1 pair of wing strut 1x canopy

1 pair of main wheel / wheel pants 1x hardware pack

1 set of tail wheel assembly 1 set of nylon sticker (3x ORACLE

1x landing gear and block 2x BME Aircraft)

1 set (4x) center cabane

2. Iron all film cover area---

Before you start assembling, Iron all film covered area to make sure

that the film stick on firmly.

3. Cut out film covered area

Cut out the film that covers the opening like servo mount, hinges etc.

II. Start assembling

A. Fuselage—

1. Center cabane

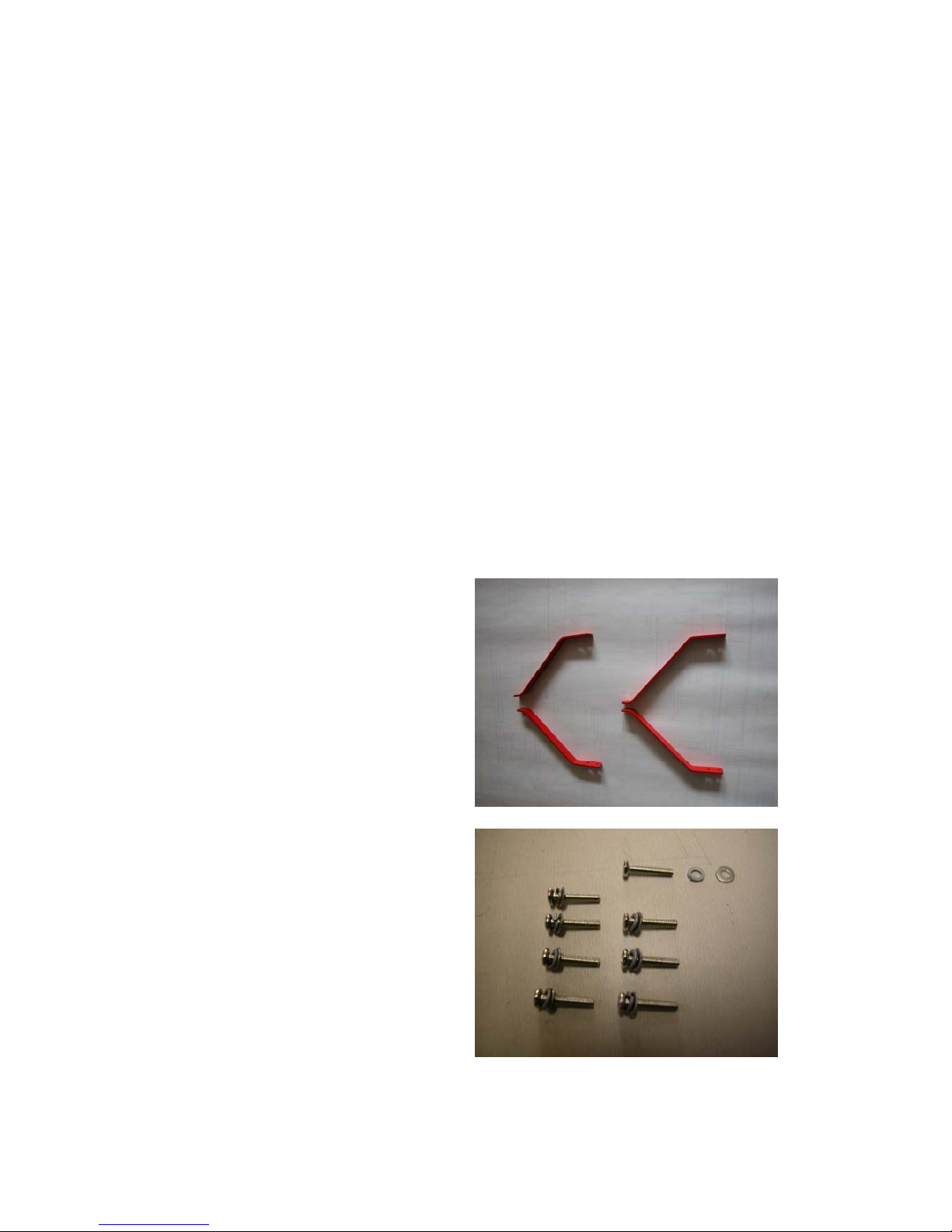

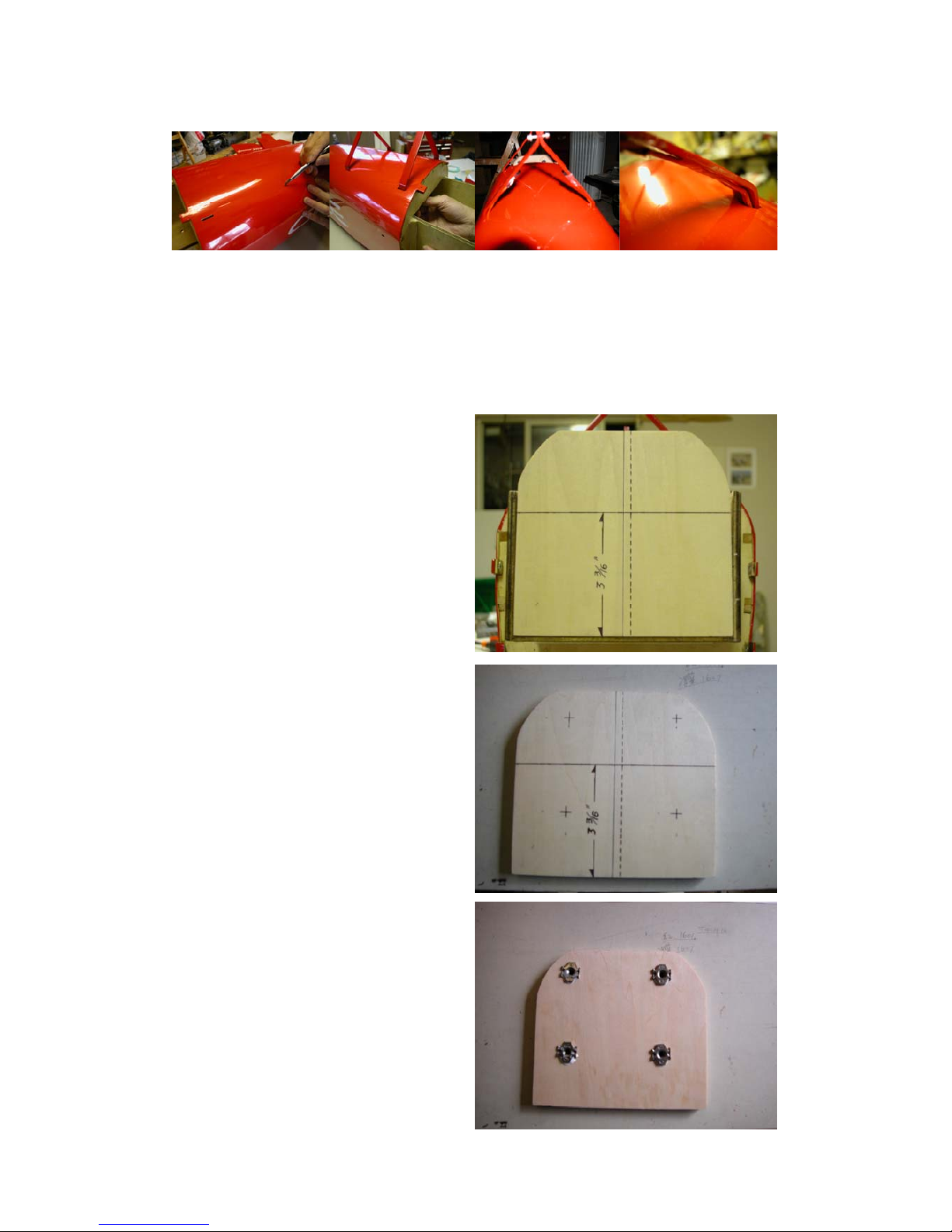

a.Find 4 pcs of aluminum

center cabane from the bags.

There should be two longer

ones and two shorter ones.

Then find the pre-cut 4 slots on

top of the fuse front. Insert 4

cabanes into 4 slots. The

shorter ones goes into the front

slot, longer ones into the rear.

Find 1/2” 4-40 screws from the

hardware pack with the washers

and spring washers to secure

the cabane in place. Thread

lock is required on these

screws.

b. Use two Y-harness, one on

each side of the rear cabane for

aileron connection.

2