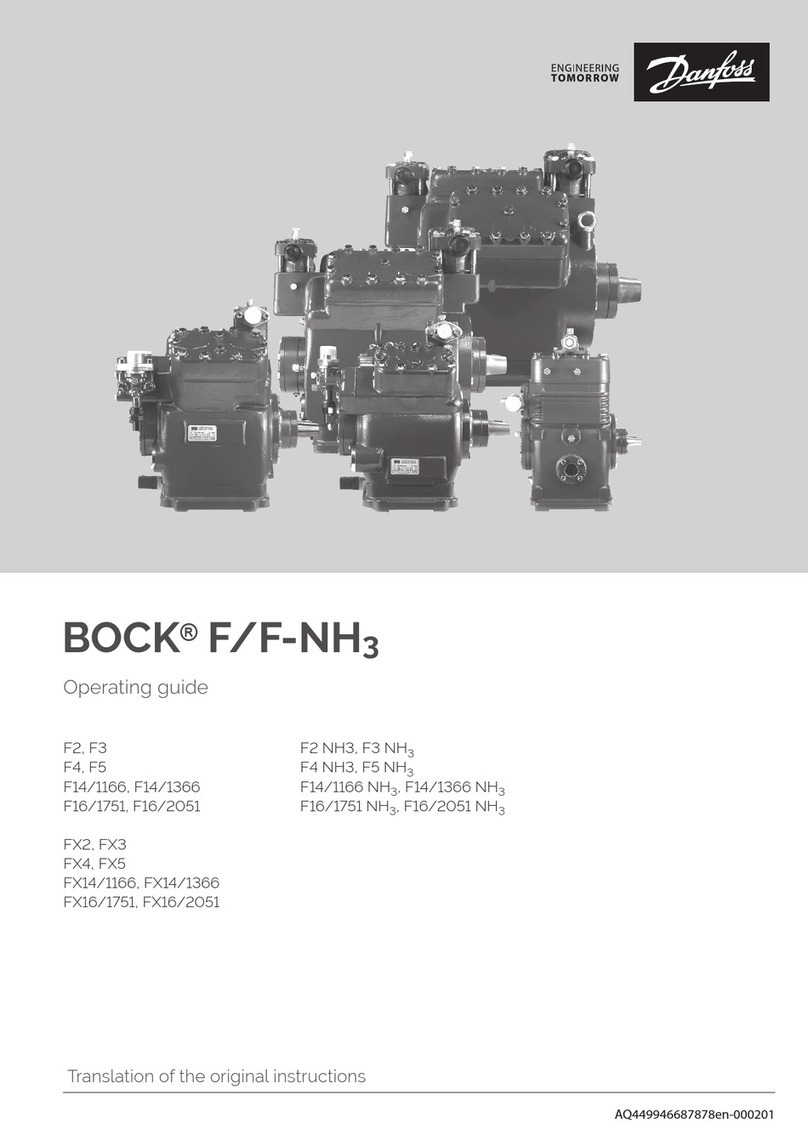

BOCK HGX46 CO2 T User manual

BOCK HGX46 CO2T

Assembly instructions

96460-05.2022-Gb

Translation of the original instructions

BOCK®colour the world

of tomorrow

HGX46/280-4 ML CO2 T HGX46/280-4 S CO2 T HGX46/280-4 SH CO2T

HGX46/310-4 ML CO2 T HGX46/310-4 S CO2 T HGX46/310-4 SH CO2T

HGX46/345-4 ML CO2 T HGX46/345-4 S CO2T HGX46/345-4 SH CO2T

HGX46/440-4 ML CO2T

HGX46/280 MLP 33 CO2T HGX46/280 SP 46 CO2T HGX46/280 SHP 46 CO2T

HGX46/310 MLP 37 CO2T HGX46/310 SP 49 CO2T HGX46/310 SHP 49 CO2T

HGX46/345 MLP 41 CO2T HGX46/345 SP 50 CO2T HGX46/345 SHP 50 CO2T

HGX46/440 MLP 53 CO2T

2

D

GB

F

E

96460-05.2022-DGb

1 Safety 4

1.1 Identicationofsafetyinstructions

1.2 Qualicationsrequiredofpersonnel

1.3 Safetyinstructions

1.4 Intendeduse

2 Product description 6

2.1 Shortdescription

2.2 Nameplate

2.3 Typekey

2.4 TypekeycompressorswithLSPMMotor(Line StartPermanentMagnet)

Contents Page

About these instructions

Manufacturer

Contact

Readtheseinstructionsbeforeassemblyandbeforeusingthecompressor.Thiswillavoidmisunder-

standings andpreventdamage.Improperassemblyanduseofthecompressorcanresultinserious

orfatalinjury.

Observethesafetyinstructionscontainedintheseinstructions.

Theseinstructionsmustbepassedontotheendcustomeralongwiththeunitinwhichthecompres-

sorisinstalled.

BockGmbH

72636Frickenhausen

BockGmbH

Benzstraße7

72636Frickenhausen

Germany

Telephone +4970229454-0

Fax +4970229454-137

www.bock.de

D

GB

F

E

3

96460-05.2022-DGb

Contents Page

3 Areas of application 8

3.1 Refrigerants

3.2 Oilcharge

3.3 Limitsofapplication

4 Compressor assembly 9

4.1 Storageandtransportation

4.2 Settingup

4.3 Connectingthepipelines-soldersystem

4.4 Connectingthepipelines-cuttingringsystem

4.5 Pipes

4.6 Flangeshut-offvalves(HP/LP)

4.7 Layingsuctionandpressurelines

4.8 Operatingtheshut-offvalves

4.9 Operatingmodeofthelockableserviceconnections

4.10 Oilreturn

4.11 Suctionpipelter

5 Electrical connection 14

5.1 Informationforcontactorandmotorcontactorselection

5.2 Standardmotor,designedfordirectorpartwindingstart

5.3 Basiccircuitdiagramforpartwindingstart

5.4 Specialmotor:designfordirectorstar-deltastart

5.5 Basiccircuitdiagramforstar-deltastartwithspecialmotor

5.6 ElectronictriggerunitINT69G

5.7 ConnectionoftheelectronictriggerunitINT69G

5.8 FunctionaltestoftheelectronictriggerunitINT69G

5.9 Oilsumpheater

5.10 Selectionandoperationofcompressorswithfrequencyconverters

6 Commissioning 24

6.1 Preparationsforstart-up

6.2 Pressurestrengthtest

6.3 Leaktest

6.4 Evacuation

6.5 Refrigerantcharge

6.6 Start-up

6.7 Pressureswitch

6.8 Decompressionvalves

6.9 Avoidingslugging

6.10 Filterdryer

7 Maintenance 28

7.1 Preparation

7.2 Worktobecarriedout

7.3 Sparepartsrecommendation/Accessories

7.4 Lubricants/oil

7.5 Decommissioning

8 Technical data 30

9 Dimensions and connections 34

10 Declaration of installation 36

11 Service 37

4

D

GB

F

E

96460-05.2022-DGb

1|Safety

1.1 Identication of safety instructions:

1.2 Qualications required of personnel

WARNING Inadequately qualied personnel poses the risk of accidents, the

consequence being serious or fatal injury. Work on compressors

must therefore only be performed by personnel with the

qualications listed below:

•For example, a refrigeration technician, refrigeration mechatronics

engineer. As well as professions with comparable training, which

enablepersonneltoassemble,install,maintainandrepairrefrigeration

andair-conditioningsystems.Personnelmustbecapableofassessing

theworktobecarriedoutandrecognisinganypotentialdangers.

DANGER Indicates a dangerous situation which, if not avoided, will cause

immediate fatal or serious injury

WARNING Indicates a dangerous situation which, if not avoided, may cause

fatal or serious injury

CAUTION Indicates a dangerous situation which, if not avoided, may imme-

diately cause fairly severe or minor injury.

ATTENTION Indicates a situation which, if not avoided, may cause property

damage

INFO Important information or tips on simplifying work

D

GB

F

E

5

96460-05.2022-DGb

1|Safety

1.3 Safety instructions

WARNING Risk of accident.

Refrigerating compressors are pressurised machines and therefore

require particular caution and care in handling.

The maximum permissible overpressure must not be exceeded,

even for testing purposes.

Risk of burns!

- Depending on the operating conditions, surface temperatures of

over 60 °C on the pressure side or below 0 °C on the suction side

can be reached.

- Avoid the contact with refrigerant under any circumstances.

The contact with refrigerant can lead to severe burns and skin

irritations.

Danger of suffocation.

CO2 is a nonammable, acidic, colourless and odourless gas and

heavier than air.

Never release signicant volumes of CO2or the entire contents of

the system into closed rooms!

Safety installations are designed or adjusted in accordance with EN

378-2 or appropriate safety standards.

• Therefore, we expressly point out that all information in this

assembly instruction has been provided according to our current

level of knowledge and may change due to further development.

Legal claims based on the correctness of the information cannot

be made at any time and are hereby expressly excluded.

Compressors with LSPM Motor:

When the compressor is open, there is danger from a strong mag-

netic eld.

See also Chapter 7, Maintenance.

These assembly instructions describe the standard version of the compressors named in the ti-

tle manufactured by Bock. Bock refrigerating compressors are intended for installing in a

machine (within the EU according to the EU Directives 2006/42/EC Machinery Directive and

2014/68/EUPressureEquipmentDirective).

Commissioningisonlypermissibleifthecompressorshavebeeninstalledinaccordancewiththese

assemblyinstructionsandtheentiresystemintowhichtheyareintegratedhasbeeninspectedand

approvedinaccordancewithlegalregulations.

ThecompressorsareintendedforusewithCO2intranscriticaland/orsubcriticalsystemsincompli-

ancewiththelimitsofapplication.

Onlytherefrigerantspeciedintheseinstructionsmaybeused.

Any other use of the compressor is prohibited!

1.4 Intended use

WARNING The compressor may not be used in potentially explosive

environments!

6

D

GB

F

E

96460-05.2022-DGb

2|Product description

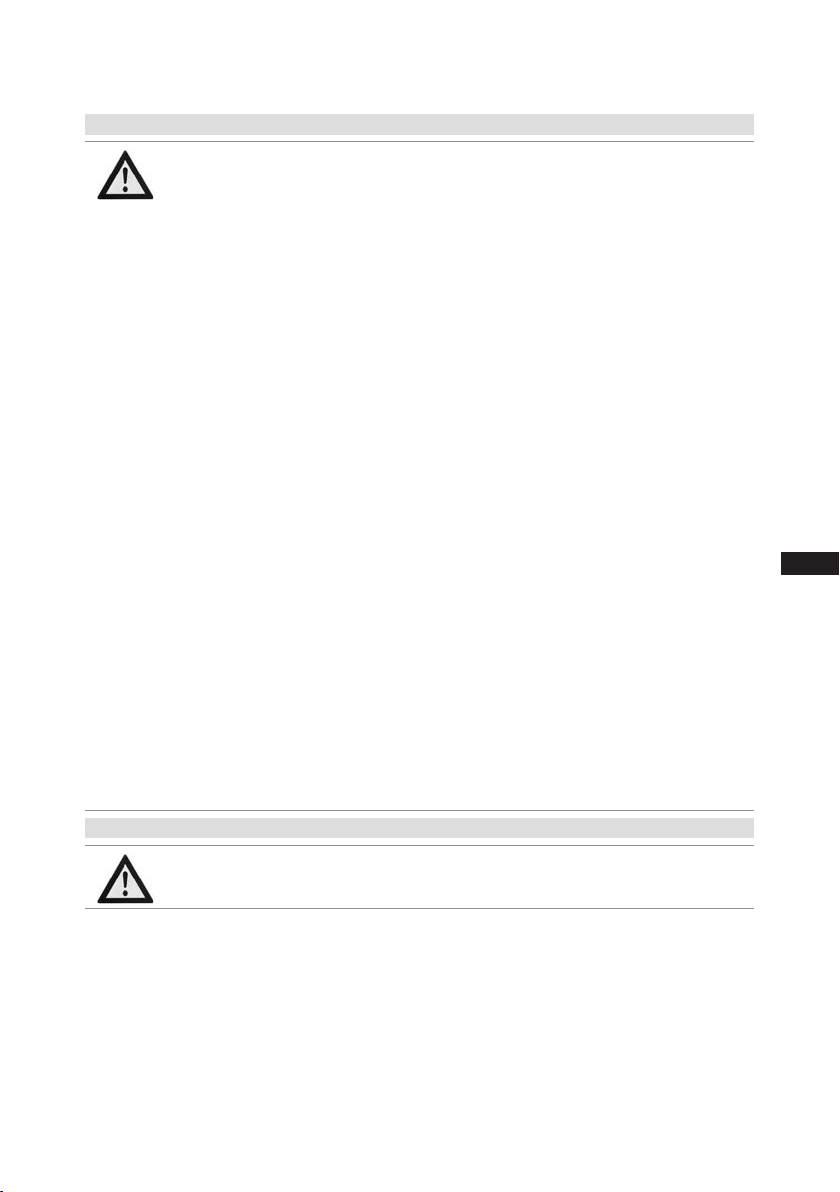

Fig.1

Fig.2

2.1 Short description

• Semi-hermeticsix-cylinderreciprocatingcompressorwithsuctiongascooleddrivingmotor.

• Theowofrefrigerantsuckedinfromtheevaporatorisledovertheengineandprovidesfora

particularlyintensivecooling.Thustheenginecanbekeptonarelativelylowtemperaturelevel

speciallyduringhighload.

• Oilpumpindependentofdirectionofrotationforreliableandsafeoilsupply.

• Onedecompressionvalveeachonthelowandhighpressureside,whichventintotheatmos-

pherewheninadmissiblyhighpressurelevelsarereached.

Oilsightglass

Valveplate

Cylinder

cover

Transporteyelet

Oilpump

Discharge

shut-offvalve

(accessories)

Nameplate

Suction

shut-offvalve

(accessories)

Terminalbox

Dimensionandconnectionvaluescanbefoundinchapter9

D

GB

F

E

7

96460-05.2022-DGb

50 Hz

60 Hz

}

}

Fig.3

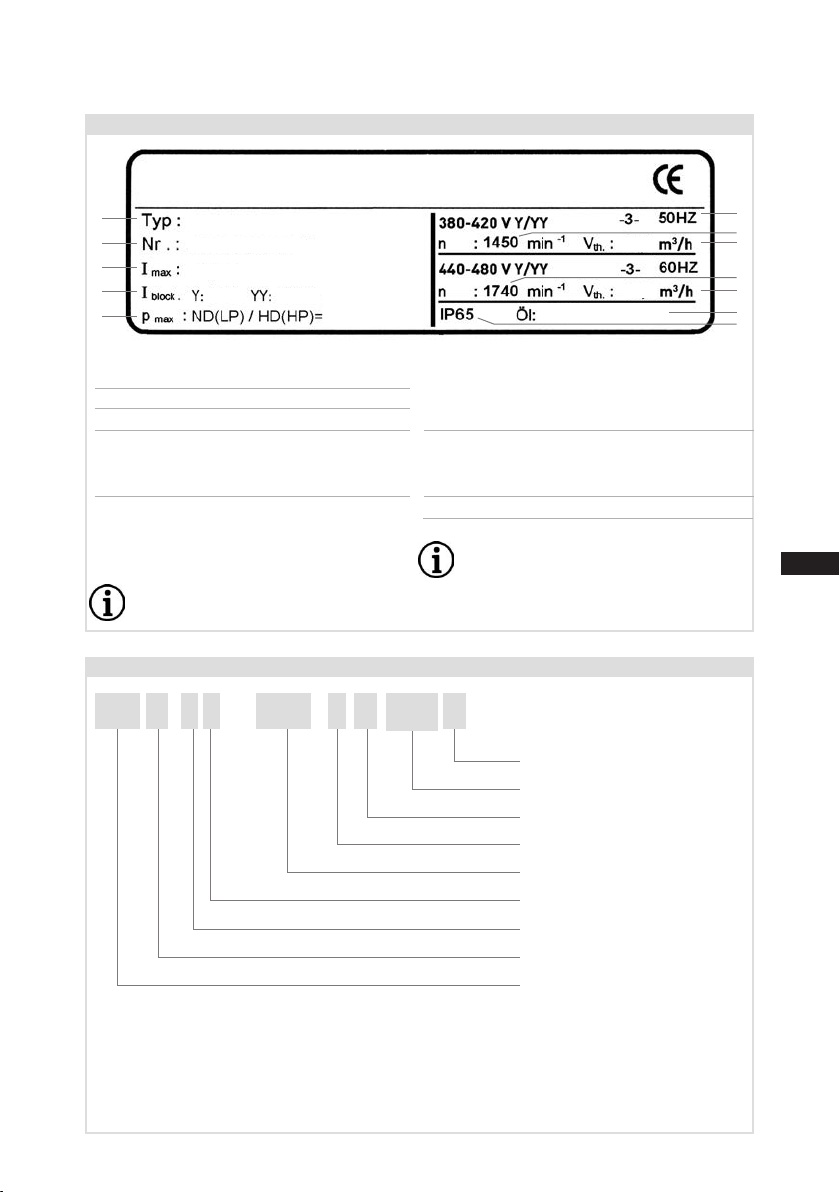

2.2 Name plate(example)

/

HG 46345-4CO2

X

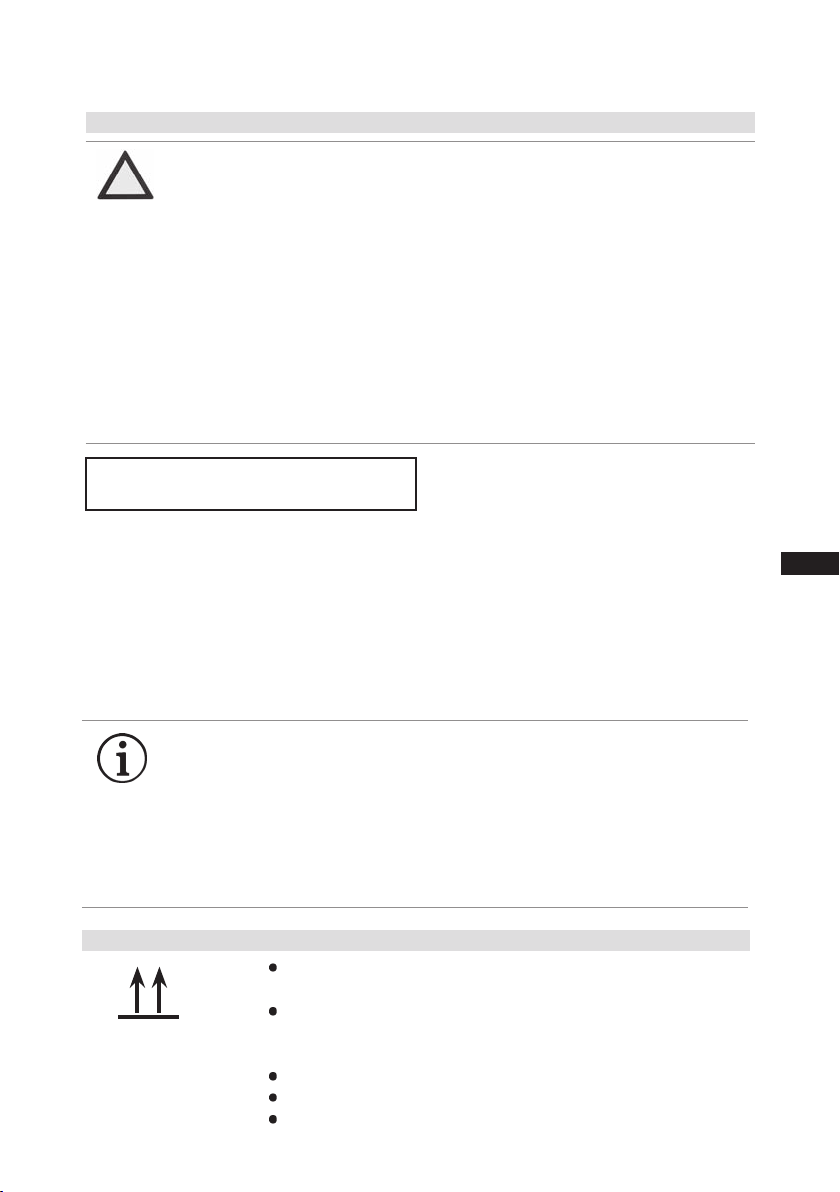

2.3 Type key(example)

T

S

1 Typedesignation

2 Machinenumber

3 Maximumoperatingcurrent

4 Startingcurrent(rotorblocked)

Y:Partwinding1

YY:Partwinding1and2

5 ND(LP):max.permissibleoperating

pressure(g)Lowpressureside

HD(HP):

max.permissibleoperating

pressur

e(g)Highpressureside

Observe the limits of

application diagrams!

6 Voltage,circuit,frequency

7 Nominalrotationspeed

8 Displacement

9 Voltage,circuit,frequency

10 Nominalrotationspeed

11 Displacement

12 Oiltypelledatthefactory

13 Terminalboxprotectiontype

Electrical accessories can change

the IP protection class!

Transcritical

CO2version

Compressorversion³)

Numberofpoles

Sweptvolume

Numberofcylinders

Size

Oilcharge²)

Series¹)

¹)HG - HermeticGas-Cooled(suctiongas-cooled)

²)X - Esteroilcharge

³) ML - Normalcoolinganddeepfreezingatlowandmediumevaporationtemperatures

S - Forfrequencyregulationandextendedlimitsofapplication

SH - Forhighevaporatingtemperatureseg.heatpumps,differentoilcharge

2|Product description

1

2

3

4

5

6

7

8

9

10

11

12

13

BC12345-001

90,9 A

222 A 361 A

30,2

36,2

HGX46/345-4 S CO2T

100/150 bar

Bock GmbH, Benzstraße 7

72636 Frickenhausen, Germany

BOCK

BOCKlub E85

8

D

GB

F

E

96460-05.2022-DGb

Thecompressorsarelledatthefactorywiththefollowingoiltype:

Compressorversion ML(P) and S(P): BOCK lubE85

Compressorversion SH(P): BOCK C170E

(only this oils may be used)

3.1 Refrigerants

• CO2: R744 (Recommendation CO2 quality 4.5 (< 5 ppm H2O))

3.2 Oil charge

ATTENTION Property damage possible.

The oil level must be in the

visible part of the sight glass;

damage to the compressor

is possible if overfilled or

underfilled! Fig.4

Max.

Min.

1.0Ltr.

Oillevel ~

~

3|Areas of application

/

HG 46345 CO2

X

2.4 Type key compressors with LSPM Motor (example)

¹)HG - HermeticGas-Cooled(suctiongas-cooled)

²)X - Esteroilcharge

³) MLP- Normalcoolinganddeepfreezingatlowandmediumevaporationtemperatures

SP - Forfrequencyregulationandextendedlimitsofapplication

SHP- Forhighevaporatingtemperatureseg.heatpumps,differentoilcharge

Transcritical

CO2version

MotorpowerinHP

LSPMMotor

Compressorversion³)

Sweptvolume

Numberofcylinders

Size

Oilcharge²)

Series¹)

50 T

S P

2|Product description

D

GB

F

E

9

96460-05.2022-DGb

ATTENTION Compressor operation is possible within the operating limits

shown in the diagrams. Please note the signicance of the

shaded areas. Thresholds should not be selected as design or

continuous operation points.

- Permissible ambient temperature (-20 °C) - (+60 °C).

- Max. permissible discharge end temperature 160 °C.

- Min. discharge end temperature ≥50 °C.

- Min. oil temperature ≥ 30 °C.

- Max. permissible switching frequency 12x /h.

- A minimum running time of 3 min. steady-state condition

(continuous operation) must be achieved.

Avoid continuous operation in limit range.

3.3 Limits of application

3|Areas of application

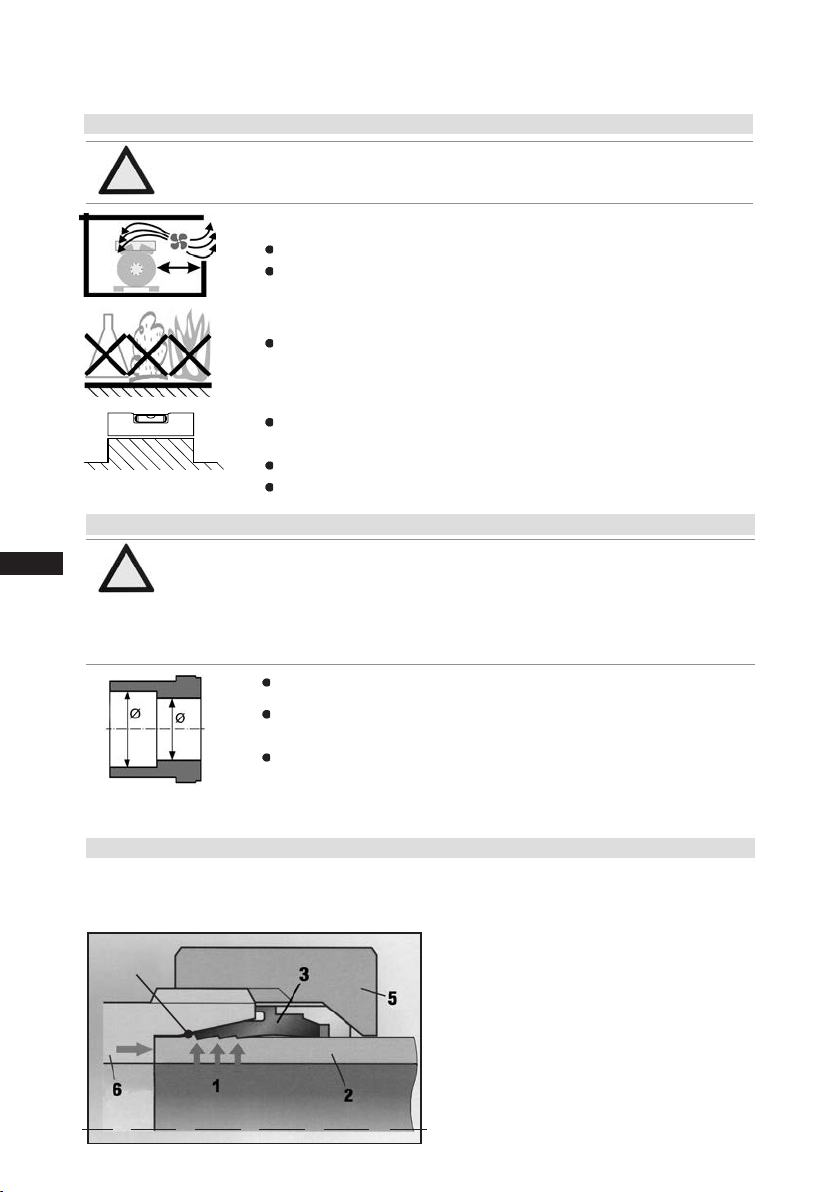

4|Compressor assembly

INFO New compressors are factory-lled with inert gas. Leave this

service charge in the compressor for as long as possible and prevent

the ingress of air.

Immediately after refrigeration technological connection of

the compressor close the shut-off devices in suction-, dis-

charge-, oil return line etc. and evacuate the compressor.

Check the compressor for transport damage before starting any

work.

?

4.1 Storage and transportation

Usetransporteyelet.

Donotliftmanually!

Useliftinggear!

Storageat(-30°C)-(+70°C),maximumpermissiblerelativehumidity

10%-95%,nocondensation.

Donotstoreinacorrosive,dusty,vaporousatmosphereorinacom-

bustibleenvironment.

Maximum permissible operating

pressure (LP/HP)1): 100/150 bar

1) LP=Lowpressure

HP=Highpressure

10

D

GB

F

E

96460-05.2022-DGb

4|Compressor assembly

Material soldering / welding connection: S235 (JRG2C)

The pipe connectionshavegraduatedinsidediameterssothatpipeswith

standardmillimetreandinchdimensionscanbeused.

Theconnectiondiametersoftheshut-offvalvesareratedformaximum

compressoroutput.The actual required pipe cross section must be

matched to the output. The same applies for non-return valves.

Fig.5:graduated

internaldiameter

4.3 Connecting the pipelines - solder system

ATTENTION Damage possible.

Superheating can damage the valve.

Remove the pipe supports therefore from the valve for soldering

and accordingly cool the valve body during and after soldering.

Only solder using inert gas to inhibit oxidation products (scale).

•Onitshigh-pressureside,thecompressorhasashut-offvalvewithmulti-sidedcuttingringforsafe

installationofthedischargeline.

Cuttingringfunctionaftertighteningtheunionnut

. . . . .

4.4 Connecting the pipelines - cutting ring system

Fig.6

Figuresimilar

Collar

4.2 Setting up

Setuponanevensurfaceorframewithsufcientload-bearing

capacity.

Singlecompressorpreferablyonvibrationdamper.

Duplexandparallelcircuitsalwaysrigid.

Provideadequateclearanceformaintenancework.

Ensureadequatecompressorventilation.

Donotuseinacorrosive,dusty,dampatmosphereoracom-

bustibleenvironment.

F

E

D

C

B

A

1

2

3

4

F

E

D

C

4

3

2

1

A

B

Tol.-Ang. DIN ISO 2768-mK

Ra Rz

Maß

Passung

Freigabe

Alternativbezug:

Baumustergeprüft

Teil inaktiv

Lieferantenzeichnung

-

-

K.-Auftrag:

PL:

Zeichnung ungültig

Entwicklungsstand

Teil keine Serie

120

400

±0.5

über 0.5

bis 6

Benzstraße 7 - 72636 Frickenhausen - Germany - www.bock.de

-

-

Unbemaßte Radien:

-

Diese Zeichnung ist unser Eigentum!

Sie darf ohne unsere Genehmigung weder nach-

gebildet, vervielfältigt, oder Dritten Personen zu-

gänglich gemacht werden. Der Nachbau nach

dieser Zeichnung, oder an Hand der nach dieser

Zeichnung hergestellten Gegenstände durch den

Abnehmer oder Dritte ist nicht gestattet.

Wir behalten uns alle Rechte, gemäß DIN ISO 16016

an dieser Zeichnung vor.

Bearb.

Datum

Änderungs-Nr.

Werkstoff:

Ausgangsteil, bzw. Rohteil:

--

Gepr.

Name

Datum

19.04.

Werkstückkanten

DIN ISO 13715

Ersatz für:

Ersetzt durch:

Erstellt

2010

Geprüft

-

Kurz

Zone

1/x

Oberflächenbehandlung / Härte:

-

Blatt:

Änderungsbeschreibung

400

Benennung:

±0.8

1000

30

6

-

±0.3

120

30

±0.2

Zeichn.-Nr. Teile-Nr.

Oberflächenangaben ISO 1302

x.xxxx-xxxxx.x

Zust.

Gußtoleranzen:

Gewicht: (kg)

±0.1

Maßstab:

1:1

Wasserwaage

für Indesign

Der Lieferant muß sicherstellen, dass die Ware in

einwandfreiem Zustand angeliefert wird (Korrosions-

schutz, Verpackung für sicheren Transport).

Rz 25

Rz 160

s

25

z

y

x

w

u

t

0,05

Rz 1,6

0,3

0,7

1,6

2

Rz 16

6,3

Rz 63

Rz 6,3

Rz 12,5

F:\user\kurz\3D Sachen\3D Teile\Zeichnungen\Wasserwaage

ATTENTION Attachments (e.g. pipe holders, additional units, fastening parts,

etc.) directly to the compressor are not permissible!

D

GB

F

E

11

96460-05.2022-DGb

AB

Fig.7 Fig.8

4.6 Flange shut-off valves (HP/LP)

CAUTION Risk of injury.

The compressor must be depressurized through connections A

and B before commencing any work and prior to connecting to the

refrigerant system.

4|Compressor assembly

Tube preparation:

Thetubehastobesawninarightangle.Anangulartoleranceof±1°ispermissible.

Slightlytrimthepipeendsinsideandoutside.Forthinwalledsteelpipesorsoftpipesmadeof

nonferrousmetal,reinforcingsleeveshavetobeused.

Pipe assembly:

Pushunionnut(5)andcuttingring(3)ontopipe(2).Insertpipeintosocket(6)asfarasitwillgoand

firmly press against pipe stop, otherwise incorrect assembly. Hand tighten union nut until socket,

cuttingringandunionnut arelocked.Tightenunionnut11/2turnsusinga spannerwrench.The

cutting ring is noticeably locked to the socket face (for assembly inside pipe connection, hold up

valvewithaspannerwrench).Thisshouldcausethecuttingringwithitscuttingedges(1)tocutinto

thepiperesultinginavisiblecollar.Inordertosticktotheturnswerecommendusingmarkinglines

onunionnutandpipe.Afterassembly,itisnecessarytocheckthecollar.Thegasketmustnotbe

damaged.Atleast80%ofthecuttingfacehastobecovered.Aftercheck-up,screwonandtighten

againasdescribedabove.

4.5 Pipes

Pipesandsystemcomponentsmustbecleananddryinsideandfreeofscale,swarfandlayersof

rustandphosphate.Onlyusehermeticallysealedparts.

Lay pipes correctly. Suitable vibration compensators must be provided to prevent pipes being

crackedandbrokenbyseverevibrations.

Ensureaproperoilreturn.

Keeppressurelossestoanabsoluteminimum.

12

D

GB

F

E

96460-05.2022-DGb

Fig.10 Fig.11

4.7 Laying suction and pressure lines

A rule of thumb: Alwayslaytherstpipesectionstartingfromtheshut-offvalvedownwards and

parallel to the drive shaft.

ATTENTION Property damage possible.

Improperly installed pipes can cause cracks and tears which can

result in a loss of refrigerant.

INFO Proper layout of the suction and pressure lines directly after

the compressor is integral to the smooth running and vibration

behaviour of the system.

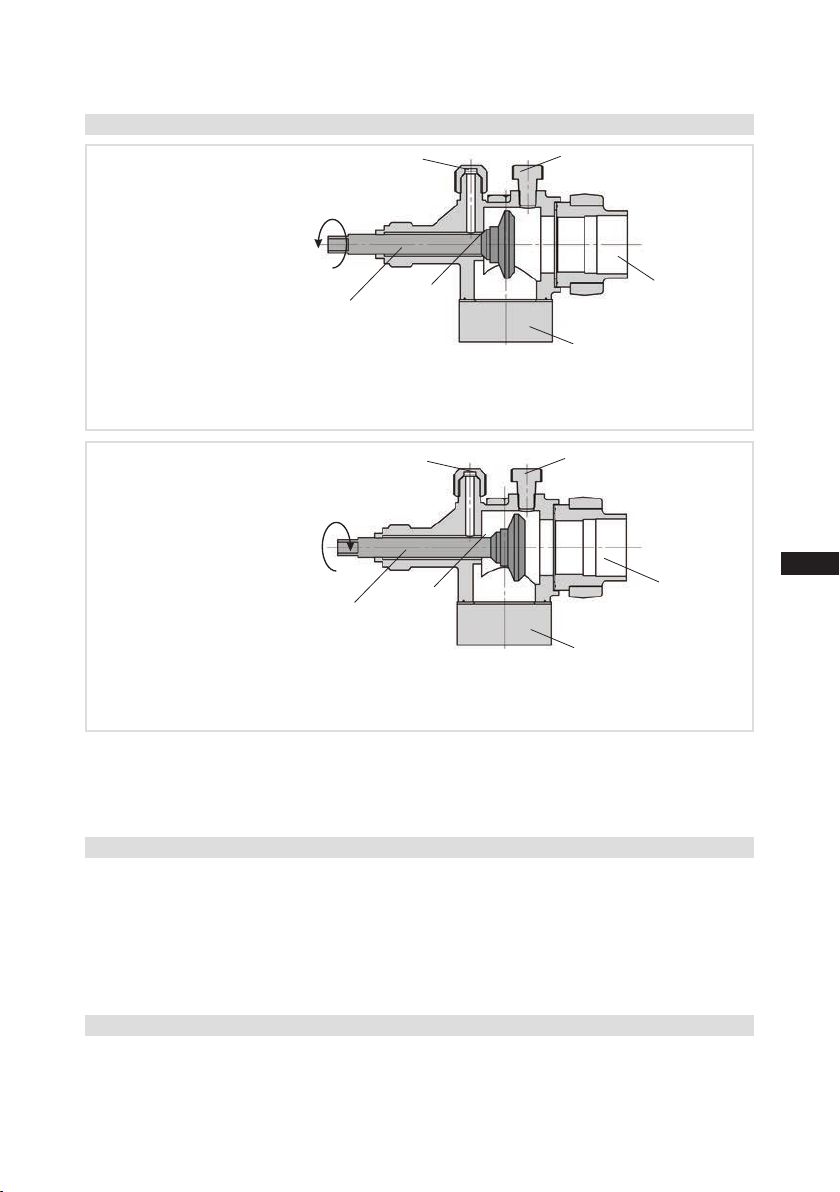

4.8 Operating the shut-off valves

Beforeopeningorclosingtheshut-offvalve,releasethevalvespindlesealbyapprox.1/4ofaturn

counter-clockwise.

Afteractivatingtheshut-offvalve,re-tightentheadjustablevalvespindlesealclockwise.

Valve spindle seal

Release Tighten

4|Compressor assembly

Fig.9

Rigid fixed

point

As short as

possible

D

GB

F

E

13

96460-05.2022-DGb

Fig.12

Fig.13

4.9 Operating mode of the lockable service connections

Opening the shut-off valve:

Spindle:turntotheleft(counter-clockwise)asfarasitwillgo.

—>Shut-offvalvecompletelyopened/serviceconnectionclosed.

Theconnectionwhichcannotbeshutoffisintendedforsafetydevices.

Opening the service connection

Spindle:Turn1/2-1turntotherightclockwise.

—>Serviceconnectionopened/shut-offvalveopened.

Theconnectionwhichcannotbeshutoffisintendedforsafetydevices.

Toensuretheoilreturnfunctionwillworkreliablynomatterwhatkindofsystemcongurationyou

areusing,Bockrecommendsincorporatingoilseparatorsoroillevelmonitoringequipment.The"O"

connectionisalreadyavailablefromthefactoryforthepurposeofinstallingtheadditionaloillevel

monitoringcomponent.Oilshouldbereturnedfromtheoilseparatortothecompressorviathe"D1"

connectionprovidedforthispurposeonthecompressor.

For systems with long pipes and higher degree of contamination, a lter on the

suction-sideisrecommended.Thelterhastobebereneweddependingonthedegreeofcontamina-

tion(reducedpressureloss).

4.10 Oil return

4.11 Suction pipe lter

Afteractivatingthespindle,generallytthespindleprotectioncapagainandtightenwith40-50Nm.

Thisservesasasecondsealingfeatureduringoperation.

Pipeconnection

Pipeconnection

Serviceconnec-

tionclosed

Connection

blocked

Spindle

Connectioncannot

beshutoff

Serviceconnec-

tionopened

Spindle Connection

open

Compressor

Compressor

Connectioncannot

beshutoff

4|Compressor assembly

14

D

GB

F

E

96460-05.2022-DGb

5|Electrical connection

5.1 Information for contactor and motor contactor selection

5 Electrical connection

INFO Connectthecompressormotorinaccordancewiththecircuitdiagram

(seeinsideofterminalbox).

Usesuitablecableglandsofthecorrectprotectiontype(seename

plate)forroutingcablesintotheterminalbox.Insertthestrainreliefs

andpreventchafemarksonthecables.

Comparethevoltageandfrequencyvalueswiththedataforthe

mainspowersupply.

Only connect the motor if these values are the same.

DANGER Risk of electric shock! High voltage!

Only carry out work when the electrical system is disconnected

from the power supply!

Allprotectionequipment,switchingandmonitoringdevicesmustcomplywiththelocalsafetyreg-

ulations and established specications (e.g. VDE) as well as the manufacturer’s specications.

Motor protection switches are required!Motorcontactors,feedlines,fusesandmotorprotec-

tion switches must be rated according to the maximum operating current (see name plate). For

motorprotection,useacurrent-dependent,time-delayedoverloadprotectiondeviceformonitoring

allthreephases.Adjusttheoverloadprotectiondevicesothatitmustbeactuatedwithin2hoursat

1.2timesthemaximumworkingcurrent.

For compressors with LSPM motor, a faster responding overload protection device is

recommended.

ATTENTION When attaching accessories with an electrical cable, a minimum

bending radius of 3 x the cable diameter must be maintained for

laying the cable.

D

GB

F

E

15

96460-05.2022-DGb

5|Electrical connection

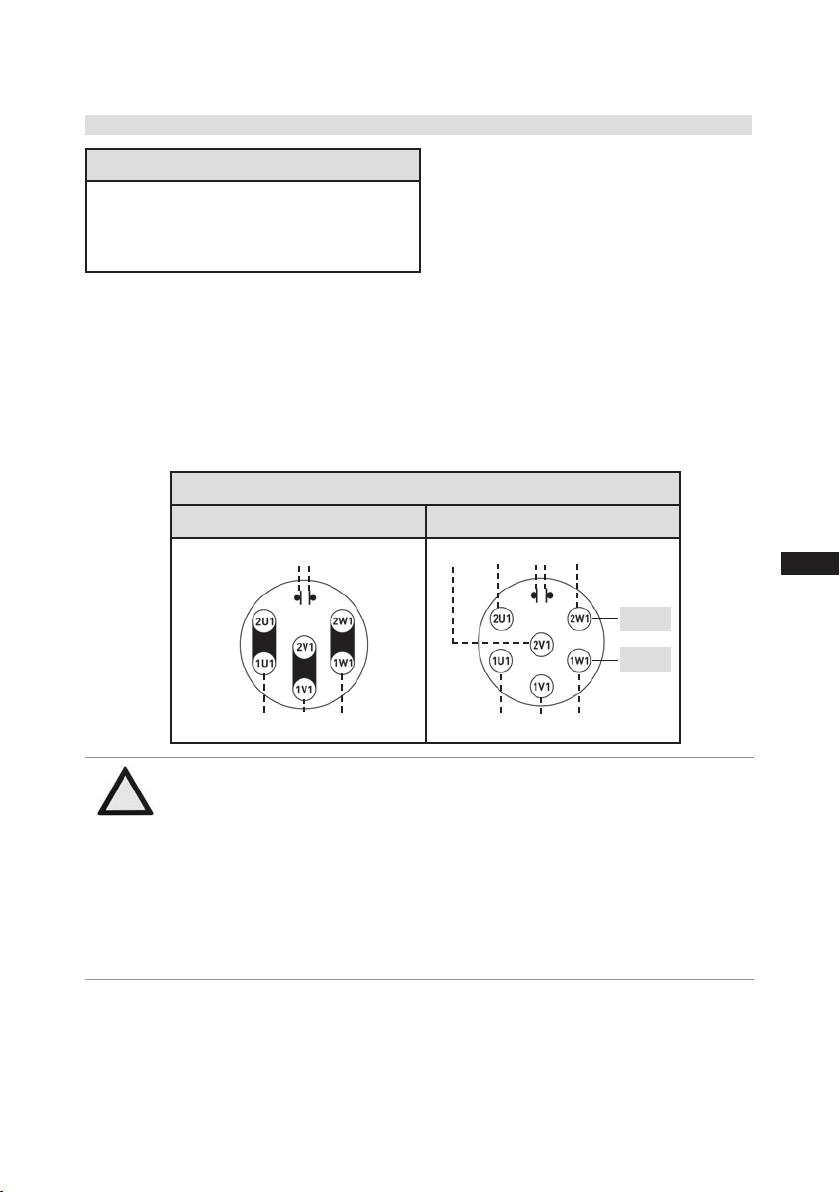

5.2 Standard motor, designed for direct or part winding start

Designationonthenameplate

Y/YY

Compressors markedin thisway aresuitablefordirectorpartwinding start.Themotor windingis

dividedintotwoparts:partwinding1=50%andpartwinding2=50%.Thiswindingdivisionreduces

thestart-upcurrentduringapartwindingstarttoapprox.50%ofthevalueforadirectstart.

Not possible on compressors with LSPM Motor!

Inthefactory,themotorisswitchedfordirectstarting(YY).Forpartwindingstart(Y/YY),removethe

bridgesandconnectthemotorfeedcableaccordingtothecircuitdiagram:

400 V

Direct start YY Part winding start Y/YY

L1

L2

L3

L1

L2

L3

L1 L3

L2

PTC

PW II

PW I

PTC

ATTENTION Property damage possible.

Failure to comply results in reversed elds of rotation and can cause

motor damage. After the motor has started up with part winding 1,

part winding 2 must be switched on after max. 1 second delay. Fail-

ure to comply can be detrimental to the service life of the motor.

Ensure that power is supplied via QA2 to winding 1 (50 %)

(1U1 / 1V1 / 1W1) and via QA3 to winding 2 (50 %) (2U1 / 2V1 / 2W1).

The motor contactors (QA2 / QA3) are each to be rated for approx.

50 % of the max. operating current.

16

D

GB

F

E

96460-05.2022-DGb

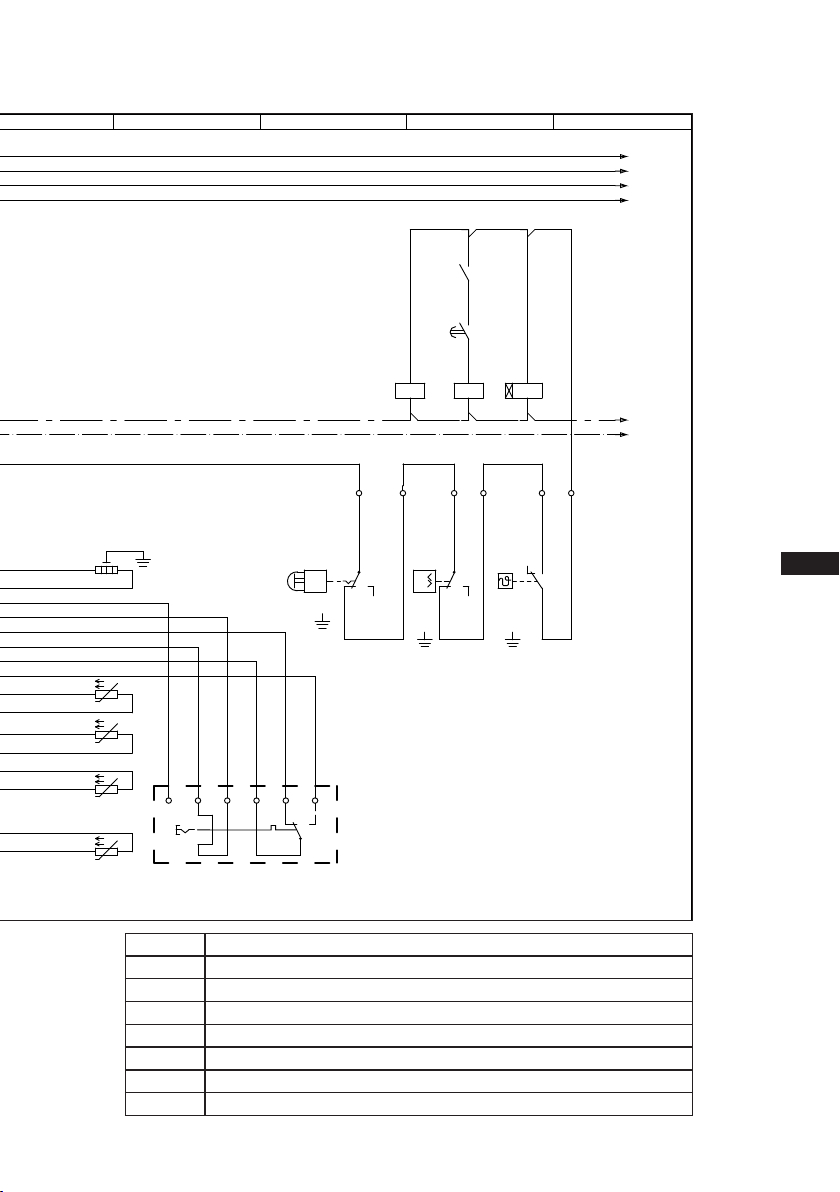

5.3 Basic circuit diagram for part winding start

*Withseveralconnecttheminseries

Fig.14

Οnderung

2

0

Datum Name

Datum

Bearb.

Gepr.

Norm

1

20.02.2009

bauknecht

26.11.2020

Urspr.

2

Ers. f.

3

Ers. d.

4

PW INT69 HG44/66

567

BOCK COMPRESSORS

8

=

+

9

Bl.

6.d Bl.

5.a

2.a

Anschlußkasten Verdichter

BT1

INT69

DELTA- P II

QA1

L1 L2 L3 N PE

FC1.1

I> I>

I>

QA2

1U1

1V1

1W1

PE

EC1

M

Y/YY

2U1

2V1

2W1

FC1.2

I> I>

I>

QA3

FC1.1

FC1.2

FC2

SF1

BP2

P>

QA2

BP3

P

QA2

KF1

KF1

QA2

L1.1

L2.1

L3.1

L1.2

N

PE

QA3

BT4

BT2

Θ

1112 14

L N B1 B2

12

11

10

9

8

7

6

5

4

3

2

1

Θ

vio bn bu gr

Θ

EB1

pk og

21

20

BT3

Θ

50% 50%

Compressorterminalbox

BP2 Highpressuresafetymonitor

BP3 Safetychain(high/lowpressuremonitoring)

BT1 Coldconductor(PTCsensor)motorwinding

BT2 Thermalprotectionthermostat*

BT3 Oiltemperaturesensor

BT4 Releaseswitch(thermostat)

DELTA-PII OildifferentialpressuresensorDELTA-PII(accessory)

EB1 Oilsumpheater

EC1 Compressormotor

D

GB

F

E

17

96460-05.2022-DGb

FC1.1/1.2 Motorprotectionswitch

FC2 Controlpowercircuitfuse

INT69G ElectronictriggerunitINT69G

KF1 Delayrelayforcontactorswitchover

QA1 Mainswitch

QA2 Mainscontactor(partwinding1)

QA3 Mainscontactor(partwinding2)

SF1 Controlvoltageswitch

Οnderung

2

0

Datum Name

Datum

Bearb.

Gepr.

Norm

1

20.02.2009

bauknecht

26.11.2020

Urspr.

2

Ers. f.

3

Ers. d.

4

PW INT69 HG44/66

567

BOCK COMPRESSORS

8

=

+

9

Bl.

6.d Bl.

5.a

2.a

Anschlußkasten Verdichter

BT1

INT69

DELTA- P II

QA1

L1 L2 L3 N PE

FC1.1

I> I>

I>

QA2

1U1

1V1

1W1

PE

EC1

M

Y/YY

2U1

2V1

2W1

FC1.2

I> I>

I>

QA3

FC1.1

FC1.2

FC2

SF1

BP2

P>

QA2

BP3

P

QA2

KF1

KF1

QA2

L1.1

L2.1

L3.1

L1.2

N

PE

QA3

BT4

BT2

Θ

1112 14

L N B1 B2

12

11

10

9

8

7

6

5

4

3

2

1

Θ

vio bn bu gr

Θ

EB1

pk og

21

20

BT3

Θ

18

D

GB

F

E

96460-05.2022-DGb

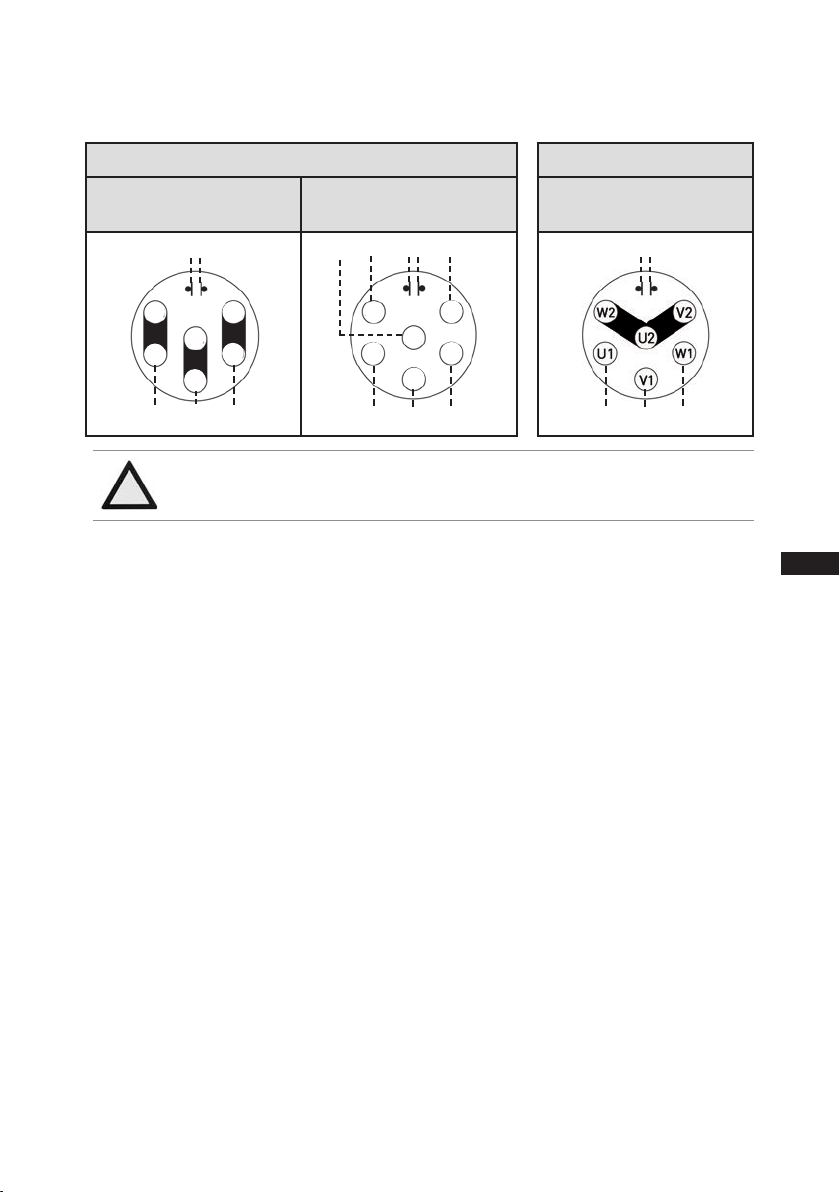

5.4 Special motor: design for direct or star-delta start

5|Electrical connection

Designationonthenameplate

∆/ Y

D

GB

F

E

19

96460-05.2022-DGb

5|Electrical connection

Star-delta start-up is only possible for 230 V power supply. Example:

400 V Y

Direct start only

L1 L3

L2

PTC

230 V Δ

Direct start Star-delta start

(not on LSPM Motor)

L1

L2

L3

L1

L2

L3

L1 L3

L2

PTC PTC

W2

U2

V2

W1

U1

V1

W2

U2

V2

W1

U1

V1

Only direct start is possible with LSPM Motor.

20

D

GB

F

E

96460-05.2022-DGb

5.5 Basic circuit diagram for star-delta start with special motor

*Withseveralconnecttheminseries

Fig.15

Οnderung

4

0

Datum Name

Datum

Bearb.

Gepr.

Norm

1

20.02.2009

bauknecht

03.11.2020

Urspr.

2

Ers. f.

3

Ers. d.

4

D/S INT69 HG44/66 neu

567

BOCK COMPRESSORS

8

=

+

9

Bl.

6.d Bl.

6.b

6.a

Anschlußkasten Verdichter

BT1

INT69G

DELTA- P II

QA1

L1 L2 L3 N PE

U1

V1

W1

PE

U2

V2

W2

FC1.1

FC1.2

FC2

SF1

BP2

P>

BP3

P

QA2

L1.1

L2.1

L3.1

L1.2

N

PE

BT4

BT2

Θ

1112 14

L N B1 B2

12

11

10

9

8

7

6

5

4

3

2

1

Θ

vio bn bu gr pk og

Θ

EB1

FC1.1

I> I>

I>

1

2

QA2

FC1.2

I> I>

I>

3

4

5

6

1

2

QA4

Y

3

4

5

6

1

2

QA3

D

3

4

5

6

EC1

M

3˜

QA2

QA2

QA4 KF1

QA4

QA3

KF1

QA3

QA4 KF1

20

21

BT3

Θ

Compressorterminalbox

BP2 Highpressuresafetymonitor

BP3 Safetychain(high/lowpressuremonitoring)

BT1 Coldconductor(PTCsensor)motorwinding

BT2 Thermalprotectionthermostat (PTCsensor)*

BT3 Oiltemperaturesensor

BT4 Releaseswitch(thermostat)

DELTAPII OildifferentialpressuresensorDELTA-PII(accessory)

EB1 Oilsumpheater

EC1 Compressormotor

This manual suits for next models

20

Table of contents

Other BOCK Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

GFA ELEKTROMATEN

GFA ELEKTROMATEN SG 85F installation instructions

A.B.S.

A.B.S. Flexilo TROUGH Assembly-, Operating-, and Filling Instructions

Berker

Berker RolloTec 2911 operating instructions

Tisch Environmental

Tisch Environmental TE-5170-BL Operation manual

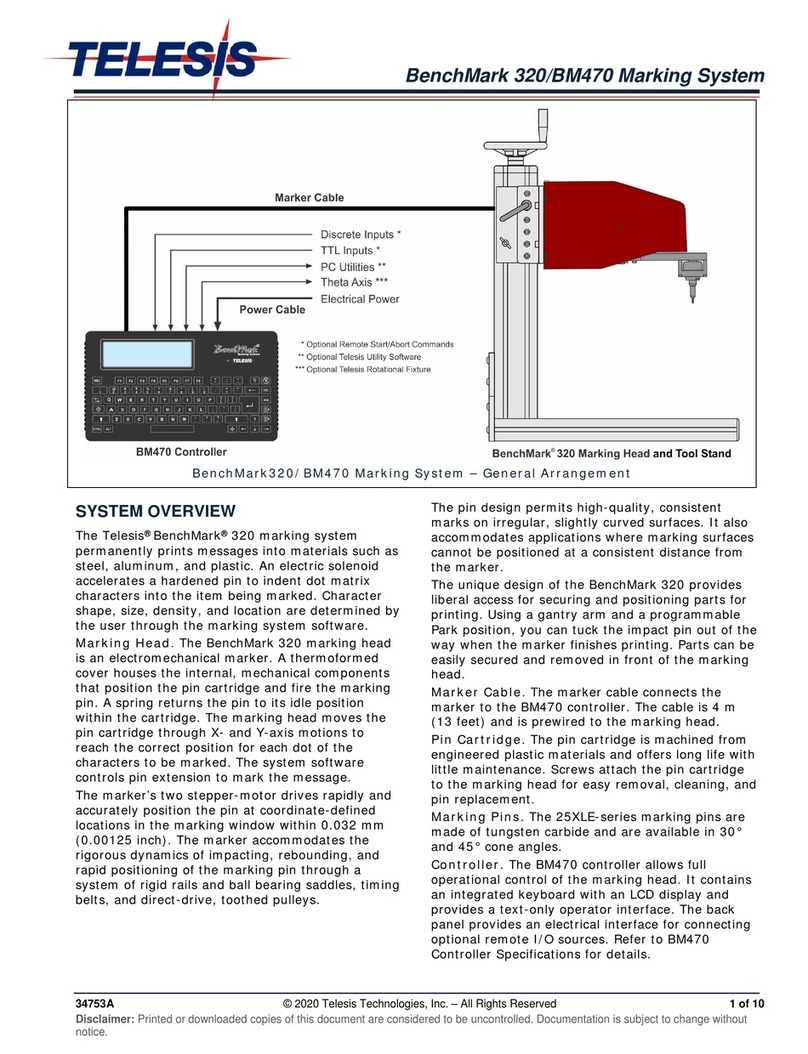

Telesis

Telesis BenchMark 320 manual

HEIDENHAIN

HEIDENHAIN ECN 413 Mounting instructions