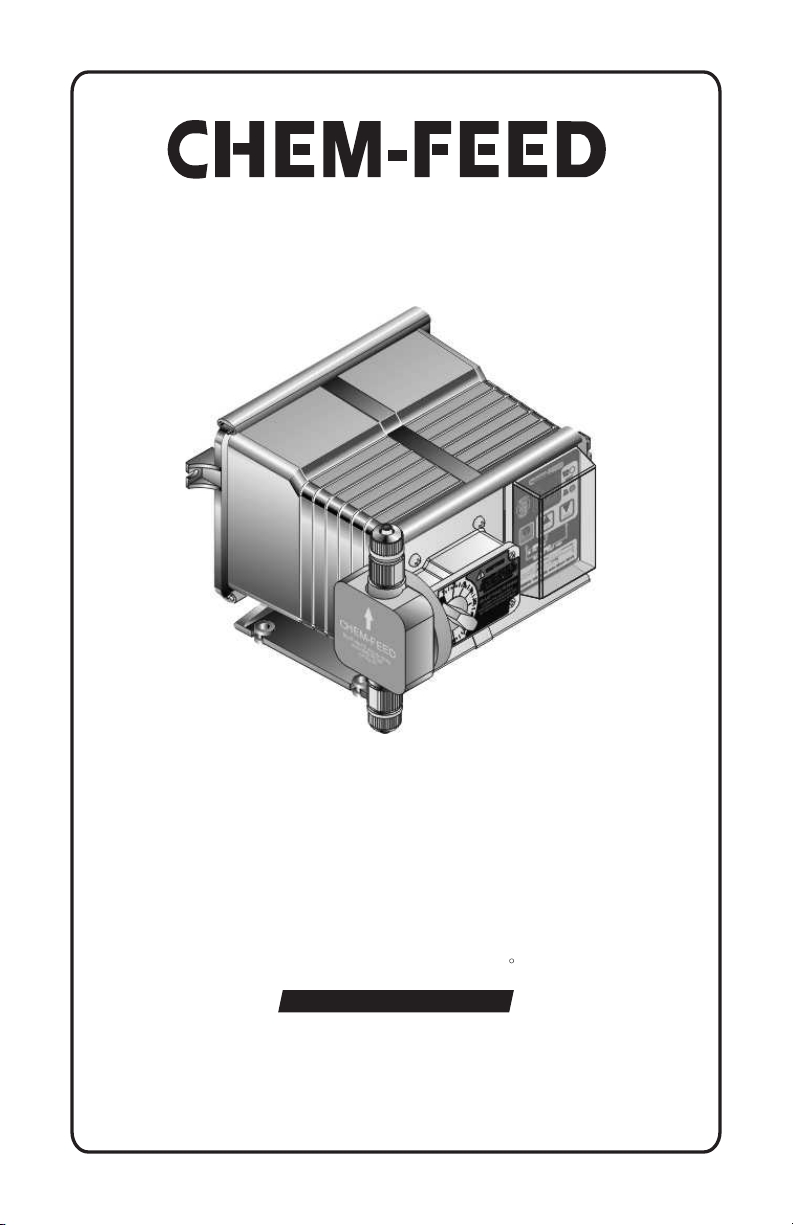

Blue-White CHEM-FEED C-1100E User manual

5300 Business Drive

Huntington Beach, CA 92649

USA

Phone: 714-893-8529 FAX: 714-894-9492

Website: www.blue-white.com

Blue-White

Industries, Ltd.

R

INJECTOR

®

MODEL C-1100 MODEL-E

POSITIVE DISPLACEMENT INJECTOR PUMP

OPERATING MANUAL

TABLE OF CONTENTS

1.....Introduction .....................................................................................3

2.....Specifications........................... ............................ ............................3

3.....Features............................................................................................3

4.....Unpacking........................................................................................3

5.....Installation ................. ............................ ............................ ..............4

5.1..Mounting location ............. ............................ ............................4

5.2..Input power connections ................. ............................ ..............5

5.3..External input signal connections................................ ..............6

5.4..How to install the tubing and fittings.........................................8

6.....How to operate the Pump .................................................................9

6.1..How to adjust the output - manual stroke adjustment................9

6.2..Electronic pump output controls ................................. ..............10

6.3..Mode 0 - FVS System set-up.....................................................10

6.4..Mode 1 - Manually Adjusting the output....... ............................13

6.5..Mode 2 - 4-20 mA input................................ ............................14

6.6..Mode 3 - 0-10 VDC input . ............................ ............................16

6.7..Mode 4 - Frequency (Hz) input ..................... ............................19

6.8..Mode 5 - Pulse input (Batch).....................................................20

6.9..Measuring the pump output - Volumetric test ............................21

7.....How to maintain the Pump....... ............................ ............................22

7.1..Routine inspection and cleaning.................................. ..............22

7.2..How to clean the pump ................... ............................ ..............22

7.3..500 hour service warning timer.................................................22

Pump head and Valve exploded view drawing .................................23

Replacement parts drawing ..............................................................24

Replacement parts list ......................................................................25

Warranty information. ............................ ............................ ..............26

Authorized service centers ....... ............................ ............................27

Page 2

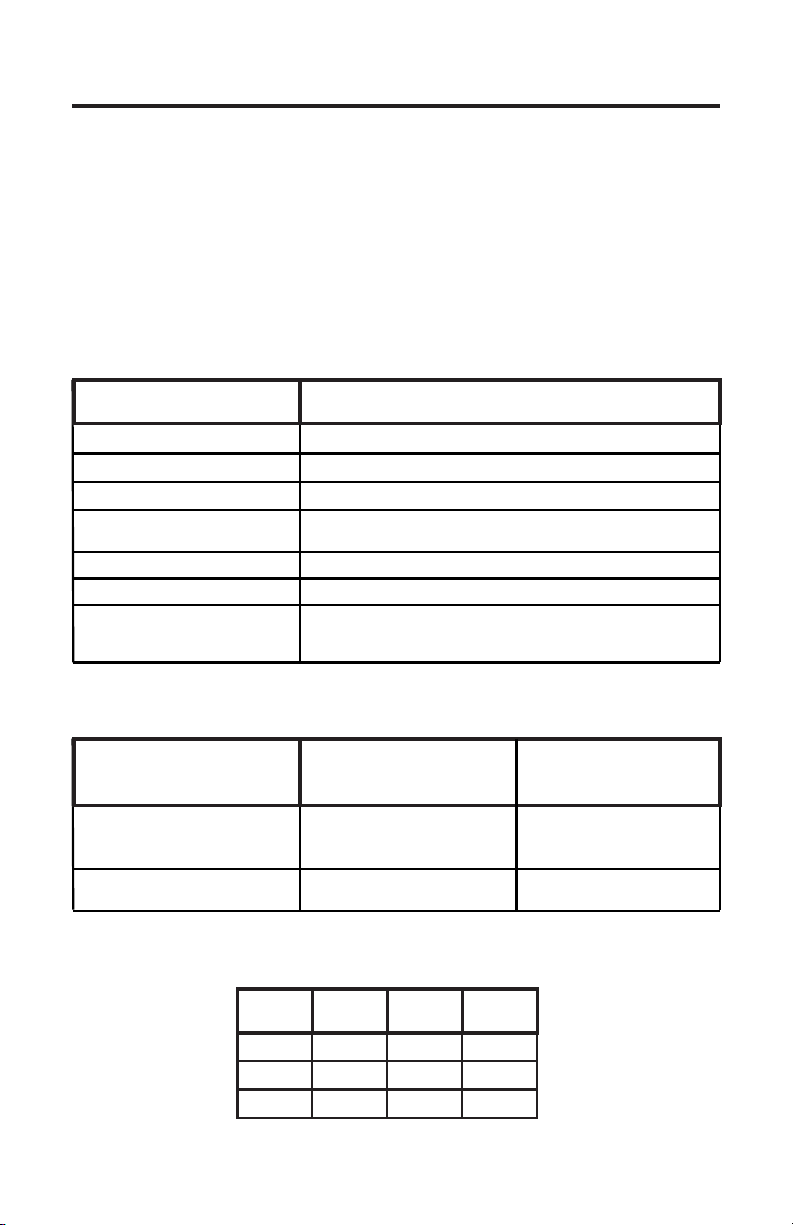

2.0 Specifications

Maximum Working Pressure 150 psig / 10.4 bar (most models)

o o

Maximum Fluid Temperature 130 F / 54 C

o o

Ambient Temperature Range 14 to 110 F / -10 to 43 C

Duty Cycle Continuous

Maximum Viscosity 1,000 Centipoise

Maximum Suction Lift up to 20 ft. water

Power Requirements 115V/60Hz 14 & 30 RPM (1.37A max.)

115V/60Hz 45, 60, 125, 250 RPM (1.87A max.)

230V/60Hz 14 & 30 RPM (0.64A max.)

230V/60Hz 45, 60, 125, 250 RPM (0.74A max.)

220V/50Hz 14 & 30 RPM (0.68A max.)

220V/50Hz 45, 60, 125, 250 RPM (1.14A max.)

240V/50Hz 14 & 30 RPM (0.66A max.)

240V/50Hz 45, 60, 125, 250 RPM (1.04A max.)

Dimensions 6-1/4” H x 10-1/8” W x 9” D

Weight 8 lb. / 3.6 Kg

Page 3

1.0 Introduction

Congratulations on purchasing the C-1100 Model-E positive displacement

metering pump. The C-1100 is designed to inject chemicals into piping

systems and is capable of injecting against a high system pressure up to 150

PSI (10.4 bar). In addition to the front mounted mechanical flow rate

adjustment, the C-1100 Model-E unit is equipped with an external input

control circuitry which allows the pumps output to be externally controlled

by either a 4-20mA input signal, a 0-10V DC input signal or a pulsed input

signal.

C-1100E C-1100E

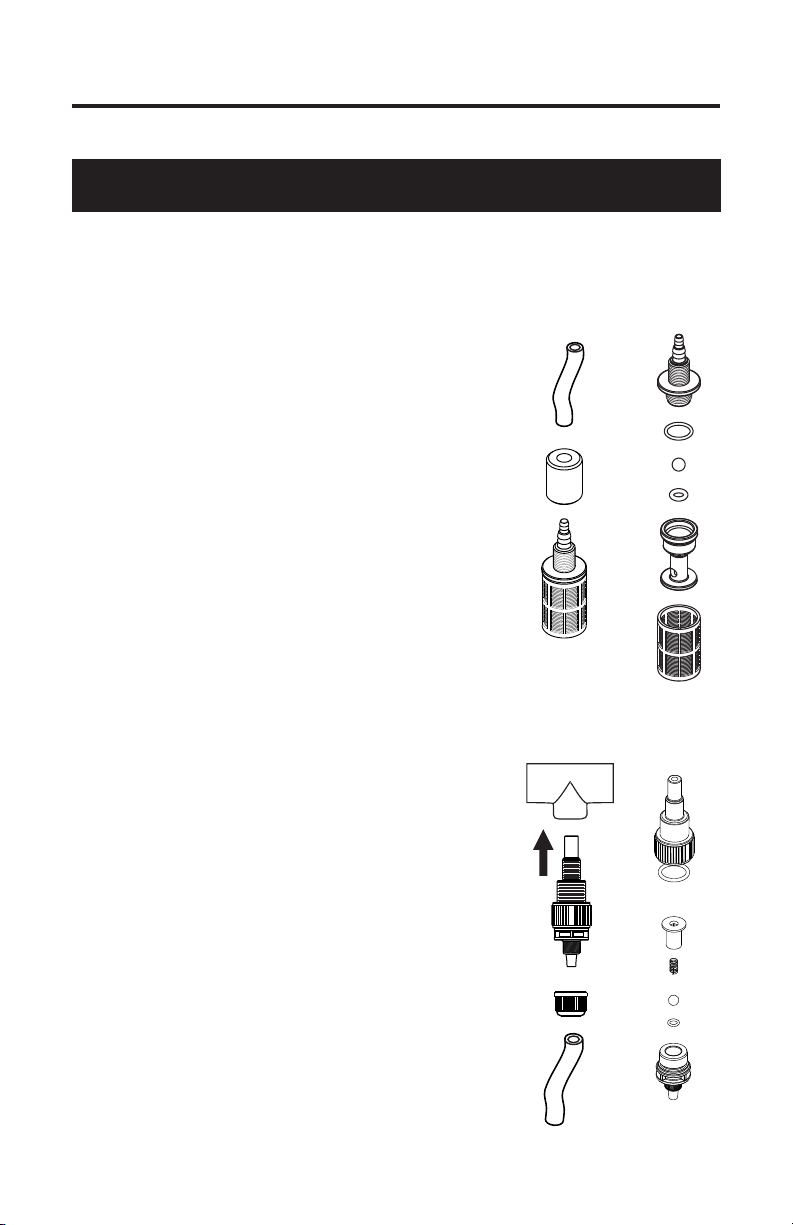

4.0 Unpacking

Your pump package should contain the following:

1 - Injector pump

1 - suction tube footvalve & strainer assembly

1 - ceramic tubing weight

1 - 5’ Length of clear PVC suction tubing

1 - 5’ Length of opaque LLDPE discharge tubing

1 - Injection fitting with internal back-flow check valve

1 - Mounting hardware kit

3.0 Features

!Double-ball, springless ceramic check valves with PVDF (Kynar) body,

TFE/P (Aflas) and Viton o-ring seals.

!Easy access, front mounted mechanical feed rate adjustment.

!High outlet pressure capability of 150 psig (most models).

!4000:1 adjustment turn down ratio.

!Digital electronic feed rate control.

!Corrosion proof Valox housing.

!Tamper resistant electronic control panel cover.

TABLE OF CONTENTS

1.....Introduction .....................................................................................3

2.....Specifications........................... ............................ ............................3

3.....Features............................................................................................3

4.....Unpacking........................................................................................3

5.....Installation ................. ............................ ............................ ..............4

5.1..Mounting location ............. ............................ ............................4

5.2..Input power connections ................. ............................ ..............5

5.3..External input signal connections................................ ..............6

5.4..How to install the tubing and fittings.........................................8

6.....How to operate the Pump .................................................................9

6.1..How to adjust the output - manual stroke adjustment................9

6.2..Electronic pump output controls ................................. ..............10

6.3..Mode 0 - FVS System set-up.....................................................10

6.4..Mode 1 - Manually Adjusting the output....... ............................13

6.5..Mode 2 - 4-20 mA input.... ............................ ............................14

6.6..Mode 3 - 0-10 VDC input . ............................ ............................16

6.7..Mode 4 - Frequency (Hz) input ..................... ............................19

6.8..Mode 5 - Pulse input (Batch).....................................................20

6.9..Measuring the pump output - Volumetric test ............................21

7.....How to maintain the Pump....... ............................ ............................22

7.1..Routine inspection and cleaning.................................. ..............22

7.2..How to clean the pump ................... ............................ ..............22

7.3..500 hour service warning timer.................................................22

Pump head and Valve exploded view drawing .................................23

Replacement parts drawing ..............................................................24

Replacement parts list ......................................................................25

Warranty information. ............................ ............................ ..............26

Authorized service centers ....... ............................ ............................27

Page 2

2.0 Specifications

Maximum Working Pressure 150 psig / 10.4 bar (most models)

o o

Maximum Fluid Temperature 130 F / 54 C

o o

Ambient Temperature Range 14 to 110 F / -10 to 43 C

Duty Cycle Continuous

Maximum Viscosity 1,000 Centipoise

Maximum Suction Lift up to 20 ft. water

Power Requirements 115V/60Hz 14 & 30 RPM (1.37A max.)

115V/60Hz 45, 60, 125, 250 RPM (1.87A max.)

230V/60Hz 14 & 30 RPM (0.64A max.)

230V/60Hz 45, 60, 125, 250 RPM (0.74A max.)

220V/50Hz 14 & 30 RPM (0.68A max.)

220V/50Hz 45, 60, 125, 250 RPM (1.14A max.)

240V/50Hz 14 & 30 RPM (0.66A max.)

240V/50Hz 45, 60, 125, 250 RPM (1.04A max.)

Dimensions 6-1/4” H x 10-1/8” W x 9” D

Weight 8 lb. / 3.6 Kg

Page 3

1.0 Introduction

Congratulations on purchasing the C-1100 Model-E positive displacement

metering pump. The C-1100 is designed to inject chemicals into piping

systems and is capable of injecting against a high system pressure up to 150

PSI (10.4 bar). In addition to the front mounted mechanical flow rate

adjustment, the C-1100 Model-E unit is equipped with an external input

control circuitry which allows the pumps output to be externally controlled

by either a 4-20mA input signal, a 0-10V DC input signal or a pulsed input

signal.

C-1100E C-1100E

4.0 Unpacking

Your pump package should contain the following:

1 - Injector pump

1 - suction tube footvalve & strainer assembly

1 - ceramic tubing weight

1 - 5’ Length of clear PVC suction tubing

1 - 5’ Length of opaque LLDPE discharge tubing

1 - Injection fitting with internal back-flow check valve

1 - Mounting hardware kit

3.0 Features

!Double-ball, springless ceramic check valves with PVDF (Kynar) body,

TFE/P (Aflas) and Viton o-ring seals.

!Easy access, front mounted mechanical feed rate adjustment.

!High outlet pressure capability of 150 psig (most models).

!4000:1 adjustment turn down ratio.

!Digital electronic feed rate control.

!Corrosion proof Valox housing.

!Tamper resistant electronic control panel cover.

CAUTION

ADJUST WHILE RUNNING

DISCHARGE LINES MAY BE

UNDER HIGH PRESSURE. USE

CARE TO PROTECT YOURSELF

WHEN DISCONNECTING.

MAX

MIN

12

3

4

5

6

7

8

9

LOOSEN THE LOCK SCREW

TURN KNOB TO DESIRED SETTING

RE-TIGHTEN THE LOCK SCREW

RUN

STANDBY

RUN

FIELD DIGIT MODE

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

INPUT MODES

1 - MANUAL 2 - 4-20mA 3 - 0-10VDC 4 - PULSE (Hz)

PROGRAM

RESET SERVICE

PRIME

DISPLAY

VARIABLE SPEED PUMP

% SPEED

1

MODE

VDC

SERVICE

1000

ALARM

mA Hz

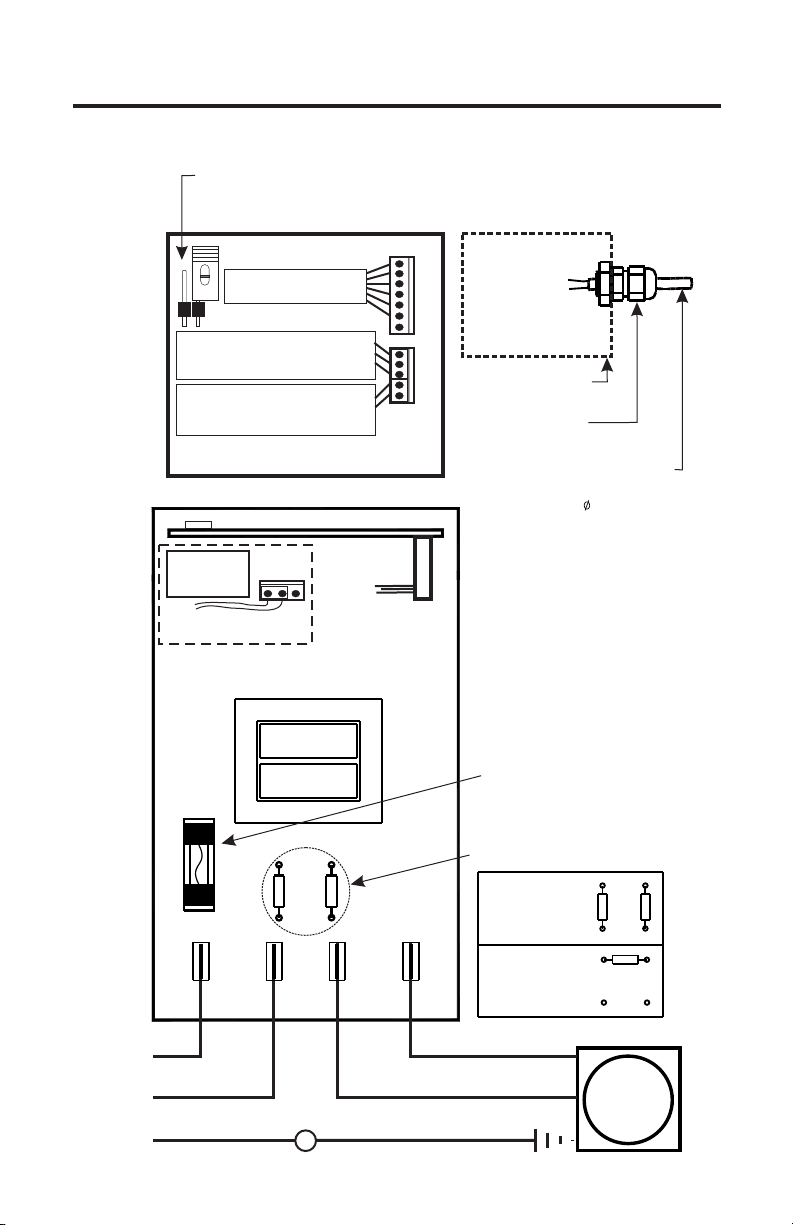

5.0 Installation

Note: All diagrams are strictly for guideline purposes only. Always consult

an expert before installing the pump into specialized systems. The pump

should be serviced by qualified persons only.

5.1 Mounting Location

Choose an area located near the chemical supply tank, chemical injection

point and electrical supply. Although the pump is designed to withstand

outdoor conditions, a cool, dry, well ventilated location is recommended.

Install the pump where it can be easily serviced.

!Mount the pump to a secure surface or wall using the enclosed hardware.

Wall mount to a solid surface only. Mounting to drywall with anchors is not

recommended.

!Mount the pump close to the injection point. Keep the inlet (suction) and

outlet (discharge) tubing as short as possible. Longer discharge tubing

increases the back pressure at the pump tube.

!Your solution tank should be sturdy. Keep the tank covered to reduce

fumes. Do not mount the pump directly over your tank. Chemical fumes

may damage the unit. Mount the pump off to the side or at a lower level

than the chemical container.

!Mounting the pump lower than the chemical container will gravity feed the

chemical into the pump. This “flooded suction” installation will aid in

priming the pump and will reduce output error due to increased suction lift.

We recommended installing a shut-off valve, pinch clamp or other means to

halt the gravity feed to the pump during servicing.

!Be sure your installation does not constitute a cross connection with the

drinking water supply. Check your local plumbing codes.

Page 4 Page 5

CAUTION: Proper eye and skin protection must be

worn when installing and servicing the pump.

Floor Mount Wall Mount

7-3/8”

7-5/8”

3-1/2”

8-3/16”

Drill .156 Dia. (5/32)

For Self-Tap Screw

#10 X 1” Phillips Steel

4 Places

Drill .156 Dia. (5/32)

For Self-Tap Screw

#10 X 1” Phillips Steel

2 Places

INJECTOR MOUNTING

Note: For wall-mounting, drill & thread into

solid wood only.

TYPICAL INSTALLATION

Suction

Tube

Chemical

Container

with cover

Discharge

Tube

Strainer

Ceramic Weight

Injection / Check valve

with 1/4” and 1/2” male

pipe threads.

Mount in upward position

to prevent trapped gasses

in the injection fitting. Wall or shelf mount

away from the top of the

solution tank. Chemical

fumes can damage the

unit.

5.2 Input Power Connections

!Be certain to connect the pump to the proper supply voltage. Using the incorrect voltage will

damage the pump and may result in injury. The voltage requirement is printed on the pump

serial label.

!Removable resistors on the circuit board are factory preset for the correct voltage. See page 7

Circuit Board Connections diagram for details.

!The pump is supplied with a ground wire conductor and a grounding type attachment plug

(power cord). To reduce the risk of electric shock, be certain that the power cord is connected

only to a properly grounded, grounding type receptacle.

!POWER: 115V/60Hz 14 & 30 RPM (1.37A max.), 115V/60Hz 45, 60, 125, 250 RPM (1.87A

max.), 230V/60Hz 14 & 30 RPM (0.64A max.), 230V/60Hz 45, 60, 125, 250 RPM (0.74A

max.), 220V/50Hz 14 & 30 RPM (0.68A max.), 220V/50Hz 45, 60, 125, 250 RPM (1.14A

max.), 240V/50Hz 14 & 30 RPM (0.66A max.), 240V/50Hz 45, 60, 125, 250 RPM (1.04A

max.)

Note: When in doubt regarding your electrical installation, contact a licensed electrician.

WARNING: Risk of electric shock.

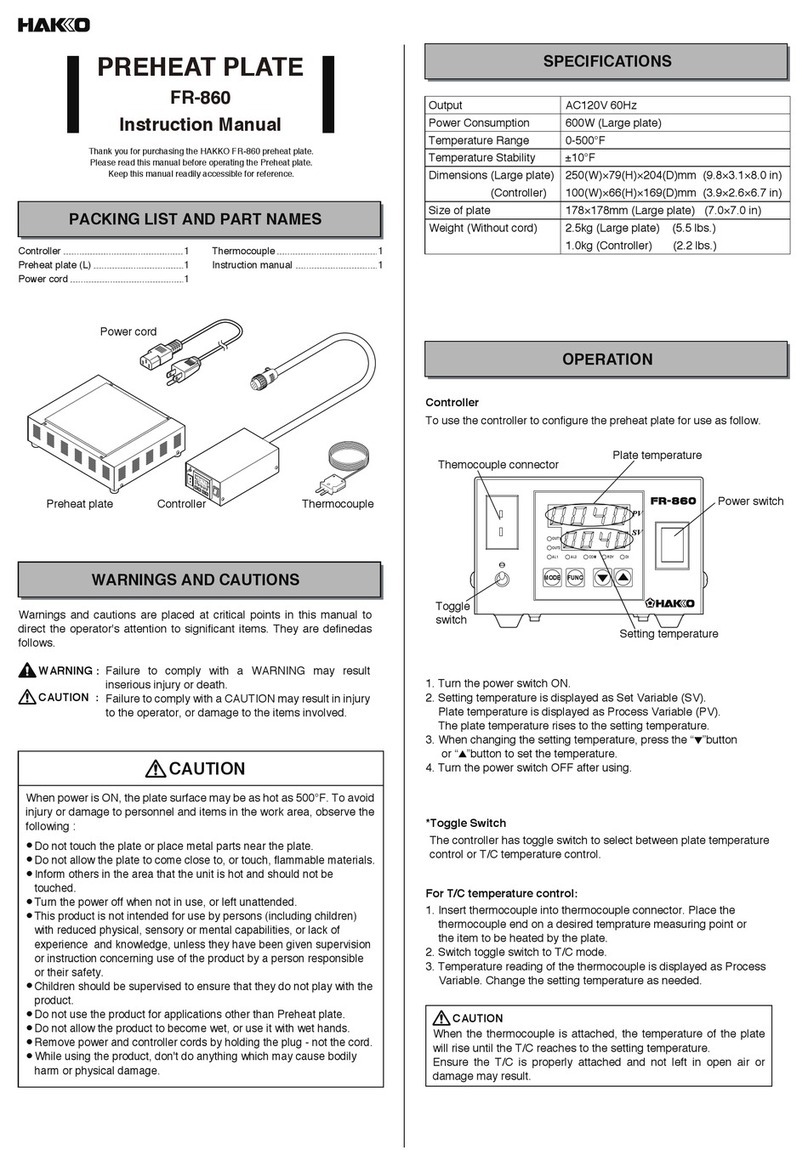

PARTS LOCATOR DRAWING

®

J-Box

Control Cover

Motor Housing

Rear Cover

Pumphead

6

Slide Clamps*

CAUTION

ADJUST WHILE RUNNING

DISCHARGE LINES MAY BE

UNDER HIGH PRESSURE. USE

CARE TO PROTECT YOURSELF

WHEN DISCONNECTING.

MAX

MIN

12

3

4

5

6

7

8

9

LOOSEN THE LOCK SCREW

TURN KNOB TO DESIRED SETTING

RE-TIGHTEN THE LOCK SCREW

Adjustment knob

10 IN. (254 MM)

1

4

IN.

10 IN. (267 MM)

(159 MM)

1

2

RUN

STANDBY

RUN

FIELD DIGIT MODE

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

INPUT MODES

1 - MANUAL 2 - 4-20mA 3 - 0-10VDC 4 - PULSE (Hz)

PROGRAM

RESET SERVICE

PRIME

DISPLAY

VARIABLE SPEED PUMP

% SPEED

1

MODE

VDC

SERVICE

1000

ALARM

mA Hz

Control Panel

C-1100E C-1100E

CAUTION

ADJUST WHILE RUNNING

DISCHARGE LINES MAY BE

UNDER HIGH PRESSURE. USE

CARE TO PROTECT YOURSELF

WHEN DISCONNECTING.

MAX

MIN

12

3

4

5

6

7

8

9

LOOSEN THE LOCK SCREW

TURN KNOB TO DESIRED SETTING

RE-TIGHTEN THE LOCK SCREW

RUN

STANDBY

RUN

FIELD DIGIT MODE

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

INPUT MODES

1 - MANUAL 2 - 4-20mA 3 - 0-10VDC 4 - PULSE (Hz)

PROGRAM

RESET SERVICE

PRIME

DISPLAY

VARIABLE SPEED PUMP

% SPEED

1

MODE

VDC

SERVICE

1000

ALARM

mA Hz

5.0 Installation

Note: All diagrams are strictly for guideline purposes only. Always consult

an expert before installing the pump into specialized systems. The pump

should be serviced by qualified persons only.

5.1 Mounting Location

Choose an area located near the chemical supply tank, chemical injection

point and electrical supply. Although the pump is designed to withstand

outdoor conditions, a cool, dry, well ventilated location is recommended.

Install the pump where it can be easily serviced.

!Mount the pump to a secure surface or wall using the enclosed hardware.

Wall mount to a solid surface only. Mounting to drywall with anchors is not

recommended.

!Mount the pump close to the injection point. Keep the inlet (suction) and

outlet (discharge) tubing as short as possible. Longer discharge tubing

increases the back pressure at the pump tube.

!Your solution tank should be sturdy. Keep the tank covered to reduce

fumes. Do not mount the pump directly over your tank. Chemical fumes

may damage the unit. Mount the pump off to the side or at a lower level

than the chemical container.

!Mounting the pump lower than the chemical container will gravity feed the

chemical into the pump. This “flooded suction” installation will aid in

priming the pump and will reduce output error due to increased suction lift.

We recommended installing a shut-off valve, pinch clamp or other means to

halt the gravity feed to the pump during servicing.

!Be sure your installation does not constitute a cross connection with the

drinking water supply. Check your local plumbing codes.

Page 4 Page 5

CAUTION: Proper eye and skin protection must be

worn when installing and servicing the pump.

Floor Mount Wall Mount

7-3/8”

7-5/8”

3-1/2”

8-3/16”

Drill .156 Dia. (5/32)

For Self-Tap Screw

#10 X 1” Phillips Steel

4 Places

Drill .156 Dia. (5/32)

For Self-Tap Screw

#10 X 1” Phillips Steel

2 Places

INJECTOR MOUNTING

Note: For wall-mounting, drill & thread into

solid wood only.

TYPICAL INSTALLATION

Suction

Tube

Chemical

Container

with cover

Discharge

Tube

Strainer

Ceramic Weight

Injection / Check valve

with 1/4” and 1/2” male

pipe threads.

Mount in upward position

to prevent trapped gasses

in the injection fitting. Wall or shelf mount

away from the top of the

solution tank. Chemical

fumes can damage the

unit.

5.2 Input Power Connections

!Be certain to connect the pump to the proper supply voltage. Using the incorrect voltage will

damage the pump and may result in injury. The voltage requirement is printed on the pump

serial label.

!Removable resistors on the circuit board are factory preset for the correct voltage. See page 7

Circuit Board Connections diagram for details.

!The pump is supplied with a ground wire conductor and a grounding type attachment plug

(power cord). To reduce the risk of electric shock, be certain that the power cord is connected

only to a properly grounded, grounding type receptacle.

!POWER: 115V/60Hz 14 & 30 RPM (1.37A max.), 115V/60Hz 45, 60, 125, 250 RPM (1.87A

max.), 230V/60Hz 14 & 30 RPM (0.64A max.), 230V/60Hz 45, 60, 125, 250 RPM (0.74A

max.), 220V/50Hz 14 & 30 RPM (0.68A max.), 220V/50Hz 45, 60, 125, 250 RPM (1.14A

max.), 240V/50Hz 14 & 30 RPM (0.66A max.), 240V/50Hz 45, 60, 125, 250 RPM (1.04A

max.)

Note: When in doubt regarding your electrical installation, contact a licensed electrician.

WARNING: Risk of electric shock.

PARTS LOCATOR DRAWING

®

J-Box

Control Cover

Motor Housing

Rear Cover

Pumphead

6

Slide Clamps*

CAUTION

ADJUST WHILE RUNNING

DISCHARGE LINES MAY BE

UNDER HIGH PRESSURE. USE

CARE TO PROTECT YOURSELF

WHEN DISCONNECTING.

MAX

MIN

12

3

4

5

6

7

8

9

LOOSEN THE LOCK SCREW

TURN KNOB TO DESIRED SETTING

RE-TIGHTEN THE LOCK SCREW

Adjustment knob

10 IN. (254 MM)

1

4

IN.

10 IN. (267 MM)

(159 MM)

1

2

RUN

STANDBY

RUN

FIELD DIGIT MODE

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

INPUT MODES

1 - MANUAL 2 - 4-20mA 3 - 0-10VDC 4 - PULSE (Hz)

PROGRAM

RESET SERVICE

PRIME

DISPLAY

VARIABLE SPEED PUMP

% SPEED

1

MODE

VDC

SERVICE

1000

ALARM

mA Hz

Control Panel

C-1100E C-1100E

ACCEPTABLE CABLE JACKET RANGE:

.118 - .255 INCH .( 3,0 - 6,5 MM)

EXTERNAL INPUT CABLE

5.3 External Input Signal Connections

The pump will accept a variety of external control input signals; 4-20 mA ,

0-10 VDC, TTL, CMOS, AC Sine Waves, Contact Closures, Hall Effect,

NPN. The 4-20mA and 0-10 VDC loops must be powered.

All wiring connections are to be made inside of the junction box located on

the side of the pump. Special connectors are not required. A liquid-tite

connector is supplied and should be used for the external signal cable. The

signal input wires are color coded to the type of signal being used.

Page 6 Page 7

INPUT

VOLTAGE

115V 60Hz

220V 50Hz

HOT

LEADWIRE

NEUTRAL

LEADWIRE

GROUND

LEADWIRE

230V 60Hz

YELLOW

YELLOW

YELLOW

BLUE

BROWN

RED

GREEN

GREEN

GREEN

MOTOR LEADWIRES

SIGNAL INPUT WIRE COLOR CODES

CIRCUIT BOARD CONNECTIONS

AC

MOTOR

Neutral (blue/brown/red)

Hot (yellow)

Ground (green)

Ground (green)

Common

Hot

AC

Input

Power

Power Circuit Board

(Top view)

Protector Fuse

2 Amps, 250 Volt AC

(little Fuse #235002

or Equivalent)

R R

2A

250VAC

T3

T2

T1

T4

LINE

HOT

LINE

NEUTRAL

MOTOR

NEUTRAL

MOTOR

SWITCHED

115V 50/60Hz

INPUT VOLTAGE

RESISTOR PLACEMENT

220V 50/60Hz

230V 50/60Hz

R R

R

MA = BLUE

GND = BLACK

RELAY = PURPLE (2)

VDC = ORANGE

VS = RED (+17V DC)

PLS = WHITE

JUNCTION BOX

LIQUID-TIGHT

CONNECTOR

MTR = BROWN

Alarm Relay

3A/125VAC

N/C

COM

N/O

Purple connection wires

Default is N/O

VS

VDC

MA

MTR

GND

PLS

CN3

VS

FVS

GND

TFD

GND

FVS+

CN4

Control Circuit Board

(Back view)

Program Disable Jumper - Located on front of Control board.

Un-installed = enable front panel programming (default)

Installed = disable front panel programming

External input connections

6 Wire bundle to junction box

Flow verification sensor connector

3 Wire bundle to junction box.

red/black/yellow

Tube failure detection sensor connector

2 Wire bundle to pump head sensor

(A-100N series pumps only)

WIRE COLOR CODE

INPUT TYPE

MOTOR ON SIGNAL

5-20V DC open collector output

closed while motor is energized

FLOW VERIFICATION SENSOR

4-20 mA

0-10 VDC

ALARM RELAY

BROWN (+) & BLACK (-)

PURPLE & PURPLE

WHITE (+) & BLACK (-)

BLUE (+) & BLACK (-)

TTL, CMOS

ORANGE (+) & BLACK (-)

RED/WHITE (+ 20VDC) & BLACK (-) & YELLOW (signal)

CONTACT (10v @ 2 mA max)

HALL EFFECT, NPN RED (+) & WHITE (-)

C-1100E C-1100E

PADDLEWHEEL SENSOR SIGNAL INPUT WIRING

PADDLEWHEEL SENSOR

WIRE COLOR CODE

BLUE-WHITE

PADDLEWHEEL

SENSOR TYPE

MODEL FH

HALL EFFECT SENSOR

BLACK (-)

RED (+)

PUMP INPUT

WIRE COLOR CODE

MODEL FC

AC SINE WAVE SENSOR

BARE (signal)

BLACK (-)

RED (+ 20VDC)

WHITE (signal)

BLACK (-)

RED (+)

BLACK (-)

WHITE (+)

ACCEPTABLE CABLE JACKET RANGE:

.118 - .255 INCH .( 3,0 - 6,5 MM)

EXTERNAL INPUT CABLE

5.3 External Input Signal Connections

The pump will accept a variety of external control input signals; 4-20 mA ,

0-10 VDC, TTL, CMOS, AC Sine Waves, Contact Closures, Hall Effect,

NPN. The 4-20mA and 0-10 VDC loops must be powered.

All wiring connections are to be made inside of the junction box located on

the side of the pump. Special connectors are not required. A liquid-tite

connector is supplied and should be used for the external signal cable. The

signal input wires are color coded to the type of signal being used.

Page 6 Page 7

INPUT

VOLTAGE

115V 60Hz

220V 50Hz

HOT

LEADWIRE

NEUTRAL

LEADWIRE

GROUND

LEADWIRE

230V 60Hz

YELLOW

YELLOW

YELLOW

BLUE

BROWN

RED

GREEN

GREEN

GREEN

MOTOR LEADWIRES

SIGNAL INPUT WIRE COLOR CODES

CIRCUIT BOARD CONNECTIONS

AC

MOTOR

Neutral (blue/brown/red)

Hot (yellow)

Ground (green)

Ground (green)

Common

Hot

AC

Input

Power

Power Circuit Board

(Top view)

Protector Fuse

2 Amps, 250 Volt AC

(little Fuse #235002

or Equivalent)

R R

2A

250VAC

T3

T2

T1

T4

LINE

HOT

LINE

NEUTRAL

MOTOR

NEUTRAL

MOTOR

SWITCHED

115V 50/60Hz

INPUT VOLTAGE

RESISTOR PLACEMENT

220V 50/60Hz

230V 50/60Hz

R R

R

MA = BLUE

GND = BLACK

RELAY = PURPLE (2)

VDC = ORANGE

VS = RED (+17V DC)

PLS = WHITE

JUNCTION BOX

LIQUID-TIGHT

CONNECTOR

MTR = BROWN

Alarm Relay

3A/125VAC

N/C

COM

N/O

Purple connection wires

Default is N/O

VS

VDC

MA

MTR

GND

PLS

CN3

VS

FVS

GND

TFD

GND

FVS+

CN4

Control Circuit Board

(Back view)

Program Disable Jumper - Located on front of Control board.

Un-installed = enable front panel programming (default)

Installed = disable front panel programming

External input connections

6 Wire bundle to junction box

Flow verification sensor connector

3 Wire bundle to junction box.

red/black/yellow

Tube failure detection sensor connector

2 Wire bundle to pump head sensor

(A-100N series pumps only)

WIRE COLOR CODE

INPUT TYPE

MOTOR ON SIGNAL

5-20V DC open collector output

closed while motor is energized

FLOW VERIFICATION SENSOR

4-20 mA

0-10 VDC

ALARM RELAY

BROWN (+) & BLACK (-)

PURPLE & PURPLE

WHITE (+) & BLACK (-)

BLUE (+) & BLACK (-)

TTL, CMOS

ORANGE (+) & BLACK (-)

RED/WHITE (+ 20VDC) & BLACK (-) & YELLOW (signal)

CONTACT (10v @ 2 mA max)

HALL EFFECT, NPN RED (+) & WHITE (-)

C-1100E C-1100E

PADDLEWHEEL SENSOR SIGNAL INPUT WIRING

PADDLEWHEEL SENSOR

WIRE COLOR CODE

BLUE-WHITE

PADDLEWHEEL

SENSOR TYPE

MODEL FH

HALL EFFECT SENSOR

BLACK (-)

RED (+)

PUMP INPUT

WIRE COLOR CODE

MODEL FC

AC SINE WAVE SENSOR

BARE (signal)

BLACK (-)

RED (+ 20VDC)

WHITE (signal)

BLACK (-)

RED (+)

BLACK (-)

WHITE (+)

Page 8 Page 9

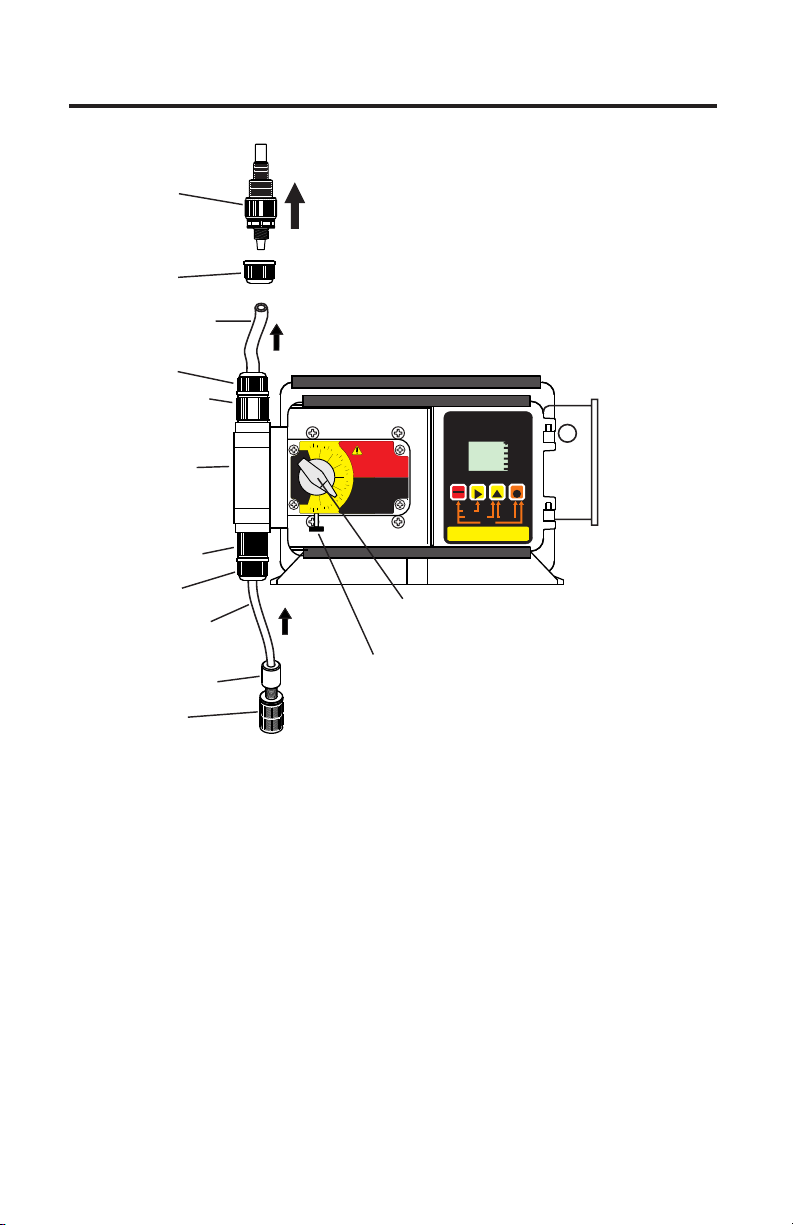

5.4 How To Install the Tubing and Fittings

!Inlet Tubing - Locate the inlet fitting of the pump head. Remove the tube

nut. Push the clear suction tubing through the tube nut and onto the fitting

barb. Hand tighten the tube nut to secure the tubing.

CAUTION: Proper eye and skin protection must be

worn when installing and servicing the pump.

!Footvalve/Strainer - Trim the inlet end

of the suction tubing so that the strainer

will rest approximately two inches from

the bottom of the solution tank. This will

prevent sediment from clogging the

strainer. Slip the ceramic weight over

the end of the suction tube. Press the

strainer’s barbed fitting into the end of

the tube. Secure the ceramic weight to

the strainer. Drop the strainer into the

solution tank.

!Injection/Check Valve Fitting

Installation - The Injection/Check valve

fitting is designed to install directly into

either 1/4” or 1/2” female pipe threads.

This fitting will require periodic

cleaning, especially when injecting

fluids that calcify such as sodium

hypochlorite. See section 7.0.

Install the Injection/Check valve directly

into the piping system. To prevent

trapped gasses, install the fitting in an

upward direction. Use PTFE thread

sealing tape on the pipe threads.

Push the opaque outlet (discharge)

tubing through the tube nut and onto the

compression barb of the Injection/Check

valve fitting. Hand tighten the tube nut

to secure the tubing.

FootValve

Strainer

Assembly

Ceramic

Weight

Suction Tubing

FOOTVALVE/STRAINER

!Outlet Tubing - Locate the outlet

fitting of the pump head. Remove the

tube nut. Push the opaque discharge

tubing through the tube nut and onto the

compression barb of the fitting. Hand

tighten the tube nut to secure the tubing.

Keep outlet tube as short as possible.

Discharge

Tubing

Tube retaining

nut

Injection

Check valve

Discharge Tube

(Rigid P.E.)

Outlet Adapter

Tube Nut

Inlet Adapter

Tube Nut

Suction Tubing

(clear PVC)

Manual

Stroke length

Adjustment knob

Footvalve

CAUTION

ADJUST WHILE RUNNING

DISCHARGE LINES MAY BE

UNDER HIGH PRESSURE. USE

CARE TO PROTECT YOURSELF

WHEN DISCONNECTING.

MAX

MIN

12

3

4

5

6

7

8

9

LOOSEN THE LOCK SCREW

TURN KNOB TO DESIRED SETTING

RE-TIGHTEN THE LOCK SCREW

Tube Nut

Injection

Check valve

RUN

STANDBY

RUN

FIELD DIGIT MODE

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

INPUT MOD ES

1 - MANUAL 2 - 4-20mA 3 - 0-10VDC

4 - 0-1000 Hz

PROGRAM

RESET SERVI CE

PRIME

DISPLAY

DIGITAL TIMER PUMP

1VDC

SERVICE

1000

ALARM

mA Hz

MODE

TFD

FVS

ON-T

TOT-TSECMINHR DAY

5 - PULSE (BATCH)

INJECTION/CHECK VALVE

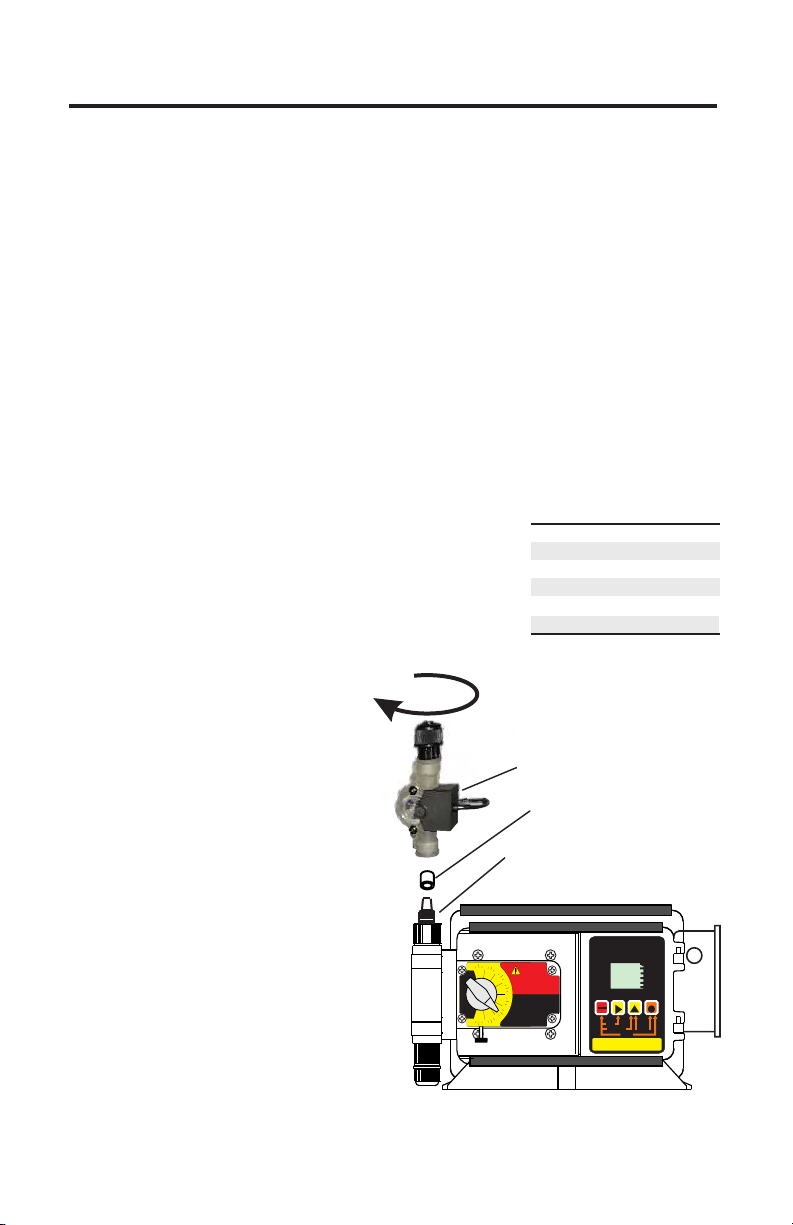

6.0 How To Operate The Pump

6.1 How to adjust the output- manual stroke adjustment The

Pump flow rate can be adjusted within a range of 5% -100% of maximum

output (20:1 turndown ration) by means of a mechanical, cam type

mechanism. The mechanism adjusts the pump’s stroke length to an infinite

number of settings within the flow range.

ø Note: The pump’s output will reduce due to increased system pressure,

increased suction lift, and increased fluid viscosity. The pump must be over-

sized to allow for these factors. Sizing the pump to allow adjustment within

the midrange is preferred to maintain accuracy. Consult the factory for

individual pump model output curve data.

To adjust the pump’s output:

1. With the pump running, loosen the lock screw.

2. Turn the adjustment knob to the desired setting.

3. Re-tighten the lock screw.

Ceramic Weight

Lock Screw

Pump Head

C-1100E C-1100E

Pipe tee

Install

upward

Install

upward

Page 8 Page 9

5.4 How To Install the Tubing and Fittings

!Inlet Tubing - Locate the inlet fitting of the pump head. Remove the tube

nut. Push the clear suction tubing through the tube nut and onto the fitting

barb. Hand tighten the tube nut to secure the tubing.

CAUTION: Proper eye and skin protection must be

worn when installing and servicing the pump.

!Footvalve/Strainer - Trim the inlet end

of the suction tubing so that the strainer

will rest approximately two inches from

the bottom of the solution tank. This will

prevent sediment from clogging the

strainer. Slip the ceramic weight over

the end of the suction tube. Press the

strainer’s barbed fitting into the end of

the tube. Secure the ceramic weight to

the strainer. Drop the strainer into the

solution tank.

!Injection/Check Valve Fitting

Installation - The Injection/Check valve

fitting is designed to install directly into

either 1/4” or 1/2” female pipe threads.

This fitting will require periodic

cleaning, especially when injecting

fluids that calcify such as sodium

hypochlorite. See section 7.0.

Install the Injection/Check valve directly

into the piping system. To prevent

trapped gasses, install the fitting in an

upward direction. Use PTFE thread

sealing tape on the pipe threads.

Push the opaque outlet (discharge)

tubing through the tube nut and onto the

compression barb of the Injection/Check

valve fitting. Hand tighten the tube nut

to secure the tubing.

FootValve

Strainer

Assembly

Ceramic

Weight

Suction Tubing

FOOTVALVE/STRAINER

!Outlet Tubing - Locate the outlet

fitting of the pump head. Remove the

tube nut. Push the opaque discharge

tubing through the tube nut and onto the

compression barb of the fitting. Hand

tighten the tube nut to secure the tubing.

Keep outlet tube as short as possible.

Discharge

Tubing

Tube retaining

nut

Injection

Check valve

Discharge Tube

(Rigid P.E.)

Outlet Adapter

Tube Nut

Inlet Adapter

Tube Nut

Suction Tubing

(clear PVC)

Manual

Stroke length

Adjustment knob

Footvalve

CAUTION

ADJUST WHILE RUNNING

DISCHARGE LINES MAY BE

UNDER HIGH PRESSURE. USE

CARE TO PROTECT YOURSELF

WHEN DISCONNECTING.

MAX

MIN

12

3

4

5

6

7

8

9

LOOSEN THE LOCK SCREW

TURN KNOB TO DESIRED SETTING

RE-TIGHTEN THE LOCK SCREW

Tube Nut

Injection

Check valve

RUN

STANDBY

RUN

FIELD DIGIT MODE

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

INPUT MOD ES

1 - MANUAL 2 - 4-20mA 3 - 0-10VDC

4 - 0-1000 Hz

PROGRAM

RESET SERVI CE

PRIME

DISPLAY

DIGITAL TIMER PUMP

1VDC

SERVICE

1000

ALARM

mA Hz

MODE

TFD

FVS

ON-T

TOT-TSECMINHR DAY

5 - PULSE (BATCH)

INJECTION/CHECK VALVE

6.0 How To Operate The Pump

6.1 How to adjust the output- manual stroke adjustment The

Pump flow rate can be adjusted within a range of 5% -100% of maximum

output (20:1 turndown ration) by means of a mechanical, cam type

mechanism. The mechanism adjusts the pump’s stroke length to an infinite

number of settings within the flow range.

ø Note: The pump’s output will reduce due to increased system pressure,

increased suction lift, and increased fluid viscosity. The pump must be over-

sized to allow for these factors. Sizing the pump to allow adjustment within

the midrange is preferred to maintain accuracy. Consult the factory for

individual pump model output curve data.

To adjust the pump’s output:

1. With the pump running, loosen the lock screw.

2. Turn the adjustment knob to the desired setting.

3. Re-tighten the lock screw.

Ceramic Weight

Lock Screw

Pump Head

C-1100E C-1100E

Pipe tee

Install

upward

Install

upward

Page 10 Page 11

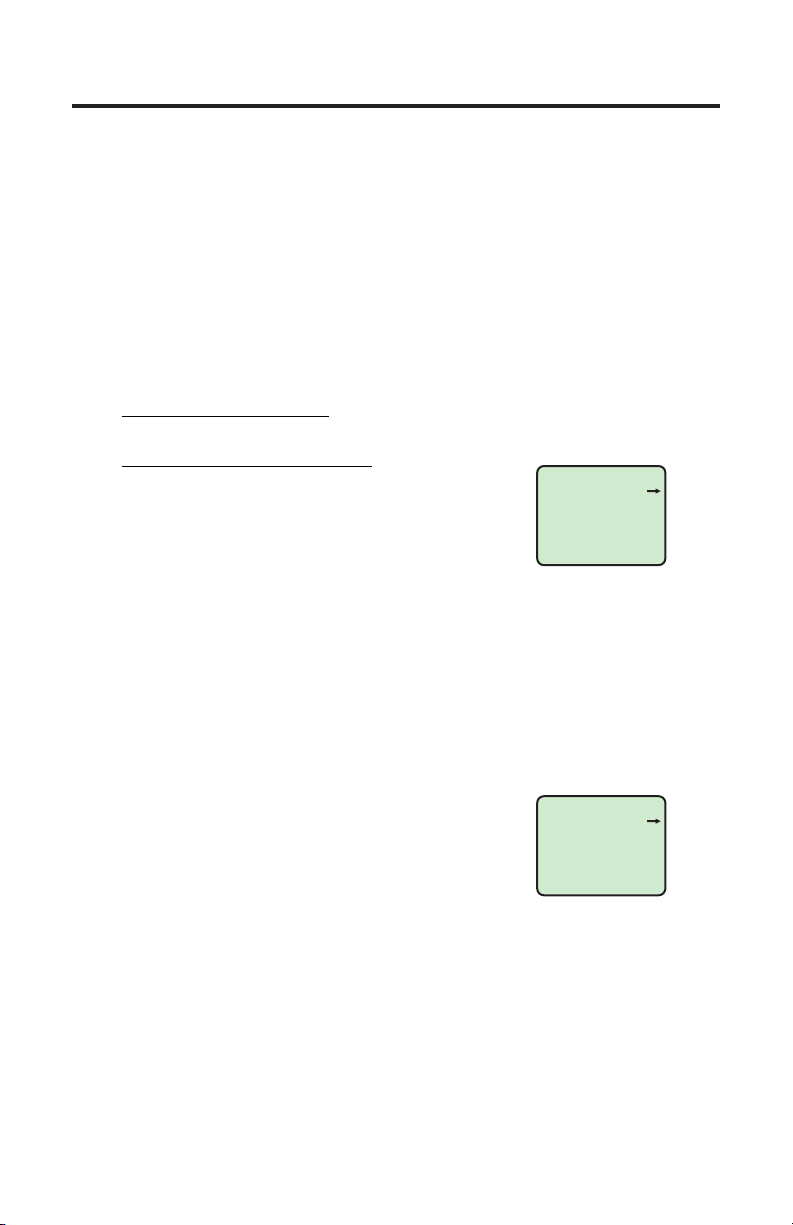

Install the FVS Flow Sensor -

The Flow Verification Sensor

(FVS) should be installed on the

discharge (outlet) pump head

valve. The sensor includes a

PVC tubing insert, located

inside the sensor’s female

thread connection, that is

designed to seal the sensor onto

the pump tube inlet adapter.

Thread the sensor onto the

pump tube until the tubing

insert is snug against the pump

tube inlet fitting - do not over-

tighten.

Connect the red/white, black,

and white wires from the sensor

to the red, black, and yellow

wires located in the pump’s

junction box. See page 7.

6.3 MODE 0 - FVS system set-up (sensor sold separately)

! (FVS) Flow Verification System The C-1100E is equipped with a -

Flow Verification System which is designed to stop the pump and provide a

contact closure output in the event the sensor does not detect chemical

during pump operation. This could indicate a clogged injection fitting,

empty chemical solution tank, loose tubing connection, etc.

To allow the pump to clear any gasses that may have accumulated during

stopped operation, an alarm delay time value from 1-256 seconds must be

programmed (An alarm delay value of 000 seconds disables the FVS

system). The pump will stop, and the alarm mode activated, if no pulses are

received by the pump and the alarm delay time period has ended. Press the

STAND-BY button twice to clear the alarm and restart the pump. The Flow

Verification Sensor is sold as an optional accessory.

6.2 Electronic Pump Output

Controls -

Open the control panel door by sliding the

upper and lower slide clamps to the left.

! RUN/STANDBY Button -

+Press to start and stop the pump. The

ARROW next to the word RUN will light

when in the run mode. The ARROW next

to the word STAND-BY will blink when in

the stand-by mode.

+Press to clear ALARM.

+When pressed with the FIELD Button, initiates a 99 second prime cycle

which temporarily overrides the mode setting and runs the pump motor at

100% speed. The ARROW next to the word PRIME will blink.

+When pressed with the DIGIT button, resets the 500 hour service warning

timer to zero.

+When pressed with the MODE button, initiates the programming mode.

The ARROW next to the word PROGRAM will blink.

!FIELD Button -

+In the programming mode, selects the digit to be changed.

!DIGIT Button -

+In the programming mode, increases the selected digit.

+When pressed with the MODE Button, toggles the display from operating

time cycle values to input signal value.

!MODE Button -

+Used to select one of five operating modes.

Mode 0 - FVS system set-up

Mode 1 - Manual Adjustment (external input disabled)

Mode 2 - 4-20mA input

Mode 3 - 0-10VDC input

Mode 4 - Frequency input adjusts cycle on-time

Mode 5 - Pulse input count = single batch time

RUN

STANDBY

RUN

FIELD DIGIT MODE

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

INPUT MODES

1 - MANUAL 2 - 4-20mA 3 - 0-10VDC

4 - 0-1000 Hz

PROGRAM

RESET SERVICE

PRIME

DISPLAY

DIGITAL TIMER PUMP

1VDC

SERVICE

1000

ALARM

mA Hz

MODE

TFD

FVS

ON-T

TOT-TSECMINHRDAY

5 - PULSE (BATCH)

Confirm the FVS flow range - The Flow

Verification Sensor (FVS) will only function

within its operating range. Sensor model FV-100-

6V has an operating range of 30-300 ml/min (1-10

oz/min). If the pump’s output is less than 30

ml/min (0.5 ml/sec), the sensor will not detect

chemical and a signal will not be sent to the pump.

OPERATING

FLOW RANGE

(ml/min)

30-300

FV-100-6V

100-1000

FV-200-6V

200-2000

FV-300-6V

300-3000

FV-400-6V

500-5000

FV-500-6V

700-7000

FV-600-6V

SENSOR

MODEL

NUMBER

Insert Tubing Seal

CAUTION

ADJUST WHILE RUNNING

DISCHARGE LINES MAY BE

UNDER HIGH PRESSURE. USE

CARE TO PROTECT YOURSELF

WHEN DISCONNECTING.

MAX

MIN

12

3

4

5

6

7

8

9

LOOSEN THE LOCK SCREW

TURN KNOB TO DESIRED SETTING

RE-TIGHTEN THE LOCK SCREW

RUN

STANDBY

RUN

FIELD DIGIT MODE

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

INPUT MODE S

1 - MANUAL 2 - 4-20mA 3 - 0-10VDC

4 - 0-1000 Hz

PROGRAM

RESET SERVIC E

PRIME

DISPLAY

DIGITAL TIMER PUMP

1VDC

SERVICE

1000

ALARM

mA Hz

MODE

TFD

FVS

ON-T

TOT-TSECMINHR DAY

5 - PULSE (BATCH)

Outlet Adapter

FVS Sensor

C-1100E C-1100E

Page 10 Page 11

Install the FVS Flow Sensor -

The Flow Verification Sensor

(FVS) should be installed on the

discharge (outlet) pump head

valve. The sensor includes a

PVC tubing insert, located

inside the sensor’s female

thread connection, that is

designed to seal the sensor onto

the pump tube inlet adapter.

Thread the sensor onto the

pump tube until the tubing

insert is snug against the pump

tube inlet fitting - do not over-

tighten.

Connect the red/white, black,

and white wires from the sensor

to the red, black, and yellow

wires located in the pump’s

junction box. See page 7.

6.3 MODE 0 - FVS system set-up (sensor sold separately)

! (FVS) Flow Verification System The C-1100E is equipped with a -

Flow Verification System which is designed to stop the pump and provide a

contact closure output in the event the sensor does not detect chemical

during pump operation. This could indicate a clogged injection fitting,

empty chemical solution tank, loose tubing connection, etc.

To allow the pump to clear any gasses that may have accumulated during

stopped operation, an alarm delay time value from 1-256 seconds must be

programmed (An alarm delay value of 000 seconds disables the FVS

system). The pump will stop, and the alarm mode activated, if no pulses are

received by the pump and the alarm delay time period has ended. Press the

STAND-BY button twice to clear the alarm and restart the pump. The Flow

Verification Sensor is sold as an optional accessory.

6.2 Electronic Pump Output

Controls -

Open the control panel door by sliding the

upper and lower slide clamps to the left.

! RUN/STANDBY Button -

+Press to start and stop the pump. The

ARROW next to the word RUN will light

when in the run mode. The ARROW next

to the word STAND-BY will blink when in

the stand-by mode.

+Press to clear ALARM.

+When pressed with the FIELD Button, initiates a 99 second prime cycle

which temporarily overrides the mode setting and runs the pump motor at

100% speed. The ARROW next to the word PRIME will blink.

+When pressed with the DIGIT button, resets the 500 hour service warning

timer to zero.

+When pressed with the MODE button, initiates the programming mode.

The ARROW next to the word PROGRAM will blink.

!FIELD Button -

+In the programming mode, selects the digit to be changed.

!DIGIT Button -

+In the programming mode, increases the selected digit.

+When pressed with the MODE Button, toggles the display from operating

time cycle values to input signal value.

!MODE Button -

+Used to select one of five operating modes.

Mode 0 - FVS system set-up

Mode 1 - Manual Adjustment (external input disabled)

Mode 2 - 4-20mA input

Mode 3 - 0-10VDC input

Mode 4 - Frequency input adjusts cycle on-time

Mode 5 - Pulse input count = single batch time

RUN

STANDBY

RUN

FIELD DIGIT MODE

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

INPUT MODES

1 - MANUAL 2 - 4-20mA 3 - 0-10VDC

4 - 0-1000 Hz

PROGRAM

RESET SERVICE

PRIME

DISPLAY

DIGITAL TIMER PUMP

1VDC

SERVICE

1000

ALARM

mA Hz

MODE

TFD

FVS

ON-T

TOT-TSECMINHRDAY

5 - PULSE (BATCH)

Confirm the FVS flow range - The Flow

Verification Sensor (FVS) will only function

within its operating range. Sensor model FV-100-

6V has an operating range of 30-300 ml/min (1-10

oz/min). If the pump’s output is less than 30

ml/min (0.5 ml/sec), the sensor will not detect

chemical and a signal will not be sent to the pump.

OPERATING

FLOW RANGE

(ml/min)

30-300

FV-100-6V

100-1000

FV-200-6V

200-2000

FV-300-6V

300-3000

FV-400-6V

500-5000

FV-500-6V

700-7000

FV-600-6V

SENSOR

MODEL

NUMBER

Insert Tubing Seal

CAUTION

ADJUST WHILE RUNNING

DISCHARGE LINES MAY BE

UNDER HIGH PRESSURE. USE

CARE TO PROTECT YOURSELF

WHEN DISCONNECTING.

MAX

MIN

12

3

4

5

6

7

8

9

LOOSEN THE LOCK SCREW

TURN KNOB TO DESIRED SETTING

RE-TIGHTEN THE LOCK SCREW

RUN

STANDBY

RUN

FIELD DIGIT MODE

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

INPUT MODE S

1 - MANUAL 2 - 4-20mA 3 - 0-10VDC

4 - 0-1000 Hz

PROGRAM

RESET SERVIC E

PRIME

DISPLAY

DIGITAL TIMER PUMP

1VDC

SERVICE

1000

ALARM

mA Hz

MODE

TFD

FVS

ON-T

TOT-TSECMINHR DAY

5 - PULSE (BATCH)

Outlet Adapter

FVS Sensor

C-1100E C-1100E

!Enable and Program the FVS System

The FVS system must be enabled and an alarm delay time programmed.

+Set the pump for mode 0. Press the MODE button until MODE 0 is

shown on the LCD display.

+Enter the programming mode. At the same time, press the

RUN/STANDBY button and the MODE button. A blinking ARROW will

point to the word PROGRAM indicating the program mode has been

activated.

C-1100EPage 12 C-1100E Page 13

decrease the number of seconds. The number will increase to a maximum

of 256 seconds and roll over to OFF. To turn off the system, set the

number to 000 or OFF.

+To exit the programming mode, press the RUN/STANDBY button and the

MODE button at the same time. The arrow next to the word PROGRAM

will disappear and an arrow will appear next to the word RUN.

øNOTE: If while in the program mode no buttons are pressed within 10

seconds, the circuitry will automatically return to the run mode.

+The TFD system . The TFD icon will blink.

The TFD system is only used on A-100N

series peristaltic pumps. The word ON will

display indicating the TFD system is

activated. No changes are necessary.

Although it is not necessary, you may press

the DIGIT button to toggle the TFD system

on and off.

+The FVS system . Press the MODE button

to enter the FVS system programming. The

FVS icon will blink. The display will

indicate the current alarm delay time setting

in seconds. (000 = OFF).

+Press and hold he DIGIT button to increase

the number of seconds of alarm delay time,

press and hold the FIELD button to

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

0

On

MODE

TFD

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

0

001

MODE

FVS

SEC

6.4 Mode 1 - Manually adjusting the output - In this mode, the pump

is turned on and off by an electronic cycle timer. The pump will energize for

the duration of the “on time” and de-energize for the remainder of the “total

time” thus completing one cycle. The cycle then repeats.

The “on time” and “total time” cycles are independently adjustable from 0.1

to 199.9 units of measure with a 0.1 unit resolution. The units of measure

can be seconds, minutes, hours or days.

Example: If the “total time” cycle is adjusted for 90 seconds and the “on

time” portion of the cycle is adjusted for 5 seconds, the pump will run for 5

seconds and turn off for 85 seconds (90 second total cycle). This cycle is

repeated until either the standby button is pressed, the cycle time is changed

or the input power is disconnected from the pump.

+Set the pump for mode 1. Press the MODE button until MODE 1 is

shown on the LCD display.

+Enter the programming mode. At the same

time, press the RUN/STANDBY button and

the MODE button. A blinking ARROW will

point to the word PROGRAM indicating the

program mode has been activated. The total

time TOT-T icon will blink. The currently

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

1

199.9

MODE

TOT-T SEC

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

1

42.5

MODE

ON-T

SEC

selected time unit icon will be displayed. The current total time setting will

be displayed and the left most (selected) digit will blink. Note: The left most

digit can be programmed from 0 - 19. The decimal is fixed and cannot be

moved.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right or the time

unit.

+Press the DIGIT button to increase the selected digit or time unit.

+Press the MODE button to exit the total

time programming screen and enter the on

time programming screen. The ON-T icon

will blink. The currently selected time unit

icon will be displayed. The current on time

setting will be displayed and the left most

(selected) digit will blink.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right or the time

unit.

+Press the DIGIT button to increase the selected digit or time unit.

+At the same time, press the RUN/STANDBY button and the MODE

button. A blinking ARROW will point to the word RUN indicating the run

mode has been activated.

øNOTE: If while in the program mode no buttons are pressed within 60

seconds, the circuitry will automatically return to the run mode.

Contact Closure Alarm Output - A contact closure output (3A 125VAC

relay) is provided with the FVS system. The relay can be configured for

normally open (factory default) or normally closed operation by properly

positioning the connector plug on the circuit board (see page 7).

!Enable and Program the FVS System

The FVS system must be enabled and an alarm delay time programmed.

+Set the pump for mode 0. Press the MODE button until MODE 0 is

shown on the LCD display.

+Enter the programming mode. At the same time, press the

RUN/STANDBY button and the MODE button. A blinking ARROW will

point to the word PROGRAM indicating the program mode has been

activated.

C-1100EPage 12 C-1100E Page 13

decrease the number of seconds. The number will increase to a maximum

of 256 seconds and roll over to OFF. To turn off the system, set the

number to 000 or OFF.

+To exit the programming mode, press the RUN/STANDBY button and the

MODE button at the same time. The arrow next to the word PROGRAM

will disappear and an arrow will appear next to the word RUN.

øNOTE: If while in the program mode no buttons are pressed within 10

seconds, the circuitry will automatically return to the run mode.

+The TFD system . The TFD icon will blink.

The TFD system is only used on A-100N

series peristaltic pumps. The word ON will

display indicating the TFD system is

activated. No changes are necessary.

Although it is not necessary, you may press

the DIGIT button to toggle the TFD system

on and off.

+The FVS system . Press the MODE button

to enter the FVS system programming. The

FVS icon will blink. The display will

indicate the current alarm delay time setting

in seconds. (000 = OFF).

+Press and hold he DIGIT button to increase

the number of seconds of alarm delay time,

press and hold the FIELD button to

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

0

On

MODE

TFD

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

0

001

MODE

FVS

SEC

6.4 Mode 1 - Manually adjusting the output - In this mode, the pump

is turned on and off by an electronic cycle timer. The pump will energize for

the duration of the “on time” and de-energize for the remainder of the “total

time” thus completing one cycle. The cycle then repeats.

The “on time” and “total time” cycles are independently adjustable from 0.1

to 199.9 units of measure with a 0.1 unit resolution. The units of measure

can be seconds, minutes, hours or days.

Example: If the “total time” cycle is adjusted for 90 seconds and the “on

time” portion of the cycle is adjusted for 5 seconds, the pump will run for 5

seconds and turn off for 85 seconds (90 second total cycle). This cycle is

repeated until either the standby button is pressed, the cycle time is changed

or the input power is disconnected from the pump.

+Set the pump for mode 1. Press the MODE button until MODE 1 is

shown on the LCD display.

+Enter the programming mode. At the same

time, press the RUN/STANDBY button and

the MODE button. A blinking ARROW will

point to the word PROGRAM indicating the

program mode has been activated. The total

time TOT-T icon will blink. The currently

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

1

199.9

MODE

TOT-T SEC

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

1

42.5

MODE

ON-T

SEC

selected time unit icon will be displayed. The current total time setting will

be displayed and the left most (selected) digit will blink. Note: The left most

digit can be programmed from 0 - 19. The decimal is fixed and cannot be

moved.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right or the time

unit.

+Press the DIGIT button to increase the selected digit or time unit.

+Press the MODE button to exit the total

time programming screen and enter the on

time programming screen. The ON-T icon

will blink. The currently selected time unit

icon will be displayed. The current on time

setting will be displayed and the left most

(selected) digit will blink.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right or the time

unit.

+Press the DIGIT button to increase the selected digit or time unit.

+At the same time, press the RUN/STANDBY button and the MODE

button. A blinking ARROW will point to the word RUN indicating the run

mode has been activated.

øNOTE: If while in the program mode no buttons are pressed within 60

seconds, the circuitry will automatically return to the run mode.

Contact Closure Alarm Output - A contact closure output (3A 125VAC

relay) is provided with the FVS system. The relay can be configured for

normally open (factory default) or normally closed operation by properly

positioning the connector plug on the circuit board (see page 7).

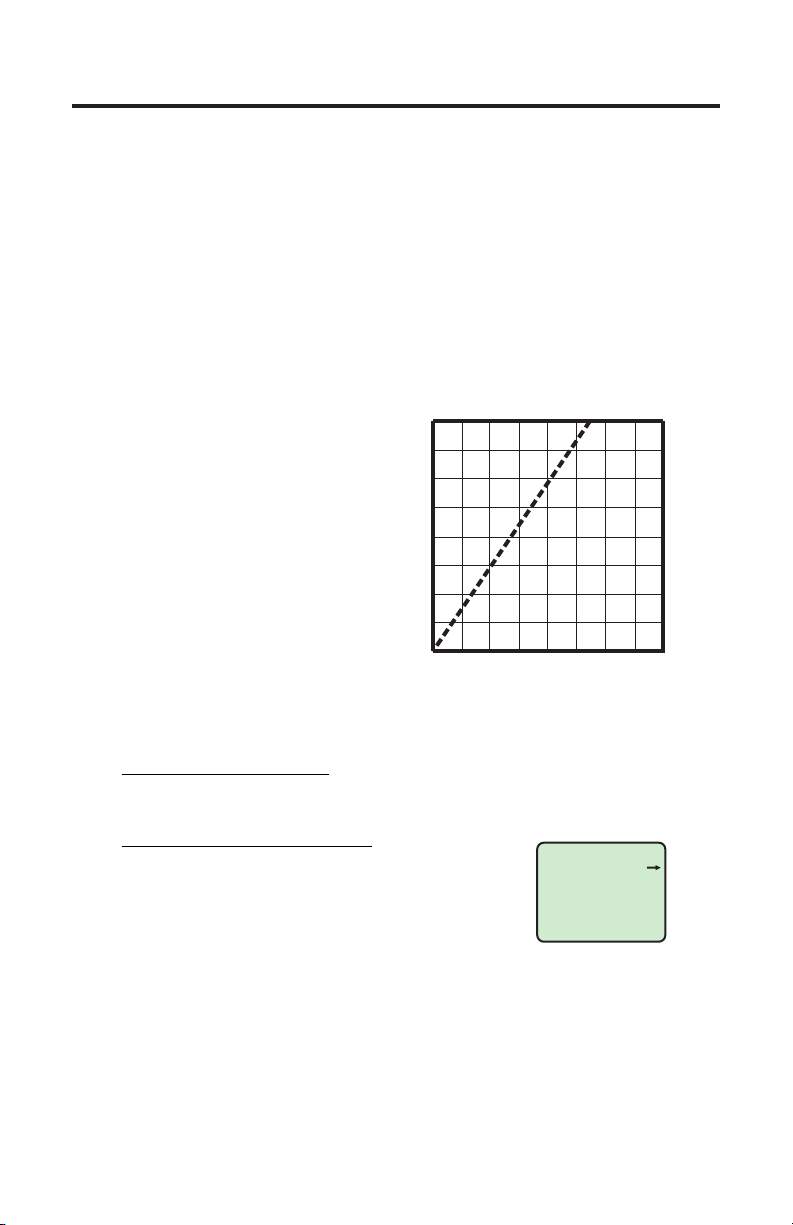

6.5 Mode 2 - 4-20 mA input - In this mode, the on-time of the cycle will

automatically adjust to match the received mA input value. When the mA

input value is equal to the programmed maximum, the pump will run

continuously.

Four values must be programmed:

1) ON-T = The amount of time the pump will run, per cycle, when the

minimum mA value is received. (Typically programmed to zero)

2) mA minimum = The mA input value that will result in the on time (ON-

T). (Typically programmed to 4 mA)

3) TOT-T = The total cycle time.

4) mA maximum = The mA input value that will result in the pump running

continuously.

Example:

ON-T setting = 0 seconds

mA minimum setting = 4mA

TOT-T setting = 8 seconds

mA maximum setting = 14.8mA

6

4810 12 14 16 18 20

0

2

4

6

8

Pump Run-Time (Sec.)

Milliamp input (mA)

Page 14 Page 15

+Set the pump for mode 2. Press the

MODE button until MODE 2 is shown on

the LCD display.

+Enter the programming mode. At the

same time, press the RUN/STANDBY

button and the MODE button. A blinking

ARROW will point to the word PROGRAM

indicating the program mode has been

activated. The on time ON-T icon will

blink. The currently selected time unit

+Press the MODE button to exit the on time

programming screen and enter the mA

minimum programming screen. The mA

icon will blink. A blinking ARROW will

appear next to the word MINIMUM. The

current minimum mA setting will be

displayed and the left most (selected) digit

will blink.

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

2

00.0

MODE

ON-T

SEC

icon will be displayed. The current on time setting will be displayed and

the left most (selected) digit will blink. Note: The left most digits can be

programmed from 0 - 19. The decimal is fixed and cannot be moved.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right or the time

unit.

+Press the DIGIT button to increase the selected digit or time unit.

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

2

04.0

mA

MODE

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right.

+Press the DIGIT button to increase the selected digit.

(selected) digit will blink. Note: The left most digit can be programmed

from 0 - 9. The decimal is fixed and cannot be moved.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right or the time

unit.

+Press the DIGIT button to increase the selected digit or time unit.

+Press the MODE button to exit the mA

minimum programming screen and enter

the total time programming screen. The

total time TOT-T icon will blink. The

currently selected time unit icon will be

displayed. The current total time setting

will be displayed and the left most

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

2

00.0

MODE

SEC

TOT-T

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

2

20.0

mA

MODE

+Press the MODE button to exit the total

time programming screen and enter the

mA maximum programming screen. The

mA icon will blink. A blinking ARROW

will appear next to the word MAXIMUM.

The current maximum mA setting will be

displayed and the left most (selected) digit

will blink.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right.

+Press the DIGIT button to increase the selected digit.

+At the same time, press the RUN/STANDBY button and the MODE

button. A blinking ARROW will point to the word RUN indicating the run

mode has been activated.

øNOTE: If while in the program mode no buttons are pressed within 60

seconds, the circuitry will automatically return to the run mode.

C-1100E C-1100E

6.5 Mode 2 - 4-20 mA input - In this mode, the on-time of the cycle will

automatically adjust to match the received mA input value. When the mA

input value is equal to the programmed maximum, the pump will run

continuously.

Four values must be programmed:

1) ON-T = The amount of time the pump will run, per cycle, when the

minimum mA value is received. (Typically programmed to zero)

2) mA minimum = The mA input value that will result in the on time (ON-

T). (Typically programmed to 4 mA)

3) TOT-T = The total cycle time.

4) mA maximum = The mA input value that will result in the pump running

continuously.

Example:

ON-T setting = 0 seconds

mA minimum setting = 4mA

TOT-T setting = 8 seconds

mA maximum setting = 14.8mA

6

4810 12 14 16 18 20

0

2

4

6

8

Pump Run-Time (Sec.)

Milliamp input (mA)

Page 14 Page 15

+Set the pump for mode 2. Press the

MODE button until MODE 2 is shown on

the LCD display.

+Enter the programming mode. At the

same time, press the RUN/STANDBY

button and the MODE button. A blinking

ARROW will point to the word PROGRAM

indicating the program mode has been

activated. The on time ON-T icon will

blink. The currently selected time unit

+Press the MODE button to exit the on time

programming screen and enter the mA

minimum programming screen. The mA

icon will blink. A blinking ARROW will

appear next to the word MINIMUM. The

current minimum mA setting will be

displayed and the left most (selected) digit

will blink.

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

2

00.0

MODE

ON-T

SEC

icon will be displayed. The current on time setting will be displayed and

the left most (selected) digit will blink. Note: The left most digits can be

programmed from 0 - 19. The decimal is fixed and cannot be moved.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right or the time

unit.

+Press the DIGIT button to increase the selected digit or time unit.

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

2

04.0

mA

MODE

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right.

+Press the DIGIT button to increase the selected digit.

(selected) digit will blink. Note: The left most digit can be programmed

from 0 - 9. The decimal is fixed and cannot be moved.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right or the time

unit.

+Press the DIGIT button to increase the selected digit or time unit.

+Press the MODE button to exit the mA

minimum programming screen and enter

the total time programming screen. The

total time TOT-T icon will blink. The

currently selected time unit icon will be

displayed. The current total time setting

will be displayed and the left most

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

2

00.0

MODE

SEC

TOT-T

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

2

20.0

mA

MODE

+Press the MODE button to exit the total

time programming screen and enter the

mA maximum programming screen. The

mA icon will blink. A blinking ARROW

will appear next to the word MAXIMUM.

The current maximum mA setting will be

displayed and the left most (selected) digit

will blink.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right.

+Press the DIGIT button to increase the selected digit.

+At the same time, press the RUN/STANDBY button and the MODE

button. A blinking ARROW will point to the word RUN indicating the run

mode has been activated.

øNOTE: If while in the program mode no buttons are pressed within 60

seconds, the circuitry will automatically return to the run mode.

C-1100E C-1100E

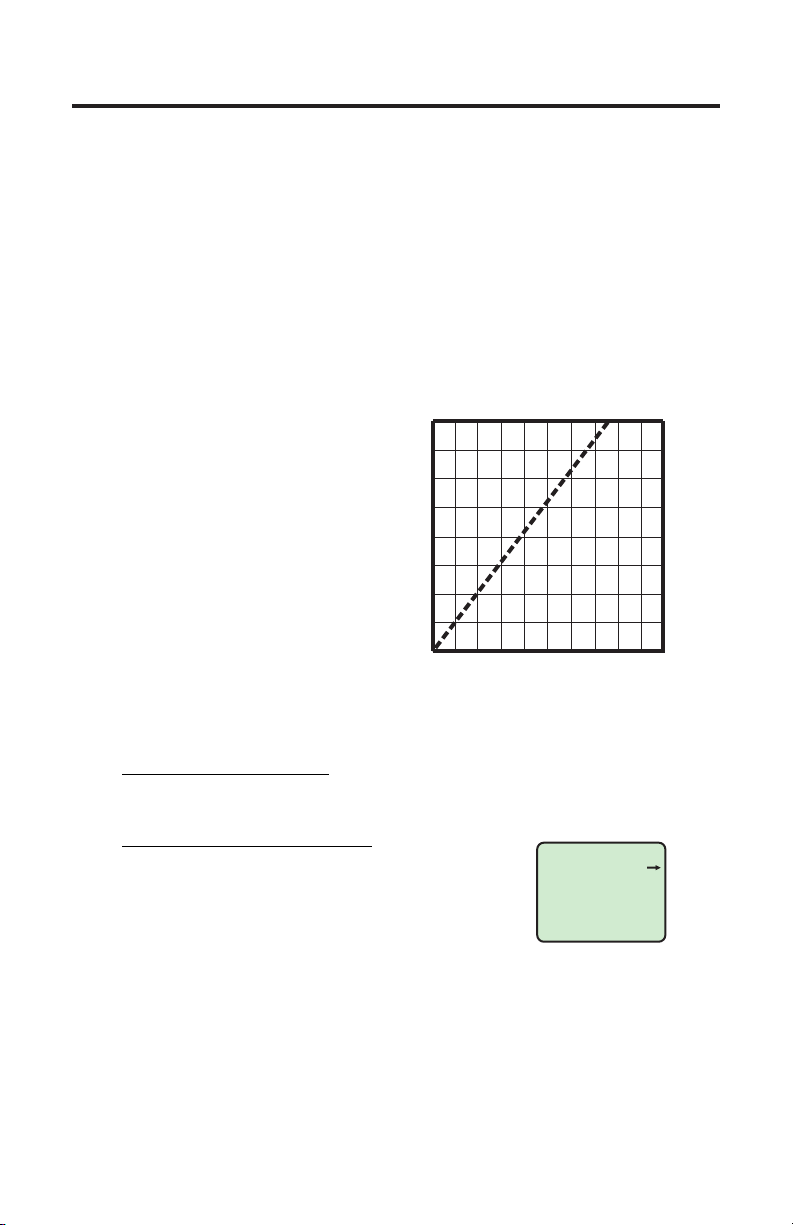

6.6 Mode 3 - 0-10V DC input - In this mode, the on-time of the cycle

will automatically adjust to match the received VDC input value. When the

VDC value is equal the programmed maximum, the pump will run

continuously.

Four values must be programmed:

1) ON-T = The amount of time the pump will run, per cycle, when the

minimum VDC value is received. (Typically programmed to zero)

2) VDC minimum = The VDC input value that will result in the on time

(ON-T). (Typically programmed to 0 VDC)

3) TOT-T = The total cycle time.

4) VDC maximum = The VDC input value that will result in the pump

running continuously.

Example:

ON-T setting = 0 seconds

VDC minimum setting = 0 VDC

TOT-T setting = 6 seconds

VDC maximum setting = 7.5 VDC

Page 16 Page 17

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

3

00.0

MODE

ON-T

SEC

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

3

00.0

MODE

SEC

TOT-T

+Set the pump for mode 3. Press the

MODE button until MODE 3 is shown on

the LCD display.

+Enter the programming mode. At the

same time, press the RUN/STANDBY

button and the MODE button. A blinking

ARROW will point to the word PROGRAM

indicating the program mode has been

activated. The on time ON-T icon will

blink. The currently selected time unit

+Press the MODE button to exit the on time

programming screen and enter the VDC

minimum programming screen. The VDC

icon will blink. A blinking ARROW will

appear next to the word MINIMUM. The

current minimum VDC setting will be

displayed and the left most (selected) digit

will blink.

icon will be displayed. The current on time setting will be displayed and

the left most (selected) digit will blink. Note: The left most digits can be

programmed from 0 - 19. The decimal is fixed and cannot be moved.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right or the time

unit.

+Press the DIGIT button to increase the selected digit or time unit.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right.

+Press the DIGIT button to increase the selected digit.

(selected) digit will blink. Note: The left most digits can be programmed

from 0 - 19. The decimal is fixed and cannot be moved.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right or the time

unit.

+Press the DIGIT button to increase the selected digit or time unit.

+Press the MODE button to exit the VDC

minimum programming screen and enter

the total time programming screen. The

total time TOT-T icon will blink. The

currently selected time unit icon will be

displayed. The current total time setting

will be displayed and the left most

+Press the MODE button to exit the total

time programming screen and enter the

VDC maximum programming screen. The

VDC icon will blink. A blinking ARROW

will appear next to the word MAXIMUM.

The current maximum VDC setting will

be displayed and the left most (selected)

digit will blink.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right.

+Press the DIGIT button to increase the selected digit.

+At the same time, press the RUN/STANDBY button and the MODE

button. A blinking ARROW will point to the word RUN indicating the run

mode has been activated.

øNOTE: If while in the program mode no buttons are pressed within 60

seconds, the circuitry will automatically return to the run mode.

1

023567810

0

1.5

3.0

4.5

6.0

Pump Run-Time (Sec.)

DC voltage input (VDC)

49

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

3

9.5

MODE

VDC

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

3

0.0

MODE

VDC

C-1100E C-1100E

6.6 Mode 3 - 0-10V DC input - In this mode, the on-time of the cycle

will automatically adjust to match the received VDC input value. When the

VDC value is equal the programmed maximum, the pump will run

continuously.

Four values must be programmed:

1) ON-T = The amount of time the pump will run, per cycle, when the

minimum VDC value is received. (Typically programmed to zero)

2) VDC minimum = The VDC input value that will result in the on time

(ON-T). (Typically programmed to 0 VDC)

3) TOT-T = The total cycle time.

4) VDC maximum = The VDC input value that will result in the pump

running continuously.

Example:

ON-T setting = 0 seconds

VDC minimum setting = 0 VDC

TOT-T setting = 6 seconds

VDC maximum setting = 7.5 VDC

Page 16 Page 17

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

3

00.0

MODE

ON-T

SEC

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

3

00.0

MODE

SEC

TOT-T

+Set the pump for mode 3. Press the

MODE button until MODE 3 is shown on

the LCD display.

+Enter the programming mode. At the

same time, press the RUN/STANDBY

button and the MODE button. A blinking

ARROW will point to the word PROGRAM

indicating the program mode has been

activated. The on time ON-T icon will

blink. The currently selected time unit

+Press the MODE button to exit the on time

programming screen and enter the VDC

minimum programming screen. The VDC

icon will blink. A blinking ARROW will

appear next to the word MINIMUM. The

current minimum VDC setting will be

displayed and the left most (selected) digit

will blink.

icon will be displayed. The current on time setting will be displayed and

the left most (selected) digit will blink. Note: The left most digits can be

programmed from 0 - 19. The decimal is fixed and cannot be moved.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right or the time

unit.

+Press the DIGIT button to increase the selected digit or time unit.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right.

+Press the DIGIT button to increase the selected digit.

(selected) digit will blink. Note: The left most digits can be programmed

from 0 - 19. The decimal is fixed and cannot be moved.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right or the time

unit.

+Press the DIGIT button to increase the selected digit or time unit.

+Press the MODE button to exit the VDC

minimum programming screen and enter

the total time programming screen. The

total time TOT-T icon will blink. The

currently selected time unit icon will be

displayed. The current total time setting

will be displayed and the left most

+Press the MODE button to exit the total

time programming screen and enter the

VDC maximum programming screen. The

VDC icon will blink. A blinking ARROW

will appear next to the word MAXIMUM.

The current maximum VDC setting will

be displayed and the left most (selected)

digit will blink.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right.

+Press the DIGIT button to increase the selected digit.

+At the same time, press the RUN/STANDBY button and the MODE

button. A blinking ARROW will point to the word RUN indicating the run

mode has been activated.

øNOTE: If while in the program mode no buttons are pressed within 60

seconds, the circuitry will automatically return to the run mode.

1

023567810

0

1.5

3.0

4.5

6.0

Pump Run-Time (Sec.)

DC voltage input (VDC)

49

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

3

9.5

MODE

VDC

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

3

0.0

MODE

VDC

C-1100E C-1100E

6.7 Mode 4 - Frequency (Hz) input - In this mode, the on-time of the

cycle will automatically adjust to match the received Hz input value. When

the Hz value is equal the programmed maximum, the pump will run

continuously.

Four values must be programmed:

1) ON-T = The amount of time the pump will run, per cycle, when the

minimum hZ value is received. (Typically programmed to zero)

2) Hz minimum = The Hz input value that will result in the on time (ON-

T). (Typically programmed to 0 Hz)

3) TOT-T = The total cycle time.

4) Hz maximum = The Hz input value that will result in the pump running

continuously.

Page 18 Page 19

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

4

00.0

MODE

ON-T

SEC

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

4

08.0

MODE

SEC

TOT-T

+Set the pump for mode 4. Press the

MODE button until MODE 4 is shown on

the LCD display.

+Enter the programming mode. At the

same time, press the RUN/STANDBY

button and the MODE button. A blinking

ARROW will point to the word PROGRAM

indicating the program mode has been

activated. The on time ON-T icon will

blink. The currently selected time unit

+Press the MODE button to exit the on time

programming screen and enter the Hz

minimum programming screen. The HZ

icon will blink. A blinking ARROW will

appear next to the word MINIMUM. The

current minimum Hz setting will be

displayed and the left most (selected) digit

will blink.

icon will be displayed. The current on time setting will be displayed and

the left most (selected) digit will blink. Note: The left most digits can be

programmed from 0 - 19. The decimal is fixed and cannot be moved.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right or the time

unit.

+Press the DIGIT button to increase the selected digit or time unit.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right.

+Press the DIGIT button to increase the selected digit.

(selected) digit will blink. Note: The left most digit can be programmed

from 0 - 19. The decimal is fixed and cannot be moved.

+Pressing the DIGIT button will increase the selected digit.

+Pressing the FIELD button will select a new digit to the right or the time

unit.

+Press the DIGIT button to increase the selected digit or time unit.

+Press the MODE button to exit the Hz

minimum programming screen and enter

the total time programming screen. The

total time TOT-T icon will blink. The

currently selected time unit icon will be

displayed. The current total time setting