BluePoint Fasteners NN-178 User manual

01

Instruction

Manual

NITRO NINJA

FASTENING

TOOL

NN-178

WARNING!

DO NOT OPERATE THE TOOL UNTIL YOU HAVE READ THIS

TOOL TRAINING MANUAL.

READING AND FOLLOWING THIS INSTRUCTION MANUAL CAN HELP

AVOID SERIOUS INJURY OR DEATH.

NITRO NINJA TOOL IS TO BE OPERATED ONLY AFTER YOU HAVE THOROUGHLY

READ THIS MANUAL AND UNDERSTOOD THE OPERATION AND SAFELTY

REQUIREMENTS. PER ANSI A10.3 & DOT EX2019072001, NITRO NINJA TOOLS

AND FASTENERS ARE NOT CLASSIFIED AS POWDER ACTUATED, THUS NO

LICENSING REQUIRED. PLEASE CONTACT YOUR LOCAL DISTRIBUTOR, OR VISIT

www.bpfasteners.com FOR MORE INFORMATION.

WARNING!

PRIOR TO OPERATING THE NITRO NINJA TOOL, PLEASE STUDY THIS MANUAL

CAREFULLY AND DEVELOP A THOROUGH UNDERSTANDING OF THE SAFETY

REQUIREMENTS.

LAWS, REGUATIONS, AND STANDARDS REGARDING THE USE OF SUCH TOOLS MAY

PERIODICALLY BE REVISED WITHOUT NOTICE. ANY SUCH REVISIONS MAY CHANGE

THE SAFETY AND OPERATING PROCEDURES DESCRIBED IN THIS MANUAL. BLUEPOINT

FASTENERS IS NOT RESPONSIBLE FOR ANY SUCH REVISIONS WHICH OCCUR AFTER

PUBLICATION OF THIS MANUAL. IT IS THE RESPONSIBILITY OF THE USER TO

MAINTAIN ALL KNOWLEDGE OF THE LAWS, REGULATIONS, AND STANDARDS THAT

APPLY TO POWDER ACTUATED TOOLS.

WARRANTY

Bluepoint warranty assures that the supplied tool is free of defects in workmanship

or material. Validity of this warranty is applied as long as the tool is handled and

operated correctly, serviced and cleaned properly in accordance with the Bluepoint

Instruction Manual and only if original Bluepoint components, consumables and

spare parts or other equivalent quality products are used. Parts requiring

replacement or repairs as a result of normal wear and tear are not covered under this

warranty.

All warranties or products described herein, expressed or implied, including the

warranties of merchantability or fitness for a particular purpose, are specifically

excluded, with the following exceptions: Bluepoint Fasteners will repair or replace, at

its option, any tool, part or element holding that, within 90 days after the sale, only if

Bluepoint is found to be responsible for a defective part in material or workmanship,

excluding normal wear.

All additional claims are excluded, specifically, Bluepoint is not obligated for direct,

indirect, incidental or consequential damages, losses or expenses in connection with,

or by reason of, the use of, or inability to use the tool for any purpose.

THIS IS THE ONLY WARRANTY AND REMEDY BLUEPOINT HAS AVAILABLE AND

IS IN NO EVENT LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, OR ANY OTHER DAMAGES.

THE WARRANTY DOES NOT APPLY UNTIL BLUEPOINT FASTENERS RECEIVES A

COPY OF YOUR RECEIPT WHEN THE TOOL WAS PURCHASED.

02

DANGER!

TO AVOID SERIOUS INJURY OR DEATH:

NEVER PLACE YOUR HAND AT THE END OF THE BARREL OF THE NITRO NINJA TOOL.

OPERATORS AND BYSTANDERS AROUND THE TOOL BEING USED MUST USE EYE AND

EAR PROTECTION. ALWAYS ASSUME THAT THE TOOL IS LOADED WITH A NITRO NINJA

FASTENER. IT IS VERY IMPORTANT THAT THE OPERATOR OF THIS NITRO NINJA TOOL

READS AND UNDERSTANDS THE ENTIRE MANUAL.

NEVER OPERATING THE TOOL WITHOUT ASSEMBLING THE SPALL GUARD.

Always keep this instruction manual together with the tool and ensure that

they are handed over together to any other operator.

General information

Explanation of Terminology

WARNING

The word WARNING is used to

emphasize a potentially

dangerous situation which could

lead to severe personal injury or

death.

CAUTION

The word CAUTION is used to

emphasize a potentially dangerous

situation which could lead to minor

personal injury or damage to the

equipment or other property.

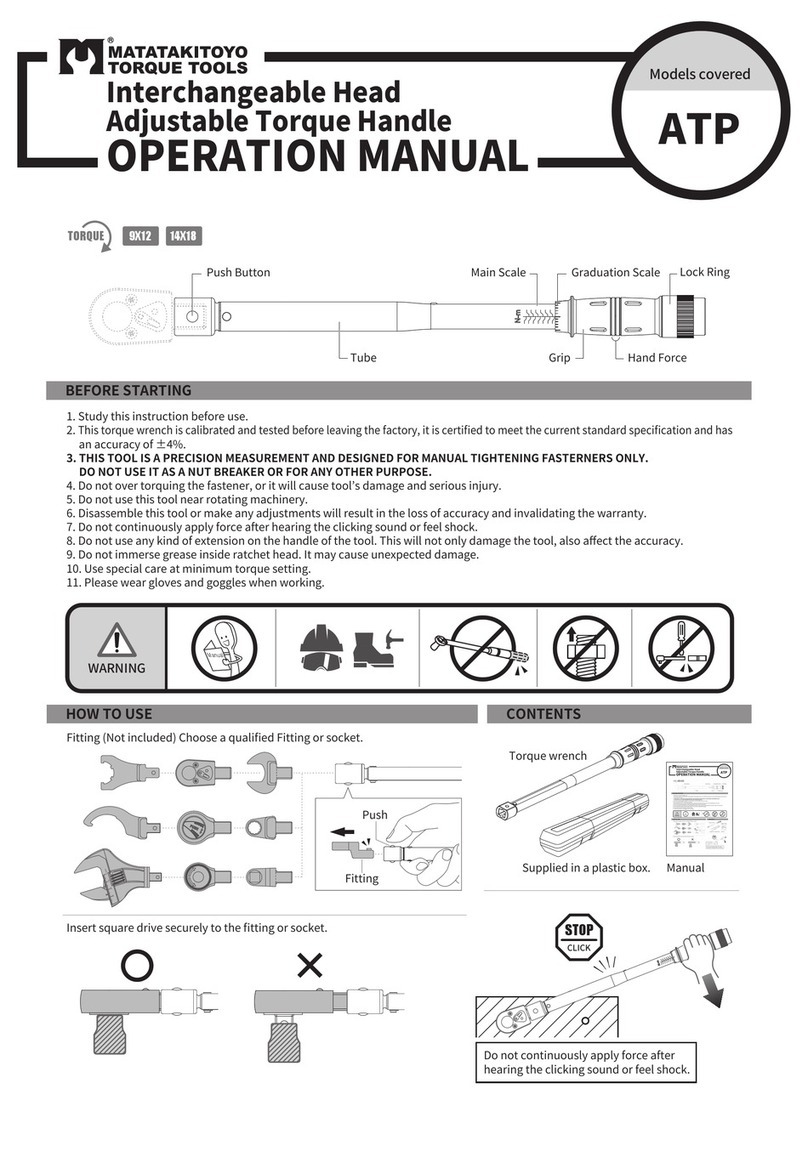

Graphic Symbols

GENERAL INFORMATION

General Warning

Read Instructions Before

Use

Use Safety Helmet

Use Eye Protection

Use Ear Protection

WARNING! Hot Surface

03

Ensure that the correct

combination of Barrel and

fasteners are used.

Check and replace the worn-

out parts if necessary.

Clean all the parts of the tool.

If the problem persists, DO

NOT use the tool . Have the

tool checked / repaired by a

Bluepoint professional.

SAFETY PRECAUTION

Do not straighten your arms while

firing the tool. Keep them flexed.

Never leave the loaded tool

unattended.

Ensure that the tool is not loaded

before servicing, cleaning or

replacing parts and before storing it.

Always Nitro Ninja Fasteners and

unused tools unloaded, in a dry

location, and in a high or locked

place, out of children’s reach.

6. Temperature

Do not dismantle the tool when it is

hot.

Never exceed the recommended

maximum fastener driving rate. (500

fastenings / hour).

7. Requirements to be met by users

(Pre-requisites for users)

Only authorized, trained

professionals should operate,

service, and repair the tool. The

professional must be informed of

any special hazards that may be

encountered.

Operate the tool only if your full

attention is on the job.

Do not use the tool if you feel

unwell.

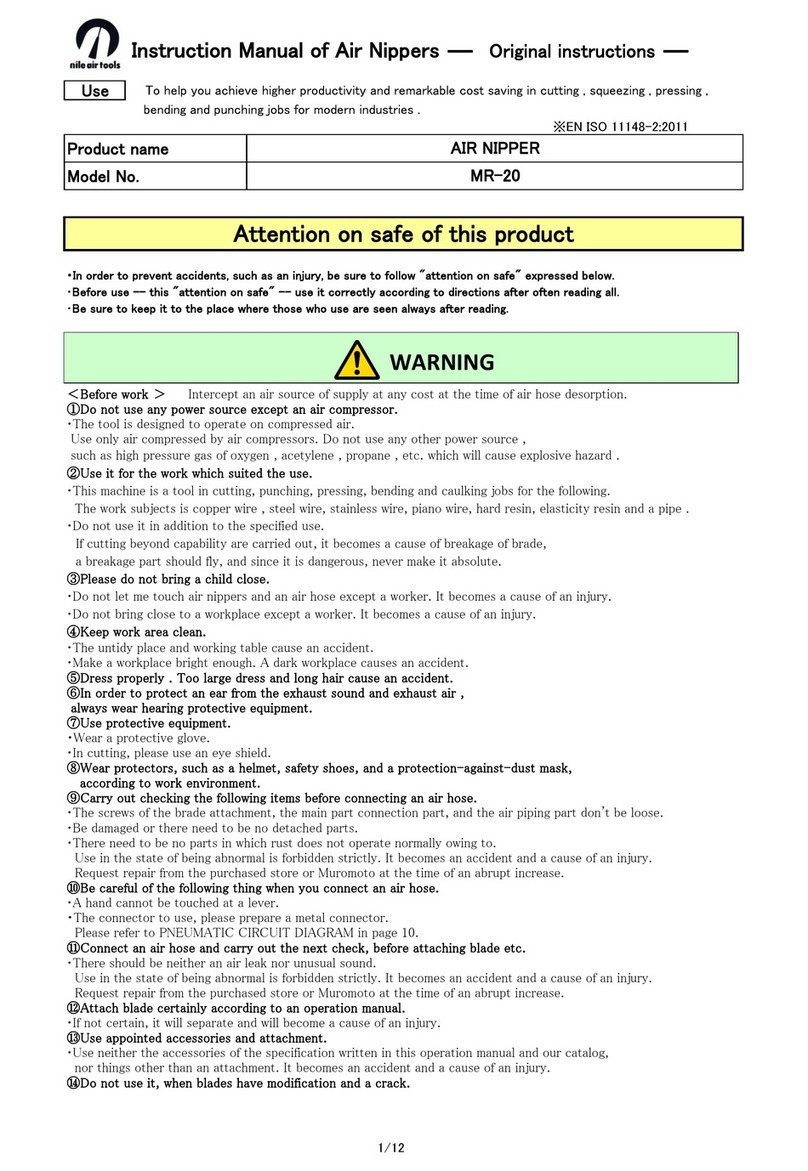

8. Personal Protective Equipment

(PPE)

The operator and all other

bystanders must always wear eye

and ear protection and a hard hat.

Prior to use

9. Read the Instruction Manual

carefully.

10. Inspection of tool

Ensure that the tool is not loaded.

Routinely check the tool for damage

and ensure that all controls operate

properly.

11. Selection of the correct Barrel /

fasteners combination

Using the wrong combination may

result in damage to the tool and / or

affect fastening quality.

0504

1. General Safety Instructions

The following points must be

strictly observed at all times, in

addition to the specific safety

precautions listed in the individual

sections.

2. Use as recommended

The tool is designed for use only by

professionals in the construction

industry for fastening applications

where drive pins or composite

fasteners are driven into steel,

concrete or sand-lime block

masonry.

3. Inappropriate use

Modification or manipulation of the

tool is not permitted.

Unless the tool is approved for such

use, it should not be used in a

flammable or an explosive

environment.

Use only BLUEPOINT fasteners,

accessories or spare parts of

equivalent quality to avoid risk of

injury.

Strictly follow the instructions for

operation, care and maintenance

given in the Instruction Manual.

The tool should never be pointed at

self or any bystander.

The muzzle of the tool should never

be pressed against a hand or any

body part.

The nails are NOT to be driven into

materials such as marble, natural

rock, glass, copper, brass, bonze,

plastic, insulation materials,

hollow brick, glazed tile, thin sheet

metal (<4 mm), grey cast iron,

spheroidal cast iron or gas

concrete.

The tool and its accessories may be

hazardous if used improperly by an

unauthorized person.

4. Workplace safety

Avoid unergonomic body postures.

Hazardous objects should be

removed from the work area.

Other bystanders, particularly

children, should not be allowed in

the work area.

Make sure nobody is behind or

below the point where the fastener

is to be driven.

The tool grip should always be kept

free of oil or grease.

5. Basic safety precautions

Operate the tool only in good

condition and only as directed.

Use the spall guard when required.

If the Nitro Ninja Fasteners fails to

ignite or misfires, please do the

following:

Hold the tool pressed against

the working surface for 30

seconds.

If the Nitro Ninja Fasteners still

fails to fire, withdraw the tool

from the working surface

making sure it is not pointed

towards anybody or yourself.

Then carefully open the tool,

remove the Nitro Ninja

Fasteners and put it in a can of

water or other non-flammable

liquid. Never discard the Nitro

Ninja Fasteners into a

dumpster.

If 2-3 Nitro Ninja Fasteners misfire

in succession (without making any

audible firing noise and if the

fastener is driven with significantly

less force), do the following:

Immediately STOP using the

tool.

Dismantle the tool.

SAFETY PRECAUTION

Safety at Work

1. Operators and bystanders must always

wear approved ear and eye protection.

Failure to do so can cause blindness or

serious eye injury from debris, and

hearing loss from exposure to constant

or repeated noise from the fastening

tool.

2. Keep the work area clear of

unnecessary materials and bystanders

that may interfere with the safe

operation of the tool. Operating tool in

a congested or disorganized area may

affect the ability to operate safely.

3. Never operate the tool when explosive

or inflammable materials are close.

Nitro Ninja may create sparks when

fired and could ignite these materials or

vapors.

Center Punch Test

MUST WEAR EYE

PROTECTION WHILE

PERFORMING THIS TEST.

1. Always check the hardness of the

base where you want to fasten.

2. Using a fastener as a center punch,

strike the fastener with a hammer

against the work surface and check

the results.

Center Punch Test Result

1. The material is too hard for a Nitro

Ninja fastening, if the fastener point is

flattened.

2. The material is too soft, if the fastener

easily penetrates it.

3. The material is too fragile, if the

material cracks or shatters.

4. The material is suitable for Nitro Ninja

fastening, if the fastener causes a small

indentation in the material.

07

PREPARATION

06

Suitable Base Materials:

Only the following materials are suitable

for Powder-actuated fastening:

Structural Steel

Masonry Joints

Poured Concrete

Sinter Block

DO NOT try to fasten into any other

type of materials. It can cause serious

injury or blindness.

Unsuitable Base materials that should

not be fastened to:

Never try to fasten into very hard or

brittle materials such as tile, glass, cast

iron or rocks of any kind. These

materials can break, or shatter causing

spall and may cause serious injury to the

tool operator and the bystanders.

Never try to fasten into brittle

materials.

Never fasten directly to a base

material easily penetrated like

wood or gypsum board. These

types of materials may cause the

fasteners to penetrate through to the

other side making it dangerous for

other people in the work area.

Never fasten into a base material

that fails the center punch test.

Failure to check the suitability of the

base material can cause serious

injury to the eyes or other body parts.

Never fasten directly to a base

material easily penetrated like

wood or gypsum board.

09

FAILURE TO FOLLOW THESE

INSTRUCTIONS CAN RESULT IN INJURY TO

THE TOOL OPERATOR OR BYSTANDERS

MISFIRE PROCEDURE

If the tool does not fire after pressing

the tool, continue to hold the

depressed tool against the work

surface for at least 30 seconds. Then

carefully open the tool, remove the

Nitro Ninja Fasteners and put it in a can

of water or other non-flammable liquid.

Never discard the Nitro Ninja Fasteners

into a dumpster.

If the tool becomes stuck or jammed

with a Nitro Ninja Fastener, point the

tool in a safe direction and label it

immediately with “DANGER – DO NOT

USE – DEFECTIVE”.Lock the tool in a box

and contact your local dealer for

assistance from BLUEPOINT.

ALWAYS FOLLOW THE

MISFIRE PROCEDURE.

FASTENER DRIVING SAFETY

1. Use this tool ONLY to fasten into a

recommended base material.

2. DO NOT fire the tool without a

fastener.

3. Always use the tool firmly and

perpendicular to the work

surface and keep your hand

flexed before firing. Otherwise

the fastener may ricochet

causing injury.

4. Never drive a fastener close to

the edge of the base material.

See installation page.

08

SAFE HANDLING OF TOOLS

1. Always make sure that the tool is

working properly before use.

Follow the ‘Daily Function Test’ on

shown on page 11.

2. Never load a tool unless you

intend to use it immediately.

Unattended loaded tool in the

workplace may result in its

accidental discharge by others.

4. Never point the tool at yourself or

others.

5. Never carry a loaded tool around

the work area.

6. Never allow anyone not trained to

use the tool.

7. Never play with the tool.

3. Never place your hands or any

other body part on the tool

muzzle. It can cause serious injury

from the fastener if the tool is fired

accidently.

SAFETY PRECAUTION

Tool operators and bystanders

must wear ear and eye protection.

Read the manual thoroughly before

operating the tool.

Never keep a hand over fastener

loading end of the tool. A serious

hand injury may occur from

penetration by a discharged

fastener.

NN-178 IS NOT A STAND-ALONE TOOL.

IT MUST BE USED WITH A HANDLE OR MOUNTED ON A BLUE POINT POLE.

10

FASTENING APPLICATIONS

Your BLUEPOINT tool can be used for a

wide range of fastening needs in a

variety of base materials. Reading and

following these important fastening

guidelines will help you get the best

results from your tool and fasteners, as

well as help you perform these fastening

operations safely and effectively.

Nitro Ninja fastenings are permanent

fastening so attempting to remove a

fastener from concrete or steel may

result in serious injury.

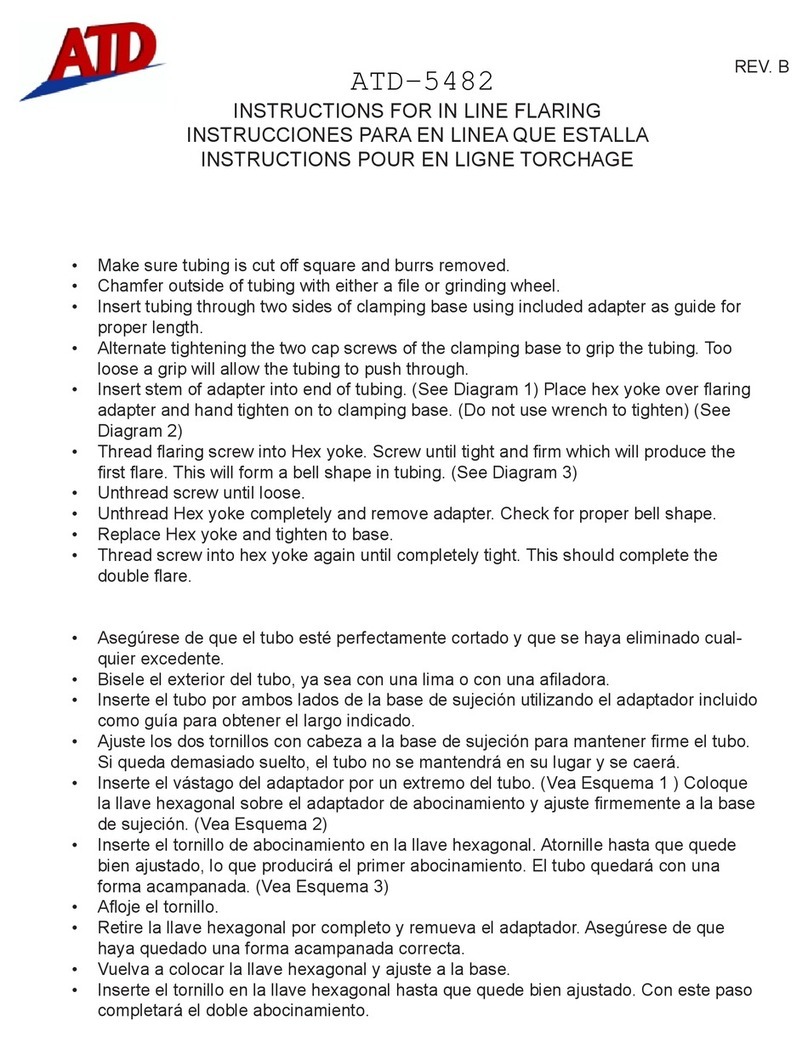

Fastening to Steel

Your BLUEPOINT tool can be used for

fastening on the flat surfaces of

structural steel. When fastening into

steel, always maintain a minimum

spacing of 1-1/2”between fastenings

and 1/2”from any edge.

SPACING IN STEEL

Fastening to Concrete

When fastening into concrete, always

maintain a minimum spacing of 3”

between fastenings and 3”from any

free edge. Concrete thickness should be

at least three times the intended

penetration depth into the concrete.

Driving fasteners too close to an edge or

too close to each other can cause the

concrete edge to fail or fasteners to fly

free.

SPACING —FASTENING INTO

CONCRETE

FASTENER LOCATIONS IN

LIGHTWEIGHT PAN DECK

FASTENER LOCATION IN PRECAST

CONCRETE

PENETRATION INTO CONCRETE

11

The Versatile Solution for Interior

Applications:

Nitro Ninja takes care of all your

wall, floor or ceiling needs.

Its fasteners range covers all

electrical, mechanical, acoustical and

interior trades.

The sleek design of the tool

combined with its light weight

provides easy access for overhead

applications, thereby increasing

productivity and being cost effective.

FEATURES

NITRO NINJA is excellent for hard concrete and it has a good holding values

into normal concrete. It has shown a fastening success rate beyond 90%in

hard concrete. Its piston-free design reduces spalling.

INTRODUCTION

Safer for Operators and for the

Environment:

Nitro Ninja fasteners are safer to use

in lead-free zones like hospitals,

schools, military bases or airports

because of their lead-free, non-toxic,

bio-degradable and primer-free

qualities.

As Nitro Ninja fasteners are brass-

free, they do not require any clean

up.

Nitro Ninja’s patented, vented tool

system makes it a very easy to use.

DAILY FUNCTION TEST

Always check the tool first to make

sure that it does not contain a Nitro

Ninja fastener.

Clear the barrel by pulling back the

Spall Guard to ensure it is free of any

debris and moves freely.

13

1. Screw the Spall Guard (Round), on

the Silencer and ensure that it is

flush.

2. Ensure that the Silencer is free of

any debris by resetting the tool

before each fastening.

a. Pull back the Silencer until reset pin

spring is fully compressed.

b. Prior to loading a new fastener

assembly, ensure that the firing pin

guide is clear of all debris.

3. Insert the fastener into the

nosepiece of the tool ensuring that

it is fully seated inside.

Caution: DO NOT force the fastener

into the barrel if it does not go in

easily, to avoid jamming of the tool.

Discard that fastener appropriately.

4. Place the Nitro Ninja tool

perpendicular (90°) to the fastening

surface.

5. Position the tool and push gently to

feel the engagement of the firing

spring and follow with a smooth

and forceful motion to trigger the

firing mechanism. This way it will

minimize spalling and noise.

INSTALLATION IN CONCRETE

HORIZONTAL:

Important: DO NOT BOUNCE FIRE THE

TOOL!

6. Reset the tool to ensure the barrel

is clear of debris and repeat Steps

(1) to (4).

7. Always use gloves while operating

this tool. The silencer and other

parts may be hot after operation.

12

1. Screw the Spall Guard with a cut,

on the barrel cap and ensure that it

is flush.

2. Ensure that the Silencer is free of

any debris by resetting the tool

before each fastening.

a. Pull back the Silencer until reset

spring is fully compressed.

b. Prior to loading a new fastener

assembly, ensure that the firing pin

guide is clear of all debris.

3. Insert the fastener into the barrel

of the tool ensuring that it is fully

seated inside.

Caution: DO NOT force the fastener

into the barrel if it does not go in

easily, to avoid jamming of the tool.

Discard that fastener appropriately.

INSTALLATION IN CONCRETE

OVERHEAD:

NEVER PLACE YOUR HANDS

OR ANY OTHER BODY PART

ON THE TOOL MUZZLE.

Important: DO NOT BOUNCE FIRE THE

TOOL!

6. Reset the tool to ensure the barrel

is clear of debris and repeat Steps

(1) to (4).

7. Always use gloves while operating

this tool. The Silencer and other

parts may be hot after operation.

5. Position the tool and push gently to

feel the engagement of the firing

spring and follow with a smooth

and forceful motion to trigger the

firing mechanism. This way it will

minimize spalling and noise.

4. Place the Nitro Ninja tool

perpendicular (90°) to the fastening

surface.

OPERATING INSTRUCTIONS

Please watch the videos on our website: http://bpfasteners.com/licensing/video

BLUEPOINT NN-178 - Disassembly: https://youtu.be/F_lUVvTcojQ

BLUEPOINT NN-178 - Assembly: https://youtu.be/z2ucIRYcvyo

NN-178 operation and maintenance is similar to NN-150.

15

NITRO NINJA FASTENERS

Your Nitro Ninja Tool uses only BLUEPOINT Nitro Ninja fasteners shown below or

listed for the tool in the Product Catalog.

NEVER USE ANY OTHER TYPES OF FASTENERS OR LOADS IN

THE NITRO NINJA TOOL. USE OF OTHER TYPES OF

FASTENERS OR LOADS MAY CAUSE UNINTENTIONAL LOAD

DISCHARGE, DAMAGE THE TOOL, CAUSE POOR FASTENING

PERFORMANCE, OR CREATE A RISK OF SERIOUS INJURY TO

THE OPERATOR OR BYSTANDERS.

FASTENERS FOR NITRO NINJA TOOLS

Nitro Ninja Pins

Pre-tied Wires with Nintro Ninja Pins

TECHNICAL SPECIFICATIONS

Nitro Ninja

Tool Length 430 mm

Tool Weight 3.75 lbs

Nitro Ninja Fasteners

Always perform the center punch test described on page 7 to test the base material.

14

BLUE POINT POLES FOR CEILING APPLICATIONS

NN-178 IS NOT A STAND-ALONE TOOL.

IT MUST BE USED WITH A HANDLE OR MOUNTED ON A BLUE POINT POLE.

16

NN-178

1 NN178-1

Spall Guard

11 NN178-11

Roll Pin

2 NN178-2

Heat Insulation Sleeve

12 NN178-12

Barrel Sleeve Cover

3 NN178-3

Silencer

13 NN178-13

Main Housing Spring

4 NN178-4

Barrel

14 NN178-14

Main Housing

5 NN178-5

Barrel Washer

15 NN178-15

Main Housing Pin

6 NN178-6

Firing Pin Guide

16 NN178-16

Outer Cover Sleeve

7 NN178-7

Firing Pin

17 NN178-17

Firing Pin Spring

8 NN178-8

Fire Pin holder

18 NN178-18

Firing Pin

Spring Holder

9 NN178-9

Reset Pin Spring

19 NN178-19

End Cap

10

NN178

-

10

Pawl

NN-178 NITRO NINJA TOOL SCHEMATIC

17

The fastener is

jammed inside

the tool.

DO NOT bang the tool against the substrate.

Remove the spall guard and remove the fastener.

If the problem continues:

Contact BLUEPOINT distributor.

Tool fails to fire. Reset the tool and clean the spall guard and barrel free

of debris.

Ensure that the substrate is appropriate.

Ensure that the tool is correctly assembled.

Ensure that the tool is held perpendicular to the

substrate while firing.

If the problem continues:

Disassemble to tool and replace broken parts, if any.

Tool fires loudly. Check if the substrate is appropriate.

Ensure that the tool is held perpendicular to the

substrate while firing.

Reset the tool and clean the spall guard and barrel free

of debris. Ensure that the vents in the barrel are clear.

Ensure the barrel and spall guard are fastened

securely.

The tool is hard

to depress. Disassemble, clean, lubricate and reassemble as per

the instruction manual.

Check if the springs are straight and clean.

Firing Pin Holder

and Guide are

damaged.

Disassemble the tool and ensure if the Firing Pin

Spring Holder is in place. It can damage the tool if it is

not.

Clean the debris from the main body of the tool.

PROBLEM POSSIBLE REMEDIES

TROUBLESHOOTING

Insert Firing Pin into Firing Pin Holder. Align the holes and insert Roll Pin in the holes.

Insert Reset Pin Spring and then Pawl into Holder. Pressing the Pawl, slide Firing Pin

Assembly in Firing Pin Guide, after aligning it with its slot, until it clicks. Insert Barrel

Sleeve Cover over it.

Insert Main Housing Spring and then Main Housing. Press the assembly from both

ends after aligning the longer slot of Firing Pin Guide, so that the Main Housing Pin

can be inserted across it. Slide Outer Cover Sleeve over the Main Housing.

Insert Firing Pin Spring, Firing Pin Spring Holder and screw End Cap onto Main

Housing.

Place Barrel Washer on the other end, insert Barrel and screw Silencer. Slide Heat

Insulation Sleeve and screw Spall Guard.

TOOL ASSEMBLY

19

TOOL DISAASEMBLY AND ASSEMBLY

Unscrew Spall Guard from Barrel. Remove Heat Insulation Sleeve, unscrew Silencer,

remove Barrel and Barrel Washer.

From the other side (rear end) unscrew End Cap, remove Firing Pin Spring Holder

and Firing Pin Spring from Main Housing. Slide Outer Cover Sleeve.

Press from both ends Main Housing and the Barrel Sleeve Cover to release the Main

Housing Pin. Remove the Main Housing and Main Housing Spring.

Press Pawl and pull out Firing Pin Assembly from Firing Pin Guide. Remove Pawl and

Reset Spring. Pull out Roll Pin and Firing Pin from the Firing Pin Holder and slide out

Firing Pin Guide from Barrel Sleeve Cover.

TOOL DISASSEMBLY

Please watch the videos on our website: http://bpfasteners.com/licensing/video

BLUEPOINT NN-178 - Disassembly: https://youtu.be/F_lUVvTcojQ

BLUEPOINT NN-178 - Assembly: https://youtu.be/z2ucIRYcvyo

NN-178 operation and maintenance is similar to NN-150.

18

NOTES

21

Tool Grip Assembly for NN-178

Screw the plastic grip onto the end cap of NN-178

Pole Extension Assembly with NN-178

Screw the extension pole onto the end cap of NN-178

TOOL GRIP DISAASEMBLY AND ASSEMBLY

20

NOTES

2322

NOTES

24

WARNING

14728 Yorba Court,

Chino, CA 91710 USA

Tel: 1-877-779-2583

www.bpfasteners.com

1. NN-178 is not a stand-alone tool.

It must be used with a handle or

mounted on a Blue Point pole.

2. Read the manual before using the

tool.

3. Never put your hand over the

barrel or compress with your

hand.

4. Never point the tool at yourself or

bystanders.

5. Only adults that are qualified, may

operate the NITRO NINJA tool.

6. Always unload the tool prior to

cleaning or maintenance.

7. Do not operate the tool in an

explosive or flammable

atmosphere.

8. When removing an unfired pin,

always keep the tool aimed away

from yourself and others.

SAFETY PRECAUTIONS

Table of contents

Other BluePoint Fasteners Tools manuals