BlueRange UN09/RED User manual

USER MANUAL

POWERED AIR PURIFYING RESPIRATOR (PAPR) SYSTEM

MODEL NUMBERS:

UN09/RED

UN09/BLUE

IMPORTANT NOTICE:

Please read these instructions carefully before using this unit, failure to comply with

them may reduce the performance of the unit risking your safety and invalidate the

guarantee.

Digital Display

Air Filter

Lithium Battery

Air Hood / Visor

Helmet

1. INTRODUCTION

The BLUERANGE® PAPR system is an integrated face, eye and breathing protection device

designed to improve operator safety and comfort during the welding process.

The kit includes the following –

1.1 Auto Darkening Welding helmet

1.2 Blower master unit,

1.3 Belt with mounting plate.

1.4 Rechargeable battery.

1.5 Hose with a bayonet connector to blower unit and a bayonet connector to

mask.

1.6 Fully automatic battery charger.

1.7 Visor for grinding operation.

If any of the above components are not included in your pack, please contact your supplier

immediately

Page 2

Auto-Darkening Filter

Welding Helmet

BEFORE WELDING

• Check the front cover lens to make sure that they are clean and there is no dirt covering the

four sensors on the front of the filter cartridge and check the front/inside cover lens to make

sure that they are secure.

• Check all operating parts before use for signs of wear or damage. Any scratched, cracked or

pitted parts should be replaced immediately before using again to avoid severe personal injury.

• Check for light tightness before each use.

Select a shade number by the shade knob (see Shade Guide Table No.1) ensuring that the shade number is

the correct setting for your application. Adjust the headband so that the helmet is seated as low as possible

on the head and close to your face. The angle of the helmet is adjusted using the buckles.

DARK SHADE NUMBER SELECTION

The shades are divided to two sections, 5-8 and 9-13. The shade section is selected by switch K4. When

used for grinding, you can set the Grind/Weld switch (K5) to “GRIND”. Refer to the shade guide table to

determine the proper shade number for your application. Select a shade number by the shade knob (Shade

guide Table No.1).The shade goes darker from 5 to 8 or from 9 to 13 gradually by turning knob K2.

Auto-darkening welding helmet is designed to protect the

eyes and face from sparks, spatter, and harmful radiation

under normal welding conditions. Auto-darkening filter

automatically changes from light to dark state when the arc

is struck, and returns to the light state when welding stops.

Auto-darkening welding helmet comes ready to use. The only

thing you need to do before welding is to adjust the position

of the headband and select the correct shade number for your

application.

There is also a visor for protection on other operations.

Page 3

PRODUCT FEATURES

The helmet is designed & equipped with a special turn over (up & down) headband mechanism. When the

user lifts the helmet, the headband mechanism aligns the helmet’s centre of gravity to with the user’s head.

This greatly reduces fatigue of the user’s head (and neck) making the user more comfortable when working.

When welding, the helmet automatically changes the filter screen from clear to dark in 1/25,000 sec. The

delay time from dark to clear is set between 0.2 sec and 1 sec, which can be adjusted by the delay knob.

The helmet utilises high performance solar cells as a power supply and 2 built-in 3V lithium batteries

(CR2032) as power back-up. The power is switched off automatically within 10-15mins of stopping work.

Under normal welding conditions, users can expect a battery lifetime of more than a year. The lithium

batteries can be replaced by ones of the same size and specification when exhausted.

The helmet is in full conformity with related DIN,ISO,EN safety standards and ANSI Z87.1-2010 standards.

The ultra-high performance of UV/IR auto-darkening filters provide full protection for the user’s eyes and

face against UV/IR radiation during the entire welding process, even in the light state. The UV/IR protection

level is up to Shade 16(DIN) at all times, which increases comfort during welding work.

WARNING

• The auto-darkening welding helmet is not suitable for laser welding or Oxyacetylene welding.

• Never place the helmet and auto-darkening filter on a hot surface.

• Never open or tamper with the auto-darkening filter.

• The auto-darkening welding helmet will not protect against severe impact hazards.

• The helmet will not protect against explosive devices or corrosive liquids.

• Do not make any modifications to either the filter or helmet, unless specified in this manual.

• Do not use replacement parts other than those specified in this manual.

• Unauthorised modification and replacement parts will void the warranty and expose the

operator to the risk of personal injury.

• Should the helmet not darken upon striking an arc, stop welding immediately and contact your

supervisor or your dealer.

• Do not immerse the filter in water.

• Do not use any solvents on the filter’s screen or helmet components.

• Use only at temperature:-5℃°C~+55℃°C.

• Storing temperature:-20℃°C~+70℃°C.

• Keep filter away from liquid and dirt.

• Clean the filter’s surfaces regularly, do not use strong cleaning solutions. Always keep sensors

and solar cells clean by using a clean, lint-free tissue/cloth.

• Regularly replace the cracked/scratched/pitted front cover lens.

Severe personal injury could occur if the user fails to follow

the aforementioned warnings, and/or operating instruction.

See spare parts list on back cover.

Page 4

TROUBLESHOOTING

• Irregular Darkening Dimming

Headband has been set incorrectly and there is an uneven distance from the eyes to the filter’s

lens. (Reset headband to reduce the difference to filter.)

• Auto-darkening Filter Does Not Darken Or Flickers

Turn the sensitivity knob to “HI” position

Front cover lens is soiled or damaged (change the cover lens)

Sensors are soiled (clean the sensors’ surfaces)

Welding current is too low.

• Slow Response

Operating temperature is too low (do not use at temperature below –5°C℃)

When the battery power in the filter screen is low, stop using and replace the filter cartridge.

• Poor Vision

Front/inside cover lens and/or filter lens are soiled (change lens)

There is insufficient ambient light.

Shade number is incorrectly set (reset the shade number).

The protective film of the front/back cover lens has not been peeled off.

• Welding Helmet Slips

Headband is not adjusted properly (readjust headband)

Warning: Operator must stop using the auto-darkening welding helmet immediately if the problems

mentioned above cannot be corrected. Contact the dealer.

LENS & HELMET MAINTENANCE

Replacing the front cover lens if it is damaged (cracked, scratched, soiled or pitted)

Step 1: Take out the old front cover lens.

Step 2: Place the new cover lens into the right position.

TECHNICAL SPECIFICATIONS( (UN09)(

Total Weight: 520g

Viewing Area: 98 ×62mm

Size of Cartridge: 110×90×9mm

Light state: DIN 4

Darken state: DIN5-8/9-13

Switching Time: 1/25,000s

Operating Temperature: -5℃°C~+55℃°C

Storing Temperature: -20℃°C~+70℃°C

Helmet Material: High-impact resistant plastic/Polyamide Nylon.

Page 5

SHADE GUIDE TABLE (No.1)

Page 6

PARTS LIST - HELMET

PARTS LIST & ASSEMBLY

1. 2 x Block Nuts

2. Front Cover Lens

3. Auto-Darkening Filter Cartridge(front)

4. Headband

5. Sweat Band

6. Auto-Darkening Filter Cartridge (back)

K1 Sensitivity knob

K2 Shade knob

K3 Delay knob

K4 Shade grades select switch

K5 Grind/Weld select switch

Page 7

PARTS LIST - HEADBAND

PARTS LIST & ASSEMBLY

1. Nut

2. Separator

3. Installation Part 1

4. Setting Hook

5. Screw

6. Leveller

Page 8

POWERED AIR PURIFYING RESPIRATOR

Contents

1. Introduction

2. Description

3. Use

3.1 Prior to use

3.1.1 Usage limitations: System

3.1.2 Usage limitations: Filter element

3.1.3 Charging batteries

3.1.4 Filter assembly

3.2 Switching on

3.3 During use

3.4 After use

4. Maintenance and inspection

5. Storage

6. Faults/troubleshooting

7. Technical specifications

7.1 Blower unit

7.2 Filter

7.3 Battery

7.4 Battery charger

7.5 Hose

8. Statutory requirements and regulations

9. General

10. Guarantee

11. Contact details

Page 9

1. Introduction

The powered respirator is used for dust removal and partial odour removal, not for gases or vapours.

Used to reduce or remove resistance to inhalation during respiration by producing a constant

airflow. The unit is designed with a manufacturer’s minimum design flow rate of 170 litres, 210

litres or 250 litres per minute (the flow rate at which the equipment still will fulfil the requirements

of the class in EN12941). The working battery life will be approximately 8 hours.

2. Description

A complete powered respirator apparatus consists of :

• Blower master unit provided with a dust P3 filter, a steel pre-filter and an activated carbon

filter (Fig1), supplied with a belt and a comfort plate.

• Rechargeable battery, which is equipped underside the apparatus.

• A hose with a bayonet connector to the blower unit and a bayonet connector to the mask.

• Fully automatic battery charger

3. Use

The unit supplies an overcapacity of clean and filtered ambient air, which is fed to the mask. It

allows the user to breathe in air without having to overcome the resistance of the filter. Considering

that an adult person requires 50 litres of air per minute, the overcapacity ensures an overpressure

and thus a high degree of protection.

With a fully charged battery the unit will operate for approximately 8 hours. The unit contains a

warning facility to warn the user against reduced air supply due to a clogged filter or low battery.

Fig1

Page 10

3.1 Prior to use

Before using the powered respirator, the user must ensure that all the conditions for safe use have

been satisfied. See below for the applicable statutory regulations and rules.

• Check that the appropriate hose connector is fitted to the hose

• Check before use that the battery is sufficiently charged and that the free flow of air is not

obstructed by a blocked hose or other causes.

• Check that a set of filters is fitted correctly.

• Check that the lock of the battery box and the lid filter housing are closed.

3.1.1 Usage limitations: System

• The space in which the unit is to be used must contain at least 17% oxygen and must not

contain any explosive gases or vapours. In enclosed spaces where there is a risk of oxygen

deficiency, use of the unit should be avoided.

• In case of physical effort, it is possible that a temporary negative pressure occurs in the blower

unit, resulting in a reduction of the protection factor of the system.

• Air speed in excess of 2m/s can affect the protection factor.

• The ambient usage temperature should be between the limits of -5°C and +50°C

• Do not use the unit in circumstances where hazardous gases and/or vapours are present.

Warning

If the user of the respirator feels dizzy or uncomfortable or can smell/taste something, they should exit the

contaminated area immediately.

3.1.2 Usage limitations: Filter element

• Used filter elements cannot be cleaned.

Warning

Never attempt to clean a filter element; the filter media may be damaged, resulting in loss of

protection.

3.1.3 Charging batteries

The battery is supplied in an un-charged state; the charging time for a fully discharged battery

is approximately 3 hours. The automatic setting of the charger prevents damage to the batteries

when the charging time is exceeded.

Under normal circumstances the battery can be charged and discharged approximately 500 times.

After the battery is completely charged, the charger will switch over to trickle charging. This will

expand the lifetime of the battery beyond 500 charge cycles. If the unit is used for more than 8

hours a day, it is recommended that user carry a second battery for backup.

Batteries may be charged on or off the unit.

Page 11

3.1.4 Filter assembly

Open the front cover by releasing the retaining clip on the side of the unit by hand (do not use

tools). Fit the filter squarely into the power unit by aligning the three concave points of the filter

box to the three convex points in the cavity. Then press the filter hard and rotate slightly clockwise

to lock. To unlock the filter, press it and rotate anticlockwise.

The pre-filter and the activated carbon filter should be installed on the inner side of the upper

cover, assembled in the order and direction indicated in Figure 1, and then pressed by the frame.

Three notches on the frame are aligned with three buckles on the top cover. Press the frame and

rotate clockwise to lock. To disassemble them, press the frame and rotated anticlockwise to unlock.

3.2 Switching on

The unit can be switched on by pushing the ON/OFF button for approximately three seconds. A

voice signal will be heard and the LCD will display the air flow, filter and the battery power. Then

the unit will start on the low speed.

3.3 During use

This product has three levels of air flow. By shortly pressing the “ SET” button, the flow level will

change according to “low - medium - high - low...” circulation accompanied by a voice signal. The

icon on LCD also changes synchronously. At the same time, the digit on LCD indicates the real air

flow rate. If during use the air supply drops or fails entirely, leave the work area immediately. If a

signal for low battery (2 beeps repeatedly) or a clogged filter element (single short beep repeatedly)

is given, leave the workroom immediately, and check according to chapter 6.

3.4 After use

By pressing the ON/OFF button for 3 seconds, the motor will stop gradually accompanied by a long

tweet. When the icons on LCD disappear after approximately 15 seconds, the apparatus will turn

off completely.

Cleaning and disinfecting

After each session clean the unit, using a mixture of water and a mild detergent. Subsequently,

rinse thoroughly with clean water. Do not use any solvent. During cleaning ensure that no water is

allowed to enter the apparatus. The unit must not be immersed in fluid. Dry the unit with a cloth

and/or leave it to dry in the open air.

Advice

For hygiene reasons, each operator should be equipped with their own hood or mask.

Page 12

4. Maintenance and inspection

Prior to use: user to check all functions.

After use: Cleaning and disinfecting of the blower unit.

Cleaning and functional checking of the complete system.

Every 6 months: Cleaning and disinfecting of the blower unit.

Cleaning and functional checking of the complete system.

Check the hose for leakage and inspect the connector for damage.

5. Storage

Before storing the unit in the carrying case, it should be thoroughly dry.

Do not keep soiled filter together with the unit and the mask in the same enclosed storage space.

Remove the filters from the unit and seal them appropriately.

The unit is only recommended for storage in the temperature range -10°C℃ to +55°C℃ and in conditions

where relative humidity does not exceed 85%.

6. Faults/troubleshooting

Blower unit fails to supply air:

• Battery is empty

• ON/SET button defective

• Plug connection defective

• Motor bearings defective

• Printed circuit-board defective

Blower supplies insufficient air:

• Filter unit blocked

• ℃Hose blocked or leaking

• Blockage or leakage in mask, air hood or breathing helmet

• ℃Suction opening clogged

Battery fails to charge:

• Power lead or plug connection defective

• ℃Charger defective

• ℃Battery defective or worn out

Battery is too fast empty:

• Charger defect

• ℃Battery defect or worn out

Repairs

Note

All other repairs should only be carried out by the manufacturer, or an authorized service and

maintenance distributor.

Page 13

7. Technical specifications

7.1 Blower unit

7.2 Filter

7.3 Battery

Airflow℃: 170 L/min,210L/min,250L/min

Motor Speed: Electronically controlled

Alarms: Electronically controlled, for low flow and low battery

Material: Impact proof ABS

Colour: Black/ Orange red

Weight: 1080 grams (including battery and filter)

Dimensions LxWxH: 165x95x200mm

Filter class: TH2 P R SL (P3)

Material filter medium: Efficient filtering low resistance papers

Material support disks: ABS

Colour: Black

Weight: 90 grams

Dimensions DxH: ø120x38mm

Type: Lithium,rechargeable

Voltage: 11.1 Volt

Capacity: 5200 mAh

Operating time: HI:7 Hours,MI:9 Hours,Lo:11 Hours

Charging time: 3 h

Charging cycles: ﹥500

Material case: Impact proof ABS

Colour: Black

Weight: 350 grams

Dimensions: 137x50x72 mm

Page 14

7.4 Battery charger

7.5 Hose

8. Statutory requirements and regulations

REGULATION(EU) 2016/425℃: European regulation for Personal protective devices

Norm EN 12941: ℃Powered filtering devices incorporating a helmet or a hood

9. General

BLUERANGE can not, in general terms, accept responsibility for damage incurred by the owner, user

other persons using the safety product or third parties, which results either directly or indirectly

from incorrect use and/or maintenance of the safety product, including use of the product for

any purpose other than that for which it was supplied and/or the non compliance or incomplete

observance of the instructions contained in this user manual and/or in connection with repairs to

the safety product which have not been carried out by us or on our behalf. Our General Sales and

Supply conditions are applicable to all transactions. BLUERANGE continually strives to improve

its products and reserves the right to change the specifications mentioned in this manual without

prior notification.

Warning

The European guideline “Personal Protection REGULATION(EU) 2016/425” stipulates that only

inspected protective equipment bearing the CE mark may be traded and used. Use of substitute,

none-original spare parts, invalidates the CE approval and, also, all rights regarding guarantee,

whereby the user and, also, the person initially marketing these spare parts, shall be punished by

the relevant authorities of the EEC member countries, whereby additionally, the entire product will

be excluded from use and withdrawn from the commercial transactions respectively. Original spare

parts can be recognized by the affixed code number, supplemented with the manufacturer’s mark

and the “CE approval” possibly supplemented with a year of applicability.

Type: Fully automatic, overcharge protection

Primary voltage: 100-240 v, 50/60 Hz

Secondary voltage: 12.6 Volt

Color: Black

Weight: 200 g

Dimensions: 110x48x30 mm

Length: 800 mm

Diameter(int): 35 mm

Connection: Bayonets for blower unit and mask

Material: HDPE

Page 15

10. Guarantee

BLUERANGE will repair or, if necessary, replace this product free of charge in the event of a mate-

rial or manufacturing defect within 12 months of the purchase date, provided that the product has

only been subjected to normal usage in accordance with the user manual. The guarantee is invali-

dated if the type or serial number marking is modified, removed or made illegible.

11. Contact Details

BLUERANGE Tools

PO BOX 29 email: sales@bluerangetools.com

BOOTLE phone: 0151 955 4725

MERSEYSIDE L20 1EJ

Parts list

Image Name Part Number

Blower Unit (Does not contain filter and

battery)

UN09BLOWERUNIT

Filter UN09FILTER

Battery UN09BATTERY

Battery Charger UN09BATTERYCHARGER

Belt UN09BELT

Parts list (cont.)

Image Name Part Number

Waist Pad UN09WAISTPAD

Visor UN09VISOR

Hood UN09HOOD

Hose UN09HOSE

Stainless Steel Mesh UN09STAINLESSSTEELMESH

Activated Carbon Filter UN09CARBONFILTER

Outside Big Lens 115*98*1mm UN09OUTSIDEBIGLENS

Inside Small Lens

96.5*67*1mm

UN09INSIDESMALLLENS

Helmet Headgear UN09HELMETHEADGEAR

Auto Darkening Helmet Filter UN09AUTODARKENINGHELMETFILTER

This manual suits for next models

1

Table of contents

Popular Respiratory Product manuals by other brands

nuVita

nuVita 5021 manual

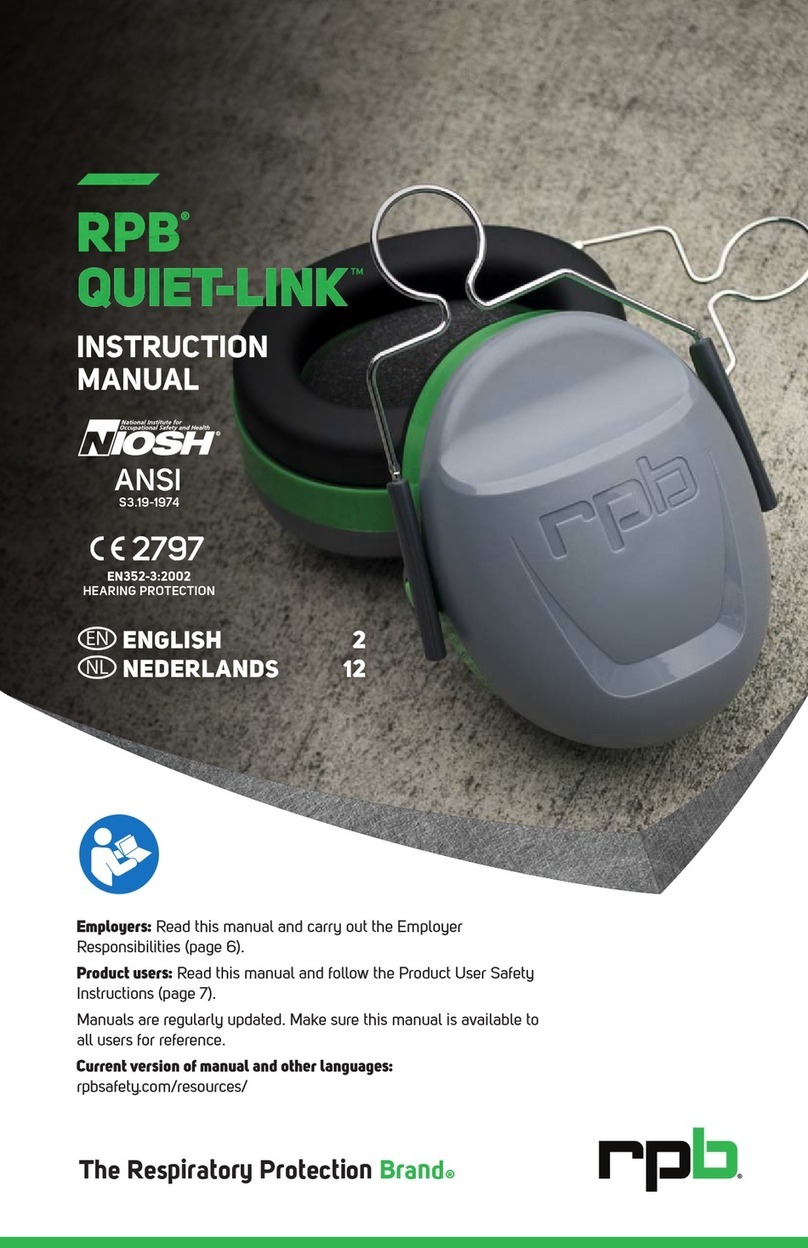

RPB

RPB QUIET-LINK instruction manual

Medline

Medline AEROMIST TREK HCS2GO instruction manual

3M

3M Air-Mate PAPR 231-01-30 User instructions

Veridian Healthcare

Veridian Healthcare 11-516 Piggy instruction manual

Vincent Medical Manufacturing

Vincent Medical Manufacturing inspired O2FLO user manual