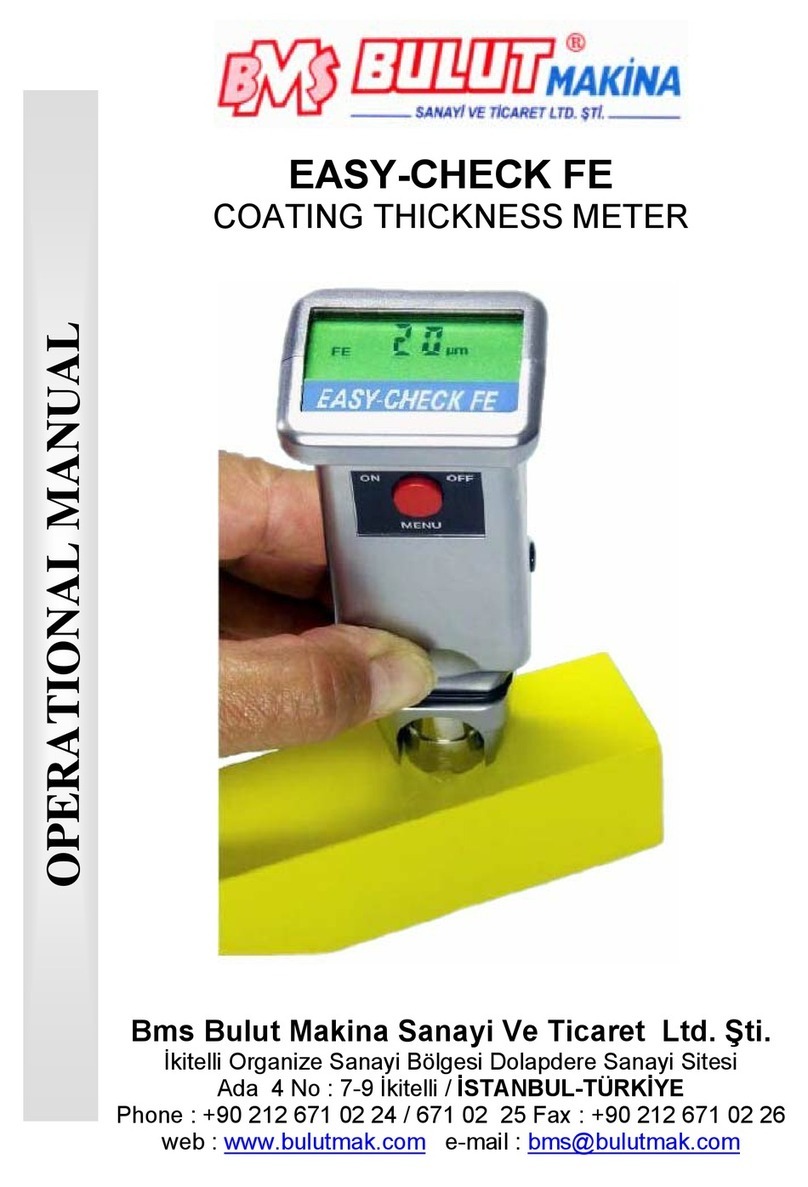

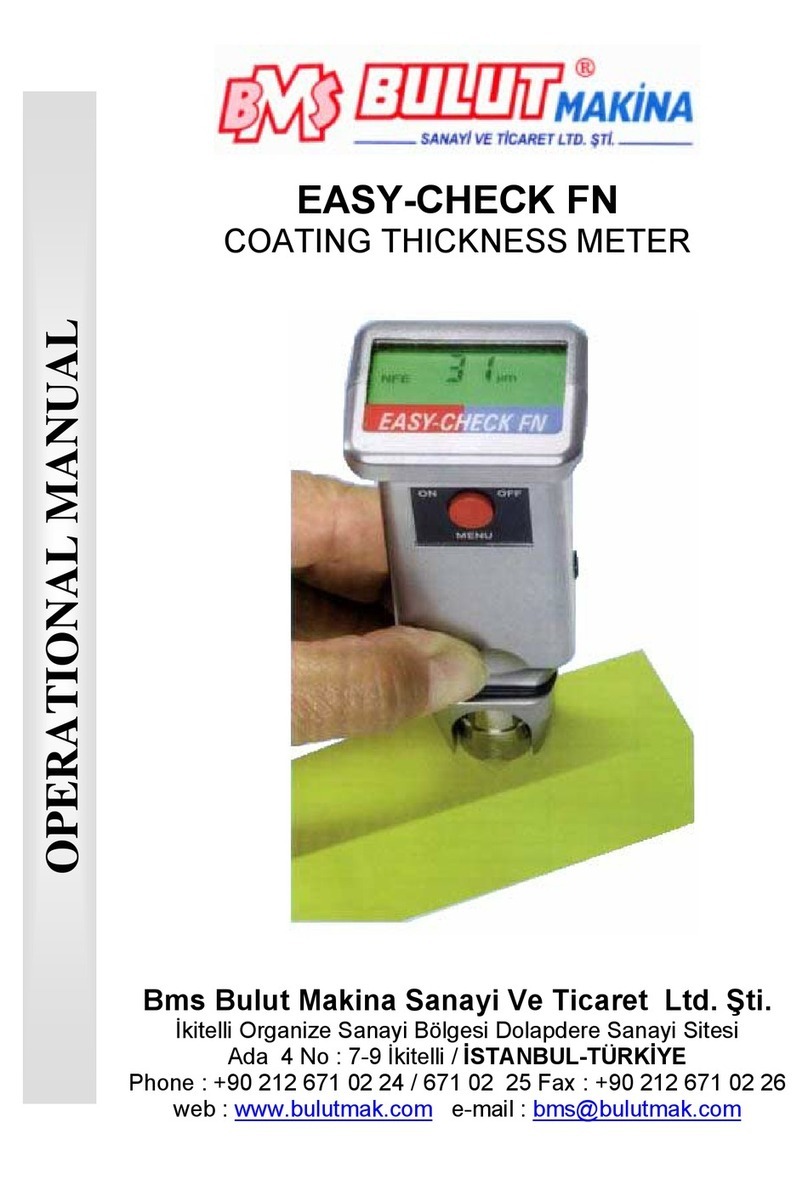

BMS ETA-0832 Quick start guide

OPERATIONAL MANUAL

ETA-0832

COATING THICKNESS METER

BMS Bulut Makina Sanayi Ve Ticaret Ltd. Şti.

İkitelli Organize Sanayi Bölgesi Dolapdere Sanayi Sitesi

Ada 4 No : 7-9 İkitelli / İSTANBUL-TÜRKİYE

Phone : +90 212 671 02 24 / 671 02 25 Fax : +90 212 671 02 26

1.Brief Introduction.............................................................................................3

2.Characteristic...................................................................................................3

3.Display Instruction ...........................................................................................3

4.Technology Parameter......................................................................................3

4.1 Standard Delivery.......................................................................................3

5.Measuring Procedure........................................................................................5

6.Calibration.......................................................................................................5

7.Battery Replacement ........................................................................................5

8.Considerations.................................................................................................6

9.Restore Factory Setting.....................................................................................6

10.Notes ............................................................................................................6

Operation

ETA-0832 Manual Rev:00 2 / 6

1.Brief Introduction

* It meets the standards of both ISO2178 and ISO-2361 as well as DIN, ASTM and

BS. Suitable for the laboratory and for use in harsh field conditions.

* The gauge can measure the thickness of non-magnetic coating layers on magnetic

substrate.Such as: (aluminum, chrome, copper, enamel, rubber, paint) on magnetic

substrate (steel, iron, alloy and magnetic stainless steel)..

* The gauge can measure the thickness of non-metals coatings layers covered on

non-magnetic metals substrate. Such as: (enamel, rubber, paint, vanish, plastic

anodic-oxide layer) covered on non-nagnetic metals substrate (aluminum, brass, zinc

and nonmagnetic stainless steel).

2.Characteristic

* Small style design, conveniently carry

* Complete intelligentized design, easily operate

* Rapid measure, excellent repeated performance

* Zero adjustment, second point adjustment

* LCD digital display

* The metric system /English system unit transform

* There is bee ring song prompt during operation

* Two types of probe heads design, which is applicable to different test situations

3.Display Instruction

* μm indicate value unit (1 μm=1/1000mm)

* CAL O ZERO Adjustment

* Fe Magnetism substrate measure state

* NFe Non-magnetism substrate

Measure state

* 9999 restore factory setting

4.Technology Parameter

* Range : 0-1000um

* Accuracy : ±[(1%~3%)]H±1.5um

* Resolution : 0.1um (0~99.9um)

1um (over 100um)

* Environment temperature : 0-40°C

* Relative humidity : ≤85%

* Power supply : 1.5V×2

* Weight : 98g

* Dimension : 102×66×24mm

4.1 Standard Delivery

Main unit(1000um) 1pc

Instruction manual 1pc

Substrate 2pc

Carrying case 1pc

Measuring foil set 1set

Operation

ETA-0832 Manual Rev:00 3 / 6

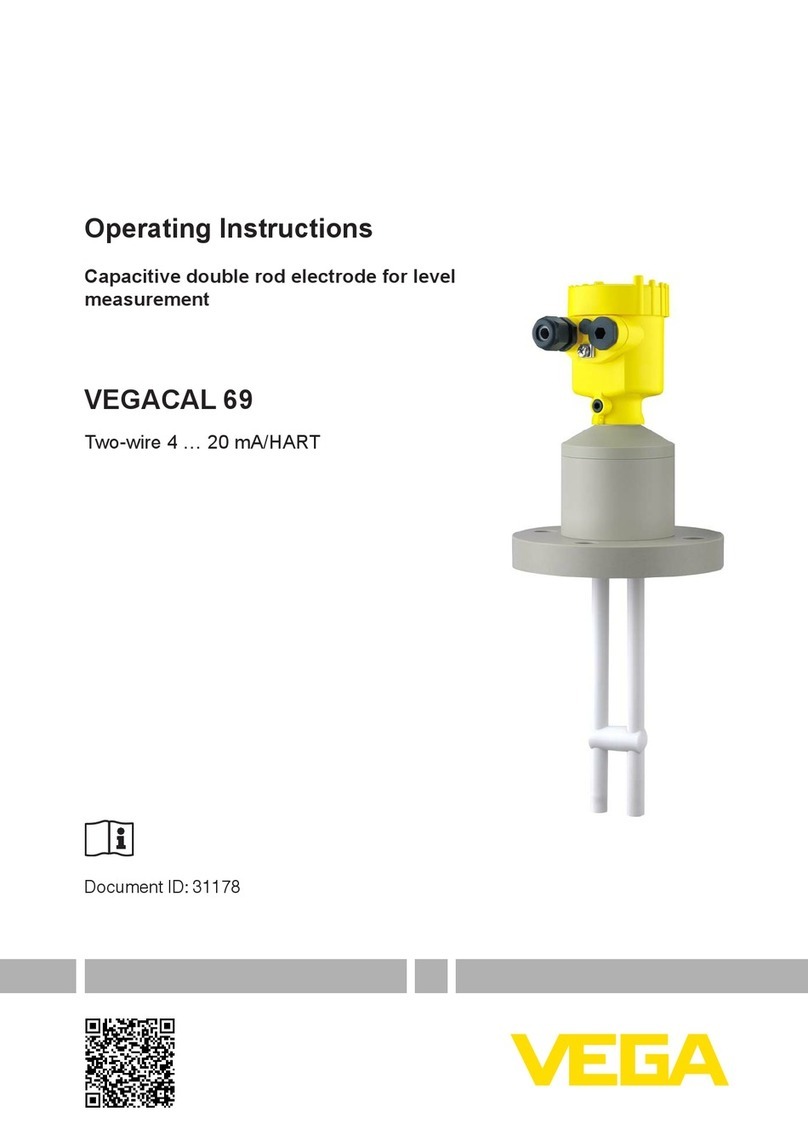

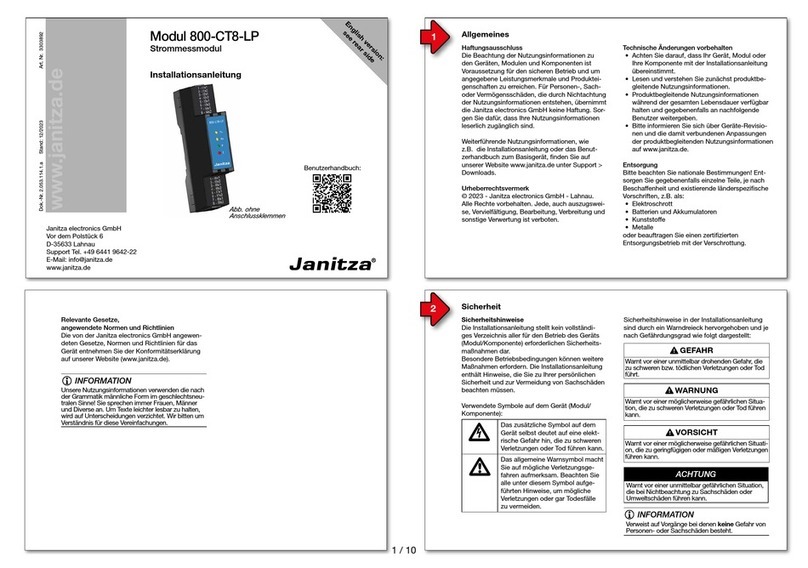

KEYPAD

SUBSTRATE (NFE)

MEASURING FOIL DIGITAL SCREEN

MAI

N

UN

IT SUBSSTRATE (FE)

PROBE

CARRYING CASE

…Figure 1…

ON-OFF KEY

VALUE INCREASING KEY

ZEROING KEY

MICRON-MICROINCH UNIT TRANSFORM KEY

VALUE DECREASING KEY

Operation

ETA-0832 Manual Rev:00 4 / 6

5.Measuring Procedure

5.1 Press the"POWER" key to start the gauge The gauge will restore the state

of last operation itself. The gauge will display "Fe / 0um"or"NFe / 0um" , if you want

change the state of "Fe or NFe"press the"ZERO"key and the "POWER" key at the

same time, and then release "POWER" key firstly, 2 seconds later release the

"ZERO" key, the translation of "Fe or Nfe" finished.

5.2 Place the probe on the substrate or an uncoated standard steadily. Press

the "ZERO" key and "CAL0 OK" will be on the Display before lifting the probe. If

pressing the "ZERO" key but the probe is not placed on the substrate or an uncoated

standard, the zero adjustment is invalid.

5.3 Place the probe onto a coating layer to be measured. The reading on the

Display is the thickness of the coating layer.

5.4 To take the next measurement, just lift the probe to more than 1

centimeter and then repeat the step 5.3.

5.5 If suspecting the accuracy of measurement , you should calibrate the

gauge before taking the measurements. For the calibration procedures, please refer

to the calibration part 6.

5.6 The gauge will power itself off about 20 seconts after the last operation. It

can not be switched off by pressing the "POWER" key.

5.7 Pressing the "um/mil" key can change the measurement unit um or mil.

6.Calibration

6.1 Zero adjustment

Zero calibration for 'Fe' and 'NFe' should be carried out separately. Take the iron

substrate if 'Fe' on the Display and take the aluminium substrate if 'NFe' on the

Display. Place the probe on the substrate steadily. Press the "ZERO" key and "CAL0

OK" will be on the Display before lifting the probe. If pressing the "ZERO" key but the

probe is not placed on the substrate or an uncoated standard, the zero adjustment is

invalid.

6.2 Select an appropriate calibration foil according to your measurement

range.

6.3 Place the standard foil selected onto the substrate or the uncoated

standard.

6.4 Place the probe mildly onto the standard foil and lift. The reading on the

display is the value measured. The displayed reading can be corrected by pressing

the plus key or minus key while the probe is away from the substrate or the measure

body.

6.5 Repeat step 6.4 until the result is correct.

7.Battery Replacement

7.1 It is necessary to replace the battery, when the display reading changes

darkly.

7.2 Slide the Battery Cover away from the gauge and remove the batteries.

7.3 Install the batteries (2*1.5V) correctly into the case.

7.4 If the gauge will not to be used for a long time, remove batteries.

Operation

ETA-0832 Manual Rev:00 5 / 6

8.Considerations

8.1 In order to weaken the influence of the measured material on the

accuracy of measurement, it is recommended that the calibrations should be done on

the uncoated material to be measured.

8.2 Probe will eventually wear. Probe life will depend on the number of

measurements taken and how abrasive the coating is. Replacement of a probe can

be fitted by qualified persons only.

9.Restore Factory Setting

9.1 When to restore?

It is recommended to restore factory setting in the one of following cases.

A. The gauge does not measure any more.

B. Because misoperation "+"key or "-"key causes the gauge not normally to

measure.

C. Measurement accuracy is degraded caused by environmental conditions

changed greatly.

9.2 How to restore?

9.2.1 Press the "um/mil" key and the "POWER" key at the same time,

and then release the "POWER" key firstly, 2 seconds later release the "um/mil" key

9.2.2 When the "9999" appears on the display, press the "POWER" key,

the factory setting is restored.

10.Notes

It is strongly recommened that no changes should be made to the value of Ln.

Generally, the larger the value of Ln, the smaller the reading on a same thickness. A

little variation of value of Ln will cause a great change in reading at high end (e.g. at

515um). The rules to adjust the value of Ln are as follow:

A. Reading at low end can be adjusted to the

exact value by the plus or minus key.

B. To enlarge the Ln if readings at low end (e.g.at 50 um) is ok but reading at

high end (e.g.at 388um) is too large. On the contrary, to decrease the Ln if reading at

low end (e.g. at 51 um) is ok but reading at high end (e.g. at 388um) is too small.

C. Repeat procedures from A to B till the readings on the every standard foil

are satifying the accuracy.

Operation

ETA-0832 Manual Rev:00 6 / 6

Table of contents

Other BMS Measuring Instrument manuals