BN Products BNCE Series User manual

Page | 1

BNCE-45_Operations_Manual.indd September 27, 2023

BNCE-45 Cutting Edge Saw™

Customer Service: (800) 992-3833

BNCE-45

120V AC | 45MM | MULTI-MATERIAL SAW

MODEL BNCE-45 SN#_______________________________

Keep this booklet and enter your tool serial number

in the space provided above.

BN Products-USA™

3450 N. Sabin Brown Road

Wickenburg, AZ 85390

(800) 992-3833 | www.BNProducts.com

OPERATOR &

INSTRUCTION MANUAL

Page | 2

BNCE-45_Operations_Manual.indd September 27, 2023

BNCE-45 Cutting Edge Saw™

Customer Service: (800) 992-3833

2 ExternalParts&Specications

3 Purpose of this Manual

3 Safety Instructions and General Guidelines

3 Work Area Safety

3 Electrical Safety

3 Personal Safety

4 Power Tool Use & Care

4 Contents of BNCE-45 Package

4 Intended Use

OPERATOR & INSTRUCTION MANUAL

Please read this manual before operating this tool.

TABLE OF CONTENTS

External Parts & Specications

5 Operating Conditions

6 Operating Instructions

6 Routine Maintenance

6 Blade Replacement

7 Carbon Brush Replacement

8 General Operating Conditions

8 One-Year Limited Manufacturer Warranty

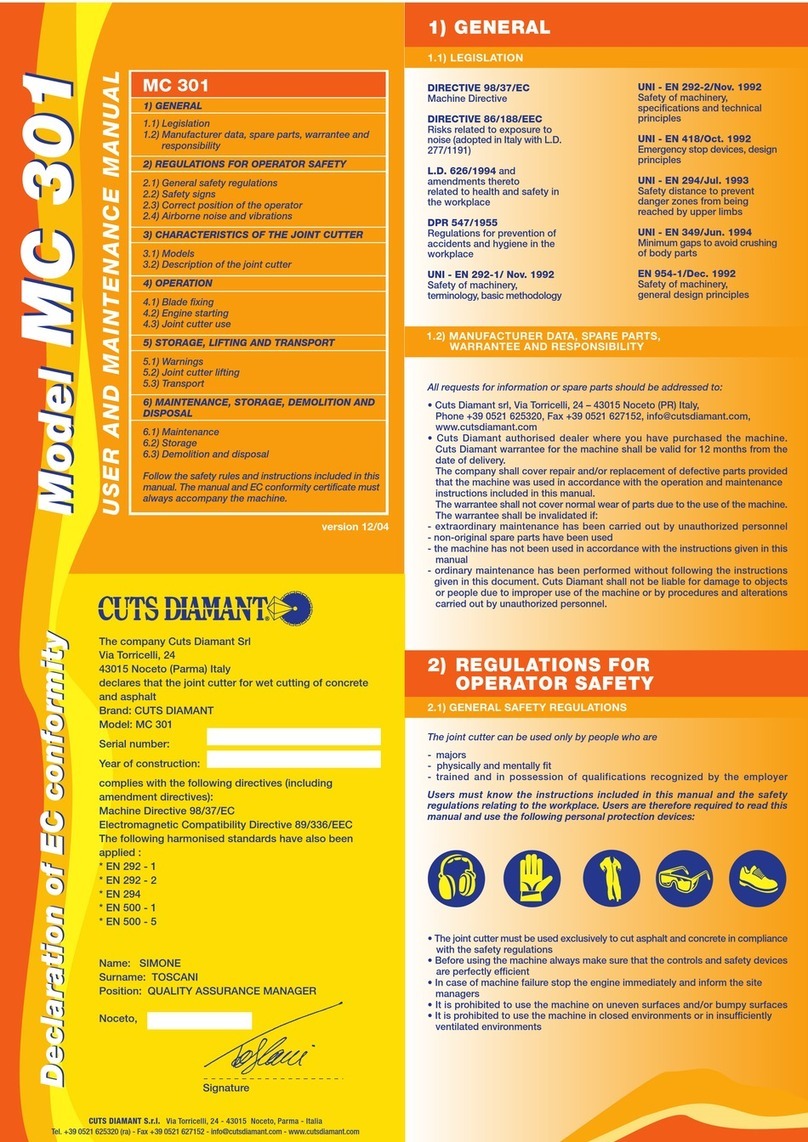

BNCE-45 External Parts

Diagram:

Operator controls and terms

used in this Manual

BNCE-45 Cutting Edge

Saw™ Tool Specications:

Technical Specications, Tool

Capacity, and Included

Accessories

Figure 1

Page | 3

BNCE-45_Operations_Manual.indd September 27, 2023

BNCE-45 Cutting Edge Saw™

Customer Service: (800) 992-3833

Purpose of this Manual

This manual is intended to provide users with

correct knowledge and the procedures for

operation, maintenance and inspection of the

BNCE-45 Cutting Edge Saw™. This tool is used

to cut rebar, strut, all-thread rod, pipe, tubing,

and conduit. Improper use of the tool may lead

to a serious accident. Therefore, always read

this instruction manual before using the tool to

familiarize yourself with its correct usage, operating

method, and warnings.

Safety Instruction & General Guidelines

Warning! Read and understand all

instructions. Failure to follow all

instructions listed below may result in

electricshock,reand/orserious

personal injury.

- PLEASE SAVE THESE INSTRUCTIONS -

Work Area Safety

• Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

• Do not operate power tools in explosive

atmospheres, such as in the presence of

ammableliquids,gasesordust.Powertools

create sparks which may ignite the dust or

fumes.

• Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

Electrical Safety

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools.Unmodiedplugsandmatchingoutlets

will reduce risk of electric shock.

• Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

• Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not use the cord for any purpose that it

was not intended for. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords

increase the risk of electric shock. Replace

damaged cords.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk

of electric shock.

• If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the

risk of electric shock.

NOTE: The term residual current device (“RCD”)

may be replaced by the term “ground fault circuit

interrupter” (“GFCI”) or earth leakage circuit breaker

(“ELCB”).

Personal Safety

• Always wear eye protection. Care must be taken

to prevent chips from hitting other workers in

the same area.

• Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired

orundertheinuenceofdrugs,alcoholor

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

• Usepersonalprotectiveequipment.Always

wear eye protection.Protectiveequipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

• Prevent unintentional starting. Ensure the switch

isintheo-positionbeforeconnectingto

powersourceand/orbatterypack,pickingupor

carrying the tool. Carrying power tools with your

ngerontheswitchorenergizingpowertools

that have the switch on invites accidents.

Page | 4

BNCE-45_Operations_Manual.indd September 27, 2023

BNCE-45 Cutting Edge Saw™

Customer Service: (800) 992-3833

• Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool

may result in personal injury.

• Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewelry. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewelry

or long hair can be caught in moving parts.

• If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

Power Tool Use and Care

• Power tools are dangerous in the hands of

untrained users.

• Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

• Do not use the power tool if the switch does not

turnitonando.Anypowertoolthatcannot

be controlled with the switch is dangerous and

must be repaired.

• Disconnecttheplugfromthepowersourceand/

or the battery pack from the power tool before

making any adjustments, changing accessories,

or storing power tools. Such preventive safety

measures reduce the risk of starting the power

tool accidentally.

• Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool.

• Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

andanyotherconditionthatmayaectthe

power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

• Use the power tool, accessories and tool bits

etc., in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power tool

foroperationsdierentfromthoseintended

could result in a hazardous situation.

Service

Haveyourpowertoolservicedonlybyaqualied

repair person using only identical replacement parts.

This will ensure that the safety of the power tool is

maintained.

Contents of the Cutting Edge Saw Package

Upon purchasing the Cutting Edge Saw™, open

the carrying case and check the contents for the

following:

120 Volt BNCE-45 Package

1. BNCE-45 Corded Cutting Edge Saw with

blade (RB-BNCE-45) mounted : 1 unit

2. Handle and chip collector

attachment: 1 unit

3. Allen Wrenches for Blade Removal and

Installation: 1 unit

4. Additional RB-BNCE-45 saw blade: 1 unit

5. Operation Manual: 1 copy

6. Replacement set of carbon brushes

If any contents are missing or damaged, please do

not return this packaged unit to the distributor,

please call BN Products-USA™ Customer Service

department: (800) 992-3833.

Intended Use of the BNCE-45 Saw

This section describes the functions, applications,

service environment and other aspects of the

Cutting Edge Saw. The Cutting Edge Saw is a power

tooldevelopedforfastandecientcuttingof

various ferrous and non-ferrous materials. This

multipurpose tool can be used by a variety of

contractors however the primary design was for

ushcuttingorfreecuttingreinforcingbars,coilrod

and all-threaded rod used in construction.

Page | 5

BNCE-45_Operations_Manual.indd September 27, 2023

BNCE-45 Cutting Edge Saw™

Customer Service: (800) 992-3833

The BNCE-45 Cutting Edge Saw™ is designed for

cutting:

• Grade 60 rebar (reinforcing bars), up to #11 (1-

1/2”)

• 1-3/4”copperwaterpipe,tubing,conduit,

squaresteel tubing and bar

• 1-3/4” All-threaded or Coil rod

• 1-5/8” Strut

Usage Guidelines and Storage

To use the tool to its fullest performance, the

Cutting Edge Saw™ should be clean and stored in its

proper case and free of excessive heat or cold.

Before using this product, it is extremely important

to be fully familiar with the tool and it’s controls,

the cutting blades, and storage procedures upon

completion of work.

This power tool is a multipurpose saw with an

enclosed guard.

Standard Blade (Best for Ferrous Metals)

The BNCE-45 is supplied with two (2) 6.5” (165 mm)

diameterblades(36teeth,withlaserweldedange

for mounting to Cutting Edge Saw spindle). The no-

load blade RPM is 1200 RPM.

Operating Conditions

Working Environment:

Before using the Cutting Edge Saw, be aware of

weather conditions.

Do not use in the rain or snow.

! DANGER: The Cutting Edge Saw

is not a waterproof power tool. If

it becomes wet, the power source

system may become faulty or the

operator is at risk for electric shock.

When it is raining or snowing, never operate this

saw outdoors, on top of buildings or under roofs

with rain or snow exposure. Do not use where

water accumulates or is prone to splashing.

! DANGER: Electric Shock Hazard. Ignoring

this warning may lead to death or serious

injury. When raining or snowing, do not

operate outdoors or indoors where rain or

snow enters freely or in extreme

temperatures.

Do not use under high temperature, humidity or

extremely cold temperature conditions.

This tool is designed for use under an ambient

temperature of 100°F (37° C). Operation at higher

temperature may cause the tool motor to overheat.

Operation in extreme temperature or high humidity

may cause the tool to fail due to condensation buildup

inside the tool housing.

Do not operate the Cutting Edge Saw in temperatures

belowfreezing(32°F/0°C).

Inspect the State of Your Work Site

Before using the tool, always determine that:

• The worksite is free of foreign objects, debris, water,

ice, snow, powered electrical cables, and excessive

dust

• Theoorisfreeofobstructions

• Thereisadequateventilationfortheimmediatearea

• TheworkerisequippedwithproperPPEand

clothing, including but not limited to PPE, enclosed

footwear, and gloves.

Always follow the operation instructions; avoid

hazardous conditions and scenarios.

Remove Hazardous Substances

Thistoolisanelectric/powertool.Asparkcancausean

explosionorareifoperatedneargascylinders,paint

thinner,orammablematerials,includingammable

gasses. Do not use near or expose the tool to hazardous

orammablematerials.

! DANGER May cause an explosion or a

re.Ignoringthiswarningmaycause

death or serious injury. Never use the tool

nearammablegasorammable

materialsorliquids.

Page | 6

BNCE-45_Operations_Manual.indd September 27, 2023

BNCE-45 Cutting Edge Saw™

Customer Service: (800) 992-3833

Operating Instructions

• Adjust the rear handle position to comfortably

grip the tool. (The rear handle changes position

using the button located on the top of the

handle.)

• Locate the front handle in the mounting hole

that provides the best grip.

• To operate the trigger, depress the trigger lock

button on the left side of the tool above the

trigger; (See Figure 1) and then depress the

trigger to start the saw.

• Start the saw before cutting and then apply a

light pressure moving forward through the cut.

Cutting Edge Saw™ Routine Maintenance

• Always unplug the saw from the electric outlet

before attempting any maintenance.

• Clean the entire unit occasionally by removing

dust, debris and oils.

• Occasionally remove the bottom plate; remove

any cutting chips that remain lodged in the area

where the cutting blade rotates.

• Remove and inspect the cutting blade for

material residue. This should be done after 4-8

hours of use.

• Most material cutting debris will be expelled

through the chip exhaust area and into the

Cutting Chip Catch Bag. It is recommended that

the Cutting Chip Catch bag be emptied when it

becomes2/3fullofcuttingdebrisandmaterials.

Blade Replacement

The standard blade (RB-BNCE-45) for the BNCE-

45 Cutting Edge Saw™ should be replaced when

the blade is dull or visibly worn, or when there is a

noticeabledecreaseincuttingeciency.

To change the Blade:

• Unplug the saw before performing any work

on the tool blade.

• Using the smaller Allen key tool, remove the

four (4) screws that hold the Blade Cover to the

body of the saw. See Figure 2

• Remove the cover, being careful to set the four

mounting screws and the accompanying locking

nuts aside in a safe place.

• Presstheblade/spindlelockbuttontosecure

the blade spindle (See Figure 1). You may need

to manually rotate the blade so that the lock

button engages and is secured in a locked

position.

• When the blade is locked, use the larger Allen

key to remove the blade mounting screw and

blade locking head at the center of the blade

(Figure 3). Note: With the blade spindle locked,

you will need to rotate the screw in a counter-

clockwise direction.

• Make sure that when the blade is removed, that

the blade head is free of any metal debris that

has not escaped the tool. As needed, clean the

tool to remove any metal chips or particles from

the blade head area.

• Install the new blade over the spindle at the

center opening. BN Products-USA™ blades will

be marked “This Side Up” to ensure that the

blade is not installed upside-down. In addition,

each blade is printed with a directional arrow

(Figure 3). This arrow must always point in the

same direction as the arrow marked on the top

side of the blade cover, as shown in Figure 4.

• Replace the blade locking head using the blade

mounting screw, using the Allen key to securely

tighten the screw in a clockwise direction. DO

NOT OVERTIGHTEN.

• Replace the blade cover using the four (4)

mounting screws, making sure that the locking

nuts are still inserted in the threaded hole for

each mounting screw. Securely fasten each

screw without overtightening.

See Figures 2, 3, and 4 on the next page.

Follow this same procedure when installing a

specialty blade, such as the RB-BNCE-45S Strut

Cutting Blade (sold separately). Always save the

Allen key tools with the saw in a safe place for

future use.

Please contact your distributor or call

BN Products-USA™ Customer Service at the

number above or visit us on the web www.

bnproducts.com for more information or assistance

with product operating instructions, or essential

maintenance.

Page | 7

BNCE-45_Operations_Manual.indd September 27, 2023

BNCE-45 Cutting Edge Saw™

Customer Service: (800) 992-3833

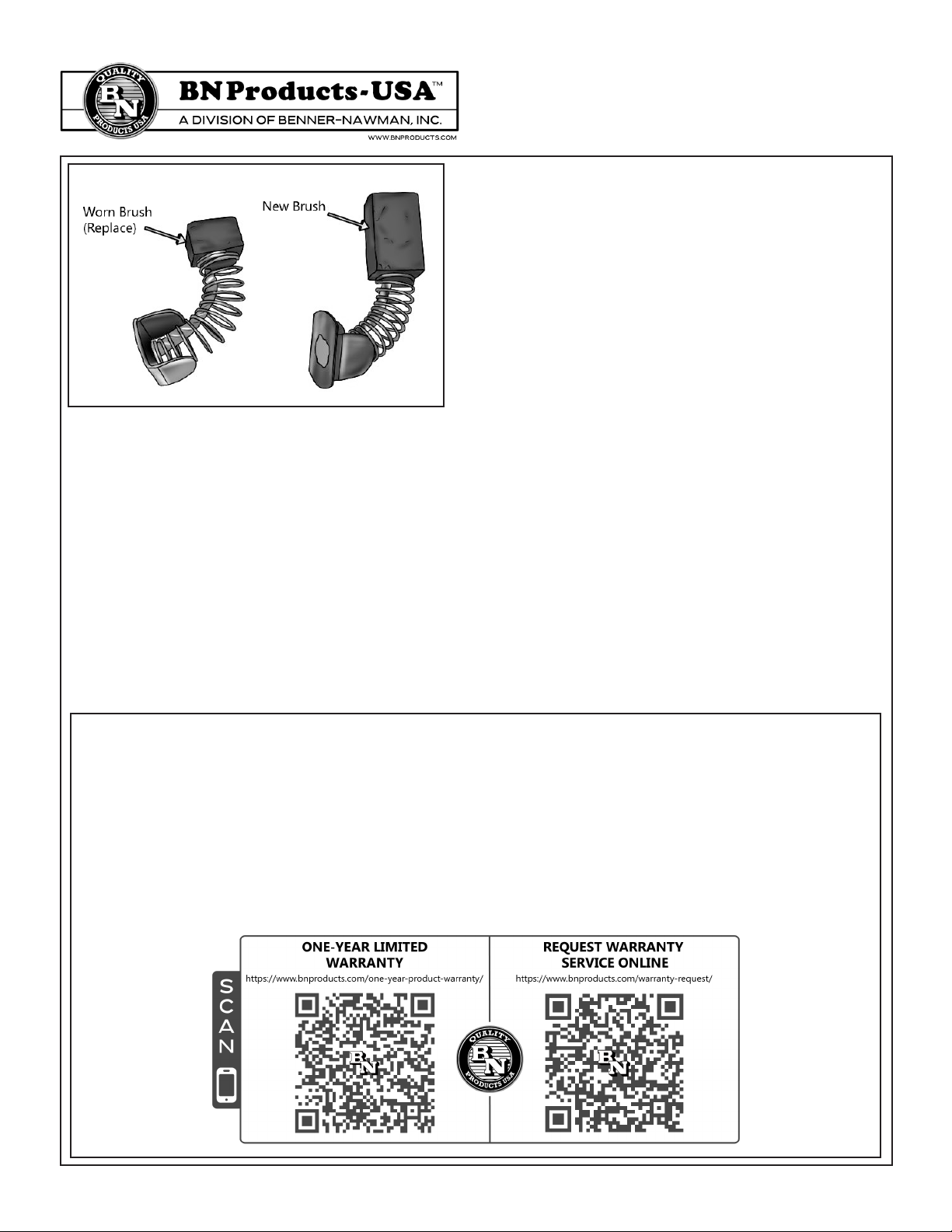

Carbon Brushes - Inspect & Replace

Carbon Brushes are subject to wear over time.

Brushes should be inspected after every 100 hours

ofuse.Atleast1/4”ofthewearablesurfaceshould

remain for the tool to perform optimally.

To inspect (and replace when necessary) carbon

brushes on the Cutting Edge Saw™:

• Unplug the tool before performing any work,

allow the tool to cool if it has recently been

used.

• Locate the Brush Cap(s) on either side of the

saw (Figure 5)

• Useasmallatheadscrewdrivertoremovethe

cap by turning counter-clockwise, using the slot

provided at the center of the cap, and remove

the cap.

• Remove the brush from the socket; use a small

screwdriver to gently pry the brass spring seat, if

necessary (See Figure 6).

• Inspect the brushes to determine if they should

be replaced. Use the diagram in Figure 7 as a

general guide for determining the condition of

each brush.

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

Page | 8

BNCE-45_Operations_Manual.indd September 27, 2023

BNCE-45 Cutting Edge Saw™

Customer Service: (800) 992-3833

General Operating Cautions

The following describe the general cautions on

operating tool. Always observe the cautions stated

in each item.

• Do not depress the operating trigger if the tool

is pointed toward another individual. Operating

the tool by holding it toward anyone may cause

injury from contact with the blade.

• Do not use the Cutting Edge Saw for purposes

it is not intended, or attempt to cut materials

widerthanrecommendedspecications,as

doing so may lead to injury or damage to the

Cutting Edge Saw™

• Use only replacement saw blades recommended

by BN Products-USA™. Recommended blades

aredesignedspecicallyforthetool,andhave

beentestedforsafetyandeectiveusewiththe

Cutting Edge Saw™

• This Product is subject to ongoing enhancement

and development. Parts, part numbers, design,

andspecicationsmaybechangedpertaining

to this product at any time, with or without

priornoticationtoendusers,distributors,or

manufacturer representatives.

Figure 7

• To re-install the brushes or replace with a new

set, the brush should be inserted into the

brush carrier socket on each side of the tool.

The brass spring seat should be positioned so

thatittscompleteintothesockettoensure

connectivity to the motor’s electrical circuit.

• Re-install the brush cap (Figure 5) by threading

the cap back into the brush cap receptacle,

turningclockwiseusingasmallathead

screwdriver. Do not overtighten.

• This procedure should be completed on both

brushes, one each on the right and left side of

the tool handle.

ONE-YEAR LIMITED MANUFACTURER WARRANTY

BN Products-USA™ warrants our tools to the original purchaser to be free of defects in materials and

workmanship under everyday and appropriate use and service for one year. Use the applicable QR code or

web URL below to access our full One-Year Warranty policy and procedure, or to complete a Warranty Service

Requestforthisproduct.

IfyouarerequestingWarrantyService,itisrecommendedthatyouhaveyouroriginalpurchaseorder

available to upload or scan using a mobile device. Questions with regard to our One-Year Limited

Manufacturer Warranty may be directed to BN Products-USA™ Customer Service at (800) 992-3833.

This manual suits for next models

1

Table of contents

Other BN Products Saw manuals

Popular Saw manuals by other brands

Parkside

Parkside PDS 120 B2 Operating and Safety Instructions, Translation of Original Operating Manual

Garland

Garland SET 352 E instruction manual

Bosch

Bosch GST 90 BE Original instructions

Altocraft

Altocraft J1X-KZ18-255 Operator's manual

Mopec

Mopec 5000 user manual

Bosch

Bosch Professional GTS 18V-216 Original instructions