8

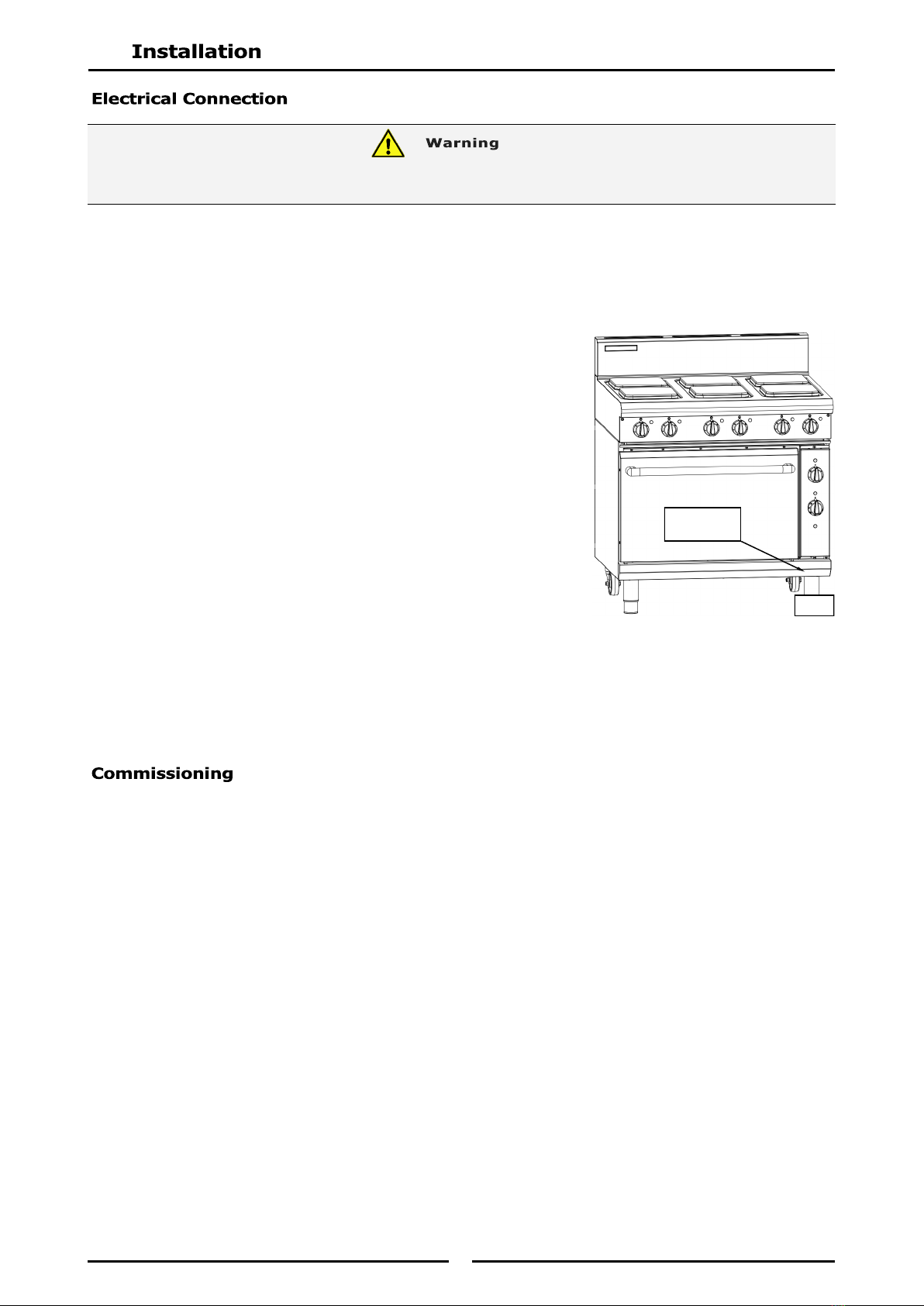

The controls for the cast iron hotplate elements may be set at any position between high and low to

provide the desired level of heating. An individual green neon for each element, will glow when the

element is powered on, i.e. heat control is set to an “ON” position.

Start cooking at the highest setting, and change to a lower setting when the desired temperature is

reached.

For maximum speed and economy, it is most important that cooking pots/pans should cover the

hotplate completely and have perfectly flat bases. Any part of the hotplate which is not making

effective contact with the base of the pot/pan decreases the life and efficiency of the hotplate.

Pots/pans which are significantly larger than the hotplate may also reduce hotplate life and

efficiency.

The oven is fitted with top and bottom elements. The thermostat maintains the overall oven

temperature. The top element is further controlled by the oven top heat control.

NOTE: The thermostat on the oven provides overall control of temperature within the oven by

controlling both elements, whereas the Oven Top Heat Control provides a means of

balancing the distribution of heat between the top and bottom of oven.

Convection ovens (E56S) are fitted with a circulation fan.

Place oven racks in the desired position.

Preheat:

Preheat the oven by selecting the desired temperature, and turning the oven top heat control (Refer

to Fig 2 on previous page) to a maximum of 2. When the desired temperature is reached, the amber

neon will go out.

Cooking:

When the desired temperature has been reached, load oven with product and set the oven top heat

control to the desired setting.

NOTE: When the oven top heat control is set to a high setting, proportionally more heat is

produced at the top of the oven. (This can be used for browning, etc, during the cooking

operation). With the oven top heat control set on a low setting, less heat is produced from

the top oven elements. (This mode is used for general baking purposes to prevent cakes,

etc, from getting too brown and crisp on the top, but allow the cake to cook through).

To obtain more top heat during cooking, turn the oven top heat control to a higher position. (The

higher the setting, the more top heat).

Turning ‘OFF’ the Oven:

a. Turn the oven top heat control to the ‘O’ off position. The top heating will be turned ‘OFF’ and

the upper heating indicator lamp (Amber) will extinguish.

b. Turn the thermostat control knob to the ‘O’ off position and the lower heating indicator lamp

(Amber) will extinguish. The oven is now turned ‘OFF’.

NOTE:

• If for some reason it is not possible to get the unit to operate correctly, turn off the

electrical power supply and contact a qualified service person. The supplier of this unit

will be able to recommend a suitable person.

• Make sure that the electrical supply is turned “Off” before any service or maintenance

work is carried out.

DO NOT USE aluminium foil or trays directly on the cast iron sole plate(s).

NEVER block or cover the openings on each side of the sole plate(s).

! IMPORTANT