WARNINGS

High

Pressure Spray Can Cause Serious Injury. Observe All W

arnings.

Read and understand all instruction manuals before operating equipment.

FLUID

INJECTION HAZARD

General

Safety

This

equipment is used in a system which generates very high

fluid

pressure. Spray from leaks or ruptured components can in

-

ject fluid through your skin and into your body and cause ex-

tremely

serious bodily injury

, including the need for amputation.

Also,

fluid injected or splashed into

the eyes or on the skin can

cause

serious damage.

Never try to stop or deflect leaks with your hand or body

.

Keep

hands away

from the end of the drain valve when opening

the

drain valve.

Medical

Alert – Airless Spray W

ounds

If

any fluid appears to penetrate your skin, get

emergency

medical care at once. Do not treat as a simple cut.

T

ell the

doctor exactly what fluid was injected.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic

injury.

It is important to treat the injury surgically as soon

as possible.

Do not delay treatment to research toxicity

. T

ox-

icity is a concern with some exotic coatings injected directly

into the blood stream. Consultation with a plastic surgeon or

reconstructive hand surgeon may be advisable.

Pressure

Relief Procedure

To

reduce the risk of serious bodily injury

, including fluid injec

-

tion,

splashing in the eyes or on the skin, or injury from moving

parts, always follow this procedure whenever you install,

remove,

clean or repair any part of the system.

1. Engage the spray gun safety latch and any other equip-

ment safety locks.

2.

Shut of

f the air or hydraulic supply to the pump.

3.

Disengage the gun safety latch.

4. Hold

a metal

part of the gun firmly to the side of a grounded

metal

pail, and trigger the gun to relieve pressure.

5.

Engage the gun safety latch.

6. Keeping

your

hands away from the end of the drain valve,

slowly

open the drain valves (required in your

system) hav

-

ing

a container ready to catch the drainage.

7. Leave

the drain valves open until you are ready to use the

system

again.

EQUIPMENT MISUSE HAZARD

General

Safety

Any misuse of the equipment or accessories, such as

overpressurizing, modifying parts, using incompatible chemi-

cals and fluids, or using worn or damaged parts, can cause

them

to rupture and result in fluid injection, splashing in the eyes

or

on the skin, or other serious bodily injury

, or fire, explosion or

property

damage.

Never

alter or modify any part of this equipment; doing so

could

cause

it to malfunction.

System

Pressure

Do

not exceed

3000 psi (210 bar) Maximum Working

Pressure

,

or the maximum working pressure of the lowest rated compo-

nent or accessory in your system.

Be

sure all components and accessories are

rated to withstand

the

maximum working pressure of your pump.

Fluid

Compatibility

Be

sure that all fluids and

solvents used are chemically compat

-

ible

with the wetted parts shown in the

T

echnical Data

on

page 1 and in all other components used in the system.

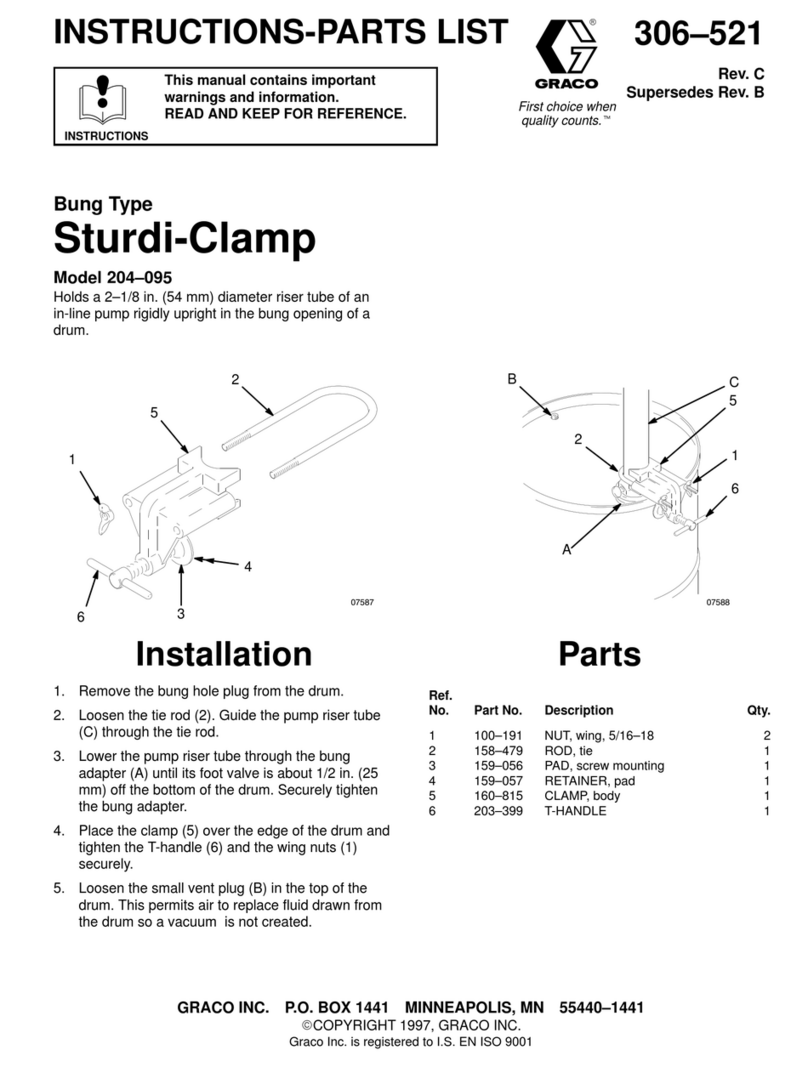

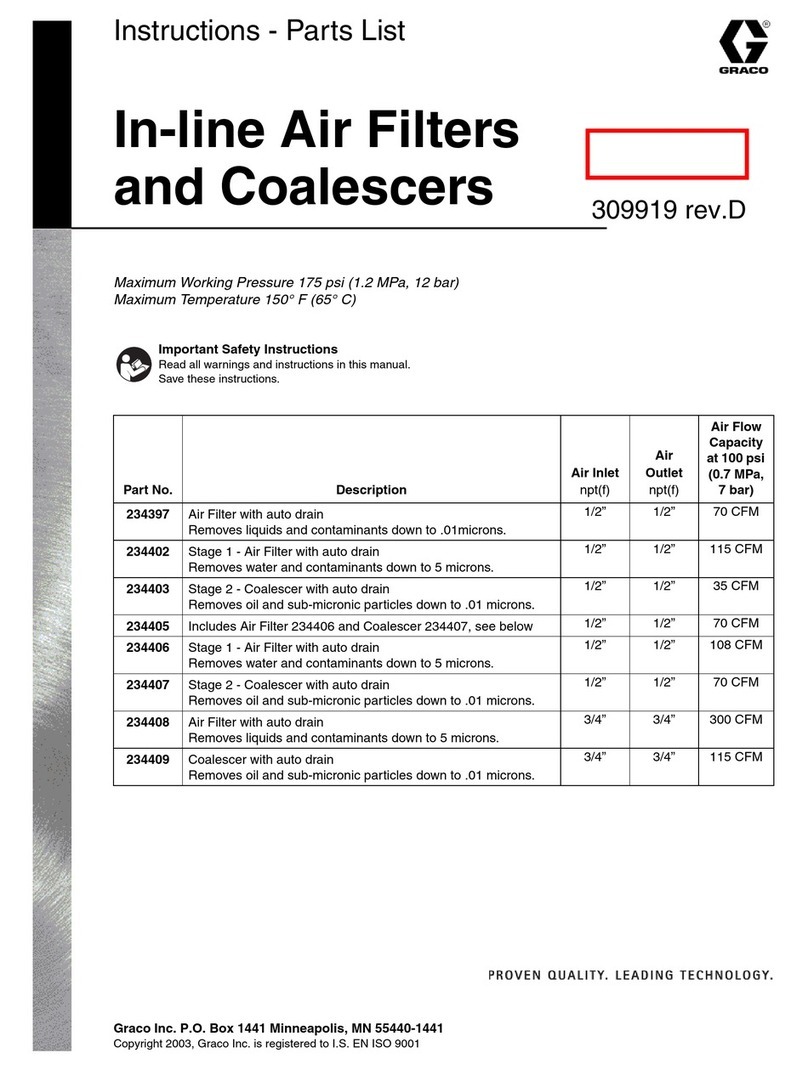

Installation

To

clean or service the filter without shutting down the system,

install

a dual filter or a filter bypass system

as explained below

.

The

numbers and letters in parentheses refer

to Figs. 1, 2, and

3

and the

Parts Drawing.

Accessories

and

T

echnical Data

are

on

the front page.

NOTE:

Allow 3 in. (76 mm) minimum clearance

below the filter

for

easy removal of the bowl (10).

Fluid

Drain V

alve (required in all systems)

WARNING

A

fluid drain valve is required in the base of

each fluid filter

.

Use

this drain valve to relieve fluid pressure in the filter

, to

reduce

the risk of serious injury

, including fluid injection and

splashing

in the eyes or on the skin.

Remove the 3/4 unf plug (12) from the bottom of the filter and

install

a high pressure adapter and drain valve (A,B). See Fig.

1.

Dual Filter System

This

setup enables you to redirect the fluid to

another filter while

one

filter is cleaned or serviced.

Install

two filters

as shown in Fig. 1. Install four suitable shutof

f

valves

(D), one at each filter and outlet, to redirect the fluid

and

isolate

the filter not in use.

Filter Bypass System

This

setup enables you to redirect the fluid through pipes which

bypass

the filter while cleaning or servicing the filter

.

Install

the filter and bypass pipes as shown in Fig. 2. Install four

suitable

shutof

f valves (D), one

each at the filter inlet, the filter

outlet,

the bypass pipe inlet, and the bypass pipe outlet.

These

valves redirect the fluid and isolate the filter while cleaning and

servicing.