8

• BlueBirdoriginalspare parts aredesignedand

specifiedtomaintain highqualityand correctfit

for optimal durability and life-span. From a

safety point of view, you should only use

BlueBird original spare parts.

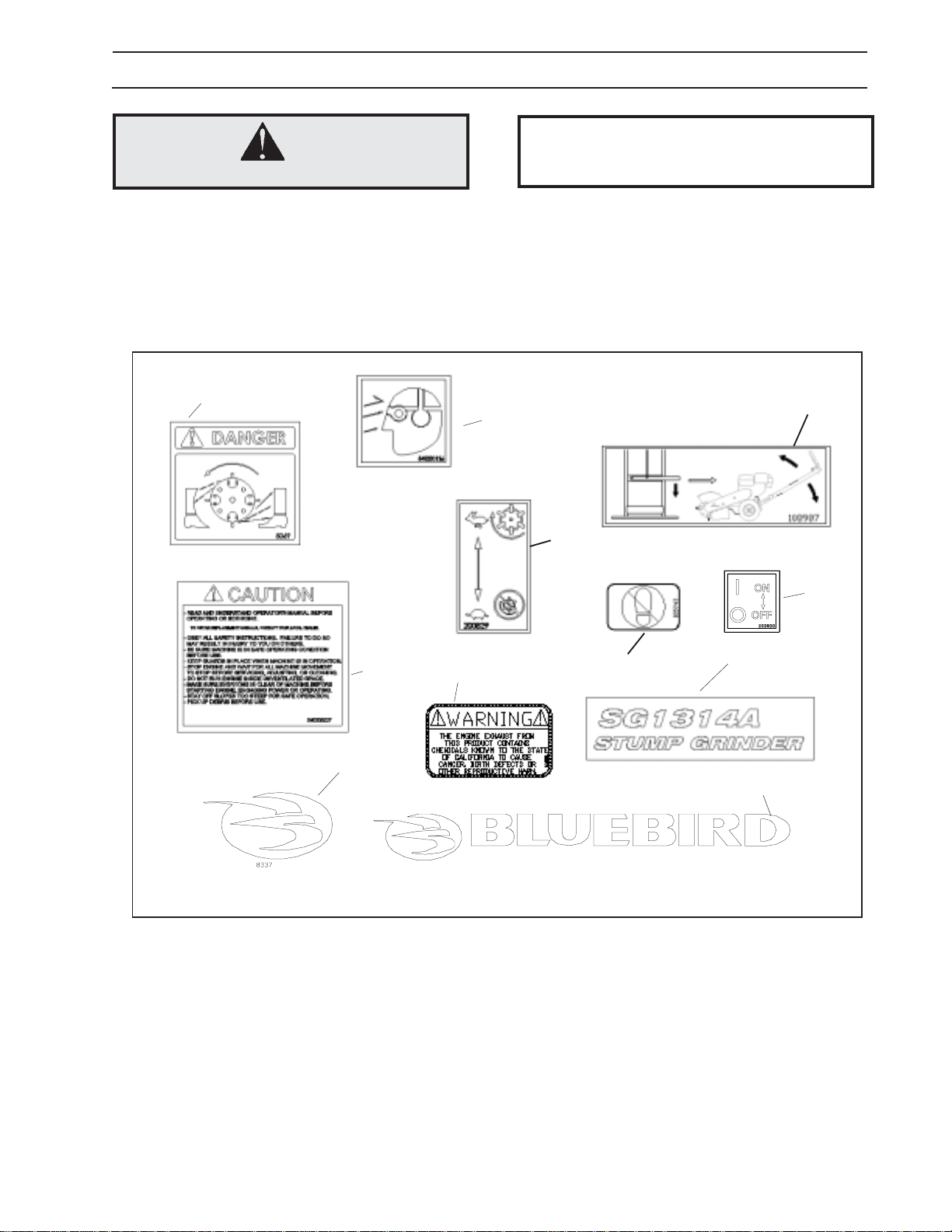

•Learn how to use the machine and its controls

safelyandlearn torecognize thesafetydecals.

•Onlyusethemachinefor removingtreestumps.

It is not intended for any other use.

• Check that the machine is in serviceable

condition prior to use; see the chapter

”Maintenance/Maintenanceschedule”.

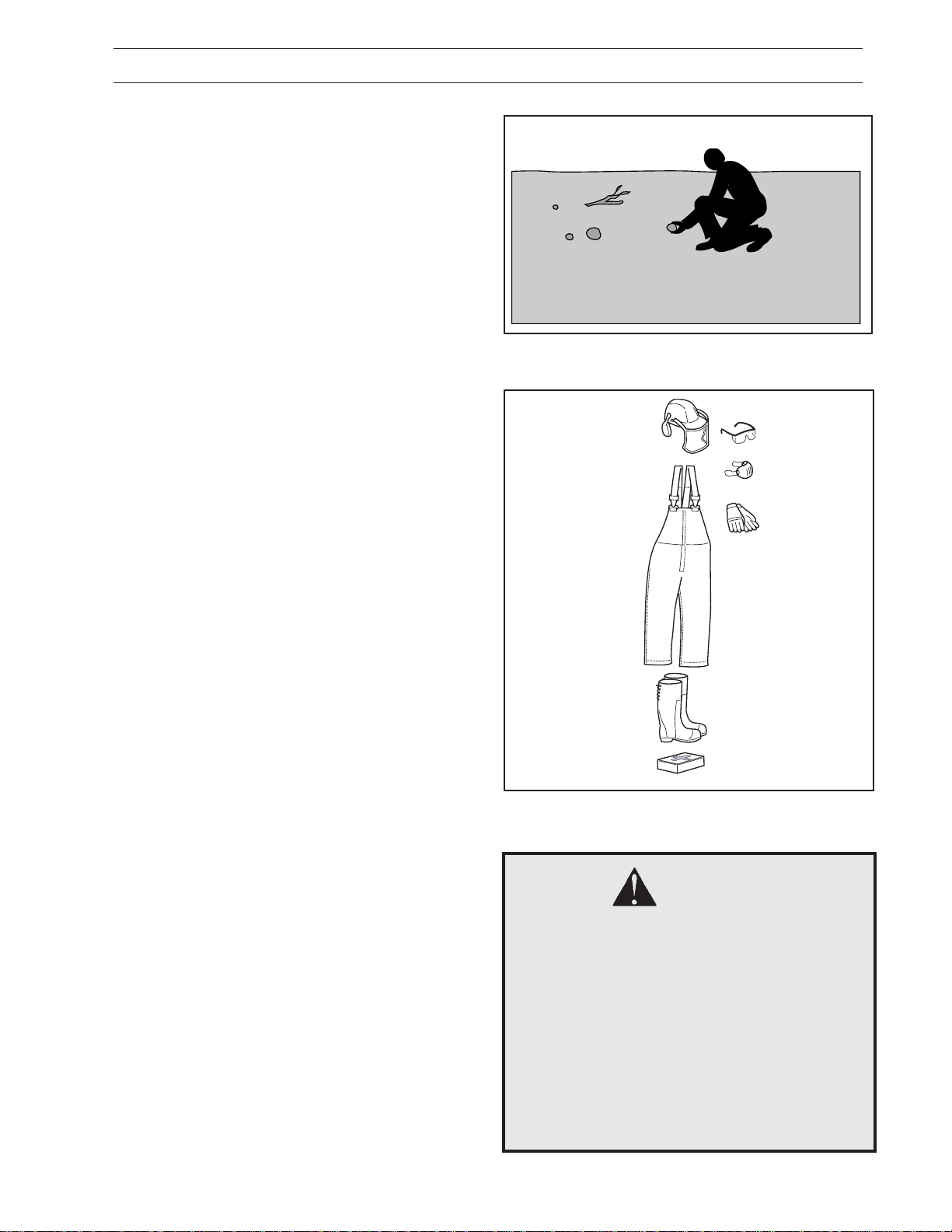

• Onlyusethemachine indaylightor inotherwell-

litconditions. Keepthe machineasafedistance

from holes or other irregularities in the ground.

Pay attention to other possible risks.

• Only allow the machine to be used by adults

who are familiar with its use.

• Follow all safety instructions. Failure to do so

may result in injury to yourself or others.

• Accidentprevention regulations,othergeneral

safety regulations, occupational safety rules

andtrafficregulationsmustbefollowedwithout

fail.

• Allusersshallbetrainedinuseof themachine.

The owner is responsible for training users.

• Engage an authorized BlueBird workshop for

all service and repairs not described in this

manual.

• Never allow children or persons not trained in

the use of the machine to use or service it.

Local laws may regulate the age of the user.

• People and animals can distract you causing

you to lose control of the machine. For this

reason, you should always concentrate and

focus on the task at hand.

• Neverleave themachine unsupervisedwith the

enginerunning.

• Make sure that other people are nearby when

you are using the machine so that you can call

for help should an emergency arise.

• The machine is tested and approved only with

the equipment originally provided or

recommended by the manufacturer.

Overexposure to vibration may lead to

circulatory or nerve damage, particularly

in people who have impaired circulation.

Contact your doctor if you experience

symptoms that could have been caused

by overexposure to vibration. Examples

ofcommonsymptomsincludenumbness,

pain, muscle weakness, change of skin

color or an uncomfortable feeling of

tingling. These symptoms appear most

frequently in the fingers, hands or wrists.

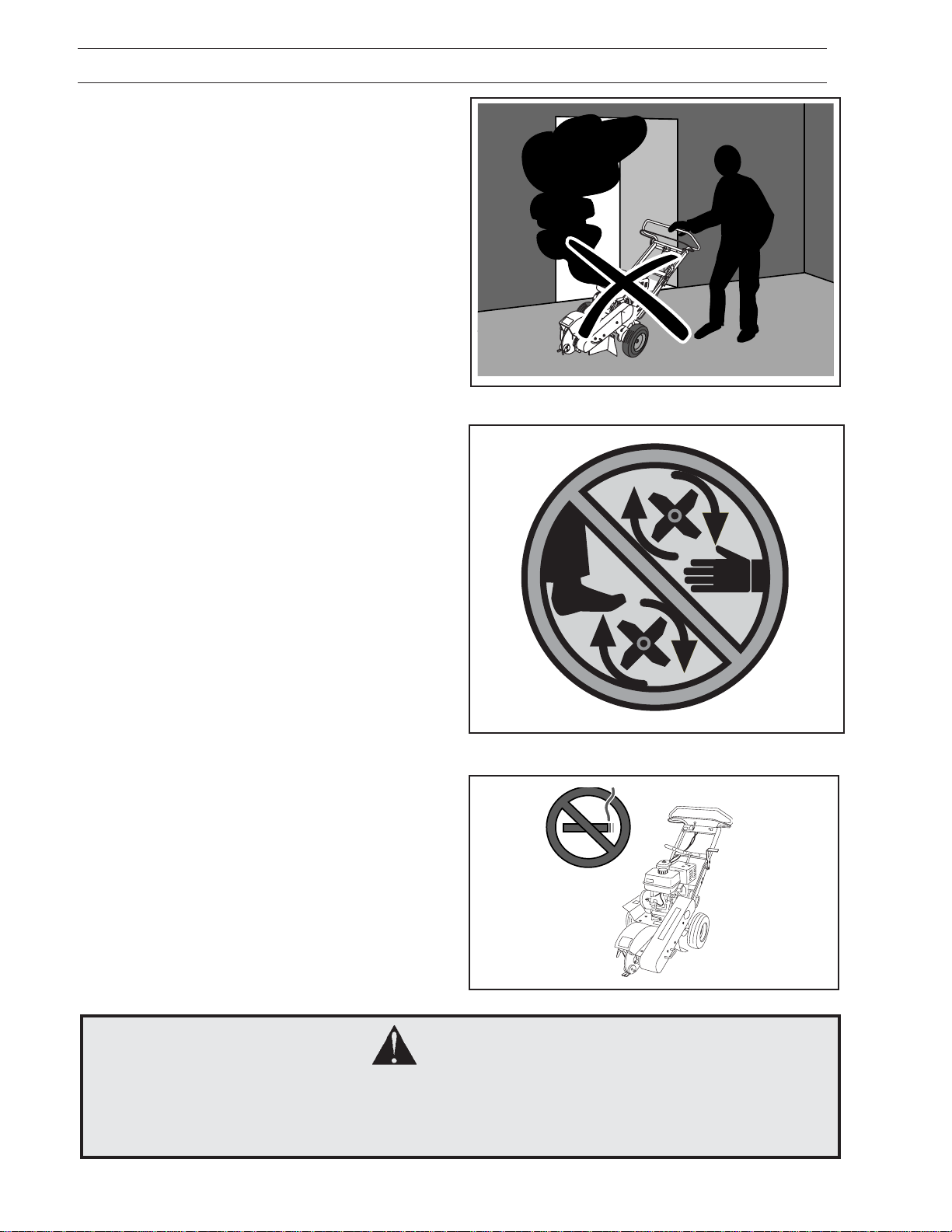

WARNING!

The engine can become very hot. To

avoid being burned, you must turn off the

engine and wait until all parts have

cooled before touching the engine.

WARNING!

IMPORTANT INFORMATION

Never use a stump grinder that is

damaged or incorrectly adjusted. Never

use the stump grinder if any component

is missing or if it is not properly

assembled. Check that the cutting tools

stop rotating when you reduce the throttle.

If you find yourself in a situation where you

are not sure what to do, always seek

expert assistance. DO NOT try to attack

any problem you are not qualified to

resolve.

SAFETY INSTRUCTIONS