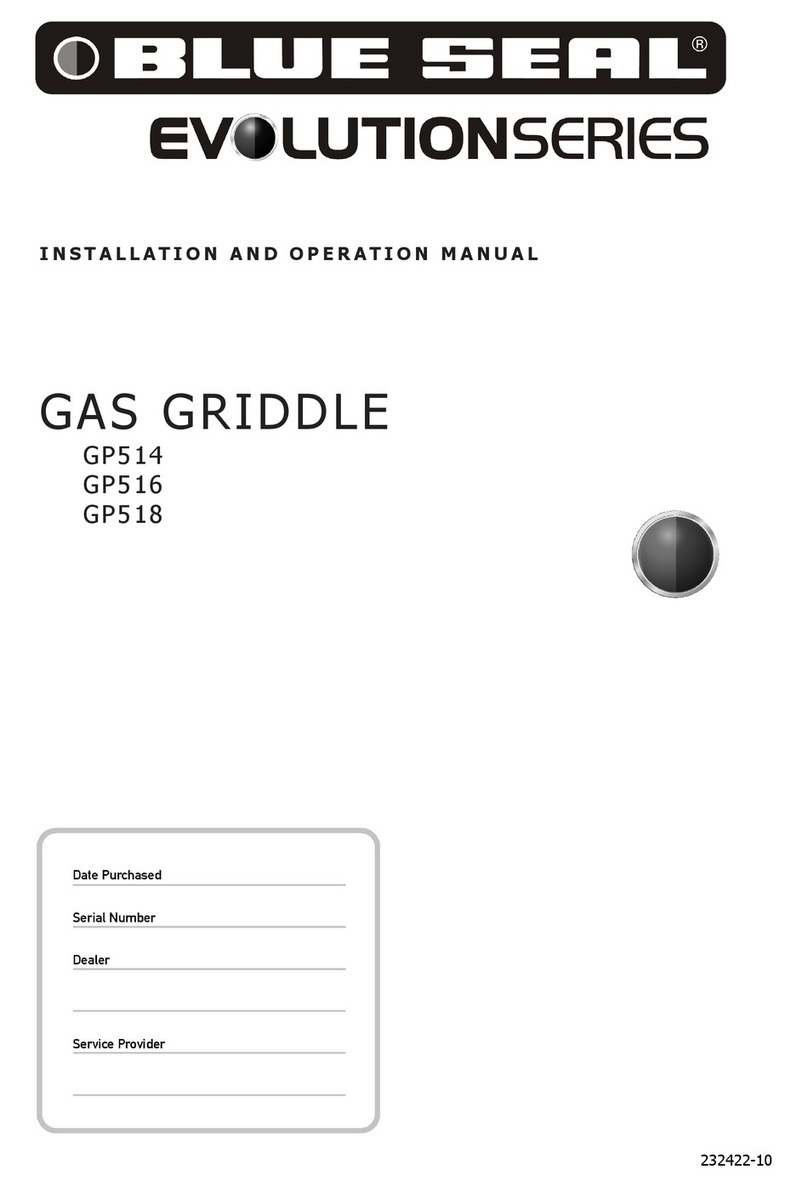

Blue Seal GP51 User manual

Other Blue Seal Griddle manuals

Blue Seal

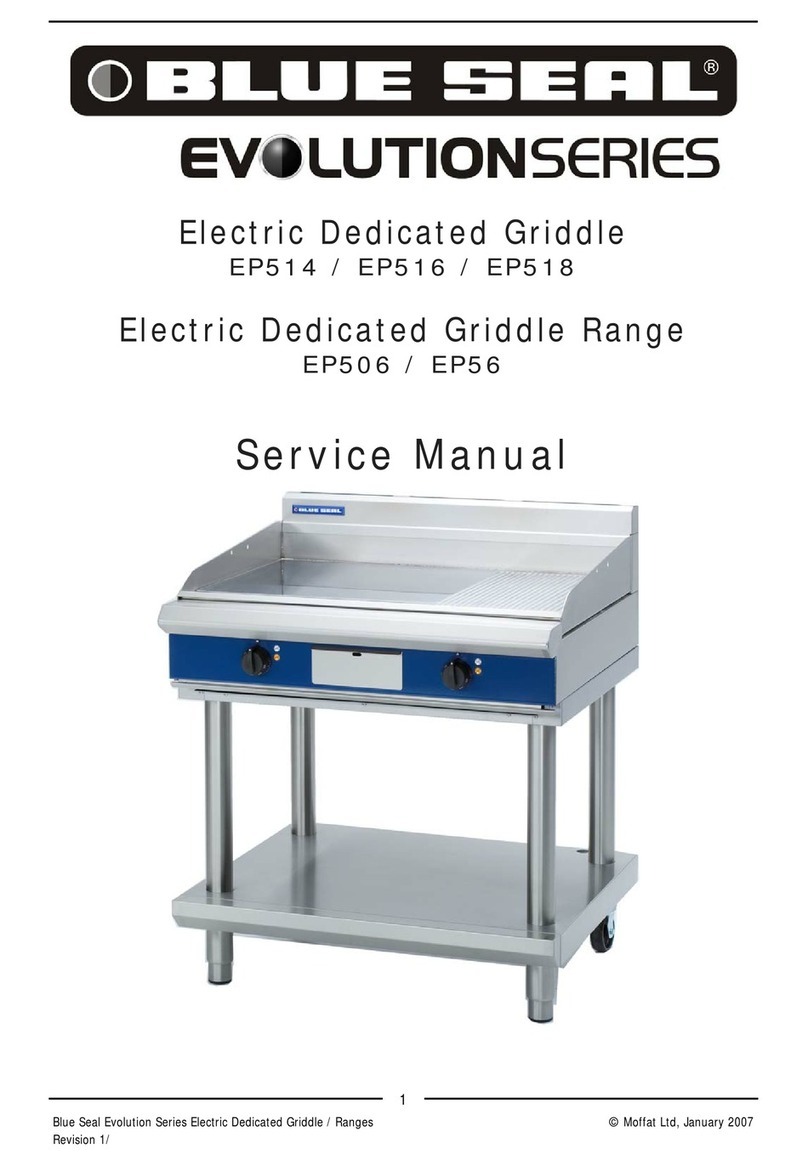

Blue Seal Evolution EP514 User manual

Blue Seal

Blue Seal Evolution G55T User manual

Blue Seal

Blue Seal Evolution GP514 User manual

Blue Seal

Blue Seal Evolution GP514 User manual

Blue Seal

Blue Seal GP513 User manual

Blue Seal

Blue Seal GP8600G User manual

Blue Seal

Blue Seal Evolution GP516 User manual

Popular Griddle manuals by other brands

Dyna-Glo

Dyna-Glo DGL260SNP manual

Char-Broil

Char-Broil 19952085 Product guide

APW Wyott

APW Wyott HMG-2424 Installation and operating instructions

Pit Boss

Pit Boss Ultimate Griddle PB2BGD2 Assembly guide

Airxcel

Airxcel Suburban Elite SOP-1005A Operation guide

Keating Of Chicago

Keating Of Chicago MIRACLEAN PRE-2000 manual

Nexgrill

Nexgrill 720-0786A owner's guide

Outwell

Outwell FH-3047C instruction manual

Rankam

Rankam Member's Mark GR2298901-MM-02 Assembly & operating instructions

Black Stone

Black Stone 1972 owner's manual

Star

Star Ultra Max 760TA Installation and operation instructions

NuWave

NuWave Precision Cast Iron Griddle User information