17

2Maintenance

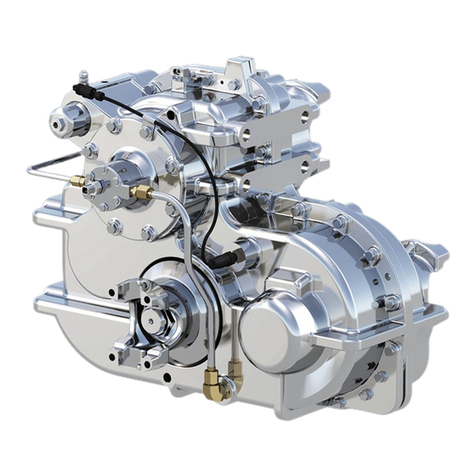

2. Calculating the Pinion Shim Pack Value.

Original Ring Gear & Pinion and Shim Pack WITH

AVAILABLE REFERENCE NUMBER.

2.1. Measure the thickness of the shim pack removed from the

old pinion/drive gear assembly. Use a micrometer or

gauge and record the reading.

2.2. Read the Pinion Cone (P.C) value marked on the drive ring

gear which is to be replaced (Fig.2.6). If it is a plus (+)

number add it to the value recorded at point 2.1

If it is a minus (-) number, subtract it from the value

recorded at point 2.1.

Record the result of the above calculation.

WARNING:

The value obtained at point 2.2 above will be used to

calculate the thickness of the shim pack required to be fitted

between the INNER pinion bearing cup and the differential

carrier to ensure a correct new final drive assembly. Spare

shims which may be required between the INNER pinion

bearing cup and differential carrier are available in

thicknesses of 0.10, 0.15, 0.20 & 0.50mm

2.3. Read the P.C. marked on the new drive gear (Fig 2.6).

Either add or subtract from the calculated value recorded at

point 2.2 above.

NOTE: Where the P.C. figure on the NEW drive gear is a + value

it must be subtracted from the calculated value at point 2.2.

Where the P.C. figure on the NEW drive gear is a - value it must

be added to the calculated value at point 2.2

Fig. 2.7

Refer to the following examples which cover all the possible

calculation combinations.

NOTE: All values are mm.

Example 1:

Original Shim Pack Thickness 0.76

Hmarked on the OLD DRIVE GEAR (-0.10) -0.10

Resulting Value 0.66

Hmarked on the NEW DRIVE GEAR (-0.12) +0.12

Thickness of new shim pack required 0.78

Example 2

Original Shim Pack Thickness 0.76

Hmarked on the OLD DRIVE GEAR (+0.10) +0.10

Resulting Value 0.86

Hmarked on the NEW DRIVE GEAR (-0.12) +0.12

Thickness of new shim pack required 0.98

Example 3

Original Shim Pack Thickness 0.76

Hmarked on the OLD DRIVE GEAR (+0.10) +0.10

Resulting Value 0.86

Hmarked on the NEW DRIVE GEAR (+0.12) -0.12

Thickness of new shim pack required 0.74

Example 4

Original Shim Pack Thickness 0.76

Hmarked on the OLD DRIVE GEAR (-0.10) -0.10

Resulting Value 0.66

H marked on the NEW DRIVE GEAR (+0.12) -0.12

Thickness of new shim pack required 0.54

* Hmarked on the new drive gear =”O” mm

Fit the shim pack as 2 calculation.

NOTE: Use a shim pack as close as possible to the calculation

value obtained. Shims are available in thicknesses of 0.10, 0.15,

0.20 & 0.50mm.

All final drive sets are stamped with a number indicating only a basic

factory backlash between pinion and drive gear. This backlash

value is shown in the previous pictures (Fig. 2.6A - 2.6B - 2.6C)

If the drive gear is not going to be replaced, we suggest the

established backlash recorded before disassembly be used.

For new gears the new backlash should be initially set at 0.38

mm (.015”). Adjust backlash by moving the gear only. This is done

by backing off one adjusting ring and advancing the opposite ring

the same amount, to ensure bearing preload is maintained.