Blue Wave FlowXtreme Plus User manual

NE4507

FlowXtreme Plus Filter System Manual

VER.0418

A. Safety Warnings

Read all Warnings and Cautions noted below. Failure to do so could result in serious or fatal

injury.

Prior to installation of this unit, carefully read and adhere to all CAUTION, ATTENTION,

and ADVICE notices located throughout this manual. Failure to comply with these instruc

tions can cause serious injury, death, or damage to the unit.

RISK OF SUCTION ENTRAPMENT HAZARD, WHICH, IF NOT AVOIDED CAN RESULT

IN SERIOUS INJURY OR DEATH. Do not block pump suction at the pump or in the pool as

this can cause severe injury or death.

Electrical wiring MUST be installed by trained professional and adhere to local code and

regulations.

Avoid electric shock. DO NOT USE power extension cords.

Connect ONLY to a Ground-Fault Circuit Interrupter (GFCI) power outlet. Consult a

qualified professional electrician for safe and proper installation of a qualified electrical

outlet.

Incorrectly installed equipment may fail, causing severe injuries or damage to the

pump-filter system.

Never submerge the filter and/or pump in water.

Never place the pump or filter in your pool.

Trapped air in the pump-filter system may cause the TANK COVER to be blown off which

can result in death, serious injury, or damage to the pump-filter system. Ensure all air is out

of system before operating.

Never change the 7 Position Multi-Port Valve while the system is operating.

ALWAYS unplug the system before changing the control valve.

Install this product with sufficient safety margin from the pool to prevent children from using

the system to access the pool.

Never PLUG or UNPLUG this unit from an electrical source while standing in water.

NEVER service this unit with electrical power cord connected.

DO NOT operate the system while the pool is being used.

KEEP CHILDREN AWAY from all electrical equipment.

NEVER ALLOW CHILDREN TO OPERATE THIS EQUIPMENT.

The Pool Owner should always exercise caution and common sense when utilizing their

swimming pool and operating equipment.

B. General Information

This manual provides information relating to the installation, utilization and maintenance of our

filtration system. We recommend that you read this manual in its entirety and keep it for future

reference.

The pump included with the filtration system is a horizontal, self-priming centrifugal pump. For

the pump to function correctly, the water temperature must not exceed 35℃/95℉. The materials

used in the pump have undergone stringent hydraulic testing and electrical inspections.

The filter tank included in the filtration system consists of high-grade polypropylene (PP). It is

manufactured as a single unit (absolutely corrosion resistant and resistant to commercially avail-

able swimming pool chemicals). (Prerequisite: Compliance with the standard recommended

Page 2

specifications for the pH- and chlorine value). It is equipped with a tank drainage system. The

filter tank comes ready to attach with an approved filter pump .

Read this manual carefully before installation. The filtration system and pump must be installed

in accordance with all federal and local codes and standards in effect for the area of installation.

We decline all responsibility for the consequences of failure to comply with the installation

instructions. We recommend that you comply with the power source instructions to avoid over-

loading the pump motor and/or electric shock.

This filtration system is not intended for use by persons with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge.

Safety notes and information boxes should always be observed.

C. Safety Notes

Your filter pump was constructed and tested and left the manufacturing plant in technically oper-

ational condition. In order to maintain this condition and ensure safe operation, the user should

observe the notes and product information contained in this technical manual. If there is any

indication that safe operation is no longer possible, the device is to be disconnected from the

power supply and secured against accidental use.

This is the case when:

The device has visible damage.

The device no longer appears functional.

After long periods of storage in poor conditions.

If the power cord or other parts of this equipment are damaged, they have to be replaced by

manufacturer or its service agent or a similarly qualified person in order to avoid danger.

D. Damage during delivery

Your filter system has been carefully and professionally packed for delivery. Please check to

ensure that the package is undamaged and that all parts are in the box. If you purchased this

product on order and the product was shipped to you, ensure that delivery is complete. Damage

to product as a result of shipping is not the responsibility of the supplier and must be immediately

reported to the shipper. The shipper assumes the liability for damages during delivery, the

supplier is not responsible for it.

E. Implied Warranty

The manufacturer warranties safe operation and reliability only under the following conditions:

The filter system is installed and operated according to the assembly and operating

instructions.

Only original replacement parts are used for repairs or replacements (consumable &

expendable parts do no fall under the warranty).

Expendable parts that do not fall under the warranty include:

All O-rings

Pressure gauge

Mechanical seal, complete

Hoses and metal hose clamps

Page 3

F. Resultant Damages

We cannot be responsible for damages to the product if the product is not used in accordance

with the instructions provided.

G. Technical Data and Specifications

1. Circulation power 1100 GPH

2. Pump is not self-priming

3. Maximum water temperature 35°(95°F)

4. 100W / 115V / 60HZ / 1/10HP

5. Tank diameter: 10’’

6. 1¼”-1½“ hose connector

7. (0.8 lbs) of cotton tails are included

8. For use on pools up to 3,000 gallon

Filtering time:

The swimming pool’s water should be circulated and filtered at least 3 to 5 times in a 4 hours

period, depending on the load and the size of the filter system. The time required is based on the

performance if the filter system and the size if the swimming pool. However, we recommend a

minimum running time of 12 hours per day.

H. Unpacking your filter system

Carefully remove the product and all component parts from the box. Cross reference all parts in

the box with the parts list reference chart to make certain all parts are present before beginning

assembly.

NOTE: Some parts may be located within the filter tank. To access these parts, you must remove

the tank cover.

Refer to *page 9 for complete EXPLODED VIEW PARTS DIAGRAMS.

I. Power source instructions

1.The Above Ground filter pump system you have purchased is equipped with a standard elec-

trical cord and plug which should only be connected to a power outlet protected by a 30 Amp

Ground-Fault-Circuit-Interrupter (GFCI) that has been installed by a professional electrician and

adheres to local codes and regulations.

2. To avoid electric shock, power cord extensions should not be used.

J. Positioning your filter system

For the operation of this filter system with Above Ground pools, you need a skimmer

installed in your pool. Either an integrated skimmer (built into the pool wall) or a suspended

skimmer (attachment to the pool wall).

The installation area must allow an adequate safety margin to the pool wall.

We recommend putting the filter system on a concrete slab or similar. Be sure the

installation is level.

Additional installation accessories such as hoses, hoses clamps are available from your

pool dealer.

Page 4

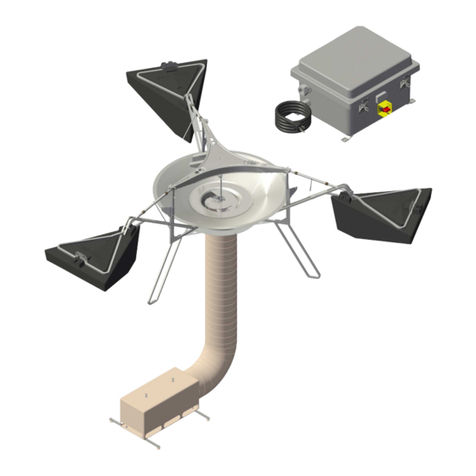

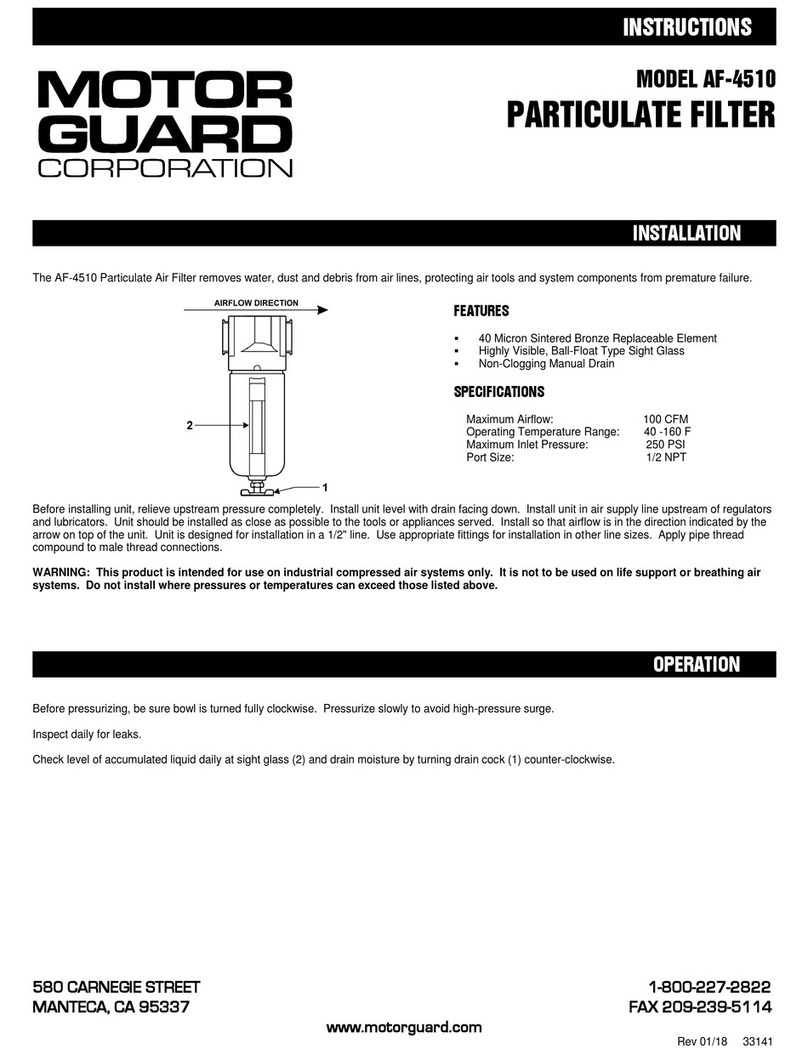

K. Filter-Pump assembly (Figure1)

1. Assemble the filter system at the location where the pump will be installed.

The filter pump consists of the following parts:

a. 90° connector

b. Transparent cover

c. Clamping ring

d. Filter tank

e. 1¼”-1½“ return to pool hose fitting

f. Tank and pump base plate

g. Filter pump

h. 1¼” diameter connection hose

2. Assembly of filter system (Figures 2,3,4,5)

a. Open the clamping ring and remove the transparent cover from the filter tank.

b. Fill the filter tank with the cotton tails which are included with the order, approx. 0.8 lbs.

c. Now place the large O-Ring onto the underside of the transparent cover.

d. Lay the transparent cover onto the upper neck of the filter tank. It is very important to ensure

that all surfaces have been cleaned once again and are free from any dirt or debris before

you do this.

e. The transparent cover is connected to the filter tank using the clamping ring. The clamping

ring is screwed together with the clamping ring screw and clamping ring screw nut.

f. Fit the 90° connector on the upper side of the transparent cover.

g. Connect the 90° connector to the filter pump by using the connection hose provided. Fasten

all connections with hose clamps and ensure that the pump connecting pieces are sealed

using “Teflon” tape, (available at any plumbing or hardware store).

3. Pump hose connections (Figure 5)

A. Return line - Connection between the filter tank and the pool’s return water fittings. The

filtered water is fed back into the pool at this point.

B. Skimmers - Connection between the pool skimmer and the filter pump. Water to be filtered

is drawn from the pool at this point.

L. Filter system start up Instructions

1. Once the filter system has been properly assembled, the cotton tails placed in the tank and

the hoses connected as described above, you may begin with filtration.

2. Do not plug the system in until advised to do so.

3. Before operating the filter system , it is important to ensure that the filter system is positioned

outside the pool and is lower than the pool’s water level. The hose connections must

also be correctly connected and fastened.

4. If you haven’t already done so, fill your pool with water. Ensure that the water level is at least

1’’-2’’ above the top of hose intake (Skimmer) and return ports in the pool.

5. Now vent the filter system. If applicable, open the vent screw on the upper side of the trans

parent filter cover until the water flows out.

6. Release the shut off valve at the intake port (Skimmer) in the pool. If you plugged the intake

port (Skimmer), remove the plug to allow the water flow into the inkate hose.

Page 5

7. If the filter-pump system is installed in a location level and lower than your pool’s water level,

water will automatically flow into the pump-filter system.

8. Allow the filter tank to fill with water.

9. Check the filter system and the connection hoses for leaks and fix as needed. Leaking at

connection points may happen due to manufacturing tolerances, these leaks are easily

resolved by wrapping Teflon tape around the connections before the connection hose is

arrached.

10. Your filter system is now ready for use.

M. Cleaning Cotton Tails

1. Do not back wash on initial operation.

No need to back wash unless tank’s pressure gauge reaches 25 PSI. We recommend

removing Cotton Tails at the end of the season, place in a mesh bag, wash in clothes

washing machine, let dry and return to tank for next season.

2. Important note regarding Clarifiers

Pool water clarifiers or other chemical additives that bond to particulate matter for the

purpose of improved filtration must not be used if Cotton Tails is the filtration media for your

pool. This is the same warning or instruction that is commenly given for pools where Diato

maceous Earth is filtration media.

Like Diatomaceous Earth, Cotton Tails filters down to a very small paiticle size, 3 microns.

Therefore, the addition of a clarifier will not improve the effectiveness of Cotton Tails. The

clarifier or a similar chemical additive is likely to cause damage to the Cotton Tails resulting

in significant reduction in the filtration capability. In addition, possible damage to the filtration

tank or its internal components may occur.

Bluewave will not be responsible for damage caused to the Cotton Tails, the filter tank or any

of the internal components of the filter tank where a clarifier or other chemical additives that

bond to particulate matter have been used in the pool.

N. Winter Storage

1. Disconnect the filter-pump assembly from the pool.

2. Drain the tank and the hoses.

3. The filter system must be thuroughly dried befor winter storage.

4. Store in a dray location protected from frost.

Page 6

Malfunction Cause Solution

Pressure gauge has

reading more than 25

PSI

Pressure is too low

Air in the pump

Pump gets too little water

Poor seal on the intake side

of pump

Check the suction line and the

water level in the pool

Tighten hose clamps and

connecting fittings

Pump does not run

Not plugged in/

Debris blocking the impeller

G.F.C.I./ or main circuit

breaker tripped

Switch on the breaker (if it is

immediately tripped again, there

is a defect in pump or controls)

Check the socket and power

cord/

Clean pump body

Leaking filte Seal is worn out or damaged Replace pump

Pump motor defective Replace motor or entire pump

The Cotton Tails have

absorbed too much dirt &

debris from the water

Clean the Cotton Tails filter

media

Q. Important Do’s & Don’ts:

DO’s:

1. Be aware and make note of the filter pressure when the Cotton Tails balls are clean.

Remove and clean the Cotton Tails when you see a pressure increase to over 25 PSI on

the pressure gauge.

2. Protect the tank’s internal plumbing while cleaning the Cotton Tails balls.

3. Follow these cleaning instructions:

Drain the water from the filter tank, remove the tank lid from the tank while leaving the

hoses attached to the lid

Empty the Cotton Tails balls on a smooth surface such as a plastic tarp.

Rinse excess dirt and debris from the Cotton Tails balls

Place the rinsed balls into a mesh bas such as a lingerie bag and wash in your clothes

washer.

Return the cleaned Cotton Tails balls to the filter tank, okay either wet or dry.

Re assemble the filter tank lid and resume filtering the pool water.

DON’TS:

1. Over clean the Cotton Tails balls. This filter media operates more efficiently during

mid-cycle when the balls are a little dirty. Too much cleaning will reduce efficiency.

2. Let the filter system run dry (without water). If your pump runs dry too long non-warranty

damage may occur. In a case of dry running damage the product warranty will be voided.

Page 7

P. Trouble Shooting

Figure 1.

Figure 2 ,3

Figure 4 Figure 5

R. FX Plus Cotton Tails System Installation Figures

Page 8

a

b

c

d

e

f

g

h

c

1¼”-1½”(32/38 mm) CONNECTOR

Page 9

S. FX PLUS FILTER SYSTEM NE4507 PARTS BREAKDOWN

1

2

3

4

5

679

8

12

15

14

10

11

13

Other Blue Wave Water Filtration System manuals

Blue Wave

Blue Wave EASY CLEAN 100 User manual

Blue Wave

Blue Wave EASY CLEAN 200 User manual

Blue Wave

Blue Wave FLOWXTREME COTTON TAILS NBP6058 User manual

Blue Wave

Blue Wave Flow Xtreme NE4486 User manual

Blue Wave

Blue Wave HYDRO NE635 User manual

Blue Wave

Blue Wave EASY CLEAN 30 User manual

Blue Wave

Blue Wave FlowXtreme Pro Series User manual