COPYRIGHT © 2023 TUFTINGSHOP Page 5 of 24

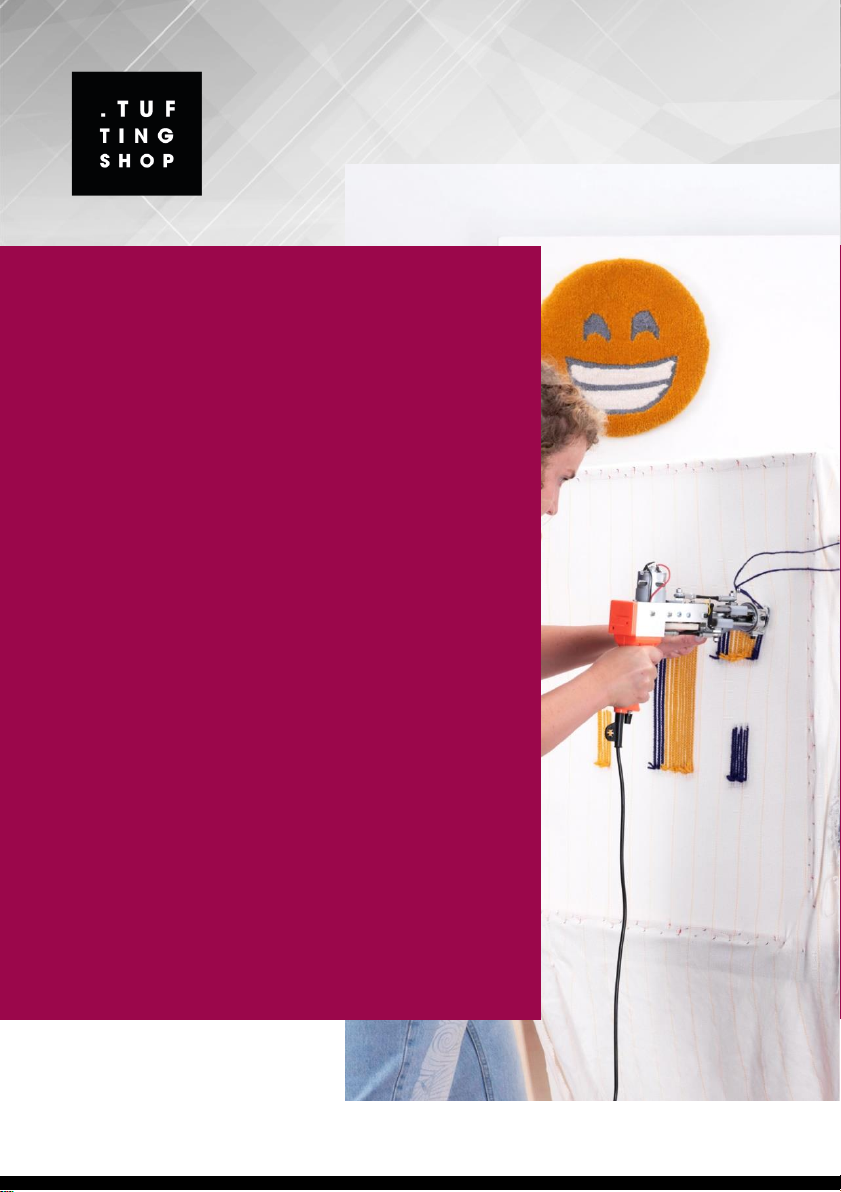

MAINTENANCE

Proper maintenance of a tufting gun is

important to ensure that it continues to

operate smoothly and effectively over

time. Here are some recommended

maintenance tasks for a tufting gun:

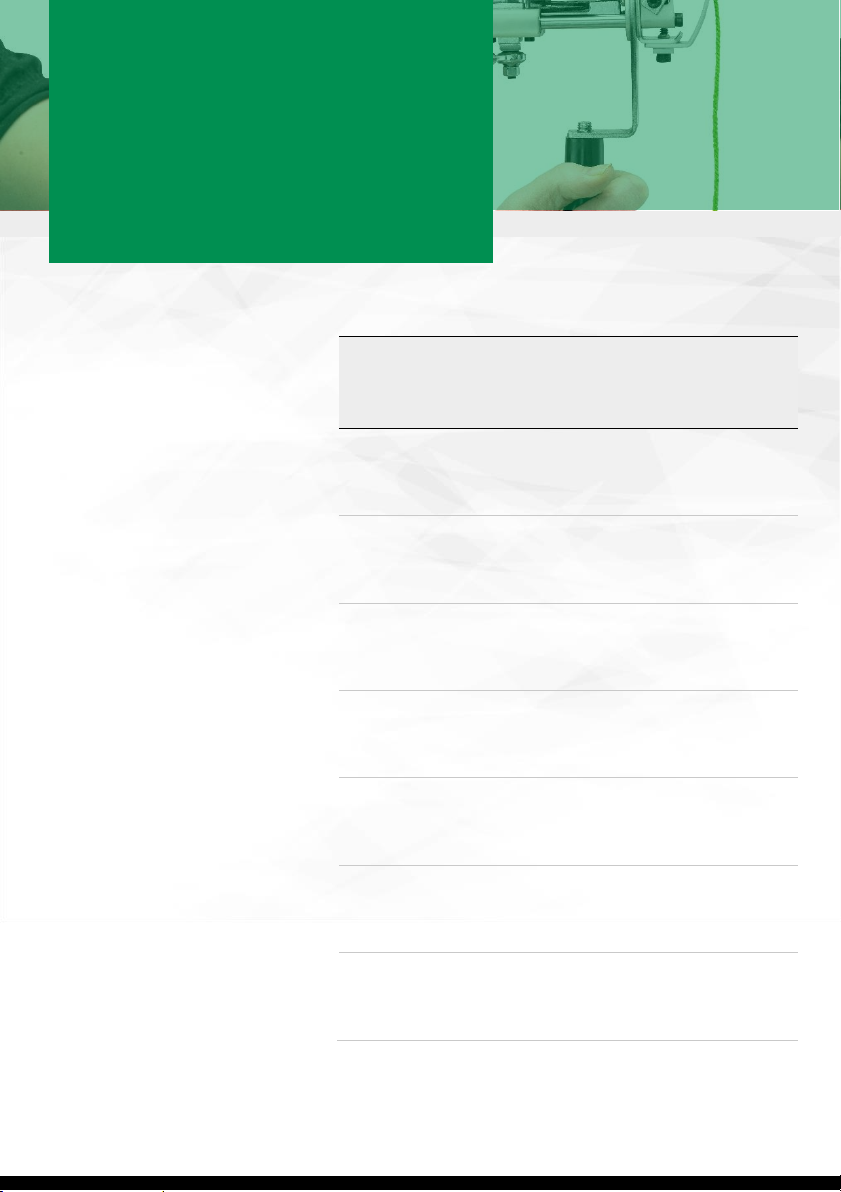

•Clean the machine regularly: Dust and

debris can accumulate in the

machine's moving parts, affecting its

performance. Regular cleaning with a

soft cloth or brush can help keep the

machine clean and free of debris.

•Replace worn or damaged parts: Over

time, the machine's parts may become

worn or damaged, affecting its

performance. Check the machine

regularly for signs of wear or damage,

and replace any parts as needed to

keep the machine running smoothly.

•Store the machine properly: When not

in use, store the tufting gun in a clean,

dry place, and cover it to protect it

from dust and debris.

•Oil the machine: Applying a small

amount of lubricating oil to the

machine's moving parts can help

prevent friction and wear, ensuring

smoother operation. Consult the

manufacturer's instructions for specific

recommendations on how to oil your

tufting gun. Oil the machine on a

regular basis. Each machine has 4 oil

holes, and each oil hole drips 3-5 drops

of oil. Turn the big gear to make the oil

fully lubricate the machine.

By following these maintenance tips, you

can help ensure that your tufting gun

stays in good condition and continues to

produce high-quality tufts for years to

come.