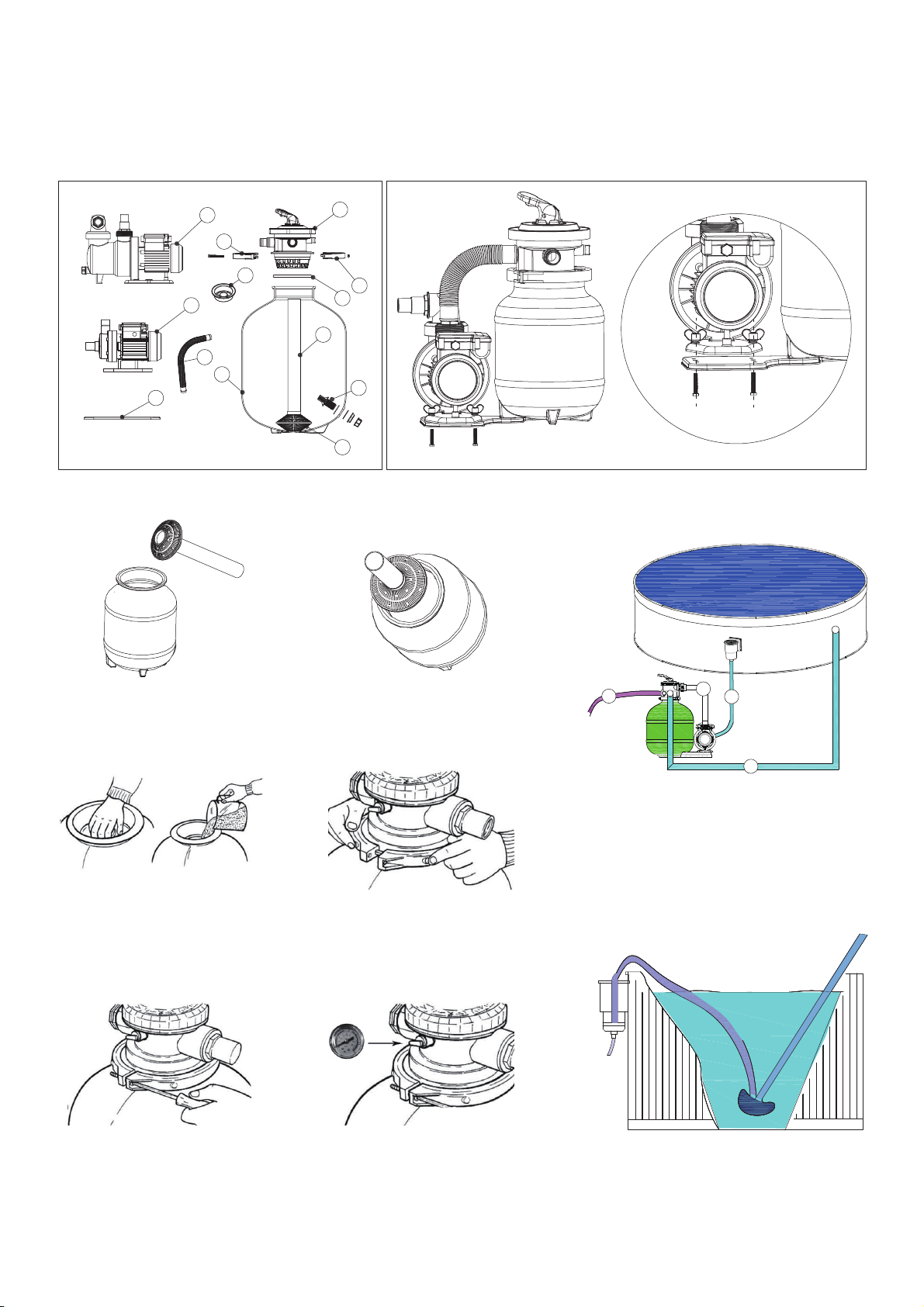

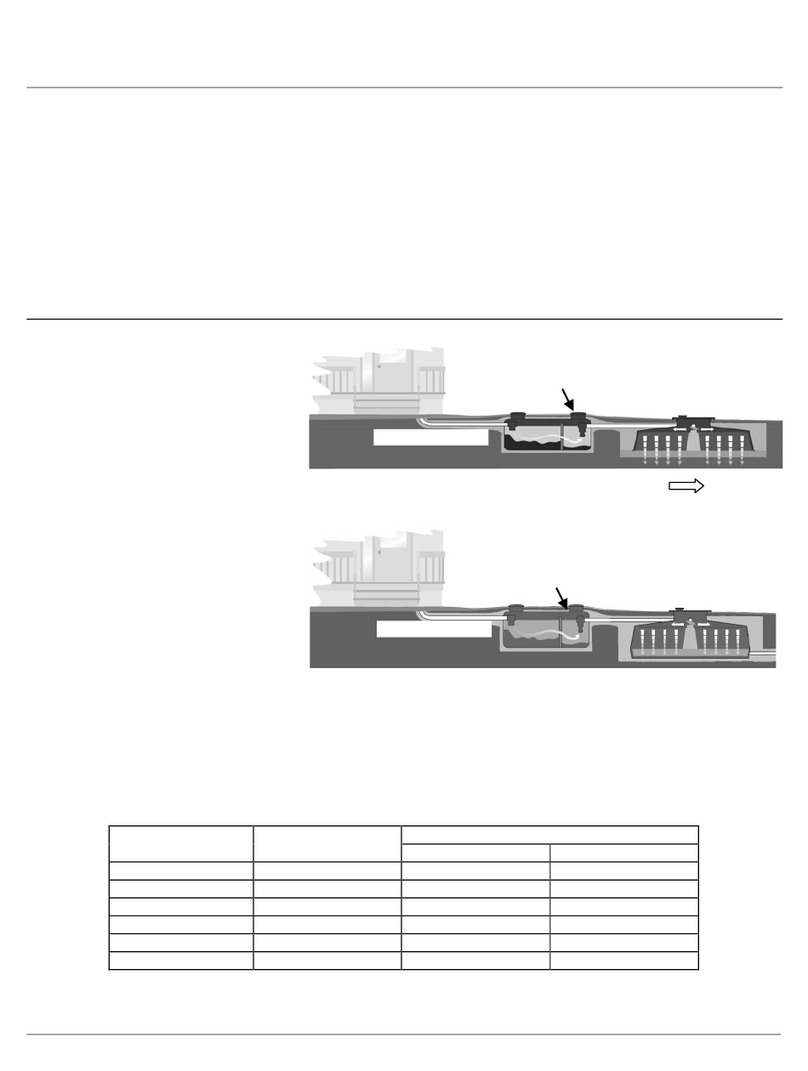

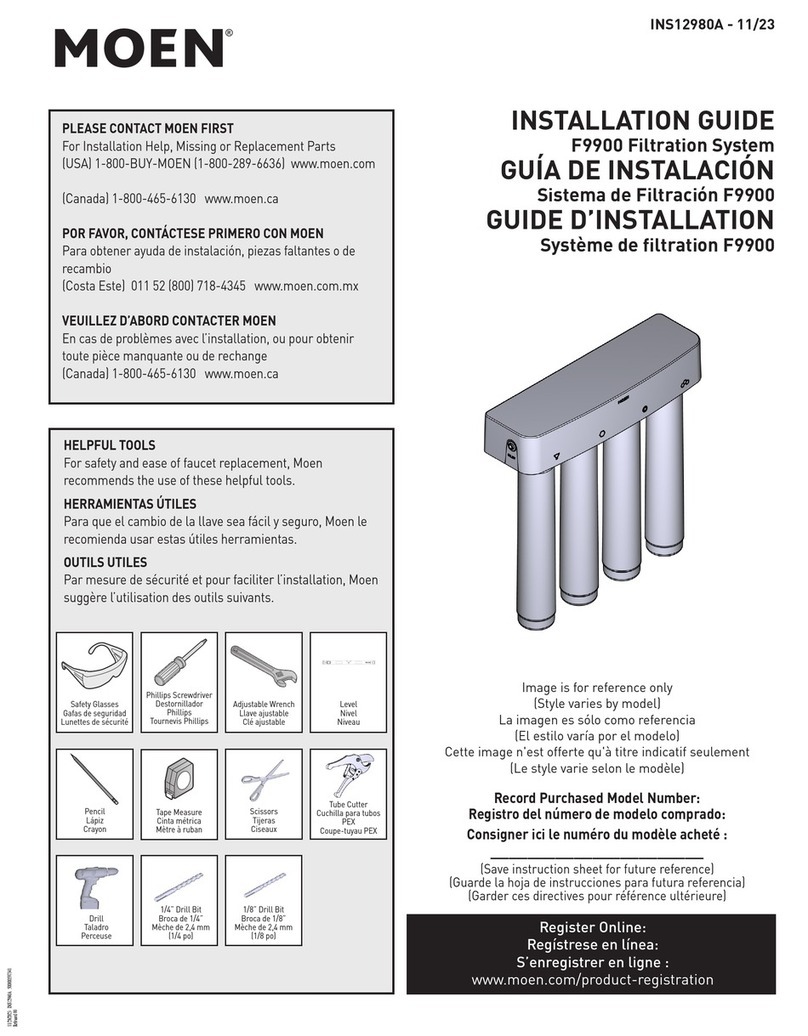

specifications for the pH- and chlorine value). It is equipped with a tank drainage system, pres-

sure gauge, built-in container components, e.g. riser pipe and under drain assembly. The filter

tank comes ready to attach and is supplied with a user-friendly 7 Position Multi-Port Valve

attached to the tank cover, an approved filter pump with hair and lint basket, and a plastic base

for ready on- site mounting.

Read this manual carefully before installation. The filtration system and pump must be installed

in accordance with all federal and local codes and standards in effect for the area of installation.

We decline all responsibility for the consequences of failure to comply with the installation

instructions. We recommend that you comply with the power source instructions to avoid over-

loading the pump motor and/or electric shock.

This filtration system is not intended for use by persons with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge.

Safety notes and information boxes should always be observed.

C. Safety Notes

Your filter pump was constructed and tested and left the manufacturing plant in technically oper-

ational condition. In order to maintain this condition and ensure safe operation, the user should

observe the notes and product information contained in this technical manual. If there is any

indication that safe operation is no longer possible, the device is to be disconnected from the

power supply and secured against accidental use.

This is the case when:

The device has visible damage.

The device no longer appears functional.

After long periods of storage in poor conditions.

If the power cord or other parts of this equipment are damaged, they have to be replaced by

manufacturer or its service agent or a similarly qualified person in order to avoid danger.

D. Damage during delivery

Your filter system has been carefully and professionally packed for delivery. Please check to

ensure that the package is undamaged and that all parts are in the box. If you purchased this

product on order and the product was shipped to you, ensure that delivery is complete. Damage

to product as a result of shipping is not the responsibility of the supplier and must be immediately

reported to the shipper. The shipper assumes the liability for damages during delivery, the

supplier is not responsible for it.

E. Implied Warranty

The manufacturer warranties safe operation and reliability only under the following conditions:

The filter system is installed and operated according to the assembly and operating

instructions.

Only original replacement parts are used for repairs or replacements (consumable &

expendable parts do no fall under the warranty).

Expendable parts that do not fall under the warranty include:

All O-rings

Pressure gauge

Mechanical seal, complete

Hoses and metal hose clamps

Page 3