BobsCNC E4 User manual

Page 1

E4

Page 2

·································································································4

Safety First

·······························································································5

Required Tools

Good Ideas

For More Informaon

···············································································6

·························································7-17

Wood Components (included with the kit)

Required Hardware (included with the kit)

Illustrated Steps

···································································18-38

Wood Components (included with the kit)

Required Hardware (included with the kit)

Illustrated Steps

·········································································39-46

Wood Components (included with the kit)

Required Hardware (included with the kit)

Illustrated Steps

········································································47-58

Wood Components (included with the kit)

Required Hardware (included with the kit)

Illustrated Steps

···············································59-63

·····································································64-67

Wood Components (included with the kit)

Required Hardware (included with the kit)

Illustrated Steps

································································68-72

Wood Components (included with the kit)

Required Hardware (included with the kit)

Illustrated Steps

Page 3

··························································································73-77

Wood Components (included with the kit)

Required Hardware (included with the kit)

Illustrated Steps

·····················································································78-86

Tips to Keep Your Controller From Being Damaged.

················································································87-91

……………………………………………………………………………………...92

················································93

···························································································94

……………………………………………………………………………….. 95

···································································································96-102

Warranty and Return Policy ··································································96

Miscellaneous Parts List········································································97

Diagram for Plywood Components ·······················································98 -102

Page 4

Specifications

The E4 CNC Router has the following features:

• Rigid laser cut frame.

• Fully supported rail system with SG20U bearings.

• GT2 belt drive on X and Y axis.

• 5/16-18 coupler nut on the Z axis.

• Home switches on all axes.

• MDF T-Slot Spoilboard with T-Nut inserts.

The assembled footprint:

Length: 30" (630 mm)

Width: 37.2" (945 mm)

Height: 18.9" (480 mm)

Assembled Weight:

32 lbs.

Cung Area:

X: 24" (610 mm)

Y: 24" (610 mm)

Z: 3.3" (85 mm)

your

Routers have a high voltage power supply and use bits that spin at 30,000

rpm with cung edges that are hazardous. The operator must understand

these hazards and is responsible to take appropriate safety precauons be-

fore operang the Router.

Page 5

• Two ½” end wrenches to ghten Z Bearing nuts.

• A pair of long nose pliers to hold the nuts.

• Diagonal Cuers or sharp knife to trim nylon es.

• Calipers or measuring tape to measure part placement.

• Small standard screwdriver to connect electronics.

• Small Phillips screwdriver to mount home switches and stepper motors.

• Medium Phillips screwdriver to build the main components.

• Sand paper to remove laser marks on the faces.

• M4 Star Driver for DeWalt disassembly.

• LOCTITE® 243 thread lock (ngernail polish can be used as a substute).

• Wood Glue (e.g. Titebond®) for Spoilboard Assembly

To operate the E4 CNC Router you will need:

7/16” & 5/8” wrench to change router bits.

Computer with control soware for GRBL.

Material for Project.

1/8” or 1/4” Router bits.

Dry lubricaon (e.g., graphite, Teon® or silicon spray).

Tools you may need for the electronic setup include:

Mulmeter to correctly connect the power supply and stepper motors. A mulmeter is a good tool to have for general

electronic trouble shoong.

Getting Started

• We recommend using a large at, clean working surface for assembling your E4.

• All screws (unless noted) should be installed snug, then rotated one 1 to 2 1/2

turns.

• Light sanding of the wood surfaces will clean up the marks made by the laser.

• Painng or applying stain with a clear coat will give added protecon to the wood

components.

• During assembly try placing 1 inch strips of blue painters tape behind the T-Slots to

hold the nuts in place during assembly.

*For More Information: Click on the Links

Page 6

Short Zip Tie

Long Zip Tie

M5

Washer

5/16”

-

Page 7

5/16”

Page 8

Page 9

Page 10

“” -

Page 11

Page 12

Page 13

.

be careful not to remove

spindle sha

’

-

Page 14

Page 15

Page 16

Page 17

Page 18

5/16”

Page 19

1” -

-

Page 20

Table of contents

Popular Network Router manuals by other brands

ZyXEL Communications

ZyXEL Communications AX Series user guide

D-Link

D-Link DIR-506L Quick installation guide

AudioCodes

AudioCodes Mediant 500L MSBR Hardware installation manual

H3C

H3C SR6600 SPE-FWM Fundamentals configuration guide

Advantech

Advantech ICR-4453W Start guide

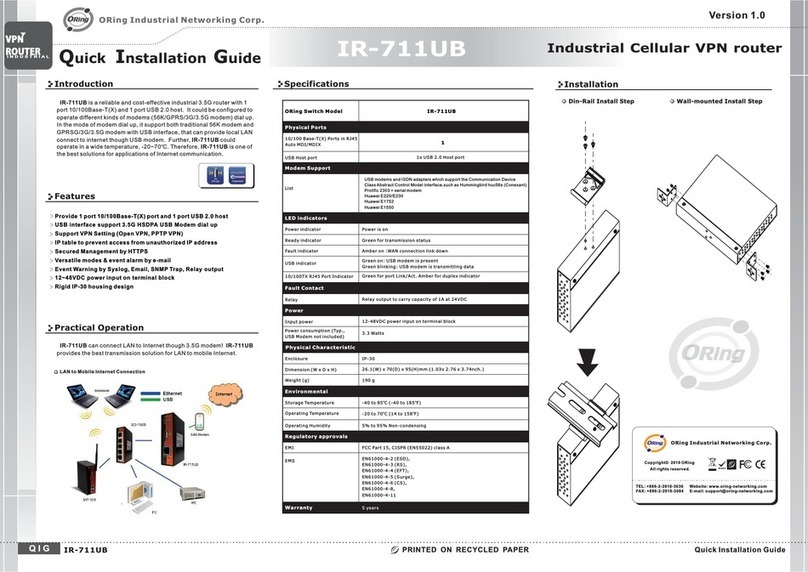

ORiNG

ORiNG IR-711UB Quick installation guide