MICRO-ePUMP

World Precision Instruments i

CONTENTS

ABOUT THIS MANUAL ................................................................................................................... 1

INTRODUCTION .............................................................................................................................. 1

Features....................................................................................................................................... 2

Benets........................................................................................................................................ 2

Applications................................................................................................................................ 2

Notes and Warnings................................................................................................................. 3

Parts List...................................................................................................................................... 3

Unpacking................................................................................................................................... 3

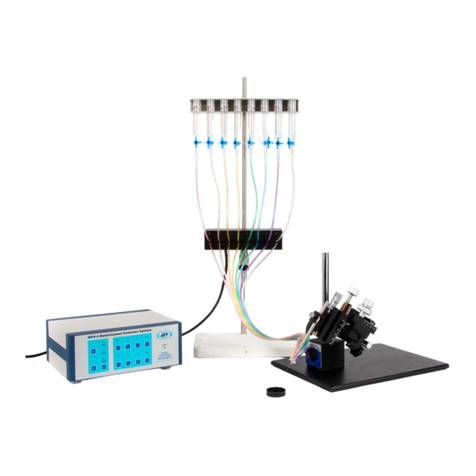

INSTRUMENT DESCRIPTION ........................................................................................................ 4

Front Panel ................................................................................................................................. 4

Rear Panel................................................................................................................................... 5

Foot Switch ................................................................................................................................. 6

Touch Panel Display ................................................................................................................. 6

Setting Menu.............................................................................................................................. 7

Setup............................................................................................................................................ 8

OPERATING INSTRUCTIONS.......................................................................................................12

Saving a Protocol.....................................................................................................................15

Loading a Protocol..................................................................................................................15

Changing the Pipette..............................................................................................................16

TECHNIQUES IN MICROINJECTION...........................................................................................16

Setting the Compensation Pressure ..................................................................................16

Manufacturing Micropipettes ..............................................................................................18

Calibrating Volume by Measuring Droplet........................................................................18

Calibrating Rate using a Known Volume ...........................................................................19

Multibarrel Microinjection ....................................................................................................20

MAINTENANCE ..............................................................................................................................21

Cleaning.....................................................................................................................................21

ACCESSORIES.................................................................................................................................21

Replacement Parts .................................................................................................................21

TROUBLESHOOTING ...................................................................................................................22

SPECIFICATIONS............................................................................................................................23

APPENDIX A: DROPLET VOLUME..............................................................................................24

Volume of a Micropipette .....................................................................................................24

BIBLIOGRAPHY..............................................................................................................................25

INDEX...............................................................................................................................................26

WARRANTY .....................................................................................................................................27

Claims and Returns ................................................................................................................27

Repairs.......................................................................................................................................27

Copyright © 2020 by World Precision Instruments. All rights reserved. No part of this publication may

be reproduced or translated into any language, in any form, without prior written permission of World

Precision Instruments, Inc.