Permit-Required

Conned Spaces

A conned space has limited openings for

entry or exit, is large enough for entering and

working, and is not designed for continuous

worker occupancy. Conned spaces include

underground reservoirs, ground storage tanks,

elevated tanks, silos, manholes, and pipelines.

Conned Space Tips

• Do not enter permit-required conned spaces

without being trained and without having a

permit to enter.

•Review, understand and follow employer’s

procedures before entering permit-required

conned spaces and know how and when

to exit.

•Before entry, identify any physical hazards.

•Before and during entry, test and monitor for

oxygen content, ammability, toxicity or

explosive hazards as necessary.

•Use fall protection, rescue, air monitoring,

ventilation, lighting and communication

equipment according to entry procedures.

•Maintain contact at all times with a trained

attendant either visually, via phone, or by

two-way radio. This monitoring system

enables the attendant and entry supervisor

to order you to evacuate and to alert

appropriately trained rescue personnel to

rescue entrants when needed.

Refer to 29 CFR 1910.146 for complete

regulations set by OSHA. Refer to your state's

regulations if your state established and operates

their own safety and health programs approved

by OSHA.

Protect Yourself

It is important that you comply with all relative

OSHA and local regulations while installing

and performing any maintenance to the mixer

circulation equipment.

Key OSHA Compliance Standards that must

be followed (and not limited to) are:

• 1910.146 Permit-required conned spaces

• 1910.147 Lockout/Tagout

• 1926.500 Fall Protection

Fall Protection Tips

•Identify all potential tripping and fall hazards

before work starts.

•Look for fall hazards such as unprotected

oor openings/edges, shafts, open hatches,

stairwells, and roof openings/edges.

•Inspect fall protection and rescue equipment

for defects before use.

•Select, wear, and use fall protection and

rescue equipment appropriate for the task.

•Secure and stabilize all ladders before

climbing.

• Never stand on the top rung/step of a ladder.

•Use handrails when you go up or down stairs.

•Practice good housekeeping. Keep cords,

welding leads and air hoses out of walkways

or adjacent work areas.

Refer to 29 CFR 1926.500 for complete

regulations set by OSHA. Refer to your state's

regulations if your state established and operates

their own safety and health programs approved by

OSHA.

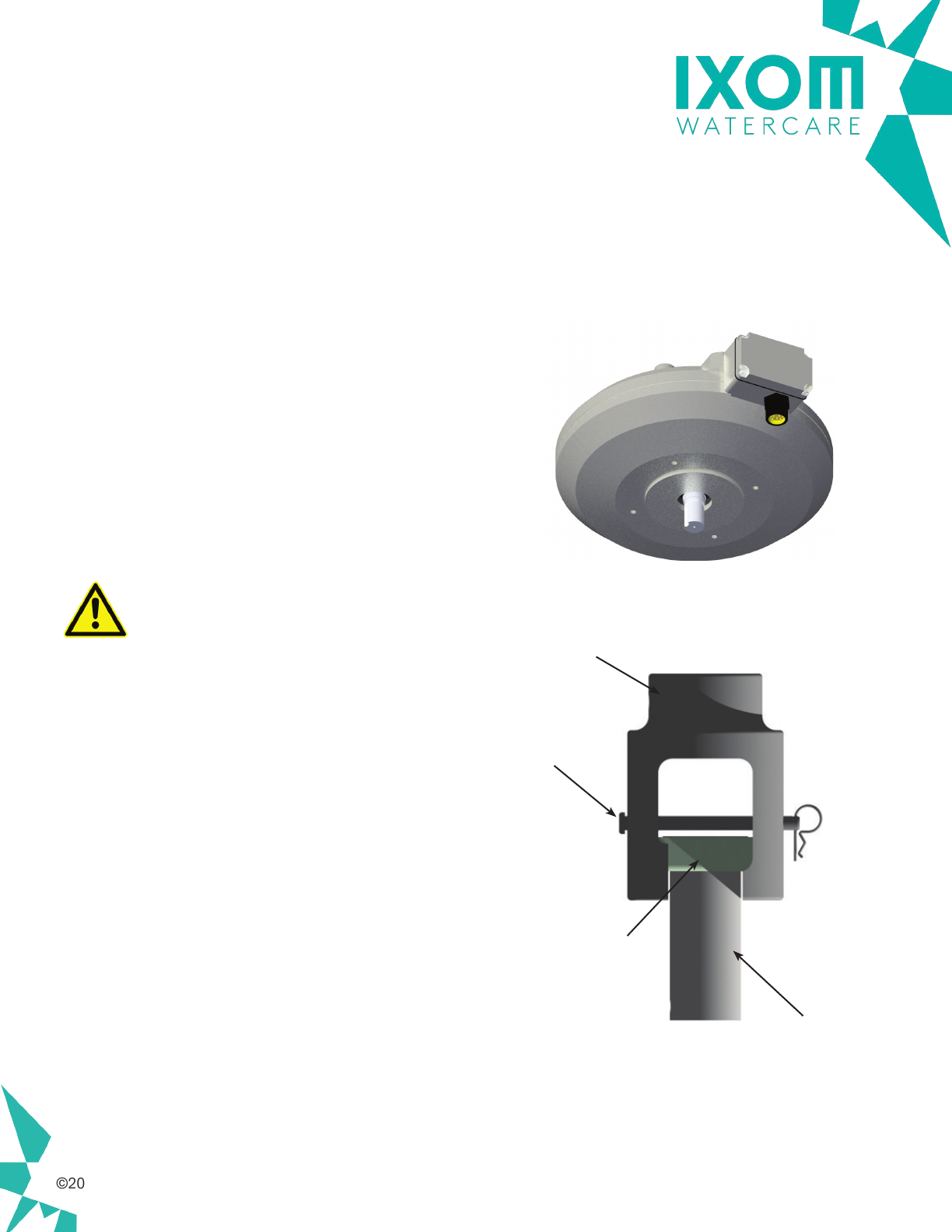

Lockout Tagout

When the On/O switch is in the "ON" position,

the mixer may start up at any time if not already

operating. The mixer's On/O switch can be

locked out by placing a pad lock thru the door latch

of the controller after the switch has been turned

to the "OFF" position. The On/O switch is to be

used as the emergency stop.

©2022

IXOM

Wa

tercare

Inc.

|

www

.ixomwatercare.com

|

866

-

43

7

-

807

6

|

[email protected] 1949_10036_20220110 O&M_GF5000PW_10307_20220121 - 3