8

NOTE: The gas pressure regulator provided with this appliance is convertible between Natural Gas

and LPG as per the ‘Gas Conversion Section’ in this manual.

Ensure the regulator is converted to the correct gas type that the appliance will operate on.

The regulator outlet pressure is fixed ex-factory for the gas type that the

regulator is converted to and it is NOT to be adjusted.

The regulator connections are 3/4" BSP female.

The connection to the appliance is 3/4" BSP male.

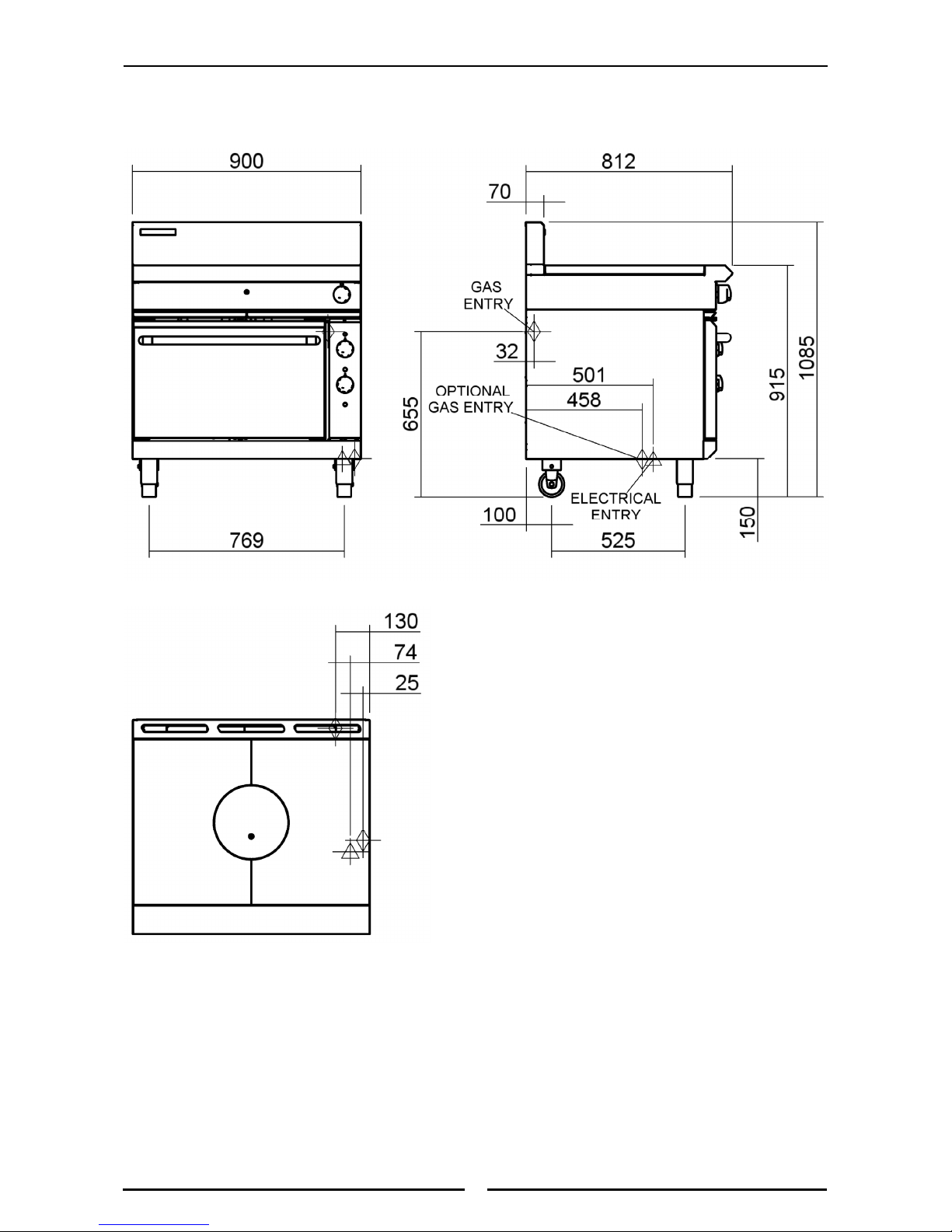

(Refer to the “Specifications” section for the gas supply location dimensions).

NOTE: A Manual Isolation Valve must be fitted to the individual appliance supply line.

3. Correctly locate the appliance into its final operating position and using a spirit level, adjust the legs

so that the appliance is level and at the correct height.

4. Connect the gas supply to the appliance. A suitable joining compound which resists the breakdown

action of LPG must be used on every gas line connection, unless compression fittings are used.

5. Check gas operating pressure is as shown in the “Specifications” section.

6. Check all gas connections for leakages using soapy water or

other gas detecting equipment.

NOTE: The burner operating pressure is to be measured at

the manifold test point with both burners operating

at ‘Full’ setting.

7. Turn off the mains gas supply and bleed the gas out of

the appliance gas lines.

8. Turn on the gas supply and the appliance.

9. Verify the operating pressure remains correct.

Electrical Connection

NOTE: ALL ELECTRICAL CONNECTIONS MUST ONLY BE

CARRIED OUT BY AN AUTHORISED PERSON.

Each appliance should be connected to an adequately protected power supply and isolation switch

mounted adjacent to, but not behind the appliance. This switch must be clearly marked and readily

accessible in case of fire.

1. Check that the electricity supply is correct as shown on the Rating Plate attached to the lower front

hand side of the front sill panel.

2. The supply terminal connections are located at the rear of the appliance. Refer to ‘Electrical

Connections’ in the ‘Dimensions’ section of the manual.

3. Open the oven door and remove the oven control panel to allow connection access for the electrical

supply.

4. Connect the mains supply to L1, L2 and L3 connection terminals. Refer to the 'Electrical Supply

Requirements' section for connection details.

NOTE: This appliance can be converted from 3 Phase to Single Phase supply by connecting the

single phase input to L1 and adding a bridge wire between the L1, L2 and L3 connections,

(refer to Fig 3 opposite and the information shown in the 'Electrical Supply Requirements

Table' in the 'Specifications' Section).

5. Connect neutral and earth conductors to neutral stud and earth stud respectively.

6. For all connections ensure that conductors are secure and appropriately terminated.

Installation

WARNING:

DONOT USE ANAKED FLAME TO CHECK FOR GAS LEAKAGES.

Fig 2

Manifold Test

Point

WARNING:

THIS APPLIANCE MUST BE EARTHED. IFTHE SUPPLY CORD IS DAMAGED, IT MUST BE REPLACED BY ASUITABLY

QUALIFIED PERSON IN ORDER TO AVOID AHAZARD.