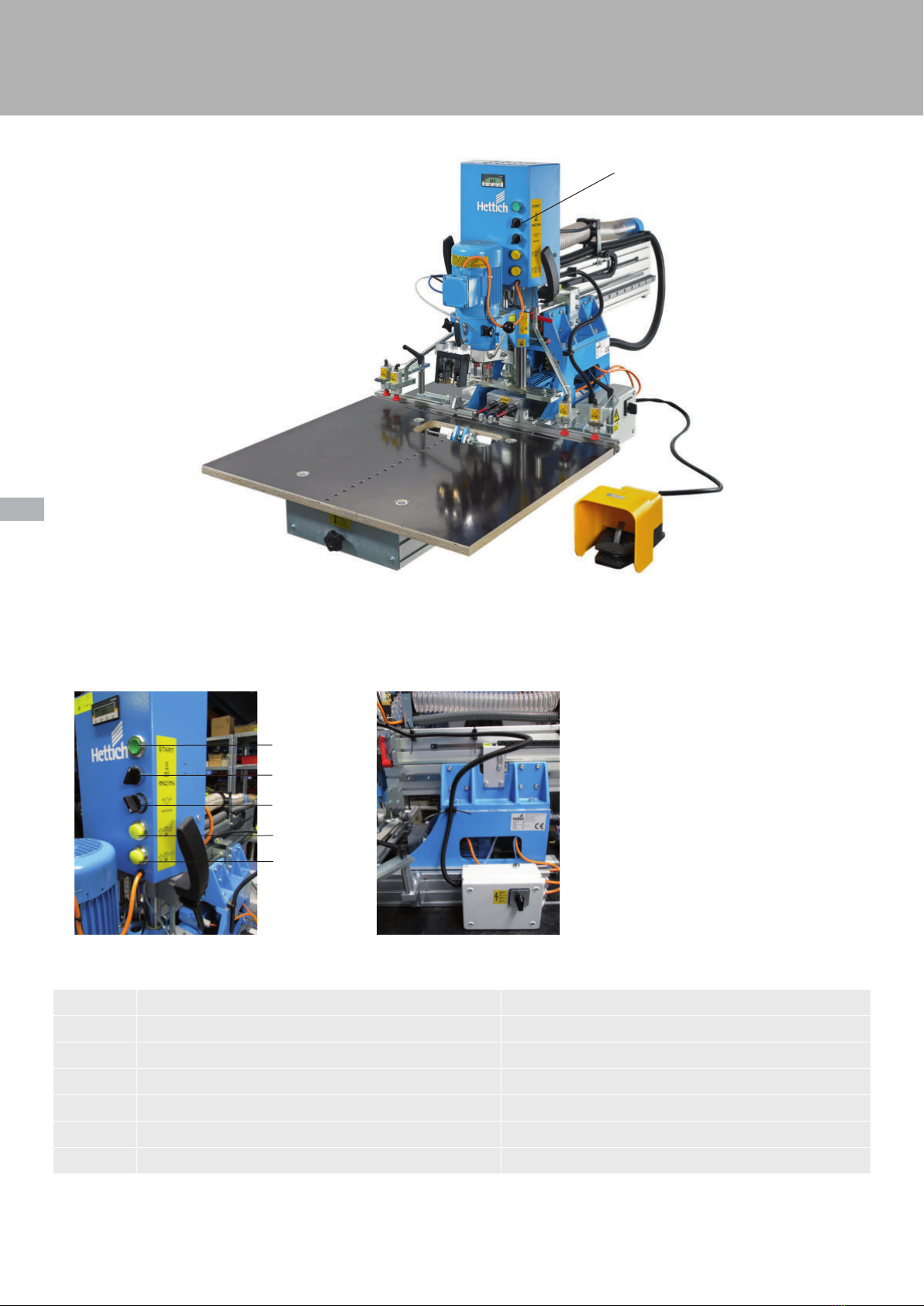

4. Equipment

Switches and other controls for operating

and monitoring the machine are described

below.

Fig. 2: Controls on the automatic drilling and insertion machines

Technical information

Item Designation Explanation

1Pushbutton For activating work process

2Change-over switch Drilling vertically / horizontally

3Change-over switch For automatically unclamping the hold-down clamps

4Pushbutton For manually releasing the front hold-down clamps

5Pushbutton For manually releasing the rear hold-down clamps

6Main switch Machine power supply ON / OFF

103

en

103103

1

2

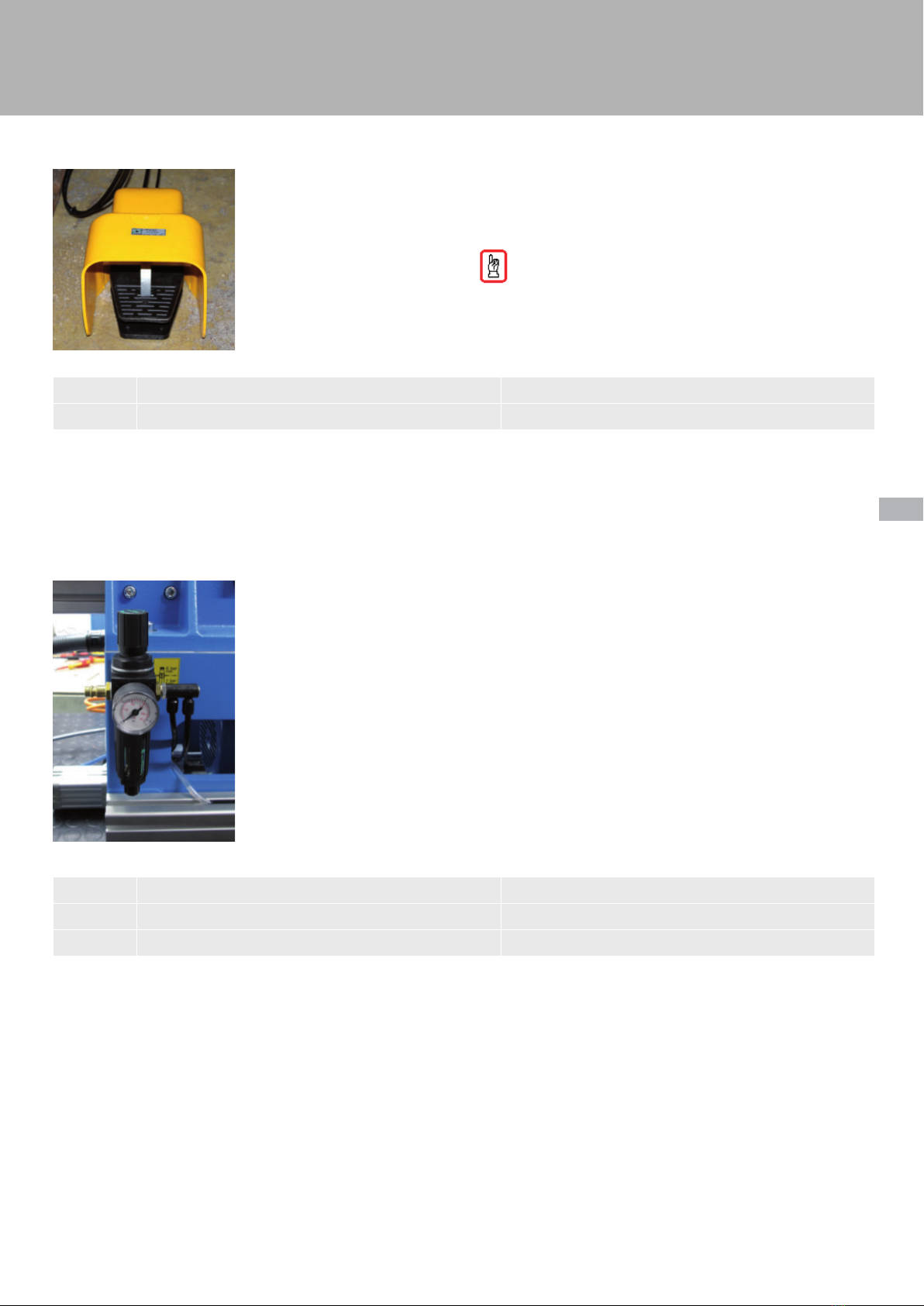

Fig. 5: Compressed air connection

Fig. 4: Foot switch (optional)

NOTE

The hand switch is not operational when using the foot

switch.

Item Designation Explanation

1Foot switch (optional) For activating work process

Item Designation Explanation

1Pressure regulator For setting operating pressure (6-7 bar)

2Plug in coupler Compressed air connection

104

en

104104

Programming digital display

• To enter the parameter programming, press the button for

a few seconds and the display will show PASS.

• Now press RESET/ ENTER, three zeroes will appear and the

first digit on the right will flash.

• Using the and buttons, now enter 273 as the password

and confirm by pressing RESET/ENTER.

Entering the incorrect password will close the menu. Otherwise,

the following menu options can be selected with the button:

To change the selected parameters:

• Press RESET/ ENTER twice (pressing once shows the value).

• Enter the chosen value with the and buttons.

• Press RESET/ ENTER to confirm your setting.

• To quit the programming mode, press the button.

The following parameters can now be programmed.

Value to be displayed after moving a 10 mm linear

shift.

Factory setting: 10.0 (given in millimetres with one decimal

place)

• First enter the chosen value and close by pressing .

• The decimal place can be moved to the chosen position with

the button.

• Then confirm by pressing RESET/ ENTER.

Number of decimal places

• Using the button, select a number between 1 and 5 to

denote the number of places after the decimal point.

• Then confirm by pressing RESET/ ENTER.

Defining button assignment

In the form of a 3-digit number, this parameter defines a wide

range of function that can be assigned to the buttons. This

is done by selecting the relevant values at the correct digit

position. (see table)

• Example: in parameter tASt I, enter the value 1 at the 3rd digit

of the code to assign the RESET function to the RESET/ENTER

button.

Technical information

111 means:

Digit 1. 2. 3.

Button RESET/ENTER

Value

0 - - -

1 mm/inch ABS/REL function RESET

2 - - PRESET

3 - - FAST PRESET

4. - - Zero oset

0; 1; 2

5 - - OFFSET

6 - - FAST OFFSET

7 - - Delayed RESET*

8 - - Delayed PRESET*

* Delayed means that the button must be pressed for 3 seconds

to activate the function.

mm / inch:

Lets you switch between inch mode and mm mode

• The mode is changed by pressing button. The inch modus has

an additional decimal place. Means that parameter nDEC=4 is

not available.

ABS / REL function

Lets you switch between the absolute and relative

position

• Pressing displays the REL symbol and the current value

is temporarily zeroed.

• It is now possible to measure a relative movement of the

sensors in relation to the current reference point.

• Pressing again displays the ABS symbol and the absolute

value reappears.

RESET

After pressing RESET/ ENTER, the value displayed is

set to zero

• Position the sensor at a known measuring point with measured

value, e.g. at the stop of the measurement path with measured

value = 0.

• In parameter tASt I, enter the value 1 at the 3rd digit of the

code (RESET) and press RESET/ENTER to confirm.

• From now on, the display will be reset to zero after pressing

the RESET/ENTER button once.

Other manuals for Mini Modular Plus

1

Table of contents

Other Blue Max Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Palazzetti

Palazzetti Palazzetti WT Series installation manual

ABB

ABB HT842309 Operation manual

SCHUNK

SCHUNK SHS Assembly and operating manual

ABB

ABB HT575635 Operation manual

Bora Portamate

Bora Portamate PM-2700 Assembly instructions

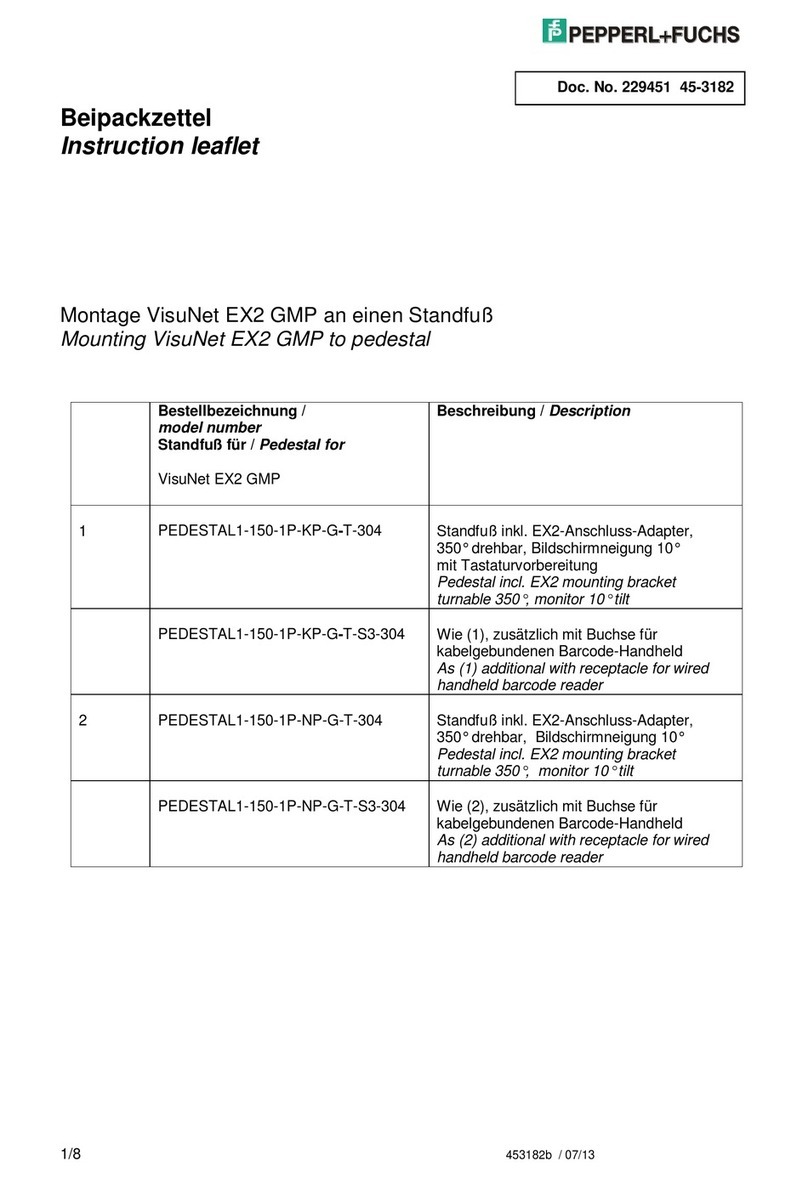

Pepperl+Fuchs

Pepperl+Fuchs VisuNet EX2 GMPRM/PC 3700 Series Instruction leaflet