Siebeck MK III Series Operational manual

Translation of the original operating manual

No. 0411 FRT-A-MKIIIbed

JET 2000 tying machine

MK III series

FRT-A-SB and FRT-AS-SB model series

GMBH

Telephone +49 (0)6271 9208 0

e-mail : info@siebeck.de

69412 EBERBACH, GERMANY

Fax +49 (0)6271 9208 88

Internet : www.siebeck.de

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

Page 2

Table of contents

Page

Hazard warnings................................................. 3

Introduction........................................................ 4

Warranty ............................................................. 5

EC declaration of conformity............................... 6

Technical data / Proper use………………………. 7

Safety.................................................................. 8

Safety instructions for transportation................... 9-11

Set-up and commissioning................................... 12-14

How the safety sensor works............................... 13

Fitting the foot pedal............................................ 15-16

Inserting the string............................................... 17-23

Operating controls................................................ 24

Cleaning and maintenance ................................... 25-30

Tensioning and adjusting the conveyor belts.... 31-32

Maintenance.......................................................... 33-34

Setting the stripper ............................................... 35

Setting the zero position knotting aggregate……… 36-37

The story of knots................................................ 38-39

Faults and their causes.......................................... 40

Further maintenance instructions.......................... 41-42

Troubleshooting .................................................... 43

Residual risks and incorrect operation ................... 44-48

Display and operating screen

Spare parts list:

Mechanical assembly groups / electrical parts

Circuit diagrams

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

Page 3

Hazard warnings

Hazard warnings are found in the respective position in the text.

They are denoted by this warning

triangle and an information text.

Caution!

The technical manual must have been read and understood

before using the machine for the first time. For personal

safety it is important to follow all the instructions listed in it.

Themanual must be kept bythe customer and must be

handed over in case the machine is passed on to third parties

or a newuser.

Caution!

Installation and repair must only be performed by qualified

persons who have the necessaryexperience and

knowledge of occupational and industrial safety and risks of

accidents. If the available staff do not have one or more of

these qualifications, specialist staff must be contracted.

Caution!

If it is necessaryto replace a components, you must

make sure that only original spare parts are used.

Improper repairs or the use of non-original spare parts

can cause considerable damage and hazards for the

user.

In case of damage which has be caused by failure to observe this operating

manual, the warranty will be rendered null and void. No liability will be

assumed for consequential damages.

No liability will be assumed in case of material damages or personal injuries

which are caused by improper use or failure to adhere to the safety

instructions.

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

Page 4

Introduction

This machine has been engineered in accordance with the recognised rules

of technology and in adherence to the regulations for occupational safety and

the prevention of accidents so that proper use cannot not cause any

hazards for the life and limb of the user or third parties.

Information on incorrect use and residual risks, which are still in place or

possible despite the integrated safety and technical protective

equipment, are described and illustrated on pages 43-47. These risks are

documented in a risk analysis and filed by the manufacturer.

Every person on the user's premises given the task of

setting up, commissioning, operating, maintaining and

repairing this machine must have read and understood

this operating manual, and in particular the chapter

"Safety".

The customer's own changes, restrictions or upgrades and the resultant

safety-related consequences are at the expense and risk of the user.

If this machine is sold or set up at another location, this

operating manual must be handed over to the new owner or the

new user. Additional copies can be ordered from the address

given below, quoting article number 0411 FRT-A-MKIIIbed.

69401 Eberbach, Germany

Friedrichsdorfer Landstrasse 64

Telephone +49 (0)6271 9208 0

Fax +49 (0)6271 9208 88

E-mail : info@siebeck.de

Internet : www.siebeck.de

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

Page 5

WARRANTY

All machines which have been manufactured at our production

facilities are covered by a warranty of 12 months, starting from the

date of commissioning, or 18 months from the date of delivery. This

warranty covers material and manufacturing faults.

The warranty covers all parts, with the exception of

expendable parts and parts which are replaced due to normal wear

during maintenance. Under the terms and conditions of the

warranty we are not liable for working hours and downtimes.

If machine damage is caused due to the use of unsuitable tying

material or material not expressly recommended by us, the warranty

will be rendered null and void.

All claims must be asserted in writing. An exact description of the

cause of damage, the part number and machine number must be

enclosed. Once we have accepted your warranty claim, the faulty

part must be returned to us.

This warranty is only valid if

original parts without any form of modification are used.

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

Page 6

EC - Declaration of Conformity

We hereby declare that the supplied model of

Manufacturer : SIEBECK

Model:

Serial No. :

complies with the following provisions applying to it:

EC Machinery Directive 2006/42/EG

Applied harmonised standards, in particular:

EN ISO 12100-1

EN ISO 12100-2

EN 60204

EC Direktive Electromagnetic

compatibility 2004/108/EG

Safety of machinery; Basic concepts,

general principles for design, basic

terminologie, methodologie

Technical principles and specification

Safety of machinery; electrical

equipment of machines

Part 1: General requirements

Only for FRT and FRS machines

EN 1672

1935/2004/EC/GS-FW 01/01

Country of Origin

Person responsible for the

technical manual:

Eberbach, 16.05.2011

Siebeck GmbH

Food processing machinery /

Basic concepts /

Part 2: Hygiene requirements

Materials and articles intendet to come in to

contact with food

Federal Republic of Germany (European

Community)

Gunter Siebeck

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

Page 7

Technical data

Machine performance: up to 60 cycles per minute

depending on the tying spacing

Machine weight: Infeed conveyor 125 kg

Outfeed conveyor 80 kg

Machine 180 kg

Total weight 385 kg

Noise pressure level: 79 dB(A) as per EN 11204

(without product / without string)

Connected elec.load: 170-260 volts / 1ph.alternat. current /

50-60 Hz / 1,6 kW

Compressed air: 50 litres per minute / 2 bar

Proper use: Tying food, in particular meat, fish,

poultry, vegetables etc.

All dimensions in mm / specifications are subject to change without notice

Compressed air

Elec.Power

400

170 - 260 V AC 1,6 KW 50/60 Hz

Power cable

Cable: 4G1,5/ 5mtr. long

1480 560 1480

3520

945

260 150

800

125

(880 FRT-AS-SB)

Comp.air

2 bar 50ltr./min.

Socket DN 7,2

1300 1385(1485 FRT-AS-SB)

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

Page 8

Safety !

The European standard EN 60204-1 requires the power

supply connection to be established by a suitable plug device.

The power supply cable must not be connected to a power

distributor directly by way of a terminal connection, without a plug

connector.

Safety limit switch S1 prevents the machine from starting up when

the machine hood is open. This safety device must be checked

before putting the machine into operation each time to make

sure it is fully functional.

Procedure:

First switch on the machine and wait for the reference run to be performed (see

last paragraph below), open the hood, do not reach into the machine (!), then

press the foot pedal. The machine must not start up.

Monitoring switch B7 prevents the machine from starting up if the

dirt pan is removed or not fully inserted. This monitoring device

must be checked before putting the machine into operation each

time to make sure it is fully functional. Procedure as described

above.

Always pull the mains plug before all maintenance and cleaning

work!

When inserting a new string bobbin, and when threading the string,

always pull the mains plug.

Reference run

Once the machine has been switched on using the master switch (Q1), a check

is automatically performed to determine whether the preset reference points for

the ring and knotting aggregate drives are positioned correctly. This run

(duration approx, 10 seconds) is performed at reduced speed and ensures that

both drives are ideally synchronised with each other. The machine is ready for

operation on completion of this reference run.

A minimum of 500 lux is required for local lighting.

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

Page

9

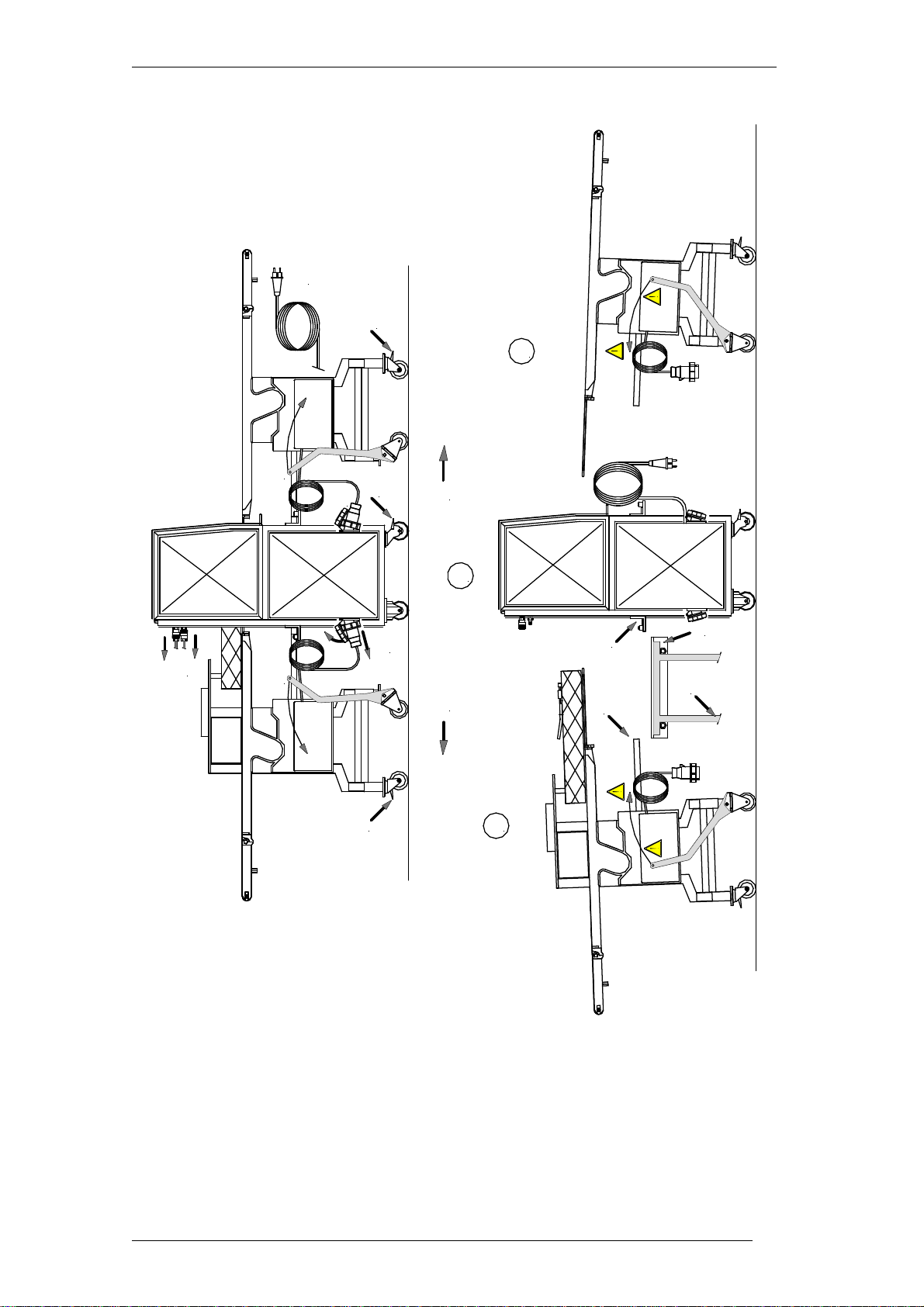

Safety instructions for transportation

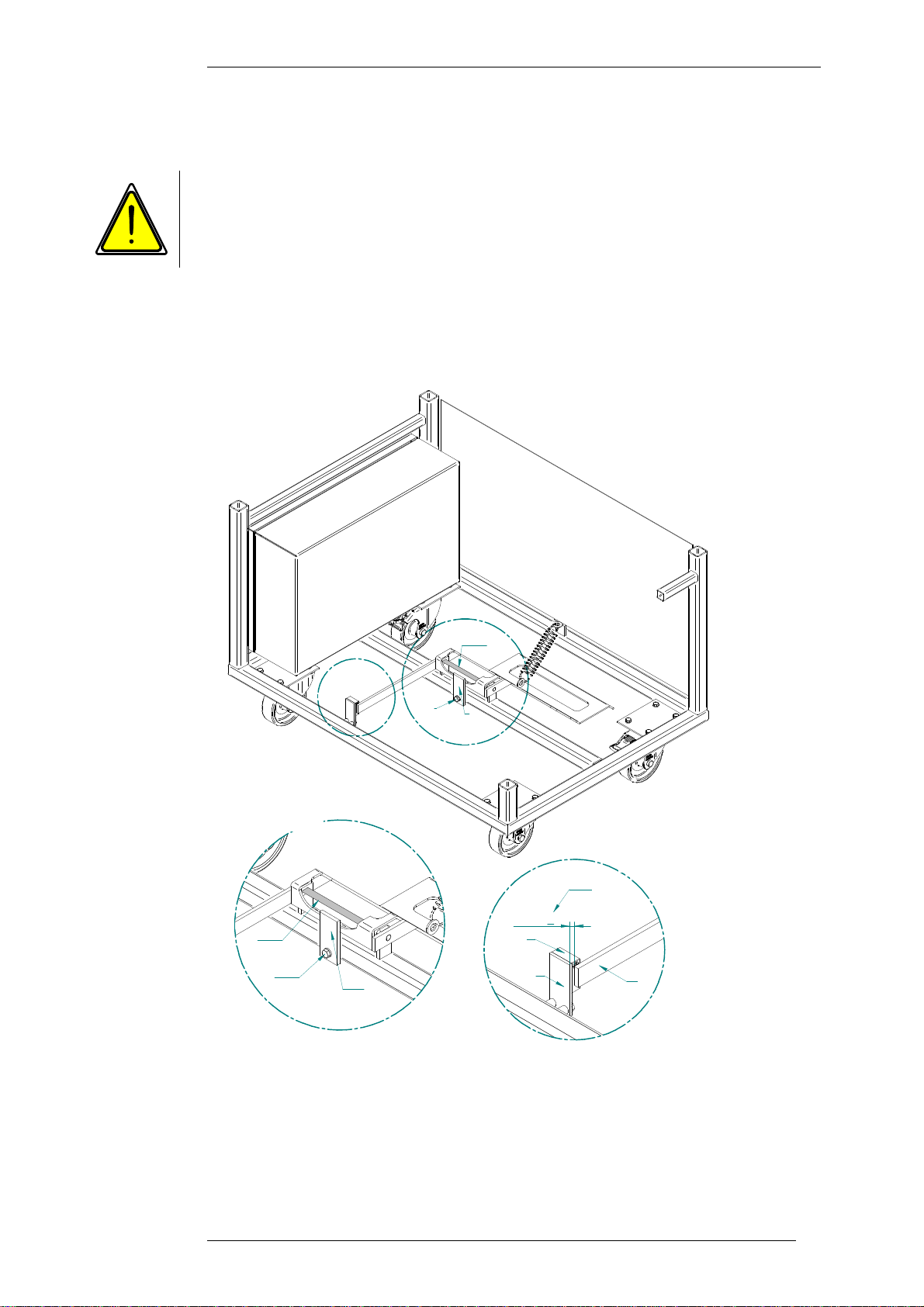

The entire machine comprises three units which, once disconnected, can

be transported or shifted separately. See page 11 for a figure.

1 - Infeed conveyor (with vertical belts)

2 - Tying machine

3 - Outfeed conveyor

Procedure for disconnecting, e.g. for cleaning purposes:

Pull the mains plug (A)

Roll up the cable and keep it safe

Disconnect both the plug connections (B) between the belt and the machine.

Caution: First lift the cover on the socket in the direction of the arrow, turn the

grey ring clockwise, then pull the plug. Roll up the cable and keep it safe.

Unfasten both compressed air connections (C) using the quick

coupling. Roll up the air hose and keep it safe.

Unfasten the wheel locks (D) on the conveyors (2 on each) by pressing

them in the direction of the arrow.

Turn the pivot lever (E) in the direction of the arrow. The conveyors are now in

a slightly inclined position and can be pulled out of the machine in the

direction of the arrows (F) or (G).

Caution! The conveyors are slightly top-heavy. Do not run

them over thresholds or uneven floor. In case of a deflection of

>10°there is a risk of tilting over and thus a ris k of injuries !

After transporting the conveyors, fasten the wheels back in place with the

wheel locks (D).

When assembling, repeat the steps described above in reverse order. Make

sure that the connecting crossbeam (H) is in the correct position to the

mounting device (J) after inserting the conveyors.

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

d

Page 10

Caution!

Because of the movement of the machine and the conveyors there is

a risk of impacts.

Caution! When lowering the conveyors using the pivot lever (E)

proceed with the upmost care. The weight of the conveyors causes

them to lower quickly and abruptly. Hold the pivot lever firmly in the

hand and lower the conveyors slowly. If lowered abruptly there is a

risk of crushing.

Caution!

There is a risk of crushing between the connecting crossbeam and the

mounting points J when lowering the conveyors.

After lowering, check whether the connecting crossbeam (H) is resting properly

in the mounting device (J). After transporting the conveyors, fasten the wheels in

place with the wheel locks (D).

Caution!

All supply lines (electrical connection cables and pneumatic hoses)

must be kept safe, both when transporting and when operating the

machine.

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

Page 11

A

B

B

C

F G

1

2

3

D

E E

D

D

HJ

HJ

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

Page 12

Set-up and commissioning

Mechanics

Erect the machine in the designated location and press the wheel locks

down so that the machine is stable (see page 14, fig. 2). In order to

transport the machine safely using a fork lift or lift truck, the foot pedal is

moved up into the machine frame before delivery.

See pages 15 and 16 for the procedure for installing the foot pedal.

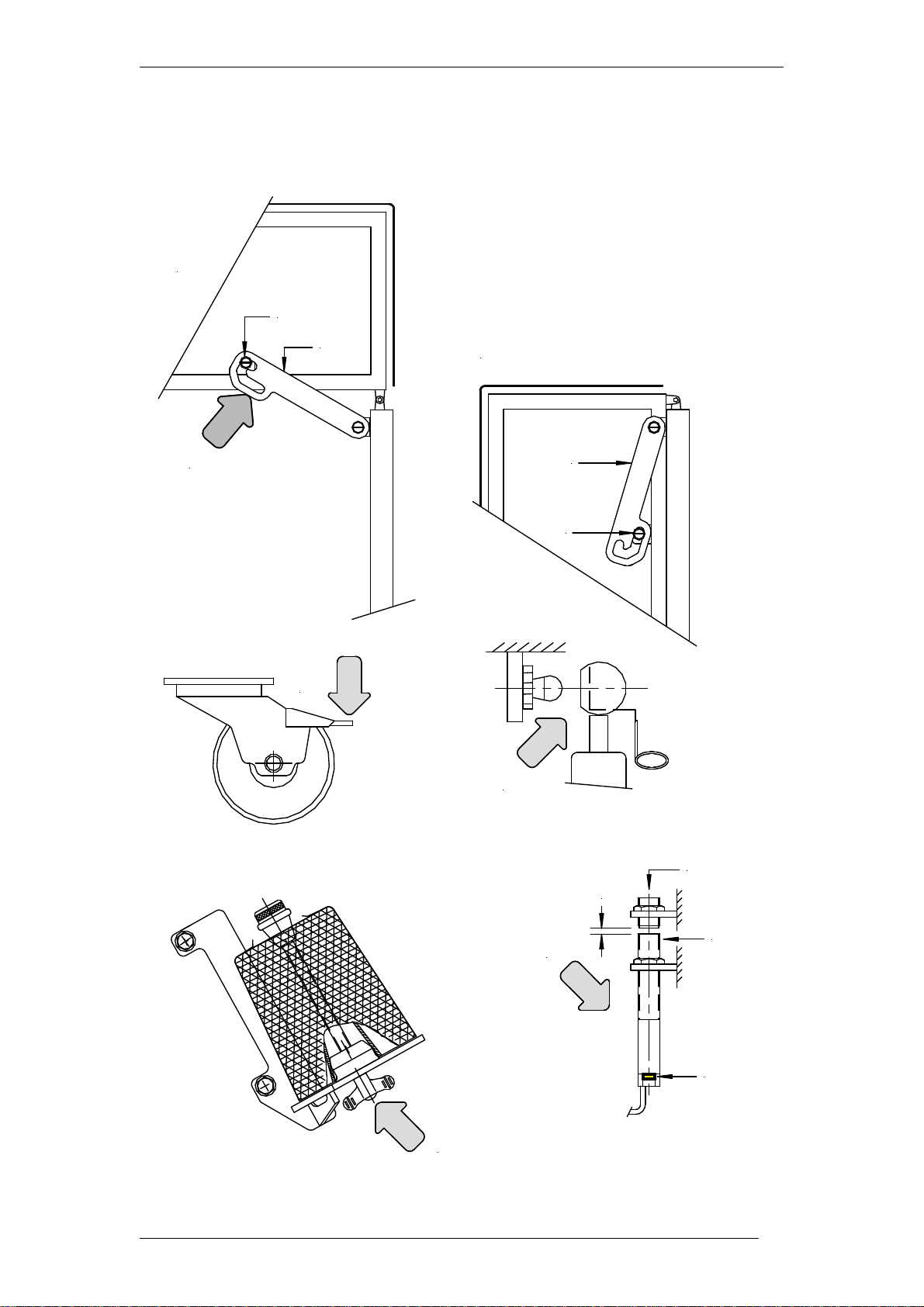

Open the machine hood and check it to make sure it moves freely. Fig. A on

page 14 shows the machine hood open. Fig. B shows the machine hood

closed. When the machine hood is open, lug C engages with bolt D and thus

prevents the machine hood from falling uncontrolledly in case of a faulty

pneumatic pressure spring.

You must make sure at all times and check that lug C moves freely

and engages with bolt D after opening the machine hood.

When closing the machine hood the lug has to be pushed upwards in the

direction of arrow 1. The machine hood cannot be closed until you have

done so.

Never attempt to close the machine hood by force without

releasing the lug from the locking mechanism. This may

otherwise cause considerable machine damage.

Check that the M8 ball heads on the pneumatic pressure spring

are firmly in place and check that the securing wires on

the pneumatic pressure springs are properly in place (see page

14, Fig. 3).

Make sure that the wing nut which fastens the string bobbin on

the bobbin holder, is tightened sufficiently firmly (see page 14,

Fig. 4).

When closing the hood, make sure that the safety sensor is

positioned correctly to the actuator (4-5mm) (see page 14, Fig. 5).

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

Page 13

To avoid collisions with other machines and to ensure operating and

maintenance staff have sufficient access, there must be minimum of

1.5 metres of clearance around the entire machine.

Electrical system:

If not otherwise stipulated, the machine is designed for 230 V 1-phase alternating

current 50/60 Hz when supplied from the factory. Measure the local mains

voltage and compare the measurement with the value specified on the type plate.

Check that the machine is correctly grounded. Adhere to the local

electrical engineering regulations. Maximum fuse protection 16

amperes. Connect the machine to the supply mains using a plug

connector. Switch on the master switch (Q1). The indicator lamp lights

up.

Once the reference run has been completed (see last paragraph on page 8), the

machine is ready for operation.

How the safety sensor woks

Mode of operation of the diagnostic LED

The green LED signals that the sensor is ready for operation. The sensor is not

actuated.

When the CSS 180 sensor is actuated by the CST 180 actuator, the LED changes

from green to yellow. The safety outputs switch to enable. If the actuator is near of

the limit of the sensor switching distance, the yellow LED flashes.

The safety outputs remain enabled. The sensor can be readjusted before the safty

outputs will be swiched off and stop the machine. Errors in the actuator coding or

the sensor outputs are signaled by a red flashing LED.

The safe outputs then switch off after a delay of 1 minute. An internal fault is

indicated by a continuous red LED and, if safe operation is not ensured, results in

an immediate disabling of the safety outputs.

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

Page 14

4

2

3

5

4-5 mm

a

b

c

1

A

B

C

D

C

D

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

Page 15

x

y

x

c

c

b

b

a

1. Unscrew the panelling from the front.

2. Remove both cable ties (x).

3. Insert the rotary axle (a) on the foot pedal into the elongated holes

(b) of both lugs (c). The tension spring (y) does not need to be

removed for this process.

4. Unfasten the hexagon screw (e) and move the lug (d) into the

vertical position and tighten the hexagon screw (e) again.

Fitting the foot pedal

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

Page 16

After fitting, check whether the limit switch (g) is correctly actuated by

the lug (f). When the foot pedal is actuated, the inner circle (h) of the

cross hairs must be covered. The gap between the limit switch (g) and

the lug (f) should not be greater than 3mm. Adjust the position of the

limit switch using the lug (i) as necessary.

5. Screw the panelling back on.

ed

d

e

if

g

3

max

h

a

Detail B

B

a

Detail C

C

Detail B

Detail C

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

Page 17

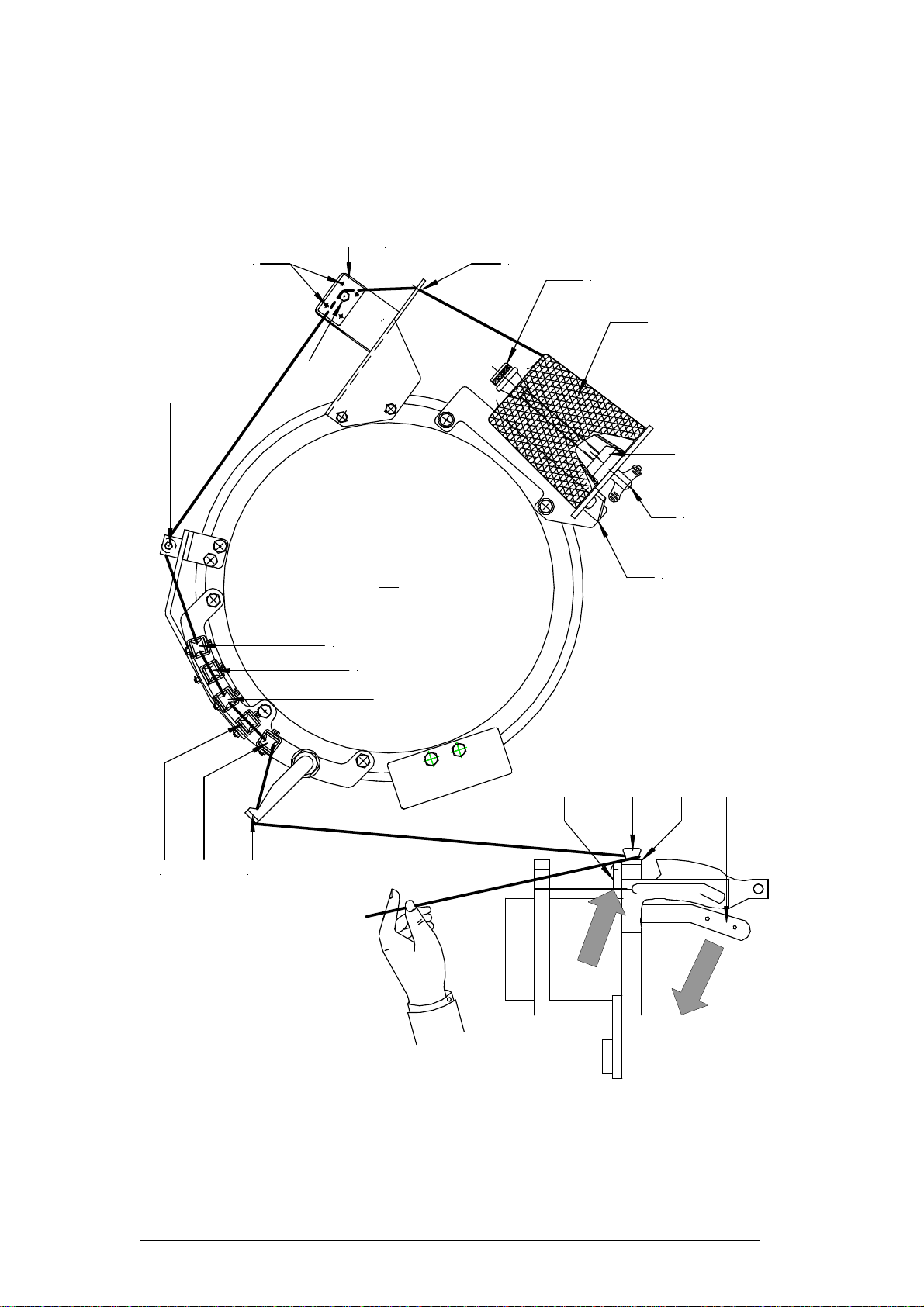

Inserting the string

When the machine leaves our premises, it includes a piece of string

completely threaded. Study the course of the string exactly to make

understanding the following description easier.

Proceed as follows in accordance with the threading diagram opposite:

Pull the mains plug and open the machine

hood

-Remove the wing nut (B) and the threaded rod (E).

-Insert the threaded rod (E) through the string bobbin (D) from above.

Place the string bobbin (D) together with the threaded rod (E) on the

bobbin holder (A). Guide the bottom end of the threaded rod (E)

through the drilled hole on the mandrel (C) and screw on and tighten

the wing nut (B). You must make sure that the string bobbin's

cardboard tube rests firmly on the mandrel (C) and that the net which

surrounds the string bobbin is securely clamped between the cardboard

tube and the mandrel (C).

-Feed the lead end of the string through the drilled hole (F).

-Insert the string in the thread brake (G). Make sure that the string

comes to rest between both pins (H) and the shaft of the hexagon

screw (I) (see figure).

-The next string guides are rollers. Thread the string in numerical order:

2 Roller on the take-up lever arm mount

3 First roller on the tying arm mount

4 First roller on the take-up lever arm

5 Second roller on the tying arm mount

6 Second roller on the take-up lever arm

7 Last roller on the tying arm mount

Guide the string through the insert (K) at the end of the tying arm tube.

Inserting the string in the knotting aggregate:

Use your left hand to wrap the string around the twine holder button

(L) upwards from below. Use the right hand to actuate the twine

holder button lifting lever in the direction of the arrow. Whilst you

hold the string tight with the left hand, the string enters between the

twine holder button (L) and the clamping head housing (P). The string is

clamped once you release the twine holder button lifting lever (M).

Use your right hand to push the knife trap lever (N) forwards in the

direction of the arrow; the string is cut off.

Close the machine hood, switch on the master switch. After the

reference run, the machine is ready for operation.

Check that the string rollers and the take-up lever move freely

and oil them as necessary.

Only use lubricants which are approved for the food sector

(see the chapter "Maintenance").

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

Page 18

Threading diagram ( model FRT-A-SB )

N L P M

345

6 7 K

2

HGE

D

A

B

C

I

F

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

Page 19

Threading diagram ( model FRT-AS-SB

)

2

3

4

5

6

7

K

L

P

N

M

A

B

C D E

F

G

I

H

Siebeck GmbH Translation of the original operating manual 0411 FRT-A-MKIIIbed

Page 20

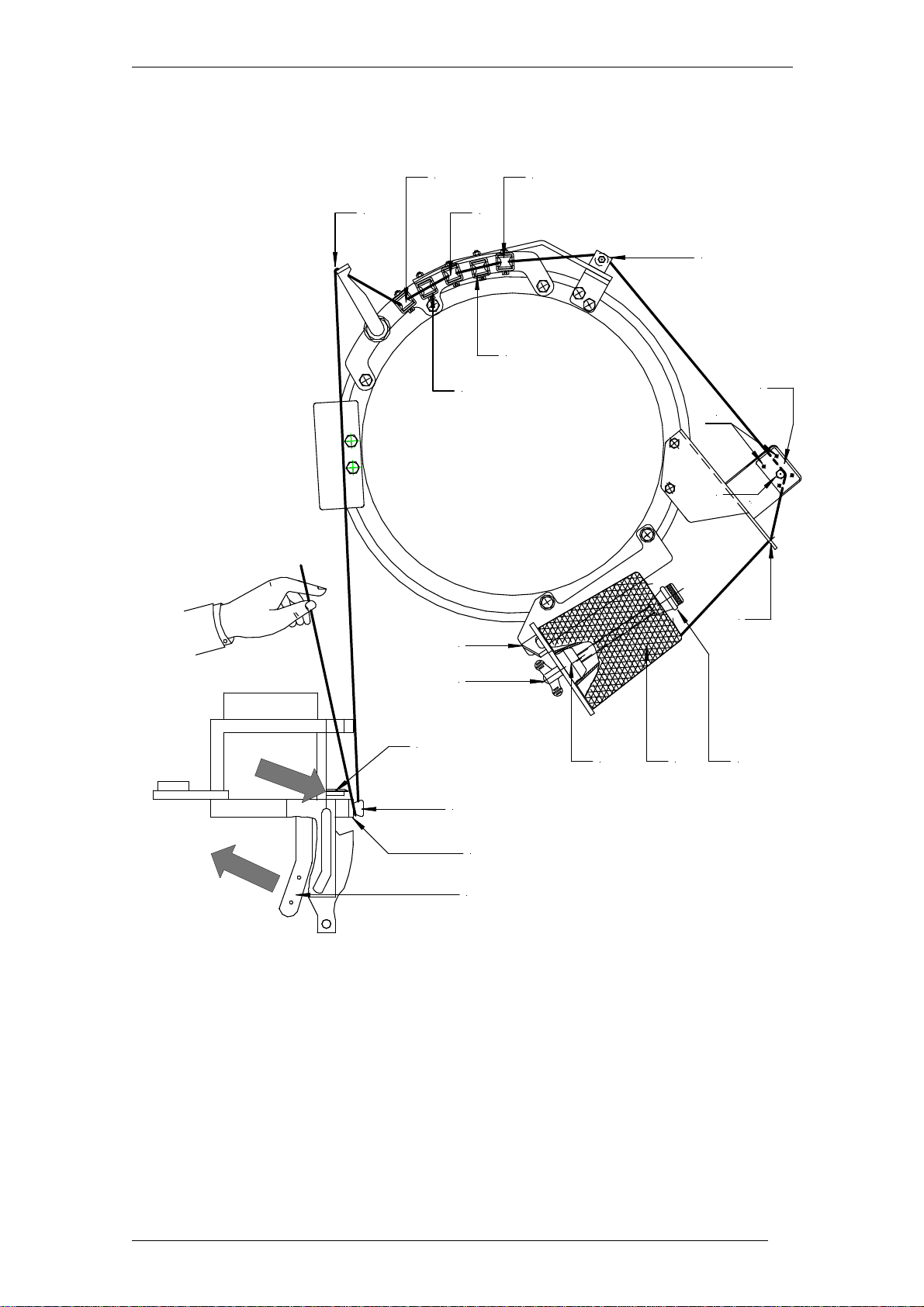

Inserting the string ( F take-up lever )

When the machine leaves our premises, it includes a piece of string

completely threaded. Study the course of the string exactly to make

understanding the following description easier. Proceed as follows in

accordance with the threading diagram opposite:

-Remove the wing nut (B) and the threaded rod (E).

-Insert the threaded rod (E) through the string bobbin (D)

from above.

Place the string bobbin (D) together with the threaded rod (E)

on the bobbin holder (A). Guide the bottom end of the

threaded rod (E) through the drilled hole on the mandrel (C)

and screw on and tighten the wing nut (B). You must make

sure that the string bobbin's cardboard tube rests firmly on

the mandrel (C) and that the net which surrounds the string

bobbin is securely clamped between the cardboard tube and

the mandrel (C).

-Feed the lead end of the string through the drilled hole (F).

-Insert the string in the thread brake (G). Make sure that the

string comes to rest between both pins (H) and the shaft of

the hexagon screw (I) (see figure).

-The next string guides are rollers. Thread the string in

numerical order:

L1 - K2 - L3 - K4 - L5 - K6 - L7 – M

Guide the string through the insert (N) at the end of the tying

arm tube. Inserting the string in the knotting aggregate:

Use your left hand to wrap the string around the twine holder

button (O) upwards from below. Use the right hand to

actuate the twine holder button lifting lever (P) in the

direction of the arrow. Whilst you hold the string tight with

the left hand, the string enters between the twine holder

button (O) and the twine holder button housing (R). The

string is clamped once you release the twine holder button

lifting lever (P). Use your right hand to push the knife trap

lever (S) forwards in the direction of the arrow; the string is

cut off. Close the machine hood, switch on the master

switch. After the reference run, the machine is ready for

operation.

Check that the string rollers and the take-up lever move freely

and oil them as necessary.

Only use lubricants which are approved for

the food sector (see the chapter

"Maintenance").

This manual suits for next models

2

Table of contents