Blue Star Imperia User manual

This manual suits for next models

6

Table of contents

Other Blue Star Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Spectra Watermakers

Spectra Watermakers Newport 700C Installation and operating manual

GE

GE 000 gpd Operation and maintenance manual

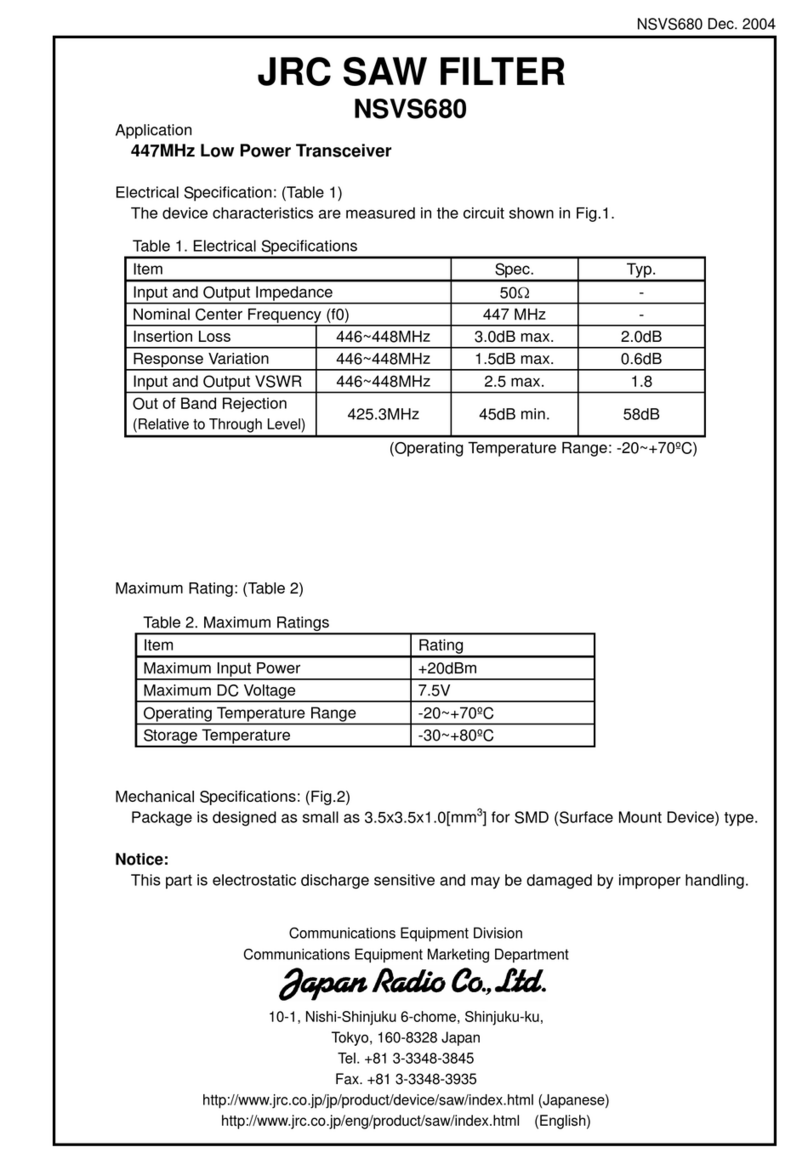

JRC

JRC NSVS680 manual

Pall

Pall FlexBowl PISIFLEXB Installation and operating instructions

GE

GE GXRQ18NBN Owner's Manual & Installation Instructions

TCi

TCi HarmonicGuard HGL Series Installation, operation and maintenance manual

amiad

amiad AGF Installation, operation and maintenance instructions

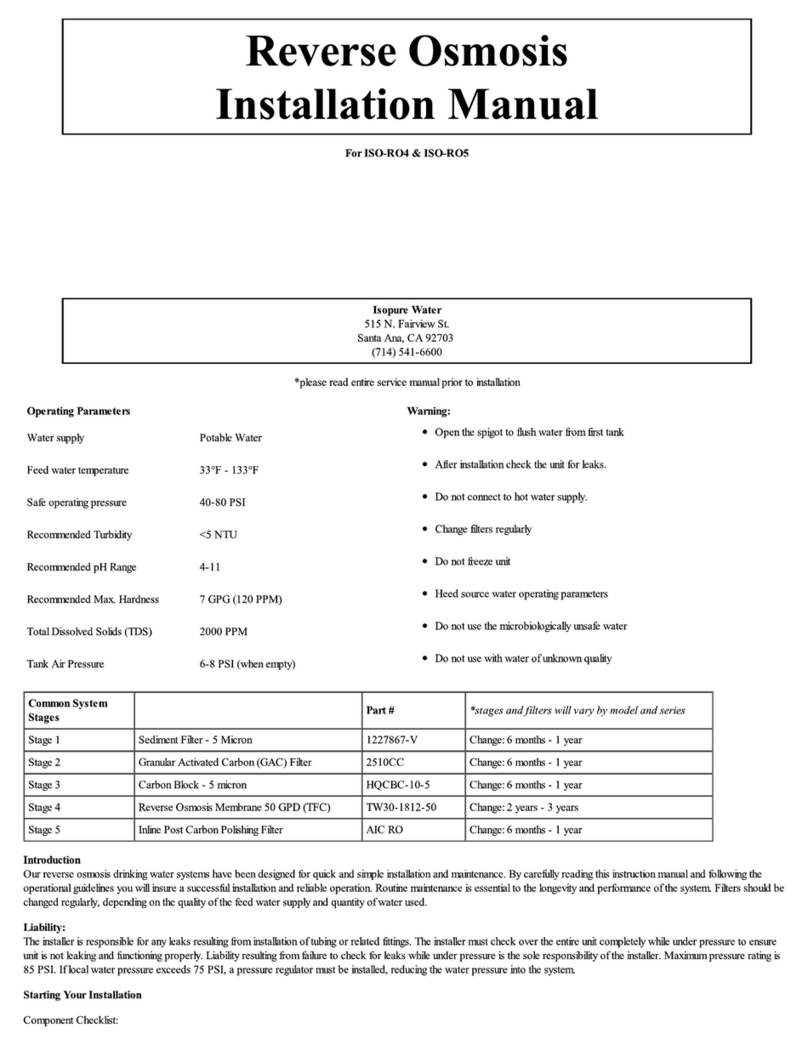

Isopure Water

Isopure Water ISO-RO4 installation manual

EXOLAUNCH

EXOLAUNCH CarboNIX 8 user manual

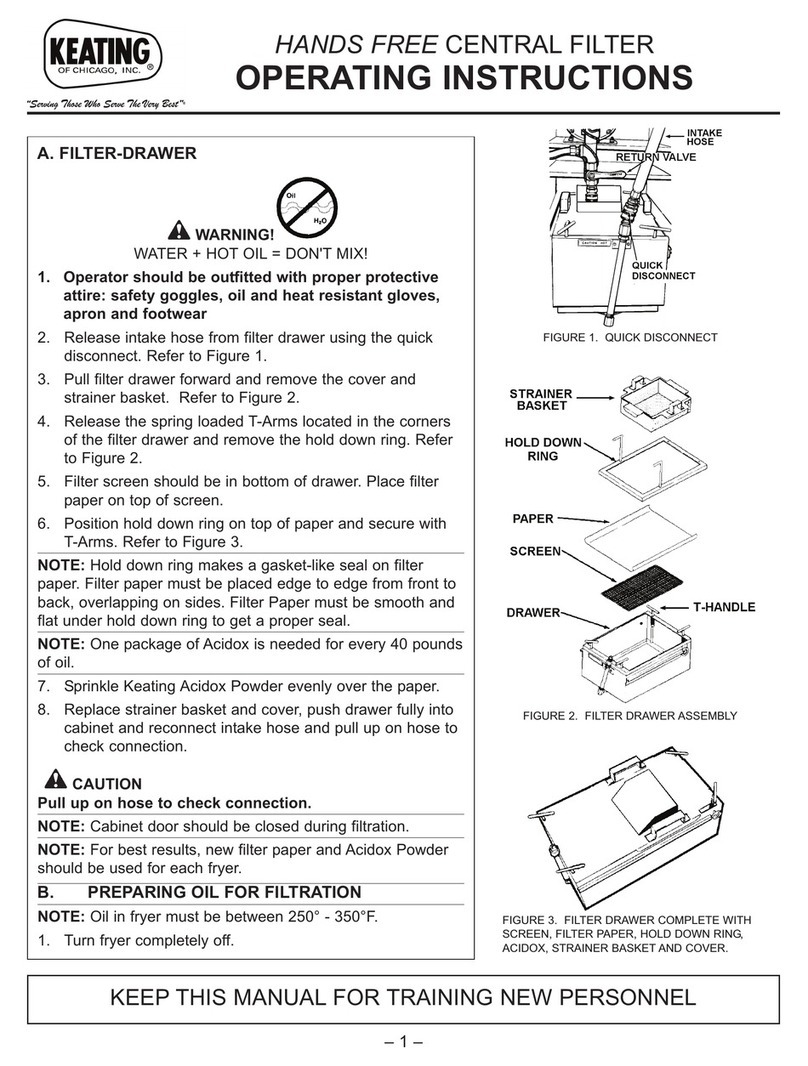

Keating Of Chicago

Keating Of Chicago Central Filter Hands Free operating instructions

BestWater

BestWater BW 1500 instruction manual

Philips

Philips AWP2950/03 user manual

WaterChef

WaterChef Countertop C7000 Installation, use and care guide

WaterLogic

WaterLogic escowa Purus iQ3 Service manual

HYTECON

HYTECON HYPRO WATER user manual

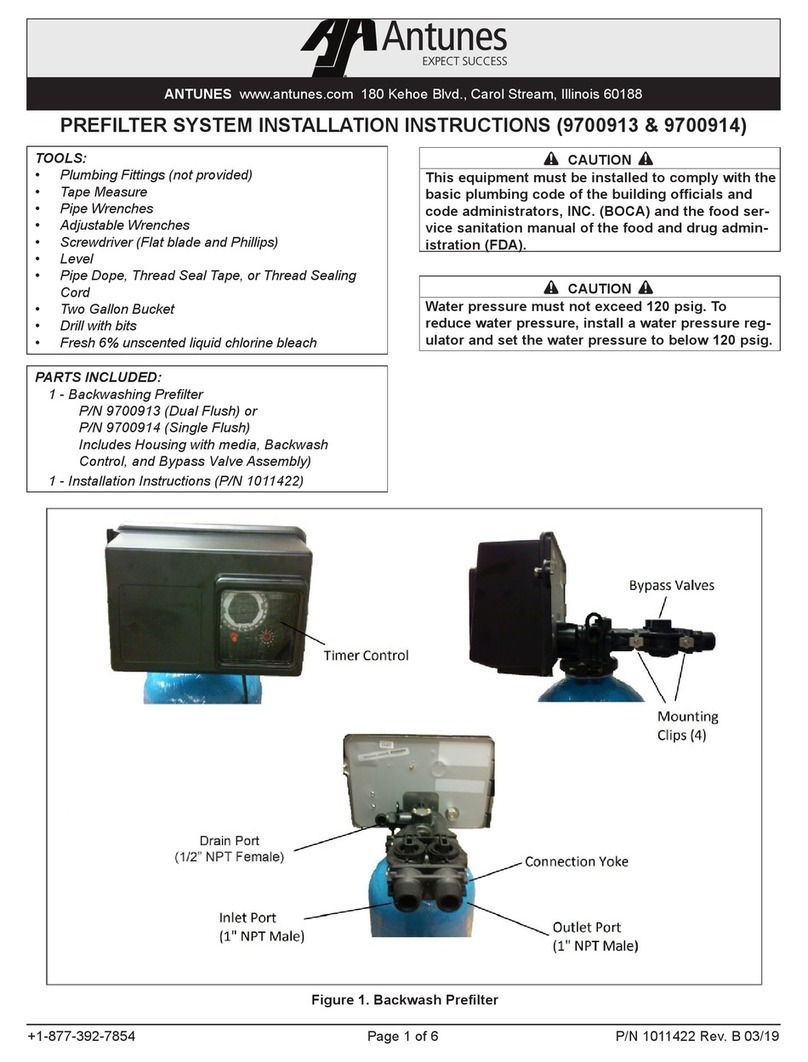

Antunes

Antunes 9700913 installation instructions

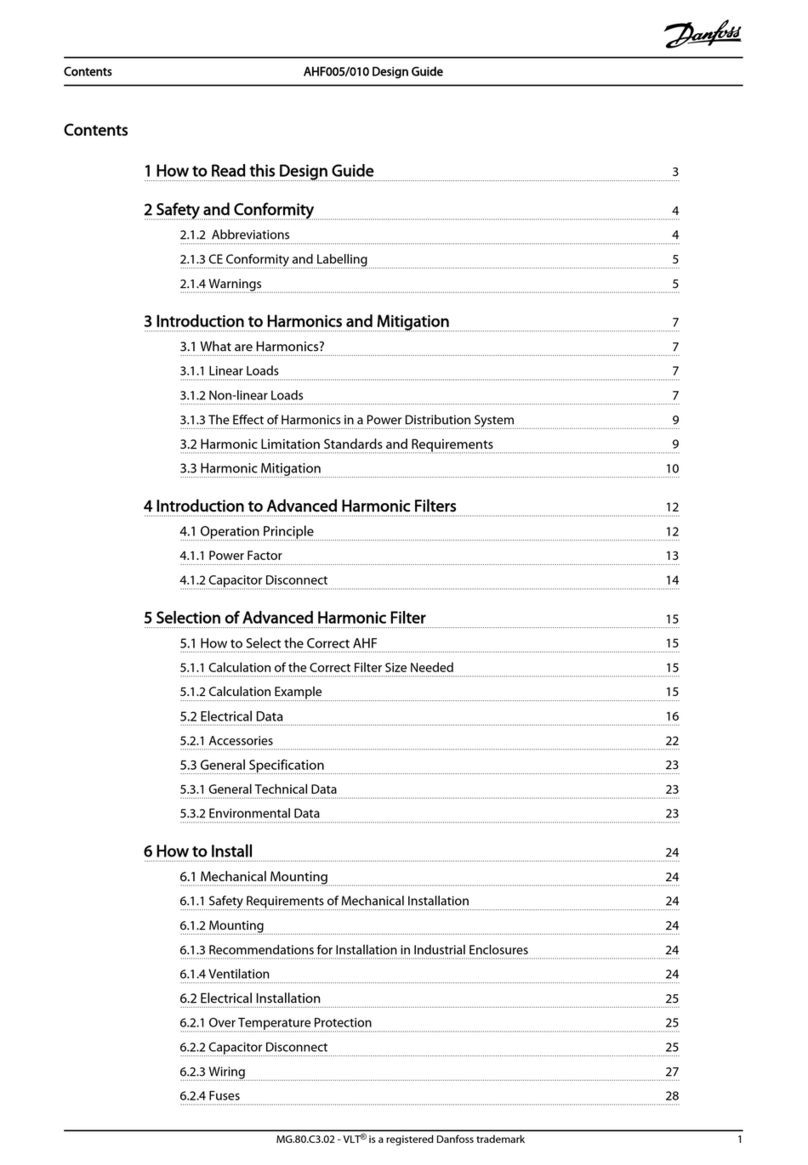

Danfoss

Danfoss VLT AHF 005 Design guide

Brita

Brita Redi-Twist USS-335 installation instructions