BluePoint Fasteners BP-27C User manual

Instruction

Manual

BP-27C

WARNING!

DO NOT OPERATE THE TOOL UNTIL YOU HAVE READ THIS TOOL TRAINING

MANUAL AND EDUCATION HAS BEEN RECEIVED ACCORDING TO

ANSI STANDARD A 10.3-1995.

READING AND FOLLOWING THIS INSTRUCTION MANUAL CAN HELP

AVOID SERIOUS INJURY OR DEATH.

01

Always keep this instruction manual together with the tool and ensure that

they are handed over together to any other operator.

General information

Explanation of Terminology

WARNING

The word WARNING is used to

emphasize a potentially

dangerous situation which could

lead to severe personal injury or

death.

CAUTION

The word CAUTION is used to

emphasize a potentially dangerous

situation which could lead to minor

personal injury or damage to the

equipment or other property.

Graphic Symbols

GENERAL INFORMATION

DANGER! TO AVOID SERIOUS INJURY OR DEATH:

NEVER PLACE YOUR HAND AT THE END OF THE NOSE PIECE OF THE BP-27C TOOL.

OPERATORS AND BYSTANDERS AROUND THE TOOL BEING USED MUST USE EYE AND

EAR PROTECTION. ALWAYS ASSUME THAT THE TOOL IS LOADED WITH A LOAD.

NEVER PLACE YOUR FINGERS ON THE NOSE PIECE OF THE LOADED OR UNLOADED

TOOL UNTIL THE TOOL NOSE PIECE IS AGAINST THE WORK BASE AND YOU ARE READY

TO DO A FASTENING. IF THE TOOL ACCIDENTALLY SHOOTS HIS/HER HAND OR ANY

PART OF THE BODY, THE PISTON CAN ENTER THE BODY AND CAUSE SERIOUS INJURY

OR DEATH. IT IS VERY IMPORTANT THAT THE OPERATOR OF THIS BP-27C TOOL READS

AND UNDERSTANDS THE ENTIRE MANUAL AND COMPLETES THE OPERATORS EXAM

WITH A 100% GRADE. THE WARRANTY DOES NOT APPLY UNTIL BLUEPOINT

FASTENERS RECEIVES A COPY OF OPERATORS EXAM AND A COPY OF YOUR RECEIPT

WHEN THE TOOL WAS PURCHASED.

General Warning

Read Instructions Before

Use

Use Safety Helmet

Use Eye Protection

Use Ear Protection

WARNING! Hot Surface

03

PRIOR TO OPERATING THE BP-27C TOOL, PLEASE STUDY THIS MANUAL CAREFULLY

AND DEVELOP A THOROUGH UNDERSTANDING OF THE CONTENTS. PROPER

TRAINING ACCORDING TO THE CURRENT ANSI STANDARD A 10.3, SAFETY

REQUIREMENTS FOR POWDER ACTUATED FASTENING SYSTEMS MUST BE

COMPLETED AND A BLUEPOINT FASTENERS QUALIFIED OPERATOR CARD MUST BE

OBTAINED PRIOR TO OPERATION OF THE TOOL. STATE, LOCAL, OR OTHER

REGULATIONS SHOULD ALSO BE FOLLOWED. LAWS, REGUATIONS, AND STANDARDS

REGARDING THE USE OF POWDER ACTUATED TOOLS MAY PERIODICALLY BE REVISED

WITHOUT NOTICE. ANY SUCH REVISIONS MAY CHANGE THE SAFETY AND OPERATING

PROCEDURES DESCRIBED IN THIS MANUAL. BLUEPOINT FASTENERS IS NOT

RESPONSIBLE FOR ANY SUCH REVISIONS WHICH OCCUR AFTER PUBLICATION OF THIS

MANUAL. IT IS THE RESPONSIBILITY OF THE USER TO MAINTAIN ALL KNOWLEDGE OF

THE LAWS, REGULATIONS, AND STANDARDS THAT APPLY TO POWDER ACTUATED

TOOLS.

WARNING!

BP-27C TOOL IS TO BE USED ONLY BY LICENSED OPERATORS. YOU MUST HAVE

A LICENSE BEFORE OPERATING IT. YOU MAY COMPLETE THE ENCLOSED EXAM

SUCCESSFULLY AND RETURN IT TO GET A TOOL OPERATOR’S CARD THAT WILL

BE ISSUED TO YOU, AND ALSO ACTIVATE YOUR WARRANTY. OPERATOR’S

LICENSE CAN ALSO BE OBTAINED DIRECTLY AT:www.bpfasteners.com

WARRANTY

Bluepoint warranty assures that the supplied tool is free of defects in workmanship

or material. Validity of this warranty is applied as long as the tool is handled and

operated correctly, serviced and cleaned properly in accordance with the Bluepoint

Instruction Manual and only if original Bluepoint components, consumables and

spare parts or other equivalent quality products are used. Parts requiring

replacement or repairs as a result of normal wear and tear are not covered under this

warranty.

All warranties or products described herein, expressed or implied, including the

warranties of merchantability or fitness for a particular purpose, are specifically

excluded, with the following exceptions: Bluepoint Fasteners will repair or replace, at

its option, any tool, part or element holding that, within 90 days after the sale, only if

Bluepoint is found to be responsible for a defective part in material or workmanship,

excluding normal wear.

All additional claims are excluded, specifically, Bluepoint is not obligated for direct,

indirect, incidental or consequential damages, losses or expenses in connection with,

or by reason of, the use of, or inability to use the tool for any purpose.

THIS IS THE ONLY WARRANTY AND REMEDY BLUEPOINT HAS AVAILABLE AND

IS IN NO EVENT LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, OR ANY OTHER DAMAGES.

02

Ensure that the correct

combination of piston,

fastener guide, and fasteners

are used.

Check the piston, nose piece

and the strip load and replace

the worn-out parts if

necessary.

Clean all the parts of the tool.

If the problem persists, DO

NOT use the tool . Have the

tool checked / repaired by a

Bluepoint professional.

SAFETY PRECAUTION

Never try to pry a cartridge from the

magazine strip or the tool.

Do not straighten your arms while

firing the tool. Keep them flexed.

Never leave the loaded tool

unattended.

Ensure that the tool is not loaded

before servicing, cleaning or

replacing parts and before storing it.

Always store cartridges and unused

tools unloaded, in a dry location,

and in a high or locked place, out of

children’s reach.

6. Temperature

Do not dismantle the tool when it is

hot.

Never exceed the recommended

maximum fastener driving rate. (700

fastenings / hour).

Stop if the plastic cartridge strip

melts. Allow the tool to cool down.

7. Requirements to be met by users

(Pre-requisites for users)

Only authorized, trained

professionals should operate,

service, and repair the tool. The

professional must be informed of

any special hazards that may be

encountered.

Operate the tool only if your full

attention is on the job.

Do not use the tool if you feel

unwell.

8. Personal Protective Equipment

(PPE)

The operator and all other

bystanders must always wear eye

and ear protection and a hard hat.

Prior to use

9. Read the Instruction Manual

carefully.

10. Inspection of tool

Ensure that the tool is not loaded.

Routinely check the tool for damage

and ensure that all controls operate

properly.

Check the buffer and piston for wear

(see table on last page of these

instructions).

11. Selection of the correct nose piece

/ piston / fastener combination

Using the wrong combination may

result in damage to the tool and / or

affect fastening quality.

05

1. General Safety Instructions

The following points must be

strictly observed at all times, in

addition to the specific safety

precautions listed in the individual

sections.

2. Use as recommended

The tool is designed for use only by

professionals in the construction

industry for fastening applications

where fasteners or composite

fasteners are driven into steel,

concrete.

3. Inappropriate use

Modification or manipulation of the

tool is not permitted.

Unless the tool is approved for such

use, it should not be used in a

flammable or an explosive

environment.

Use only BLUEPOINT fasteners,

cartridges, accessories or spare

parts of equivalent quality to avoid

risk of injury.

Strictly follow the instructions for

operation, care and maintenance

given in the Instruction Manual.

The tool should never be pointed at

self or any bystander.

The muzzle of the tool should never

be pressed against a hand or any

body part.

The nails are NOT to be driven into

materials such as marble, natural

rock, glass, copper, brass, bonze,

plastic, insulation materials, hollow

brick, glazed tile, thin sheet metal

(<4 mm), grey cast iron, spheroidal

cast iron or gas concrete.

The tool and its accessories may be

hazardous if used improperly by an

unauthorized person.

4. Workplace safety

Avoid unergonomic body postures.

Hazardous objects should be

removed from the work area.

The tool is only for hand-held use.

Other bystanders, particularly

children, should not be allowed in

the work area.

Make sure nobody is behind or

below the point where the fastener

is to be driven.

The tool grip should always be kept

free of oil or grease.

5. Basic safety precautions

Operate the tool only in good

condition and only as directed.

Use the spall guard / stabilizer

when required.

If the cartridge fails to ignite or

misfires, please do the following:

Hold the tool pressed against

the working surface for 30

seconds.

If the cartridge still fails to fire,

withdraw the tool from the

working surface making sure it

is not pointed towards

anybody or yourself.

Manually advance by one

cartridge and use the

remaining cartridges on the

strip.

If 2-3 cartridges misfire in

succession (without making any

audible firing noise and if the

fastener is driven with significantly

less force), do the following:

Immediately STOP using the

tool.

Dismantle the tool.

SAFETY PRECAUTION

04

SAFETY PRECAUTION

06

1. Always check the tool first to

ensure that it does not contain a

strip or a fastener.

DAILY FUNCTION TEST

Tool operators and bystanders

must wear ear and eye protection.

Read the manual thoroughly before

operating the tool.

Never keep a hand over fastener

loading end of the tool. A serious

hand injury may occur from

penetration by the piston or a

discharged fastener.

2. Try the tool by depressing the nose

piece, barrel and firing pin spring

completely on a hard surface. You

should hear an audible clicking

sound. Let up on the tool and make

sure the barrel is open to

semi-open position.

SAFE HANDLING OF TOOLS

07

5. Never place your hands or any

other body part on the loading

end of the tool. It can cause serious

injury by the fastener or piston if

the tool is fired accidently.

7. Never point the tool at yourself or

others.

8. Never carry a loaded tool around

or play with the tool.

9. Never allow untrained persons to

operate the tool.

10. Using or cleaning tools, or

handling loads in poorly ventilated

areas may result in exposure to

lead and other substances known

to cause birth defects and physical

changes. Always ensure adequate

ventilation at all times and wash

thoroughly after exposure.

6. Always unload the tool and store

it along with the loads safely

locked in a toolbox.Keep the keys

away from children and

unauthorized persons.

1. Always make sure that the tool is

working properly before use.

Follow the Daily Function Test.

2. Always use certified BLUE POINT

loads from a box indicating the

type of load, power and number.

Never attempt to use unknown

power loads.

3. DO NOT carry loads in pockets

with loose pins or other objects.

Doing so may cause the load to fire.

4. DO NOT load a tool unless you

intend to use it immediately.

Unattended loaded tool in the

workplace may result in its

accidental discharge by others.

BP-27C IS NOT A STAND-ALONE TOOL.

IT MUST ALWAYS BE USED MOUNTED ON A BLUE POINT POLE.

Suitable Base Materials:

Only the following materials are suitable

for Powder-actuated fastening:

Structural Steel

Masonry Joints

Poured Concrete

DO NOT try to fasten into any other

type of materials. It can cause serious

injury or blindness.

Unsuitable Base materials that should

not be fastened to:

Never try to fasten into very hard or

brittle materials such as tile, glass, cast

iron or rocks of any kind. These

materials can break, or shatter causing

splinters to fly and may cause serious

injury to the tool operator and the

bystanders.

PREPARATION

BP-27Cis a semi-automatic feeding low velocity powder-actuated fastening

tool. Continuous feeding of powder loads for a wide range of applications,

make the BP-27C tool a versatile, portable, safe and reliable tool.

INTRODUCTION

Never attach directly to a base

where it can easily penetrate like

wood or gypsum board. These

types of materials may cause the

fasteners to penetrate through to the

other side making it dangerous for

other people in the work area.

Never fasten into a base material

that fails the center punch test.

Failure to check the suitability of the

base material can cause serious

injury to the eyes or other body parts.

Never try to fasten into very hard

or brittle materials.

Never attach directly to a base

where it can easily penetrate like

wood or gypsum board.

08

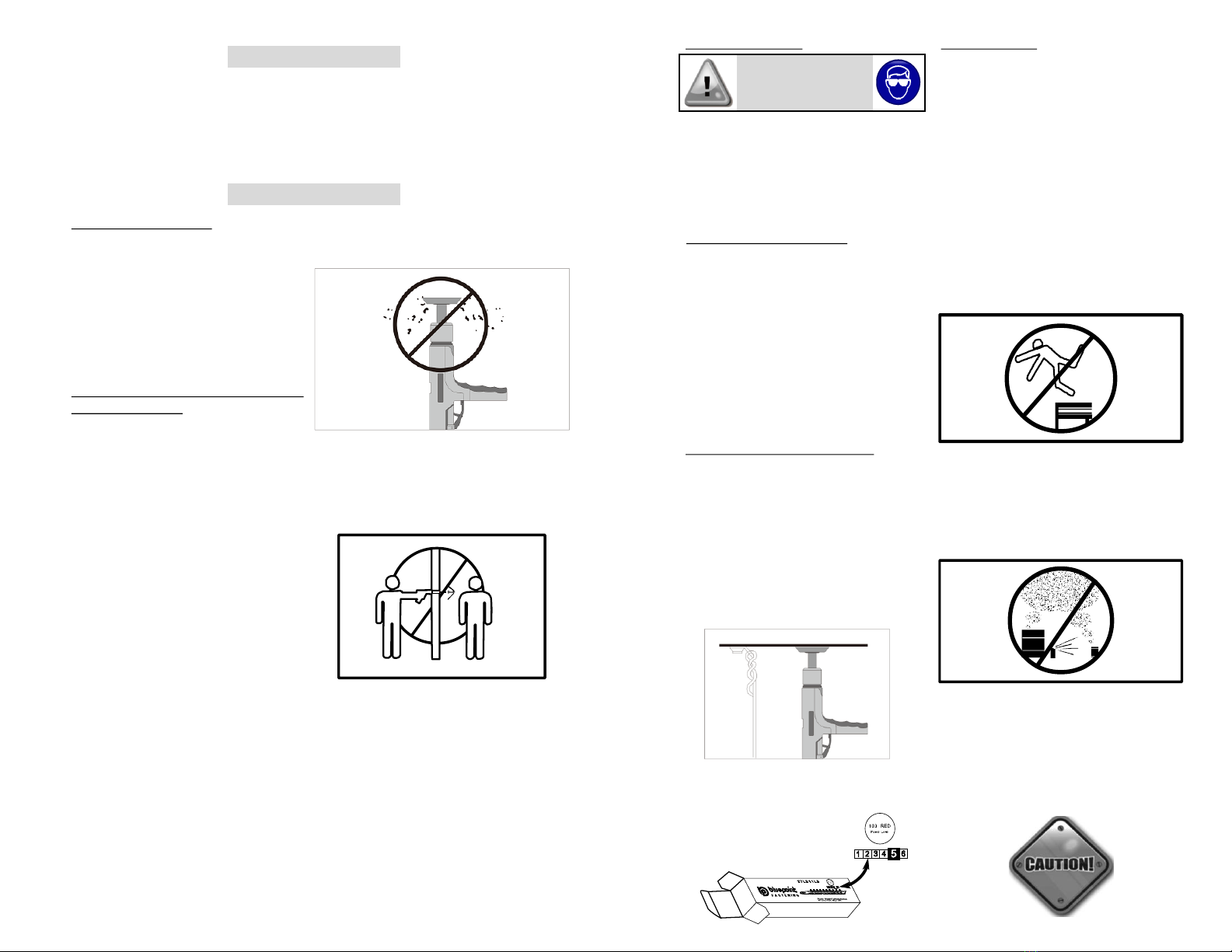

Center Punch Test

MUST WEAR EYE

PROTECTION WHILE

PERFORMING THIS TEST

1. Always check the hardness of the

base where you want to fasten.

2. Using a fastener as a center punch,

strike the fastener with a hammer

against the work surface and check

the results.

1. Operators and bystanders must

always wear approved ear and eye

protection. Failure to do so can

cause blindness or serious eye

injury from debris, and hearing loss

from exposure to constant or

repeated noise from the fastening

tool.

2. Keep the work area clear of

unnecessary materials and

bystanders that may interfere

with the safe operation of the

tool. Operating tool in a congested

or disorderly area may affect the

ability to operate safely.

Center Punch Test Result

1. The material is too hard for a

powder actuated fastening, if the

fastener point is flattened.

2. The material is too soft, if the

fastener easily penetrates it.

3. The material is too fragile, if the

material cracks or shatters.

4. The material is suitable for powder

actuated fastening, if the fastener

causes a small indentation in the

material.

Selection of Loads and Safety

1. Always make a fastening test after

ensuring that the base material is

suitable to determine the

appropriate power level. If

excessive power is used, the

fastener may pass completely

through the work material, causing

death or severe injury to someone

who may be in the path of the

fastener.

2. All operators must always select

the level of the loads by the power

level number to avoid the use of

incorrect loading.

Safety at Work

3. Never operate the tool when

explosive or inflammable

materials are close by.Powder

loads may create sparks when fired

and could ignite these materials or

vapors.

4. Always provide warnings within

50’of the area where fastening is

taking place: “CAUTION - Powder

Actuated Tool In Use”.Failure to

warn others can result in serious

injury or death to them. Contact

your supervisor for this sign.

Powder actuated

tool in use

09

BP-27C tool can be used for a wide

range of fastening applications on a

variety of substrate materials.

For best results, read and follow these

important instructions for fastening.

These guidelines will help you perform

the fastening operation most effectively

and safely. Powder actuated fastenings

are permanent solutions. Any attempt

to remove them may cause serious

injury.

This application is not recommended,

but if at all used, keep at least 3”edge

distance to avoid cracking the block and

excess penetration of fastener to avoid a

loss in holding value. Fastening is not

recommended for vertical joint.

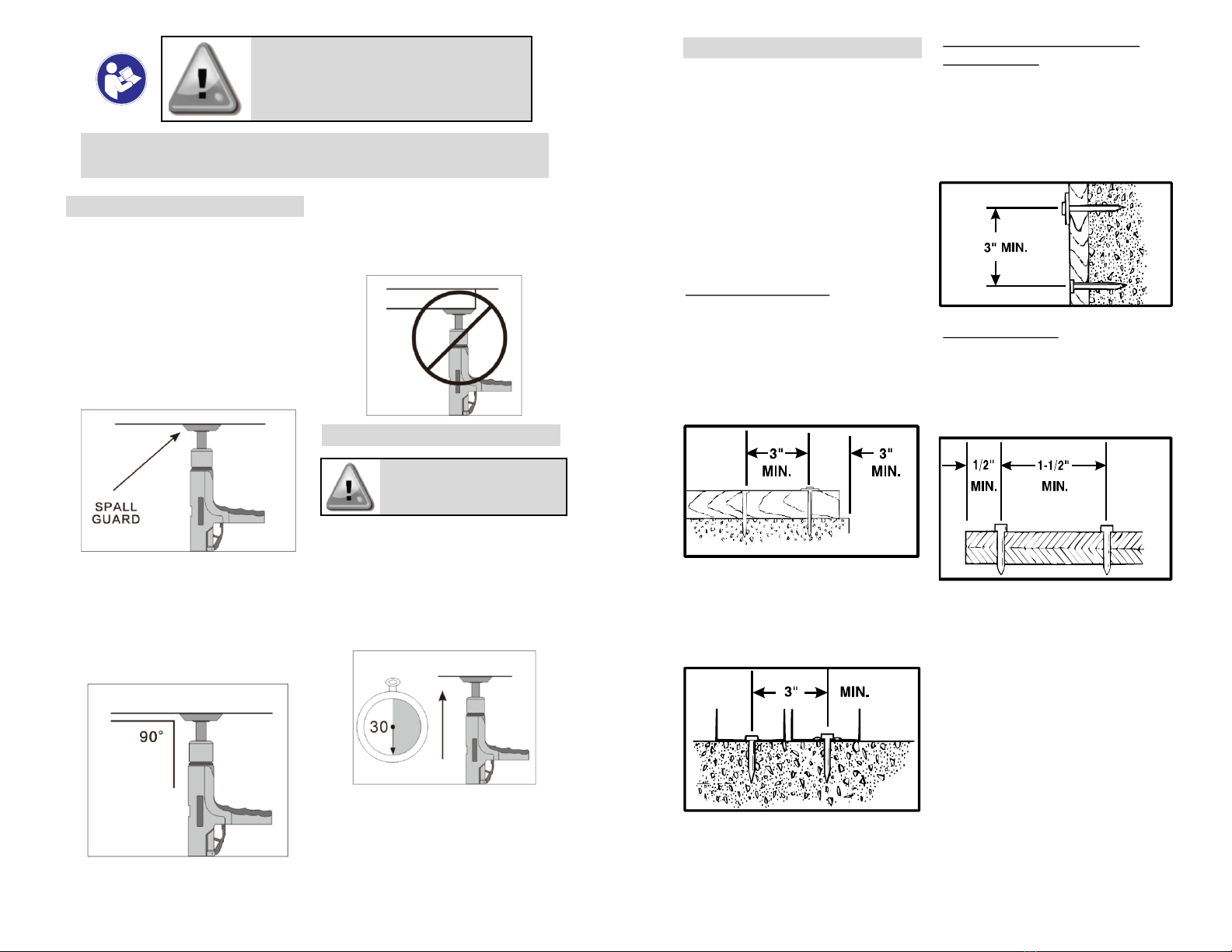

Fastening on Concrete

For fastening in concrete, keep a

minimum distance of 3”between

fastenings and 3”of any free edge.

Concrete thickness should be at least

three times the expected depth of

penetration into concrete. The drive

pin’s ideal penetration is 1”.

Fastening to Concrete Block or

Masonry Walls

Concrete Fasteners driven too close to

an edge or too close together can cause

the concrete edge to fail or transfer to

fly free.

APPLICATIONS OF FASTENERS

Fastening wood to concrete.

Penetration of thin gauge metal.

Fastening to Steel

BP-27Ctool can be used for fastening on

the flat surfaces of structural steel. For

steel fastening, always maintain a

minimum of 1-1/2”between the

fasteners and 1/2”from any edge.

11

FAILURE TO FOLLOW THESE

INSTRUCTIONS CAN RESULT IN INJURY TO

THE TOOL OPERATOR OR BYSTANDERS

10

5. Never drive a fastener close to

the edge of the base material

or close to another fastener.

See installation page.

MISFIRE PROCEDURE

If the tool does not fire, continue to

hold the tool against the work surface

for at least 30 seconds. Then carefully

open the tool, remove the load and put

it in a can of water or other non-

flammable liquid. Never discard the

load into a dumpster.

If the tool becomes stuck or jammed

with a powder charge, point the tool in

a safe direction and label it

immediately with “DANGER – DO NOT

USE – DEFECTIVE”.Lock the tool in a box

and contact your local dealer for

assistance from BLUEPOINT.

ALWAYS FOLLOW THE

MISFIRE PROCEDURE.

FASTENER DRIVING SAFETY

1. Use this tool ONLY to fasten into a

recommended base material.

2. DO NOT fire the tool without a

fastener. If the tool is fired without

a fastener, the piston can hit the

work surface causing serious injury

to you and bystanders.

3. Always use Spall Guard protection

whenever possible to minimize the

flying particles or debris.

4. Always use the tool firmly and

perpendicular to the work

surface and keep your hand

flexed before firing. Otherwise

the fastener may ricochet

causing injury.

BP-27C IS NOT A STAND-ALONE TOOL.

IT MUST ALWAYS BE USED MOUNTED ON A BLUE POINT POLE.

NOTE: Use of partially used

load strips.

If you want to use a partially fired load

strip, the end of the strip containing

the live loads should be placed into

the bottom of the tool handle. Count

the number of unfired loads in the

strip before inserting it and keep a

count as the fastenings are being

made, you can easily determine when

all the loads have been used.

13

6. Check the tool frequently to ensure

that the muzzle bushing and loads

strip track are clear, if you are

working at a site with dirt and

debris.

CHECK THE NOSEPIECE BUSHING

AND LOAD STRIP TRACK FOR

DEBRIS

IF YOU DECIDE NOT TO MAKE A

FASTENING AFTER THE TOOL HAS

BEEN LOADED, ALWAYS REMOVE

THE POWDER LOADS FIRST, THEN

THE FASTENER. THIS WILL PREVENT

ACCIDENTAL DISCHARGING OF THE

FASTENER OR PISTON INTO THE

OPERATION HAND.

Please watch the videos on our website: http://bpfasteners.com/licensing/video

5. After all 10 shots are fired, pull the

load strip from the TOP of the tool.

NEVER PULL IT FROM THE

BOTTOM.

4. After one shot is fired, point it in a

safe direction and insert the next

fastener into the Nosepiece, and

then press the Advance Lever

Assembly of the housing to

advance the next load, and repeat

the firing operation.

BP-27C OPERATING INSTRUCTIONS

12

BP-27C IS NOT A STAND-ALONE TOOL.

IT MUST ALWAYS BE USED MOUNTED ON A BLUE POINT POLE.

DO NOT USE EXCESSIVE

FORCE WHILE INSERTING A

FASTENER

3. Raise the tool upwards carefully

without bumping any other object

and gently place it on the ceiling

where you want to fasten. Hold it

perpendicular to the work surface

and push upwards to compress the

firing pin spring and release the

sear to fire the tool. If the tool

does not fire, hold the tool for 30

seconds and then follow the

misfire procedure described on

page 10.

2. With the tool pointing in a safe

direction and your fingers off the

Advance Lever, insert the strip load

through the bottom of the handle

and push through until your fingers

touch the handle recess. Never try

to insert a load strip into the tool

from the top of the receiver.

1. After checking to make sure that the

tool is not loaded, point it in a safe

direction and insert a fastener into

the Nosepiece of the tool until it is

fully seated. If a clip assembly is

being used, be sure it is positioned in

the cutout section of the Spall Guard.

FASTENERS AND FASTENER ASSEMBLIES

15

.27 Caliber - Powder Load Strip

POWDER LOADS

TECHNICAL SPECIFICATIONS

BP-27C Tool

Tool Length 13-3/4”

Tool Weight 3.00 lbs

Load Caliber .27 caliber strip loads

(Brown, Green, Yellow, Red)

Fastener Capacity 1/2” to 1-1/4”

14

Model No.

Shank

Dia.

Shank

Length Description

PD22F10

.145”

7/8"

Smooth shank with flutePD25F10 1"

PD32F10 1-1/4"

PD157-78F

.157"

7/8"

Smooth shank with flutePD157-100F 1"

PD157-114F 1-1/4"

Model No. Size Description Color Power Power

Level

27ES11L5 6.8 x 11

.27cal long strip enhanced

loads Red strong 5

27LS11L5

6.8 x 11 .27cal long strip loads

Red strong 5

27LS11L4 Yellow medium 4

27LS11L3 Green low 3

27LS11L2 Brown lowest 2

.300” Dia. Head (PD series), .157” & .145” Dia. Shank Drive Pins and Assemblies

Model No.

Shank

Dia.

Shank

Length Description

PDAC90-25F10

.145"

1" With 90° angle clip

PDAC90-32F10 1-1/4"

PDAC120-25F10 1" With 120° angle clip

PDAC120-32F10 1-1/4"

PDACTH90-22F10 7/8" With Top hat and 90° angle clip

PD157-100C90

.157"

1" With 90° angle clip

PD157-114C90 1-1/4"

PD157-100C120 1" With 120° angle clip

PD157-114C120 1-1/4"

PD157-78THC90 7/8" With Top hat and 90° angle clip

PD157-78HNC

.157"

7/8”

With Top hat and Ninja clipPD157-100HNC 1”

PD157-114HNC 1-1/4”

Model No.

Shank

Dia.

Shank

Length Description

CC25-P25

.145"

1" With 1/4” conduit clip

CC38-P25 1" With 3/8” conduit clip

CC50-P25 1" With 1/2” conduit clip

CC50-P32 1-1/4"

CC75-P25 1" With 3/4” conduit clip

CC75-P32 1-1/4"

CC100-P25 1" With 1” conduit clip

CC100-P32 1-1/4"

Model No.

Shank

Dia.

Shank

Length Description

DN22P8

.145"

7/8"

With plastic washerDN27P8 1"

DN32P8 1-1/4"

DNACTH90-27P8 1" With Top hat and 90° angle clip

DNACTH90-32P8 1-1/4"

8mm Head (DN series), .145” Dia. Shank Drive Pins and Assemblies

BLUE POINT POLES FOR CEILING APPLICATIONS

BP-27C IS NOT A STAND-ALONE TOOL.

IT MUST ALWAYS BE USED MOUNTED ON A BLUE POINT POLE.

ALWAYS USE BLUE POINT POWDER LOADS AND FASTENERS

WITH BP-27C TOOL.

16

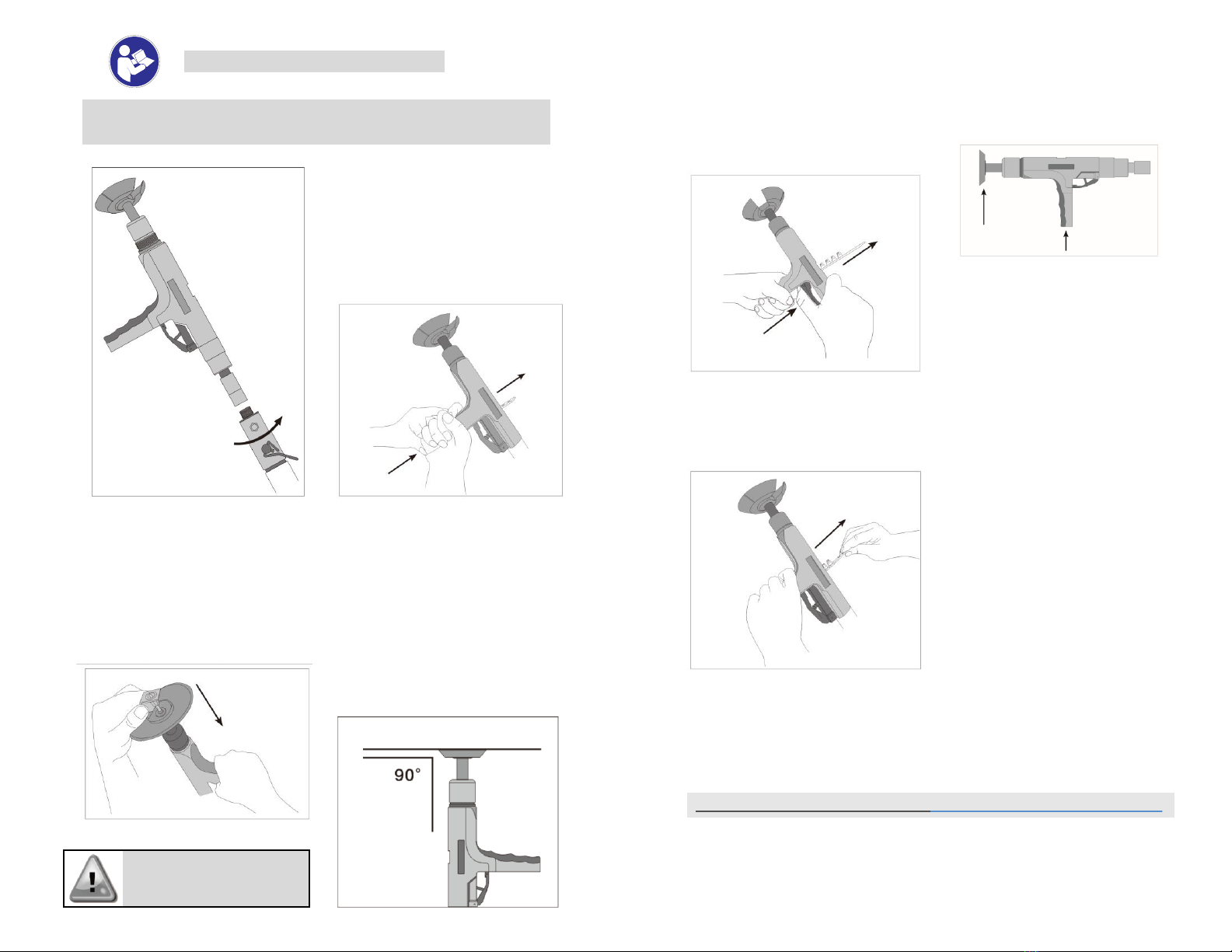

MAINTENANCE AND CLEANING TOOL

WARNING!

Remove the

cartridge strip from

the tool first.

1. All parts should be cleaned with oil

detergent and wire brushes

supplied with the tool kit.

2. Remove heavy dirt build-up with

the brush.

3. After cleaning with detergent oil,

all parts should be wiped

thoroughly dry.

4. Excess oil will tend to accumulate

dirt and dust. Use eye protection

when cleaning the tool. Excess dirt

or dust on the piston and cylinder

assembly of the receiver must be

cleaned daily.

Please review the condition of the

piston to check for damage or

deformation. For the tool to perform in

good operating condition and work well,

it is necessary to disassemble and clean

the tool when the dirt collects on the

side chamber or the tools seems to be

losing power. If the tool seems to be

losing power check for collected dirt in

the chamber, this may cause loss of

power. All parts must be cleaned as

above with oil and brushes. Be sure to

dry all parts when assembling your tool.

Depending on tool use, general

maintenance has to be done every six

months.

Use Eye Protection

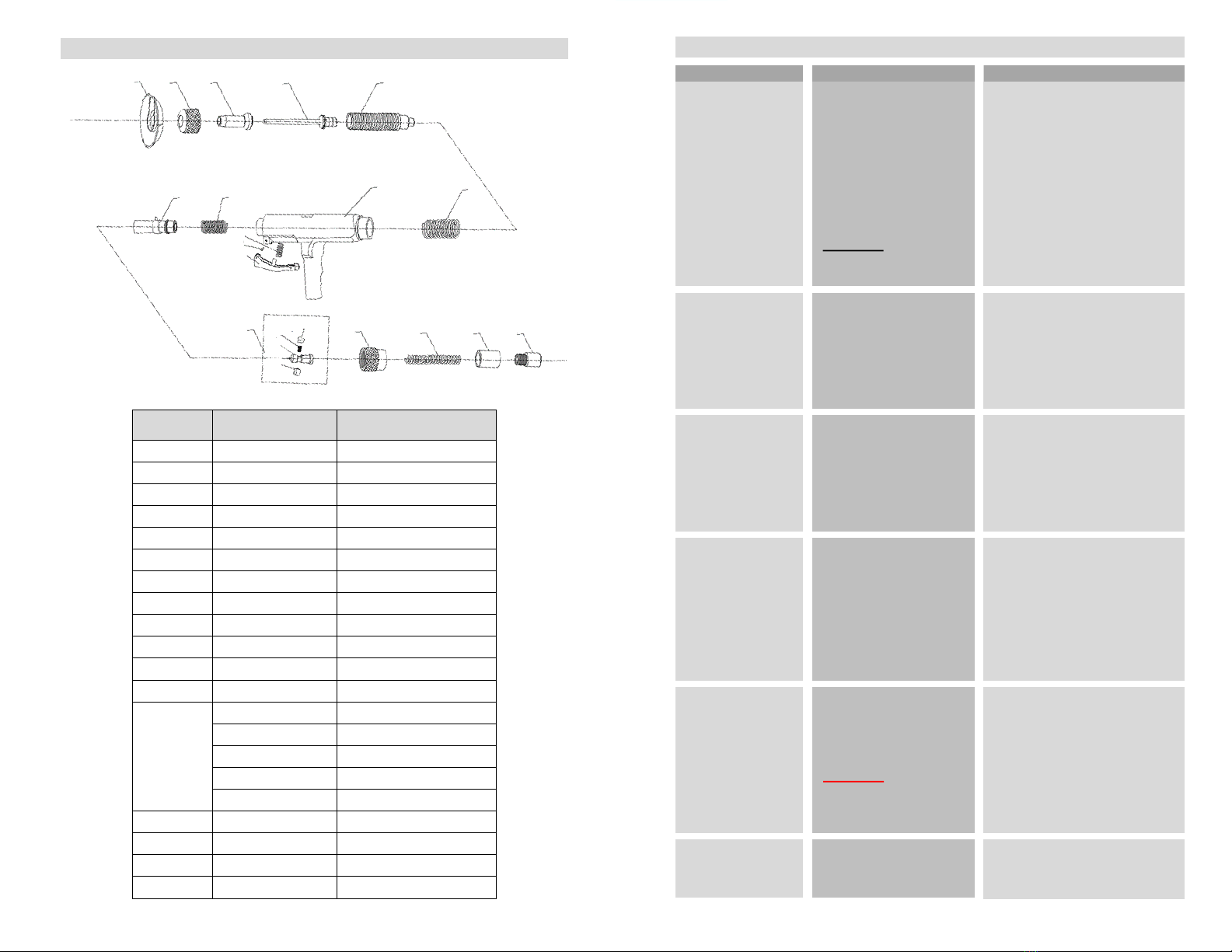

TOOL DISASSEMBLY

WARNING!

Remove the

cartridge strip from

the tool first.

Use Eye Protection

1. Remove the Spall Guard by gently

pulling it.

2. Unscrew the Guide Nut from the

Housing Assembly and pull the

Nosepiece.

Please watch the videos on our website: http://bpfasteners.com/licensing/video

BLUEPOINT BP-27C - Disassembly: https://youtu.be/c8t1VPttPXQ

BLUEPOINT BP-27C - Assembly: https://youtu.be/fBlAdIQSSYQ

17

NOTE: THE TOOL SHOULD BE CLEANED ONCE A WEEK

4. From the other end, unscrew the

Pole Connector from Firing Pin

Housing, remove Connecting Tube

and Firing Pin Spring.

3. Remove the Piston, Barrel and

Barrel Spring.

5. Press the Braking Pin and push in

the Firing Pin Assembly inside the

Firing Pin Housing. Remove it from

the other end. (You may use the

Piston to push it). Remove Firing Pin

Assembly Spring,

Press Breaking Pin

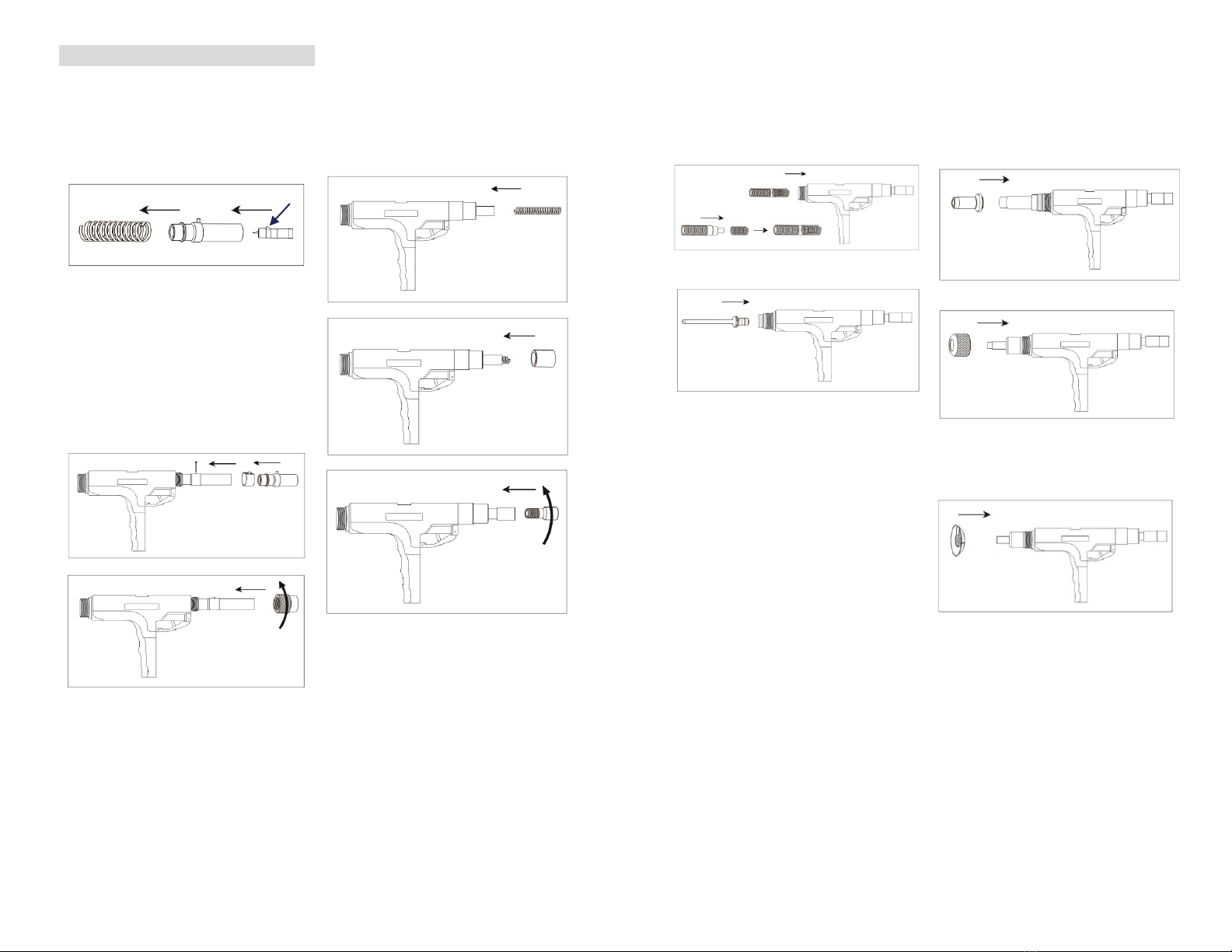

19

4. Change the direction of the Housing

Assembly, insert the Barrel Spring, the

Barrel and the Piston from the front end.

6. Assemble the Spall Guard onto the

Nosepiece.

5. Insert the Nosepiece into the Guide

Nut, then screw the Combination of

Nose Piece and Guide Nut onto the

Housing Assembly

18

HOW TO ASSEMBLE THE TOOL

3. Insert Firing Pin Spring and

Connecting Tube, press the Pole

Connector on the Firing Pin Spring and

screw it onto the Firing Pin Housing.

2. Insert the Firing Pin Assembly Spring

into rear of the Housing. Next insert the

combination of Firing Pin Housing and

Firing Pin Assembly into the Housing

Assembly. Ensure that the Braking Pin of

the Firing Pin Assembly is aligned into the

slot of the Housing Assembly and screw

the Locking Sleeve on the Housing

Assembly.

1. Press Braking Pin on Firing Pin

Assembly and push it into the Firing Pin

Housing. Piston may be used to push it

in further so that it projects out from the

other end.

Press Breaking Pin

21

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE POSSIBLE REMEDIES

Tool does not

fire Failure to depress

completely

Excessive dirt

buildup on breech

face not allowing

proper penetration

of firing pin

Firing pin and/or

firing pin assembly

damaged

WARNING

Never attempt to pry a

cartridge from the tool

See “Tool does not

completely depress”

After following misfire

procedure, check firing

pin indentation on load.

Clean breech face.

Replace damaged parts

If the problem continues:

Contact Bluepoint

distributor

Overdriving of

fasteners Excessive power

Soft base material

Use lower power level

load color and number

Check the base material

If the problem continues:

Contact Bluepoint

distributor

Tool does not

completely

depress

Incorrectly

assembled or

damaged parts

Check all parts for

damage and assemble

correctly

If the problem continues:

Contact Bluepoint

distributor

Reduction or

loss of power Piston is not

returning to the full

rear position

Worn or damaged

piston

Disassemble and clean

Barrel, Piston, Fastener

Guide and re-assemble

Replace damaged piston

If the tool cannot be

disassembled :

Contact Bluepoint

distributor

Strip does not

advance Strip not inserted in

tool correctly or is

damaged

Damaged indexing

mechanism

WARNING

Never attempt to pry a

cartridge from the

magazine strip or tool

Check load strip. Properly

dispose of damaged strip

Contact Bluepoint

distributor

Tool fails the

Daily Function

Test

Contact Bluepoint

distributor

20

12345

6

7

8

9

10

11

12

13 14 15 16 17

13-1

13-2

13-3 13-4

BP-27C TOOL SCHEMATIC

S/N Item No. Part Name

1 BP27C-01 Spall guard

2 BP27C-02 Guide Nut

3 BP27C-03 Nosepiece

4 BP27C-04 Piston

5 BP27C-05 Barrel

6 BP27C-06 Barrel Spring

7 BP27C-07 Housing Assembly

8 BP27C-08 Advance Lever Spring

9 BP27C-09 Advance Lever Pin

10 BP27C-10 Advance Lever

11 BP27C-11 Firing Pin Assembly Spring

12 BP27C-12 Firing Pin Housing

13

BP27C-13 Firing Pin Assembly

BP27C-13-1 Braking Pin

BP27C-13-2 Firing Pin

BP27C-13-3 Braking Pin Spring

BP27C-13-4 Jacket

14 BP27C-14 Locking Sleeve

15 BP27C-15 Firing Pin Spring

16 BP27C-16 Connecting Tube

17 BP27C-17 Pole Connector

23

NOTES

22

NOTES

24

WARNING

14728 Yorba Court,

Chino, CA 91710 USA

Tel: 1-877-779-2583

www.bpfasteners.com

1. BP-27Cis not a stand-alone tool.

It must always be used mounted on a

Blue Point pole.

2. Read the manual before using the tool.

3. Never put your hand over the nose

piece or compress with your hand.

4. Never point the tool at yourself or

bystanders.

5. Only adults that are certified and

qualified, may operate the BP-27C tool.

6. Always unload the tool prior to

cleaning or maintenance.

7. Do not operate the tool in an explosive

or flammable atmosphere.

8. When fastening, if the cartridge does

not fire, hold the tool in place for at

least 30 seconds.

9. When advancing an unfired cartridge,

always keep the tool aimed away from

yourself and others.

SAFETY PRECAUTION

Table of contents

Other BluePoint Fasteners Tools manuals