BlueSun BSM8K-B User manual

Bluesun Series

String Inverter

User Manual

Version: V1.0

(BSM8K-B~BSM33K-B)

About this manual

For Readers

This manual is helpful for technicians who install, debug, operate and maintain string inverters of

Please read this manual carefully before operates the product .

Readers are required to know the basic knowledge about electric components, wiring, signs and

mechanical drawings.

Outlines

Chapter Contents

1 Safety Precautions This chapter describes the safety precautions when transporting, storing, installing,

running and maintaining the Inverter.

2 Product Description This chapter describes the basic principles, naming rules, product configuration and

data.

3 System Installation This chapter describes the unpacking inspection, installation tools, installation

environment, reserved space, fixing method, cable connection.

4 Commissioning

Guide

This chapter describes the inspection before startup, Commissioning and startup of

string inverter.

5 Maintenance and

Troubleshooting

This chapter describes the daily maintenance methods, maintenance intervals and

troubleshooting of the product.

6 Inverter handling

Guide

This chapter describes the basic requirements and precautions when disassembling,

replacing, and scrapping the inverter.

Warning Signs in This Manual

DANGER

It shows that there is a significant potential danger. If the operation is not performed

according to requirements, serious injury or damage may be caused to people or

equipment.

WARNING

It shows that there is a general potential danger. If the operation is not performed

according to requirements, general injury or damage may be caused to people or

equipment.

CAUTION

It shows that there is a general potential danger. If the operation is not performed

according to requirements, general injury or damage may be caused to equipment.

Terms and Abbreviations

Terms/Abbreviations Description

MPPT Maximum Power Point Tracking

Photovoltaic string Multiple solar cell arrays in parallel or series.

EEPROM Electrically Erasable Programmable Read-Only Memory

hopeInsight A monitoring and debugging software for inverter.

Version Description

Version Release Date Description

V1.0 2021-8-5 The first version

Bluesun

Content About this manual ·················································································· 5

Content ································································································· 7

1 Safety Precautions··············································································· 1

1.1 Transportation·······················································································1

1.2 Storage ·······························································································1

1.3 Installation····························································································2

1.4 Operation·····························································································2

1.5 Maintenance·························································································3

2 Product Description············································································· 5

2.1 Product Description················································································5

2.1.1 Schematic Diagram ·············································································· 5

2.1.2 Operation Mode··················································································· 6

2.2 System Configuration and Application·························································6

2.2.1 Application Description·········································································· 6

2.2.2 Supported Grid Form ············································································ 7

2.3 Naming Rules ·······················································································7

2.4 Nameplate label ····················································································8

2.5 Machine Configuration ············································································9

2.6 Signs and labels ·················································································· 11

2.7 Warning Labels in Inverter ····································································· 11

2.8 Technical Data ···················································································· 12

2.9 Mechanical Parameters········································································· 13

2.10 Ambient Requirements ········································································ 14

3 System installation ·············································································17

3.1 Unpack and inspection·········································································· 17

3.2 Preparation of installation tools ······························································· 17

3.3 Installation environment requirements ······················································ 17

3.4 Requirements for reserved space ···························································· 18

3.5 Fixing method ····················································································· 19

3.6 Electrical connection············································································· 20

3.6.1 Cable requirements ············································································ 20

3.6.2 Recommended cable specifications······················································· 20

3.6.3 Torque requirements··········································································· 21

3.6.4 Preparation before operation································································ 21

3.6.5 Connect the ground wire ····································································· 22

3.6.6 Connect the AC output cable ································································ 22

3.6.7 Connect the communication cable························································· 24

3.6.8 Connect DC input cables ····································································· 25

4 Commissioning Guide·········································································27

4.1 Check before starting············································································ 27

4.2 Power on the system ············································································ 28

4.3 Power off the system ············································································ 28

5 Maintenance and troubleshooting ························································29

5.1 Maintenance items and cycle·································································· 29

5.2 Troubleshooting··················································································· 30

6 Inverter handling instructions ······························································35

6.1 Disassembly of the inverter ···································································· 35

6.2 Replace the inverter ············································································· 35

6.3 Package the inverter············································································· 35

6.4 Scrapped the inverter ··········································································· 35

1

1 Safety Precautions

This chapter describes the safety precautions to be observed during the installation, operation

and maintenance of inverter. Please carefully read the safety precautions before the installation,

maintenance and other operations of inverter. All personals must strictly observe safety

precautions during the operation. Personal injury or damage to inverter and associate devices

may occur if the safety precautions are ignored.

When operating the inverter, please pay particular attention to the following items:

DANGER

1. Only qualified professionals can install, operate and maintain the inverter.

2. Please avoid toppling and knocking the inverter cabinet during moving the inverter.

3. Prevent liquid, debris or chippingsfrom getting inside the inverter; a conductive fluid and debris may cause

an internal short circuit of inverter and result in equipment damage.

4. Before completing installation and maintenance, the inverter must be isolated from power grid and other

electrified devices.

5. Please make sure that relevant protective measures have been taken to avoid electric shock, fire or other

accidents.

WARNING

Don

't place explosive and inflammable substances around the inverter!

1.1 Transportation

WARNING

1. Please keep the inverter well packed and upward, avoid strong shock or collision during the transportation.

2. Please transport the inverter with package and operate in accordance with the signs and labels during the

transportation. Please refer to "2.6 Signs and labels" for detailed information.

3. Please ensure the transportation environment can meet the requirements. Please refer to "2.10 Ambient

Requirements" for detailed information.

1.2 Storage

WARNING

The storage environment of inverter should meet the corresponding requirements. Please refer to "2.10

Ambient Requirements" for detailed information.

About long-term storage:

Before or after the installation, it's regarded as long-term storage if the inverter has been in the no power

supply status for over three weeks. Please pay attention to the following issues about long-term storage:

Put the desiccant into several equipment cabinets and pack the inverter with packaging materials;

Attention must be paid to ventilation and moisture prevention where equipment is stored and any water is

strictly prohibited;

Necessary measures must be taken to deal with adverse environments, such as abrupt cooling and

heating, collision and dust storm to prevent damages to the inverter.

Regular inspection at least once a week, inspect whether the package is intact and prevent it from

damages caused by insects and rats. Please replace the damaged package immediately.

The inverter shall be unpacked, inspected, repacked, and replace the new desiccant if it is stored for over

User Manual of String Inverter

2

half a year.

Don't store the inverter without package.

1.3 Installation

DANGER

1. The DC switch and breaker of the inverter must be cut off and the inverter shell must be reliably grounded

before any operation is conducted inside the inverter.

2. The inverter must be grounded canonically and the dimension of grounding conductor must conform to the

requirements of security specifications to ensure the personal safety.

3. Don't place explosive and inflammable substances around the inverter.

WARNING

1. The installation environment of the inverter must have good ventilation and heat dissipation, the inverter

can’t expose to the sunlight directly.

2. It's advised to fix the inverter by four personals to avoid mechanical injury. Please take safety measures to

prevent injury during installation.

3. Liquid, dust or debris must be prevented from entering the inverter during installation and maintenance as

conducting liquid and debris may cause short circuit inside the inverter, thus damaging the equipment.

4. Please ensure the installing torque of power cable is proper during the wiring of external cables and

inverter, excessive torque will damage the screw, and too small torque will increase the contact resistance

and result in overheating.

5. The terminal of the power cable connected with the inverter must comply with national standard as

substandard terminal or disqualified construction may lead to overheating of the power cable and outbreak

of fire in severe cases.

6. Installation place must meet the operation environment requirements. Please refer to "2.10 Ambient

Requirements" for detailed information.

1.4 Operation

DANGER

1. During the operation of inverter, the cabinet door of inverter needs to be locked to avoid electric shock and

other personnel injuries, which can also prevent salinity, water, dust or other conducting materials in the air

from entering into inverter.

2. Please keep the surrounding environment of operating inverter non-corrosive.

3. Don't place explosive and inflammable substances within two meters from the inverter.

4. Don't touch the internal board, components, cables and terminal blocks of inverter during the powering on.

5. When there are faults or abnormal smell or sound, turn off the DC switch and open the breaker of AC side

immediately.

WARNING

1. Power on the inverter only after completing the installation and properly connecting the cables.

2. Do not conduct any insulation resistance test or high-voltage resistance test for inverter, because wrong

test may cause damages to inverter.

3. Cut off wiring between inverter and external equipment when conducting insulation and voltage resistance

test for external equipment.

2

1 Safety Precautions

3

1.5 Maintenance

c

1. Please cut off the AC side breaker first, then cut off the DC switch, and wait for at least 5 minutes before

performing maintenance.

2. Please prevent irrelevant personals from entering maintenance scene during the maintenance.

3. Please maintain the inverter under the condition of understanding this manual and being equipped with

proper tools and test devices.

4. Please wear insulating gloves and safety shoes for you safety.

WARNING

Regular check and maintenance must be performed, please refer to "5 Maintenance and troubleshooting" for

details.

--Chapter End--

4

2 Product Description

2.1 Product Description

Bluesun series three -phase string on-grid inverter is independent developed by Bluesun.

it's main function is converting DC current generated by PV arrays into AC current and feeding it

into the grid.

Bluesun BSM8K-B/10K-B/12K-B are 2-input string inverters. Bluesun BSM15K-B/17K-B are

3-input string inverters. Bluesun BSM20K-B/22K-B/25K-B are

4-input string inverters. Bluesun

BSM30K-B/33K-B

are 6-input string inverters. These products only suit for 400VAC low-voltage

grid-connected scenarios, such as village-level photovoltaic power stations below 400KW or

industrial and commercial rooftop photovoltaic power stations.

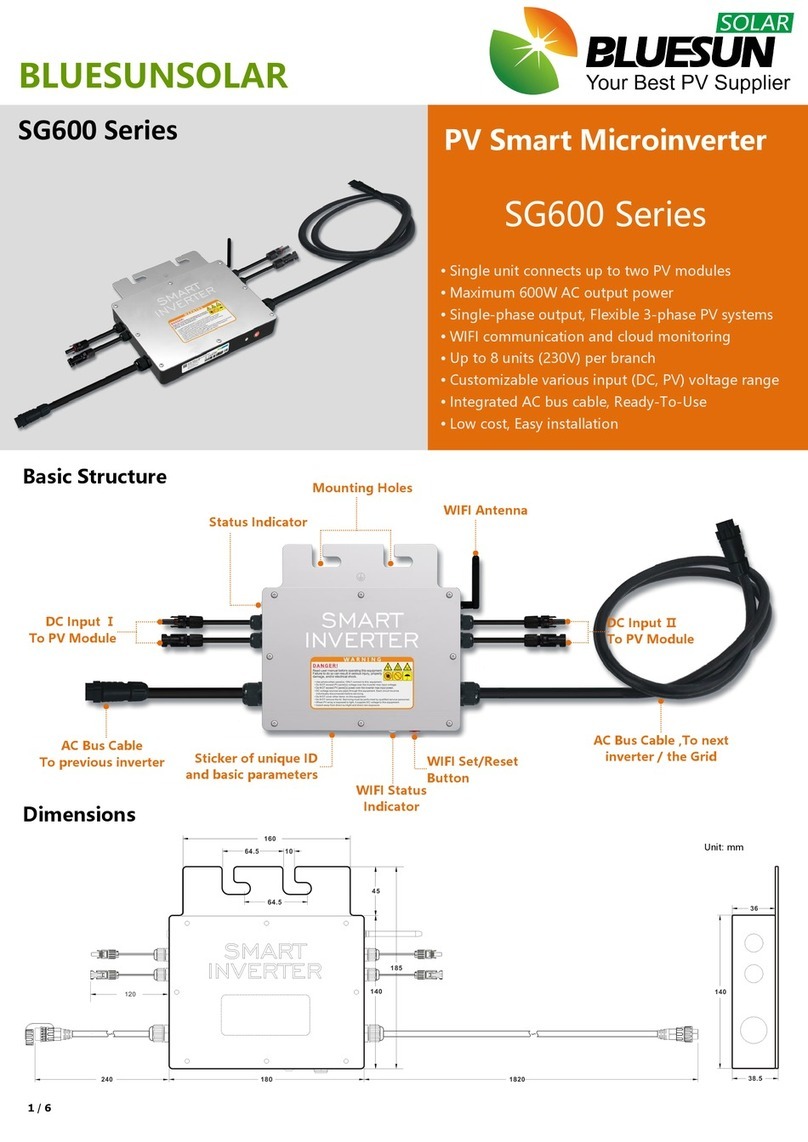

2.1.1 Schematic Diagram

Bluesun BSM8K-B/10K-B/12K-Bare connected to the inverter through 2 PV string inputs.

Bluesun BSM15K-B/17K-B are connected to the inverter through 3 PV string inputs. Bluesun

BSM20K-B/22K-B/25K-B are connected through 4 PV string inputs In the inverter. Bluesun

BSM30K-B/33K-B are connected to the inverter through 6 PV string inputs. There are 2 MPPT

inside the inverter for MPPT tracking of the strings, and then the inverter circuit realizes DC

conversion to three-phase Alternating current as he schematic diagram below.

1+2+1-2-

PE

InputEMIFilterMPPTCircuit1MPPTCirciut2

BUS+BUS-

Three-l evel invertcircuitLCLFilter

RCD l eakage curr ent detection

OutputEMIFilter

NABC

Figure 2-1 Two-input string inverter system schematic diagram

1+2+1-2-3+3-PEInputEMIFilterMPPTCircuit1MPPTCircuit2BUS+BUS-Three-levelinvertcircuitLCLFilterRCD l eakage curr ent detectionOutputEMIFilterNABC

Figure 2-2 Three-input string inverter system schematic diagram

OutputEMIFilter1+2+1-2-3+4+3-4-PEInputEMIFilterMPPTCircuit1MPPTCirciut2BUS+BUS-Three-l evel invertcircuitLCLFilterNABCRCD l eakage curr ent detection

Figure 2-3 Four-input string inverter system schematic diagram

1+2+1-2-3+4+3-4-5+6+5-6-

PE

InputEMIFilterMPPTCircuit1MPPTCircuit2

BUS+BUS-

Three-phaseinvertcircuitLCLFilterOutputEMIFilter

NABCPERCD l eakage curr ent detection

Figure 2-4 Six-input string inverter system schematic diagram

circuits

User Manual of String Inverter

6

2.1.2 Operation Mode

HV string inverter includes three operation modes: standby mode, operation mode

and shutdown mode. The three mode switching conditions are shown in Figure 2-5.

Standby

Mode

Operation

Mode

Shutdown

Mode

Operation mode to standby mode:

Insufficient sunshine or DC switch

is turned off

Standby mode to operation mode:

Abundant sunshine without

system faults

Fault or shutdown command is detected

Standby mode to

shutdown mode: fault or

shutdown command is

detected

Shutdown mode to standby

mode: fault is deleted or

startup command is detected

Figure 2-5 string inverter operation mode

Operation Mode

Description

St

andby

1) Standby mode mainly refers to the external environment doesn't meet the operation

condition, such as insufficient sunshine or DC switch is turned off. Under this mode, the

inverter continuously performs self-checking and enters operation mode once the

operation conditions are satisfied.

2) Under standby mode, the inverter will enter shutdown mode after detecting the

shutdown command or faults.

O

peration

1) Under the operation mode, the inverter converts DC current of photovoltaic arrays into

AC current and feeds it to the grid. The inverter performs MPPT arithmetic and outputs

the maximum power of photovoltaic arrays.

2) The inverter will enter shutdown mode after detecting the faults or shutdown

command.

3) The inverter will enter standby mode after detecting the input power of photovoltaic

arrays is lower than the on-grid power generation condition.

S

hutdown

1) If the inverter detects a fault occurrence or shutdown command during standby or

operation mode, it enters shutdown mode.

2) In the shutdown mode, if the inverter detects that the fault has been cleared or the

power-on command, it enters standby mode.

2.2 System Configuration and Application

2.2.1 Application Description

Figure 2-6 shows the application diagram of the string inverter network, Figure 2-7 shows the

design scheme of the distributed PV power plant.

Photovoltaic

panel

String

inverter Measuri ng unit Grid

Figure 2-6 Application diagram of the string inverter network

Bluesun

Bluesun

5

2 Product Description

String inverter

PV arrays

Box-type

transformer

Power grid

User load

WiFi/GPRS

wireless module

Mobile

Internet

Internet

Internet

hopeCloud

hopeView

Client

Central monitoring center

Figure 2-7 Design scheme of the l distributed PV power plant

2.2.2 Supported Grid Form

BluesunBSM8K-B ~ Bluesun BSM33K-B support the TN -S , TN -C , TN -C -S ,TT IT sys tems in Figure

2-8.

Figure 2-8 Schematic diagram of IT system

2.3 Naming Rules

30K-B

Rated output power:

30K--30kW 33K--33kW…String inverter series

Output side without

isolationtransformer

Figure 2-9 Naming rules

BLUESUN BSM

6

User Manual of String Inverter

8

2.4 Nameplate label

(Note: The data is for reference only; please refer to the physical or technical agreement of the

corresponding product for actual parameters)

PV Grid-interactive

Inverter

贴序列号标签

Protection Class:I Model: BSM30K-B

Serial No.:

Ingress Protection:IP65

Max.Output Power:33kW

Bluesun Solar Co., Ltd

www.bluesunpv.com

Nominal Output Voltage:400Va.c./230Va.c.;3P+N+PE

Nominal Output Frequency:50Hz/60Hz

Max.Output Current:47.8A

Rated Output Power:30kW

Operating Ambient Temperature:-40 to +60℃

Power Factor:0.8 -0.8

(lagging) (leading)

Max. Input Current:40A/40A

Isc PV:60A/60A

Max.Input Voltage:1100Vd.c.

MPP Voltage Range:200-1000Vd.c.

7

2 Product Description

8

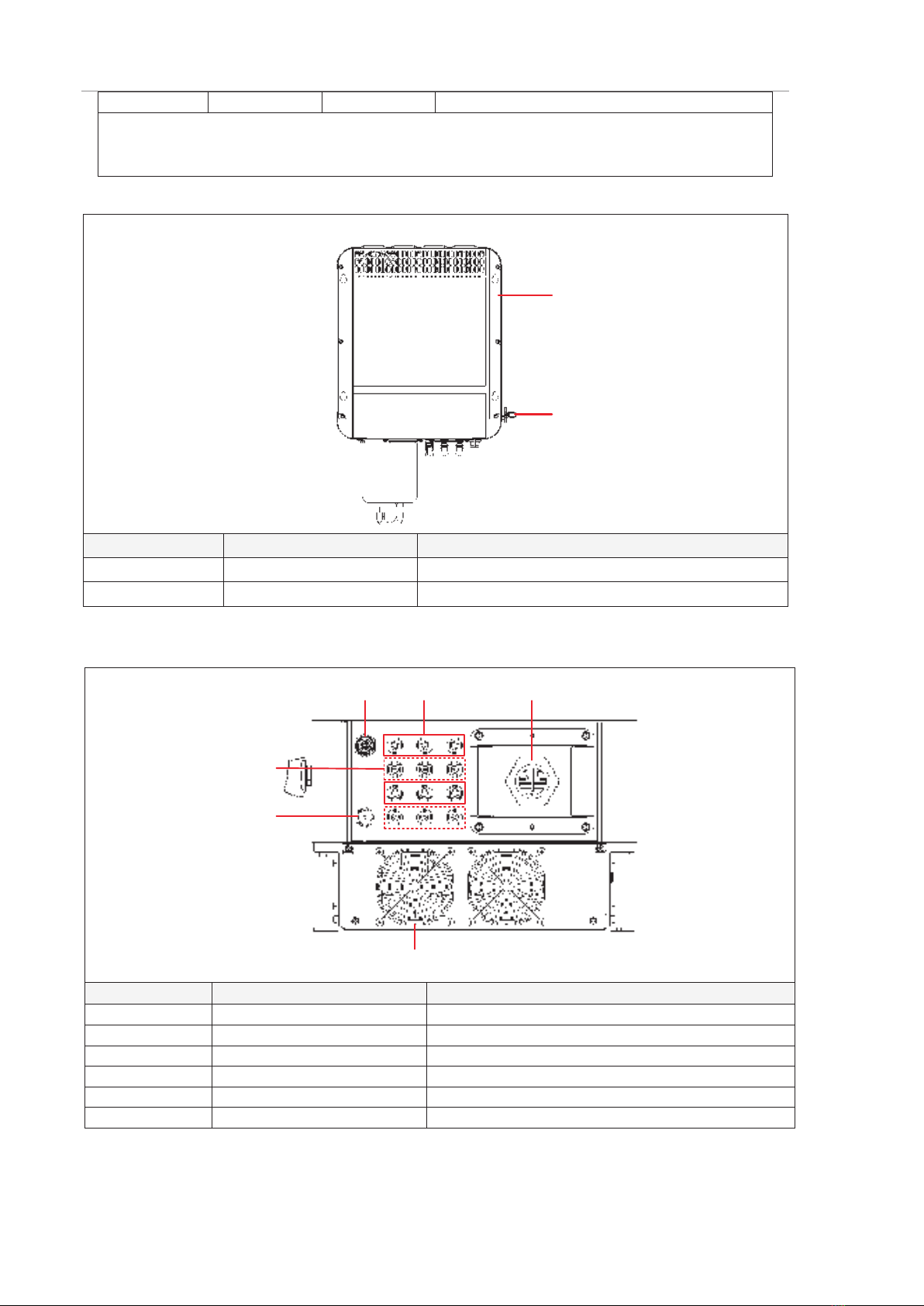

2.5 Machine Configuration

This section describes the internal components, back device, and bottom interface of the

string inverter. Bottom structure may differ from other models, the 30KTL is taken as an example

here.

CAUTION

There are components on the board that are sensitive to static electricity. Anti-static measures must be

taken before touching the board.

When touching the board, please be careful to avoid scratching the electrical components.

12

No.

Label

Component Name

1

LED indicator

2

AC cable shield

Figure 2-10 Front view of the inverter

The LED indicators from left toright are described as follows:

Table 2-1 LED Indicator Description

Indicator light Meaning Status Meaning

PV and grid

connection

Blue indicator

lights on

DC voltage is more than 200V and grid is connected

normally.

Blue indicator

flashes

DC voltage is more than 200V (grid is not

connected).

Blue indicator

lights off At least 1 PV array is normally connected.

On-grid

operation

Blue indicator

lights on The inverter is in the on-grid status.

Blue indicator

lights off The inverter is not connected to the grid.

Communication

indication

Blue indicator

flashes Normal communication.

Blue indicator

lights off Abnormal communication.

Alarm

indication

Red indicator

flashes slowly PID is operating.

Red indicator

flashes Abnormal alarm: regular alarm.

Red indicator

Critical alarm: faults.

User Manual of String Inverter

10

lights on

Remarks:

Slow flashis defined as: 1 second lights up, 2 seconds lights off.

Flashis defined as: 0.5 seconds lights up, 0.5 seconds lights off.

12

No. Label Component Name

1 Hanging Bracket

2 DC Switch

Figure 2-11 Back view of the inverter

123654

No.

Label

Component Name

1

1+ ~ 6+

PV+ terminals

2

1- ~ 6-

PV- terminals

3

Anti-backflow terminal

4

WiFi/GPRS communication interface

5

AC OUTPUT

AC terminal

6

Fan

Figure 2-12 Bottom view of the inverter

Note: Bluesun BSM8K-B/10K-B/12K-B has only 2 PV inputs at the bottom, Bluesun BSM 15K-B/17K-B

has 3 inputs, Bluesun BSM 20K-B/22K-B/25K-B has 4 inputs, and Bluesun BSM 30K-B/33K-B has 6

inputs. Bluesun models of 17K-B and below have no cooling fan at the bottom.

9

2 Product Description

2.6 Signs and labels

On the outer packaging of the product, there are some labels to guide the user to transport

and store the product. The meanings indicated by the labels are as follows:

Do not stack or

backlog

Handle with care and

avoid damage caused by

severe collision or friction

during transportation.

Forbid stampede

Pay attention to rain and

moisture-proof.

Stand upright and do

not tilt

Prohibition of tilting or

turning products

Front facing of the

inverter

Back facing of the

inverter

2.7 Warning Labels in Inverter

In order to ensure the safety of the person and property when using the product and to avoid

accidents, the following warning labels may be provided inside and outside the body of the string

inverter to remind the user of the safety precautions during operation.

PE: Here is the protective grounding terminal, requires reliable grounding to ensure the

safety of operators and equipment.

Warning: This component may present a hazard other than high voltage, which the user

should pay attention to.

High voltage hazard: This component may present a high voltage hazard and the user

must pay special attention.

Hot surface: Pay attention to the hot surface to prevent burns.

Refer to the user manual: Please refer to the corresponding instructions in the user

manual before operation.

Discharge identification: This equipment has an energy storage device. Before

maintenance, it is necessary to wait for the energy storage device to discharge to prevent

electric shock. The waiting time is not less than the indicated discharge time.

10

User Manual of String Inverter

12

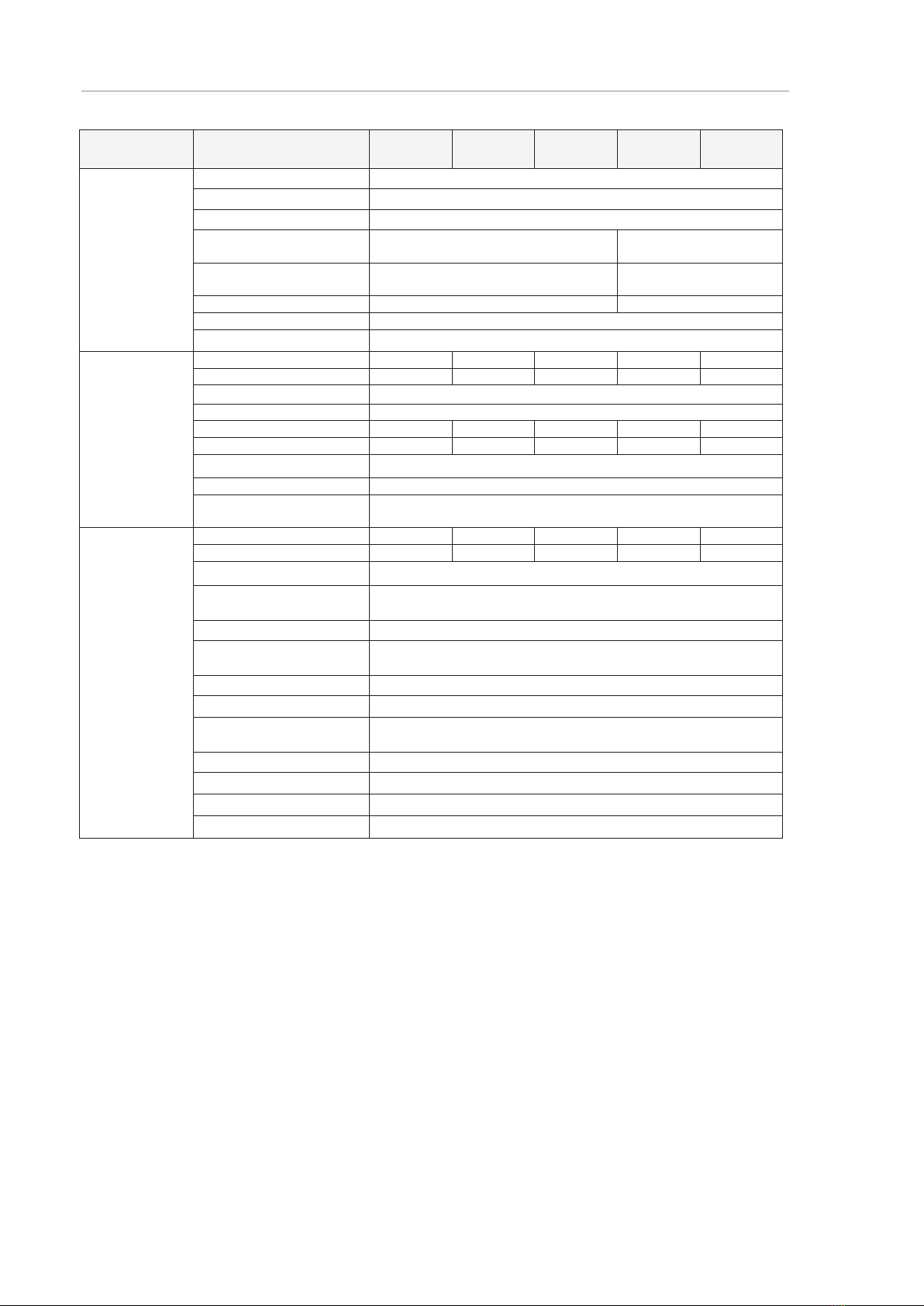

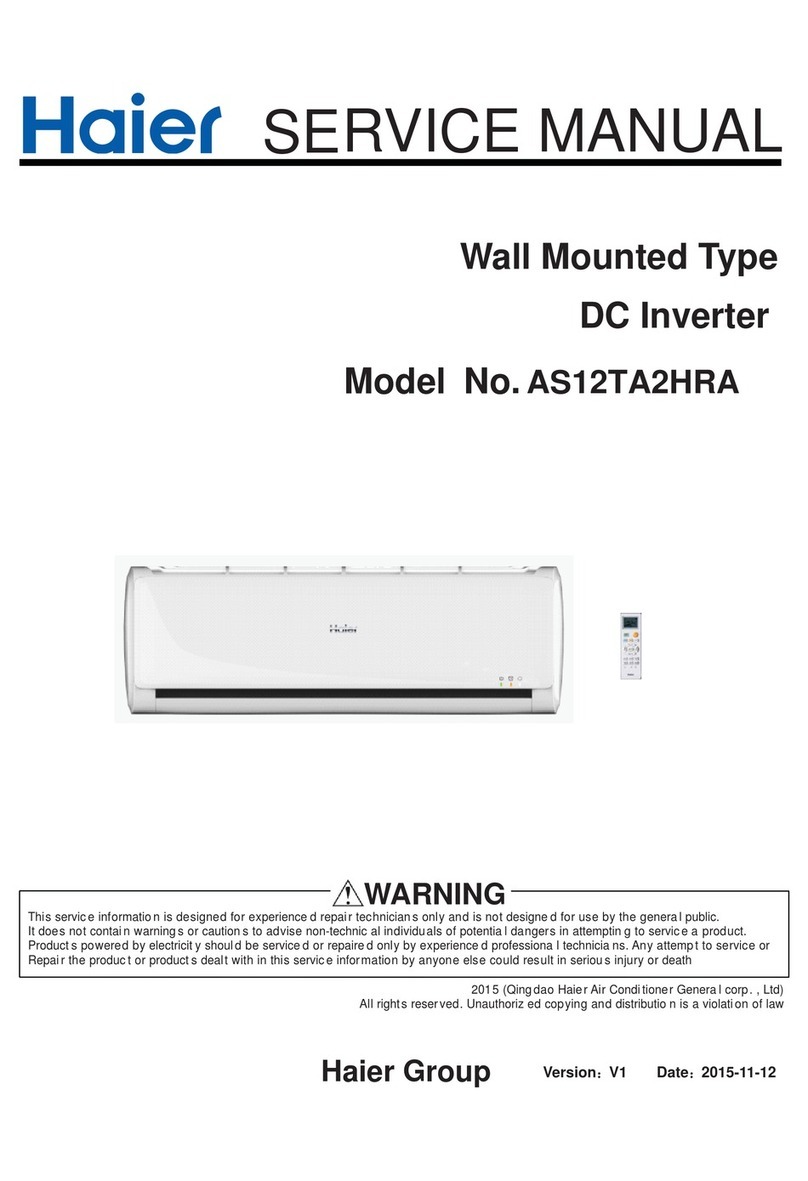

2.8 Technical Data

Model

Bluesun BSM 8K-B

Bluesun BSM 10K-B

Bluesun BSM 12K-B

Bluesun BSM 15K-B

Bluesun BSM 17K-B

DC parameters

Maximum DC voltage

1100V

Startup voltage

180V

MPPT voltage range

200V~1000V

MPPT full load working

voltage range

370V~850V 450V~850V

Maximum input current per

MPPT

20A/20A 26A/20A

Maximum input path

2

3

Number of MPPT

2

Back-feed current 0.5mA

AC parameters

Rated output power

8kW

10kW

12kW

15kW

17kW

Maximum active power

8.8kW

11kW

13.2kW

16.5kW

18.7kW

Rated grid voltage

400VAC

Allowable voltage range

300VAC~480VAC

Rated output current

11.6A

14.5A

17.4A

21.7A

24.6A

Maximum output current

12.7A

16A

19.1A

23.9A

27A

Rated grid frequency 50Hz/60Hz

Power factor

-0.8~+0.8

Total harmonic distortion

of current

<3%

System

parameters

Maximum efficiency

98.60%

98.60%

98.60%

98.61%

98.62%

European efficiency

98.30%

98.30%

98.30%

98.30%

98.30%

Insulation impedance test Supported

Residual leakage current

detection

Supported

String fault detection

Supported

Output over current

protection

Supported

Protection grade

IP65

Cooling mode

Natural cooling

Standby power

consumption

<1W

Display

LED indicators + APP

Communication interface

GPRS, 485RJ , Anti-backflow

DC terminal

MC4 plug-in terminal

AC terminal

OT terminal & Waterproof lock

11

2 Product Description

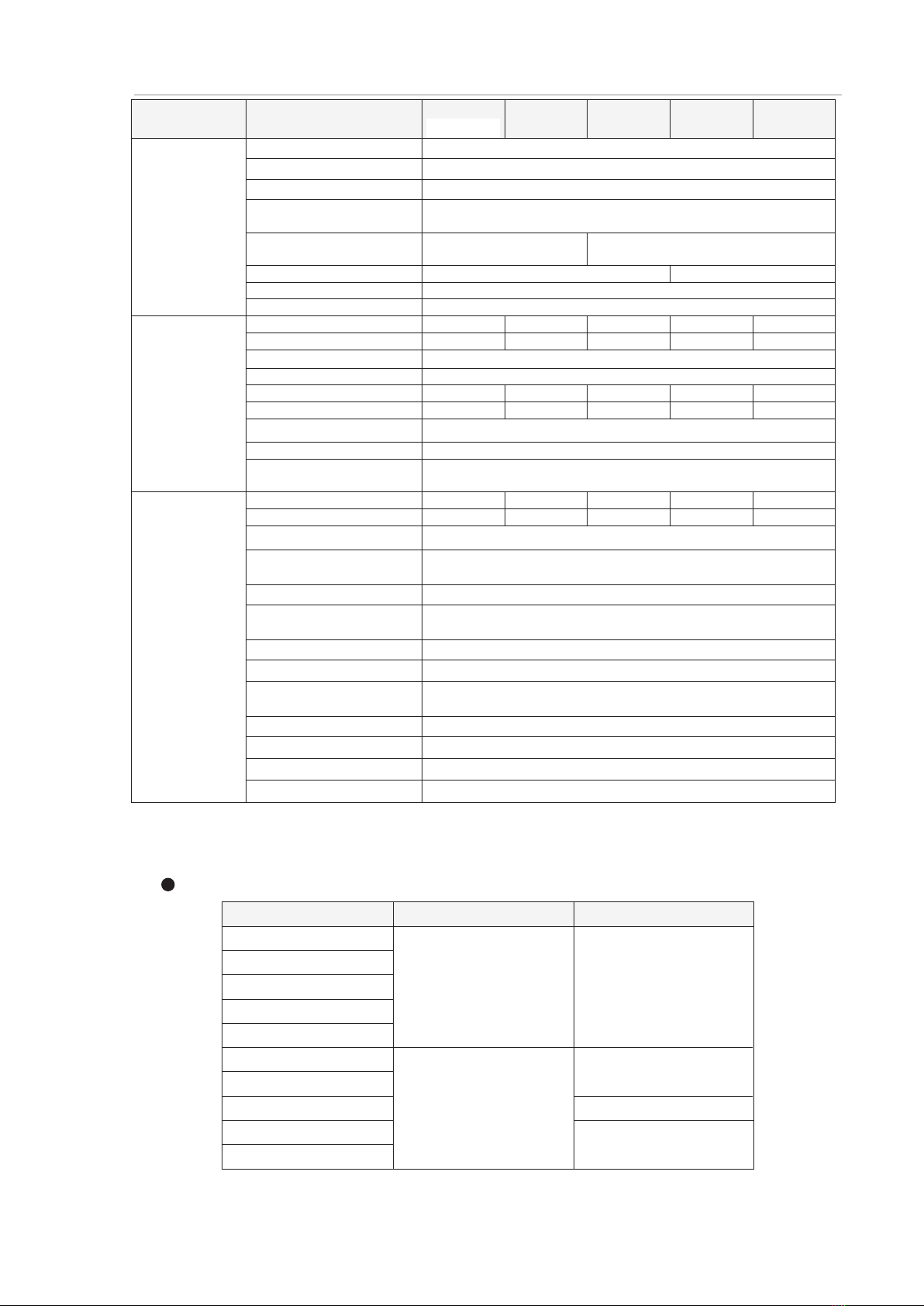

Model

Bluesun

BSM 20K-B

Bluesun

BSM 22K-B

Bluesun

BSM 25K-B

Bluesun

BSM 30K-B

Bluesun

BSM 33K-B

DC parameters

Maximum DC voltage

1100V

Startup voltage

180V

MPPT voltage range

200V~1000V

MPPT full load working

voltage range

425V~850V

Maximum input current per

MPPT

30A/30A 40A/40A

Maximum input path

4

6

Number of MPPT

2

Back-feed current

0.5mA

AC parameters

Rated output power

20kW

22kW

25kW

30kW

33kW

Maximum active power

22kW

24.2kW

27.5kW

33kW

36.3kW

Rated grid voltage

400VAC

Allowable voltage range

300VAC~480VAC

Rated output current

28.9A

31.8A

36.1A

43.5A

47.6A

Maximum output current

37.8A

35A

39.7A

47.8A

52.4A

Rated grid frequency 50Hz/60Hz

Power factor

-0.8~+0.8

Total harmonic distortion

of current

<3%

System

parameters

Maximum efficiency

98.63%

98.65%

98.94%

98.60%

98.60%

European efficiency

98.30%

98.30%

98.26%

98.30%

98.30%

Insulation impedance test Supported

Residual leakage current

detection

Supported

String fault detection

Supported

Output over current

protection

Supported

Protection grade

IP65

Cooling mode

Intelligent air cooling

Standby power

consumption

<1W

Display

LED indicators + APP

Communication interface

GPRS, 485RJ , Anti-backflow

DC terminal

MC4 plug-in terminal

AC terminal

OT terminal & Waterproof lock

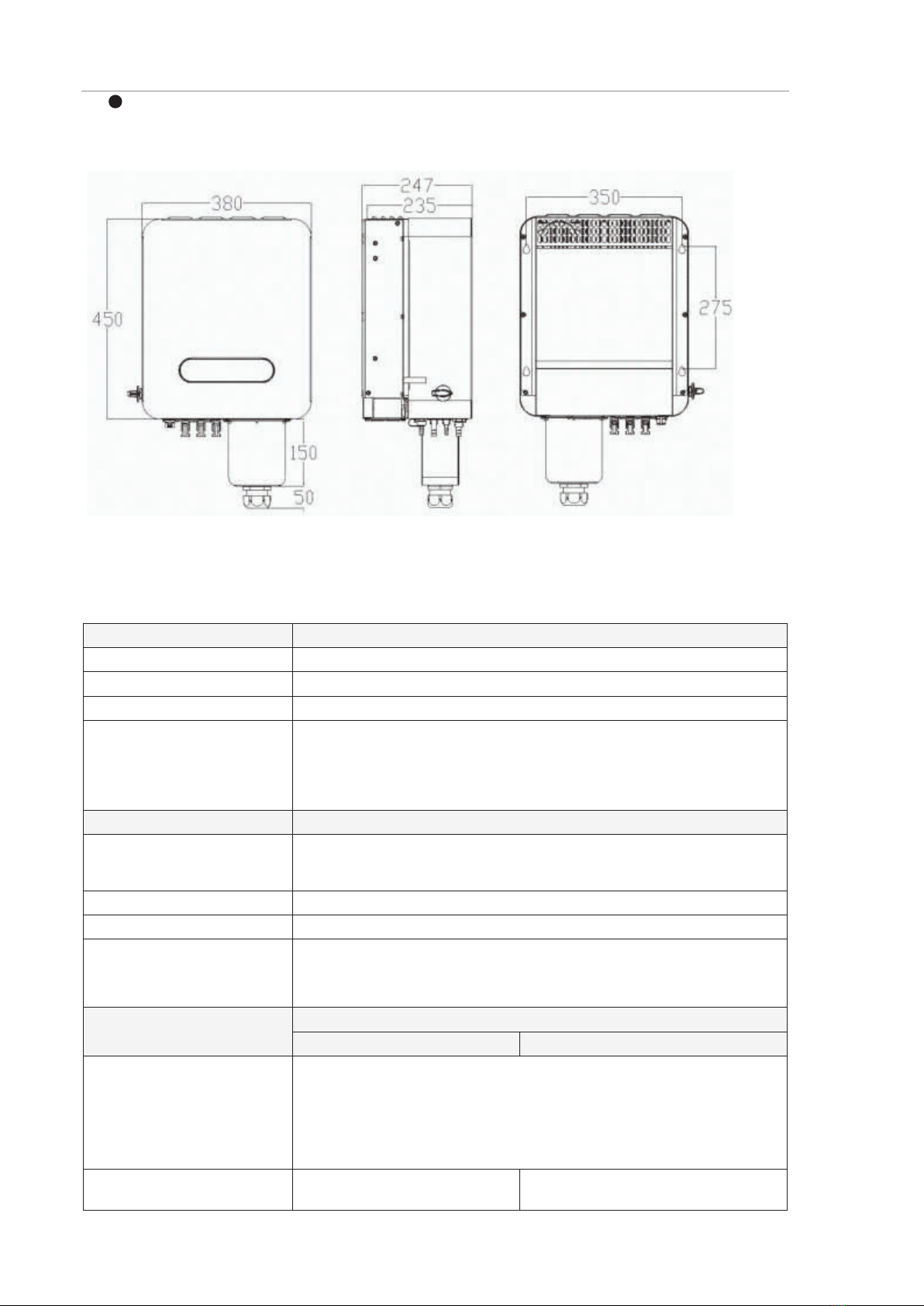

2.9 Mechanical Parameters

Size and weight

Model W*H*D (mm) Net weight (kg)

Bluesun BSM 8K-B

≤22

≤25

≤30

Bluesun BSM 10K-B

Bluesun BSM 12K-B

≤35

Note: size does not contain hangers, handles, pads, and so on. Dimensional error: ± 10mm.

Bluesun BSM 15K-B

Bluesun BSM 17K-B

Bluesun BSM 20K-B

Bluesun BSM 22K-B

Bluesun BSM 25K-B

Bluesun BSM 30K-B

Bluesun BSM 33K-B

12

380*400*247

380*450*247

User Manual of String Inverter

14

Inverter structure size

Note: The model shown in the picture below is 30KTL. The inverter sizes of other models are

similar, only the sizes of AC protection shell may be different.

Figure 2-13 Bluesun series inverter and hanging board size (left, front, back, unit: mm)

2.10 Ambient Requirements

Transportation environment Requirements

Type of shipping Waterways, railways, highways, aviation, etc.

Ambient temperature -40℃~+70℃

Relative humidity ≤95%when the temperature is +40℃

Mechanical conditions The vibration should not exceed the following limits:

2Hz≤f<9Hz, displacement 7.5mm;

9Hz≤f<200Hz, acceleration 20m/s2;

200Hz≤f<500Hz, acceleration 40m/s2;

Storage environment Requirements

Storage place Store in a warehouse with air circulation, no harmful gases, no flammable and

explosive substances, and no corrosive substances. Avoid strong mechanical

vibration and impact; stay away from strong magnetic fields.

Ambient temperature -40℃~+70℃

Relative humidity ≤95%

Mechanical conditions The vibration should not exceed the following limits:

10Hz≤f<57Hz, displacement 0.075mm;

57Hz≤f<150Hz, acceleration 10m/s2;

Working environment Requirements

Normal operating state Shut down state

Installation site Usually installed outdoors, at the bottom of the photovoltaic module.

Do not install the inverter in areas where flammable and explosive

substances are stored.

Avoid direct sunlight, rain and snow to extend the life of the inverter. It is

recommended to install in a sheltered place. If it can’t be satisfied,

please build a sunshade.

Ambient temperature -40℃~+60℃(After exceeding

45 ℃, the maximum continuous

-40℃~+70℃

13

2 Product Description

Transportation environment Requirements

input power and branch current

will be derated)

Relative humidity ≤100%, allow internal condensation

Altitude ≤4000m, must be derated above 4000m

Mechanical conditions Vibration should not exceed the following limits:

10Hz≤f<57Hz, displacement 0.075mm;

57Hz≤f<150Hz, acceleration 10m/s2;

-- Chapter end --

14

3 System installation

3.1 Unpack and inspection

After confirming that the outer packaging is intact, please perform unpacking inspection.

Unpack the box and check whether the appearance of the string inverter is good. When opening

the packing box, you need to use tools carefully to avoid scratching the string inverter;

The string inverter has been rigorously tested and inspected at the factory, but accidental

damage may occur during transportation, so please check the string inverter immediately after

receiving the goods. If you find any damage or omissions, please contact Bluesun Technology

as soon as possible, our staff will serve you as soon as possible.

3.2 Preparation of installation tools

Tool or equipment Use Remarks

4#Allen wrench Disassembly and assembly of the lower

door panel of the inverter

Phillips screwdriver (PH2) Loosen/tighten the screws of the output

terminals and baffles Bolt spec: M6,M8

Tube terminal crimping pliers Crimp the communication cable

terminal /

Socket wrench AC wiring Bolt spec: M8

MC4 Terminal crimping pliers Crimp MC4 terminal

The input cable needs to be crimped

into the MC4 terminal before it can

be connected to the PV + / PV-

terminal on the string inverter.

MC4 Removal tool Remove MC4 terminal /

Wire stripper Stripping wire /

Multimeter Measure voltage to ensure safety

during wiring and installation /

Safety protective equipment Labor protection necessary for

construction Insulation shoes, gloves, etc.

3.3 Installation environment requirements

The environmental requirements for the installation of string inverters are shown in "2.10

Ambient Requirements".

The installation method and position must be suitable for the weight and size of the string

inverter, see "2.9 Mechanical Parameters ".

The string inverter should be installed in a well-ventilated environment to ensure good heat

dissipation. Protect the inverter from direct sunlight, rain and snow can extend the life of the

inverter. It is recommended to choose a sheltered installation site. If it cannot be satisfied,

please build a sunshade (optional accessory).

During the operation of the string-type inverter, the temperature of the chassis and heat sink

will be relatively high, please installed the inverter in a location where it will not be accidentally

touched.

Note: This chapter takes Bluesun BSM 30K-B as an example to introduce the cable connection

methods for installation. The interfaces of other models may be a bit different, so please connect

cables according to actual situation while referring to this chapter.

15

User Manual of String Inverter

18

3.4 Requirements for reserved space

When installing string inverters, proper space must be reserved around the string inverters to

facilitate heat dissipation and maintenance.

≥500mm

≥300mm

≥500mm

≥

200mm

≥1000mm

Figure 3-1 Installation space of string inverter

When multiple string devices are installed on the same plane, it is recommended to install in a

straight line.

≥200mm ≥200mm

Figure 3-2 Installation space of string inverter

If you need to install it in two rows, it is recommended to install them in the shape of triangle.

≥100mm ≥300mm ≥100mm ≥300mm

Figure 3-3 Installation space of string inverter

16

3 System installation

3.5 Fixing method

WARNING

1. For precautions during inverter installation, please refer to "1 Safety Precautions"; for installation

environment requirements, please refer to "3.3 Installation environment requirements".

2. During installation, it must be confirmed that the on-site installation position can bear the total weight of the

inverter and accessories to avoid falling during installation or use.

3. It is recommended that four people work together to fix the inverter to avoid mechanical injury. During the

installation process, safety measures should be taken to prevent damage.

4. Please install it vertically or tilt it up to 15 ° backward to facilitate heat dissipation. Do not install the inverter

at an angle (tilt forward, tilt backward > 15 °, roll), horizontally, or upside down.

<15°

√√XX

5. If direct sunlight cannot be avoided, please add a sunscreen.

Installation steps

1. Refer to the fixed hole size of the inverter, use a drill with 100mm diameter to make holes

in the wall or bracket. The hole depth in the wall is about 80mm.

2. Unload 4PCS M6 casing reinforced expansion anchor into the wall holes, or use M6

combination bolts to pass it from the back to the front of the bracket. And use flat

washers/nuts to fix it in the front side.

Expansi on bolt(M8)

Dri l l on the wal l

Figure 3-4 Schematic diagram of drilling holes

3. Hang the inverter on the screw of the expansion bolt or combination screw,and use

spring washers/flat washers/nuts to fix it.

Expansi on boltSpring washer/

Fl at washer/Nut

Figure 3-5 Schematic diagram of wall-mounted (hoop) installation

17

This manual suits for next models

1

Table of contents

Other BlueSun Inverter manuals

Popular Inverter manuals by other brands

Mitsubishi Electric

Mitsubishi Electric 800 Series instruction manual

Xantrex

Xantrex Freedom SW 815-2024 owner's guide

Twin Disc

Twin Disc TECHNODRIVE TM 485-A1 operating manual

Latronics

Latronics PV Edge Grid 915-GI-72 user manual

Effekta

Effekta 10A/WRSL-12-1500 instruction manual

Haier

Haier AS12TA2HRA Service manual

ElectroDacus

ElectroDacus DSSR20 user manual

Xantrex

Xantrex 1200, 1750 owner's guide

Chicago Electric

Chicago Electric Power Systems 96706 Set up and operating instructions

DAH Solar

DAH Solar DHP60 5BB Series installation manual

SolarMax

SolarMax 360TS-SV Compact Station instruction manual

Lenze

Lenze 8200 series operating instructions