BOCK EX-HG12P User manual

BOCK EX-HG

12

P

Assembly instructions

09691-01.2021-Gb

Translation of the original instructions

colour the world

of tomorrow

BOCK®

Device category 2 G

acc. to directive 2014/34/EU

EX-HG12P75-4 EX-HGX12P/75-4 EX-HG12P/75-4HC

EX-HG12P/90-4 EX-HGX12P/90-4 EX-HG12P/90-4HC

EX-HG12P/110-4 EX-HGX12P/110-4 EX-HG12P/110-4HC

EX-HG12P/60-4S EX-HGX12P/60-4S EX-HG12P/60-4SHC

EX-HG12P/75-4S EX-HGX12P/75-4S EX-HG12P/75-4SHC

EX-HG12P/90-4S EX-HGX12P/90-4S EX-HG12P/90-4SHC

EX-HG12P/110-4S EX-HGX12P/110-4S EX-HG12P/110-4SHC

2

D

GB

F

E

I

09691-01.2021-DGbFEIRu

About these instructions

Read these instructions before assembly and before using the compressor. This will avoid misunder-

standings and prevent damage. Improper assembly and use of the compressor can result in serious

or fatal injury.

Observe the safety instructions contained in these instructions.

These instructions must be passed onto the end customer along with the unit in which the

compressor is installed.

Bock GmbH

72636 Frickenhausen

Manufacturer

Contact

Bock GmbH

Benzstraße 7

72636 Frickenhausen

Germany

Phone +49 7022 9454-0

Fax +49 7022 9454-137

www.bock.de

1 Safety 4

1.1 Identicationofsafetyinstructions

1.2 Qualicationsrequiredofpersonnel

1.3 Safety instructions

1.4 Intended use

2 Product description 7

2.1 Short description

2.2 Ignition protection concept

2.3 Name plate

2.4 Type key

2.5 ATEX-identication

Contents Page

D

GB

F

E

I

3

09691-01.2021-DGbFEIRu

Contents Page

3 Areas of application 12

3.1 Approved refrigerant

3.2 Important information on the use of hydrocarbons

3.3 Oil charge

3.4 Limits of application

4Compressor assembly 15

4.1 Ignition source control of the compressor

4.2 Storage and transport

4.3 Setting up

4.4 Pipe connections

4.5 Pipes

4.6 Laying suction and pressure lines

4.7 Operating the shut-off valves

4.7 Operating mode of the lockable service connections

4.9 Suctionpipelter

5 Electrical connection 19

5.1 Potentialequalization

5.2 Information for contactor and motor contactor selection

5.3 Terminal cross section for leads

5.4 Connection of the drive motor

5.5 Circuit diagram direct start

5.6 Electronic trigger unit INT69 EX2

5.7 Connection of the electronic trigger unit INT69 EX2

5.8 Functional test of the electronic trigger unit INT69 EX2

5.9 To verify the intrinsic safety of the PTC hot gas sensor

6 Commissioning 27

6.1 Preparations for start-up

6.2 Pressure strength test

6.3 Leak test

6.4 Evacuation

6.5 Refrigerant charge

6.6 Start-up

6.7 Avoidingliquidsluggings

6.8 Preventing icing on the compressor

7 Maintenance 29

7.1 Preparation

7.2 Work to be carried out

7.3 Spare part recommendation/accessories

7.4 Screw connections

7.5 Decommissioning

8 Accessories 31

8.1 Oil sump heater

9 Technical data 32

10 Dimensions and connections 33

ECTypeExaminationCerticate 36

IECExCerticateofConformity 39

Service 43

4

D

GB

F

E

I

09691-01.2021-DGbFEIRu

1|Safety

1.2 Qualicationsrequiredofpersonnel

DANGER Indicates a dangerous situation which, if not avoided,

will cause immediate fatal or serious injury.

WARNING Indicates a dangerous situation which, if not avoided,

may cause fatal or serious injury.

CAUTION Indicates a dangerous situation which, if not avoided,

may cause fairly severe or minor injury.

ATTENTION Indicates a situation which, if not avoided,

may cause property damage.

INFO Important information or tips on simplifying work.

WARNING Inadequatelyqualied personnelposestheriskofaccidents,the

consequencebeingseriousorfatalinjury.Work on compressors

must therefore only be performed by personnel with hereinafter

qualicationsandappropriatetoadditionalqualicationaccording

to EN 60079-14.

• For example, a refrigeration technician, refrigeration mechatronic

engineer. As well as professions with comparable training, which ena-

bles personnel to assemble, install, maintain and repair refrigeration

and air-conditioning systems. Personnel must be capable of assessing

the work to be carried out and recognising any potential dangers.

1.1 Identicationofsafetyinstructions:

D

GB

F

E

I

5

09691-01.2021-DGbFEIRu

1.3 Safety instructions

1|Safety

The Bock refrigerating compressor named in the title is intended for installation in machines that were

set up in areas falling under the EU Explosion Protection Directive 1999/92/EC (operator directive). In

the European Union, electrical as well as mechanical devices operated in explosive atmospheres must

fulfil what are known as ATEX (ATmospheres EXplosibles) conditions.

The compressors are specially designed for the category shown on the name plate in accordance with

the ATEX directive and may only be used in conformity with the conditions specified and documented

in the set-up area (explosion protection document). User safety is taken into account as a particular

focus of design. But it is permissible to start up the compressor only if it was installed in accordance

with these instructions and the entire system into which it is integrated has been inspected in accor-

dance with legal regulations and approved.

The declarations and remarks by Bock can only refer to the product itself. We assume that the appli-

cable regulations, standards and technical rules are followed in installation and during operation. The

plant constructor/operator must evaluate the interactions with other devices and components of the

system and with the environment, especially regarding potential ignition sources.

WARNING • Refrigerating compressors are pressurised machines and there-

forerequireparticularcautionandcareinhandling.

• Risk of burns! Depending on the operating conditions, surface

temperatures of over 60 °C on the pressure side or below 0 °C on

the suction side can be reached.

• The maximum permissible overpressure must not be exceeded,

even for testing purposes.

• The compressor may be operated only if it is free of defects!

• No work may be performed when an explosive atmosphere is

present!

• Smoking,reandopenamearestrictlyprohibited!Mobiletele-

phones must be switched off!

• Strongly charge-generating processes must be excluded within

2 meters. The contact of rapidly moving particles with the sur-

face of the compressor must be avoided with certainty (e.g.

pneumaticallymoveddust,owinguids,directventilation,belt

drives, brushes, foils, etc.).

• Perform installation work only if no damage, leaks and/or

appearances of corrosion can be recognized.

6

D

GB

F

E

I

09691-01.2021-DGbFEIRu

1|Safety

These assembly instructions describe the standard version of the EX-HG12(P)(e) manufactured by

Bock. The compressor is intended for use in refrigeration systems inside explosion-endangered areas

underthedesignationspeciedonthenameplateinaccordancewiththeEuropeanATEX Directives.

Useofthespeciedrefrigerantsaswellasobservanceoftheoperatinglimitsandlistedstandards

must be ensured in any case. Likewise, all accessories available from, approved and specially marked

by Bock are exclusively approved, according to their intended use, for attachment to and operation

with Bock compressors of appliance category 2 in accordance with Directive 2014/34/EU.

1.4 Intended use

WARNING Any other use of the compressor and its approved accessories is

prohibited! The ATEX permit is voided if the compressor is used

outside the operating limits or undergoes inadmissible design

changes!

D

GB

F

E

I

7

09691-01.2021-DGbFEIRu

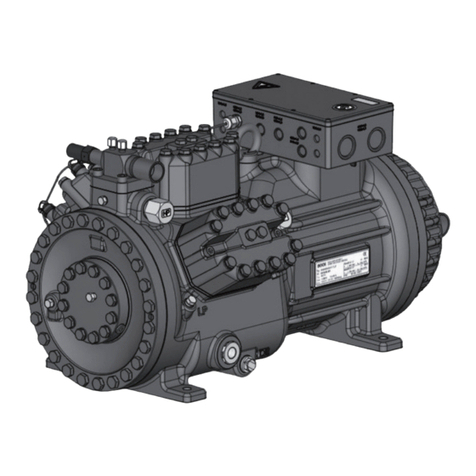

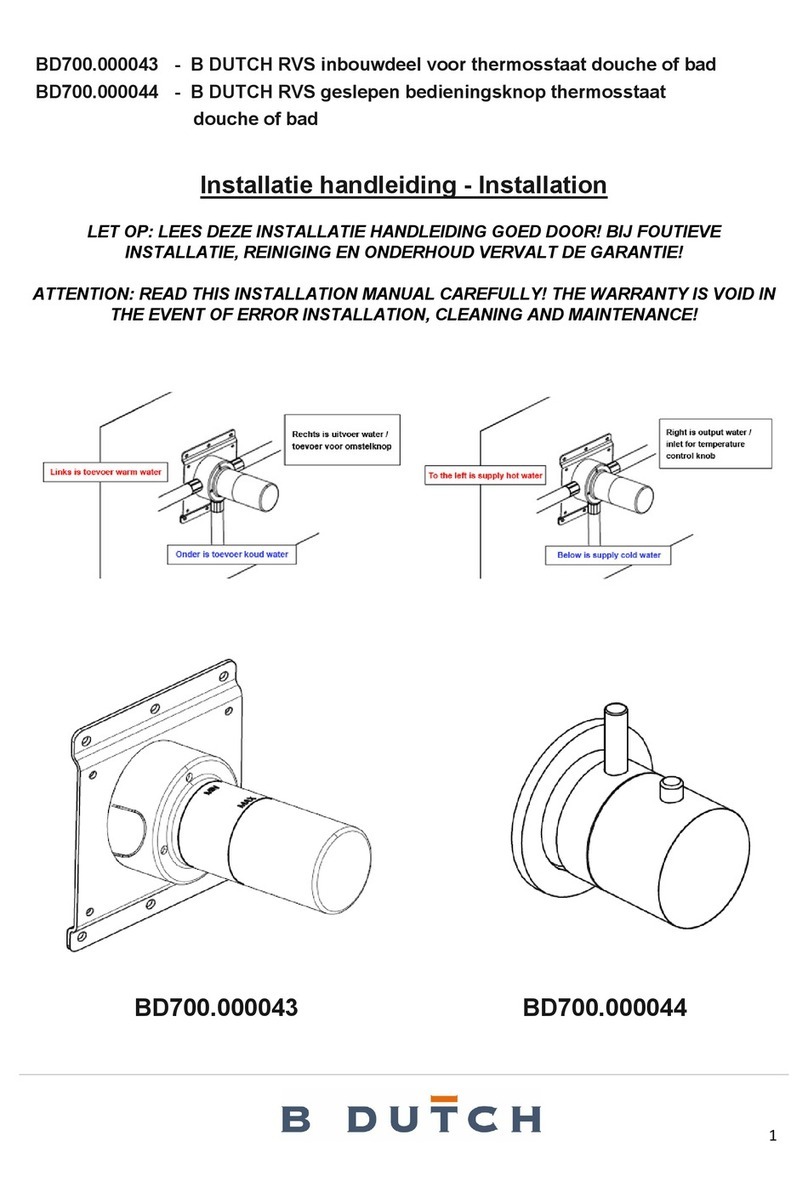

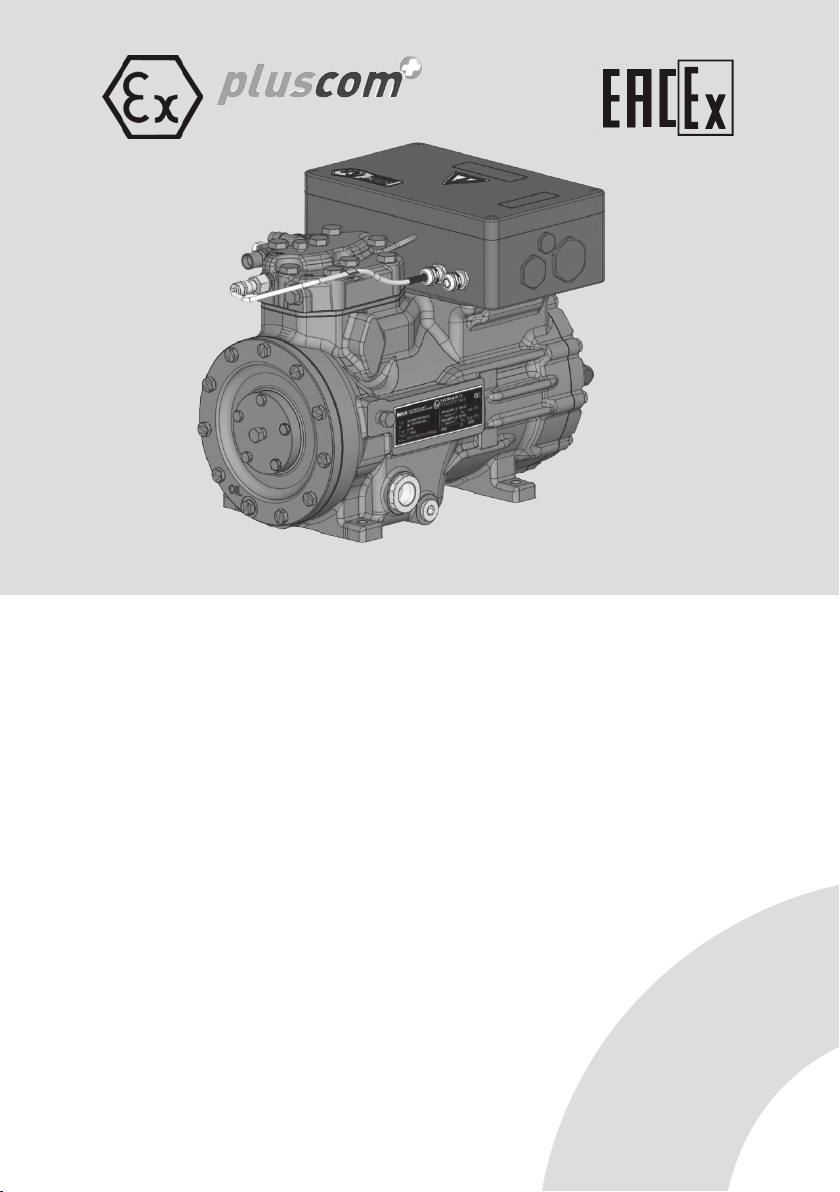

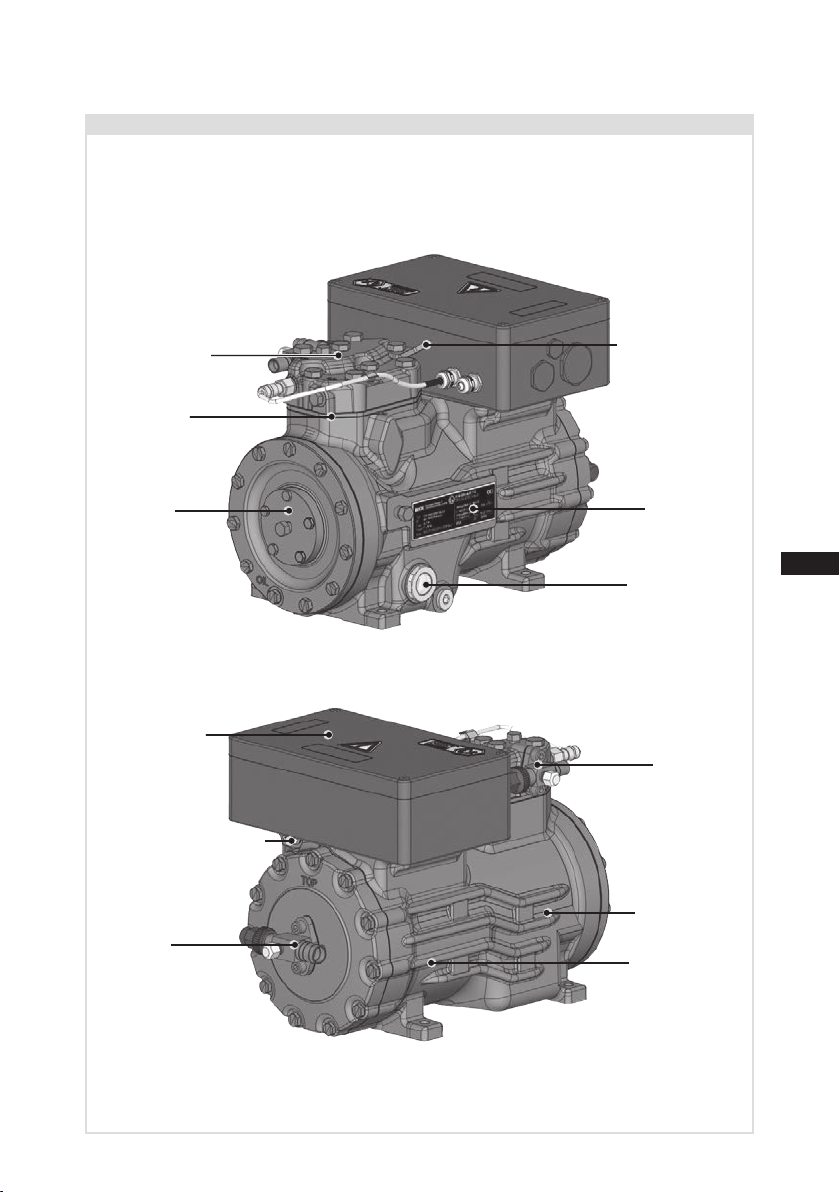

Dimension and connection values can be found in Chapter 10.

Name plate

Fig. 1

Fig. 2

Oil sight glass

Valve plate

Discharge

shut-off valve

Oil pump

Terminal box

Potentialequalization

Suction

shut-off valve

Drive section

Motor section

Transport eyelet

Cylinder cover

2|Product description

• Semi-hemetic two-cylinder reciprocating compressor with oil pump lubrication

• Suction-gas-cooled drive motor

• For use in explosion-endangered areas

2.1 Short description

8

D

GB

F

E

I

09691-01.2021-DGbFEIRu

2|Product description

2.2 Ignition protection concept

In accordance with Directive 2014/34/EU, Bock ATEX compressors are suitable for use in device

category 2 for explosive gas atmospheres up to temperature class T3 and explosion hazard subgroup

IIB/IIC.

The entire compressor, including motor, is perceived as technically tight and therefore does not need

an ignition protection.

To prevent ignition risk caused by working materials also during system malfunctions, all used work-

ingmaterialshavetomeettherequirementsforthetemperatureclassofthecompressor.Thesurface

temperature of the compressor may not exceed 80 % of the ignition temperature of the working

material. For this reason all working materials need to have an auto-ignition temperature of > 250 °C.

To protect against high temperatures that may occur during incorrect operation or faults at the com-

pressor, the areas with the highest heat potential are controlled with temperature sensors (Ex h).

The installation of the electronic control unit INT69 EX2 and the safety barrier,

both included in the scope of supply, is therefore absolutely necessary.

Theconnectionareasforloadcircuitsaredesignedaccordingtotherequirementsoftheappliance

category in Ex e. The circuits for the temperature sensors of the used ignition source control Ex h have

to be intrinsically safe to prevent inadmissibly high thermal or electric values. To ensure the intrinsic

safety, the included safety barrier has to additionally be integrated in the electric circuit according to

this assembly instruction. The terminal board is designed for the protection type Ex de. The whole

electricconnectionareaisprotectedbyahousingthatcomplieswiththerequirementsfortheprotec-

tion type increased safety (Ex e).

Thescopeofdeliveryofthestandardcompressorcomprisesaconductivepaintnish,thatissuitable

for the use in explosion group IIC. If the compressor is delivered with the accessory "Offshore Paint

Finish", the application is restricted to explosion group IIB.

D

GB

F

E

I

9

09691-01.2021-DGbFEIRu

Accessories

Heating elements for the compressors to protect against explosion risks are designed in the protection

types increased safety (Ex d) and have to have to be mounted stationary at the designated areas in

the compressor housing. The heating elements can be operated without temperature- and oil level

controlsincethethermaltypetestingbythemanufacturerveriedthattheheatingelementsprevent

the exceeding of the temperature class of the compressor. The control has to be carried out in a way

that the heating element can only be operated during shutdown of the compressor.

2|Product description

Equipment Type of ignition protection EPL1)

Terminal box Ex e b

Terminal board Ex d b

Through terminals in the terminal box Ex e b

Cable entrances /

plug

Ex e /

Ex d

b

b

Line entrances Ex d b

Oil sump heater Ex d b

Hot gas PTC sensor Ex i a

1)EquipmentProtectionLevel

10

D

GB

F

E

I

09691-01.2021-DGbFEIRu

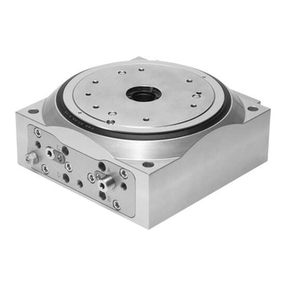

EX-HG12P/110-4 S

IP66

AY15595A008

6,1 A

26 A 11,3

9,4

II 2G Ex d e ia IIC T3 Gb / EPS 16 ATEX 1095 X

1

2

3

4

5

6

7

8

9

10

12

13

11

14

2|Product description

2.2 Name plate (example)

2.3 Name plate (example)

50Hz

60Hz

}

}

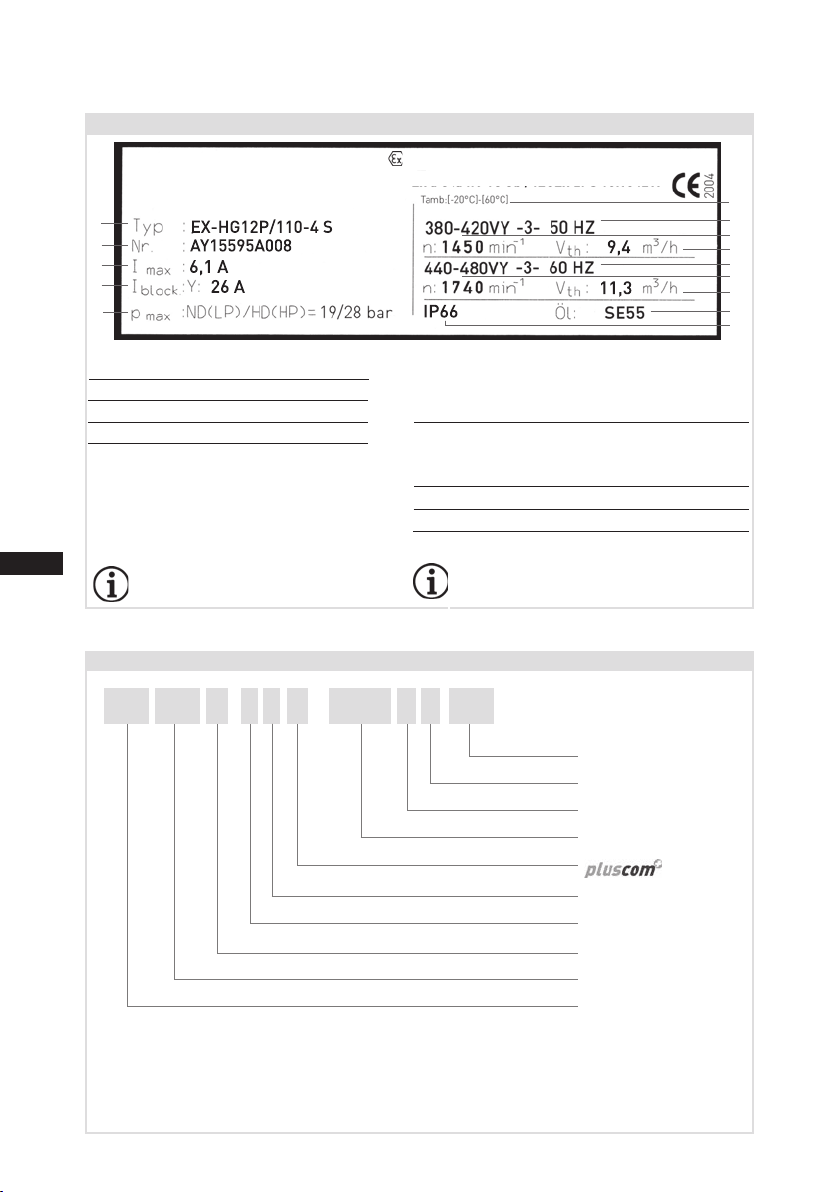

2.4 Type key (example)

¹) HG - Hermetic gas-cooled (suction gas-cooled)

²) X - Ester oil filling (HFC refrigerant ), e.g. R134a, R404A, R507, R407C)

³) Additional declaration for Pluscom compressors

4) S - More powerful motor, e.g. air-conditioning applications

1 Type designation 6 Voltage,circuit,frequency

2 Machine number 7 Nominal rotation speed

3 maximum operating current 8 Displacement

4 Starting current (rotor blocked) 9 Voltage,circuit,frequency

5 ND (LP):

max. admissible operating

10 Nominal rotation speed

pressur

e (g) Low pressure side 11 Displacement

HD (HP):

max. admissible operating

12 Oiltypelledatthefactory

pressur

e(g) High pressure side 13 Terminal box protection type

14 Permissible ambient temperature

Electrical accessories can change

the IP protection class!

Observe the limits of

application diagrams!

/

HG

EX 21 P 110-

-4 SX

for hydrocarbons

Motor variant 4)

Number of poles

Swept volume

³)

Number of cylinders

Size

Esteroillling²)

Series ¹)

Ex-design

HC

Fig. 3

Bock GmbH, Benzstr. 7

72636 Frickenhausen, Germany

BOCK II 2G Ex db eb ia IIC T3 Gb / EPS 16 ATEX 1 095 X

Ex db eb ia IIC T3 Gb / IECEx EPS 16.0042X

D

GB

F

E

I

11

09691-01.2021-DGbFEIRu

EPS 16 ATEX 1095 X / IECEx EPS 16.0042 X

Bureau Veritas (inspection authority)

Consumer Products Services

Germany GmbH

International explosion protection

Year of test/Test report number

Year of test

Bureau Veritas (inspection authority)

Consumer Products Services

Germany GmbH

ATEX-CerticateofConformityIECEx-CerticateofConformity

Special conditions:

see"ConditionsofCertication"

Special conditions:

see point 17 of the EC type

examinationcerticate

Test report number

ATmospheres EXplosibles

european explosion protection

2|Product description

2.5 ATEXidentication/IECExidentication

Explosion group II for Ex-endangered

areas (not underground buildings)

Suitability for gas-explosive area

Device category 2 (= zone 1)

Temperature class T3 (max.200 °C)

Equipmentprotectionlevel

Explosion subgroups,

IIB=Offshorepaintnish

IIC=ESDpaintnish

Intrinsicallysafeequipment

Flameproof enclosure, heater (option)

Europ. explosion protection acc. to

Direc. 2014/34/EU

Increased safety

2G T3 GbII ia IIB/IIC

Ex

db eb

12

D

GB

F

E

I

09691-01.2021-DGbFEIRu

3|Areas of application

3.1 Approved refrigerant

• HFKW / HFC: R134a, R404A, R507, R407C

• (H)FCKW / (H)CFC: R22

• Hydrocarbons: R290, R1270

3.2 Important information on the use of hydrocarbons

Hydrocarbons (combustible refrigerants) may be used in the compressors named in the title only if all

relevant and applicable regulations, standards and technical rules are followed. National safety regu-

lations must be observed. In addition, we refer to the following applicable standards and regulations:

EN 378, BGR500, TRBS 2152, EC Directives 1999/92/EC and 2014/34/EU.

The compressor and the refrigeration system must be permanently equipped with clear, identical

labels/plates (ISO3864) that state that combustible refrigerants are used. This warning plate must be

unremovably attached to the compressor.

A hazard analysis in accordance with the Operational Safety Ordinance must be performed for the

set-up location. Use and handling of the refrigeration system and compressor are to be governed in

the explosion protection document.

Installation, placement into operation, service and repair (as permitted by the manufacturer) may only

be performed by personnel who have been specially trained on combustible refrigerants.

If the compressor has to be removed from the system for inspection/maintenance/repair, the remaining

refrigerantmustbesuctionedoutandthecompressorevacuated,lledwithnitrogen(<0.5bar)and

closedgas-tight.Thecompressormustbeequippedwithatagthatclearlystatesthatthecompressor

was operated with combustible refrigerant (name the refrigerant).

If the system contains combustible refrigerants or residues, extreme caution must be exercised when

workingonthecompressorduetothedangerofexplosion.Thisappliesespeciallyfortheuseofre,open

ameorotherignitionsources(e.g.electronicdevices,mobiletelephones,staticcharges,sparks,...).

During maintenance and repair, it must be noted that hydrocarbon residues may remain dissolved in

theoil.Inadditionuseddryerscontainbottomsoftheinammablerefrigerants.Flushthedryerwith

nitrogen and supply it to the recycling.

It should be noted that the solubility of hydrocarbons in oil can be very high, especially at high suction

pressures.Ahigh-viscositylubricantmayberequired,dependingontheapplicationandexperience.

The lubricant must be released for use by Bock. Depending on the application, a pump-down switch

should also be added (e.g. when the refrigeration system is set up outside).

INFO Used refrigerants have to have a self-ignition temperature of

> 250 °C.

D

GB

F

E

I

13

09691-01.2021-DGbFEIRu

3|Areas of application

The following refrigerants are approved for the compressor:

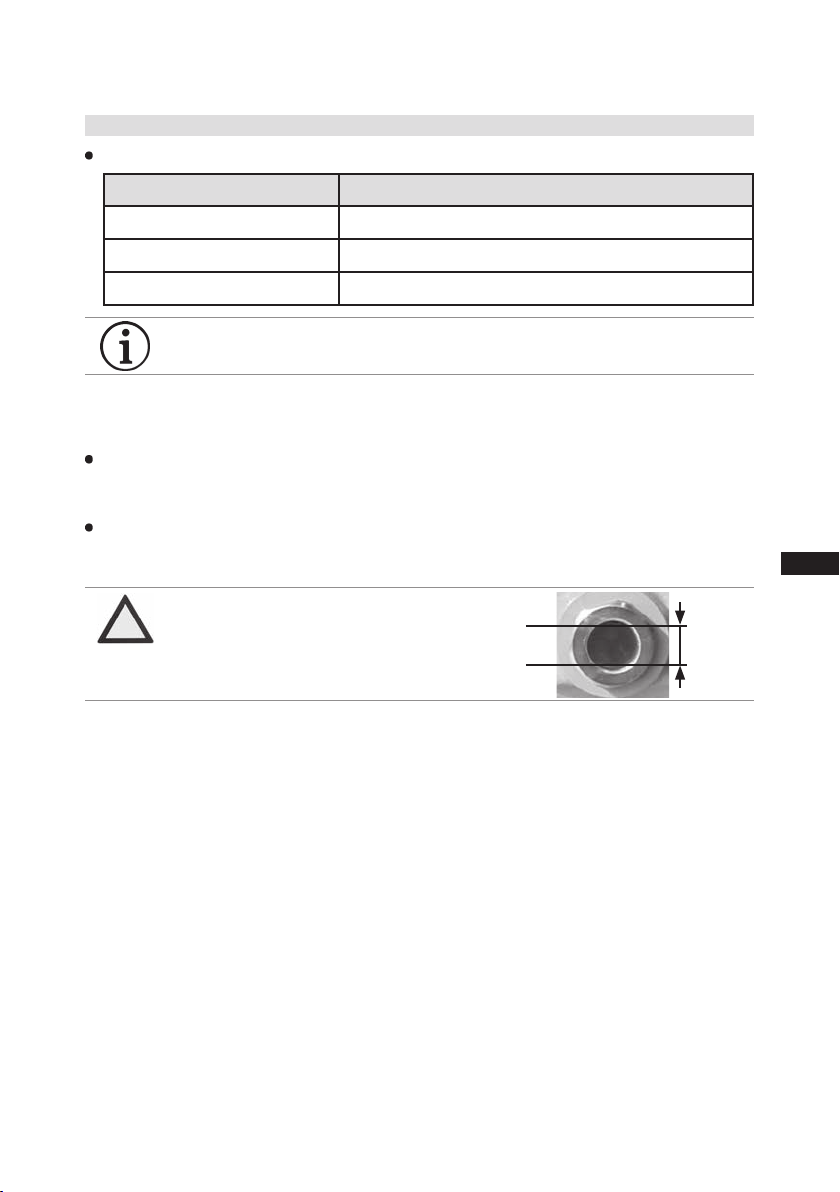

3.3 Oil charge

Refrigerant Oil grade

R22 FUCHS Reniso SP 46

R134a, R404A, R507, R407C FUCHS Reniso Triton SE 55

R290, R1270 BOCKlub G68

Compressorswithesteroillling(FUCHSRenisoTritonSE55)aremarkedwithanX in the type

designation (e.g. EX-HGX12P/110-4).CompressorswithoilllingBOCKlub G68 are marked with

HC (eg. EX-HG12P/110-4 HC).

Oil level: The oil level from the factory reaches the upper edge of the sight glass. The oil level must

be regulated in operation; if necessary to achieve a correct oil level (see Fig. 4), oil may have to be

drained off or added.

Operate compressors only with the approved refrigerants and the corresponding assigned and

approved oils. Other combinations (e.g. R22 with ester oils) are not permitted!

Conversion to another refrigerant/oil is not permitted!

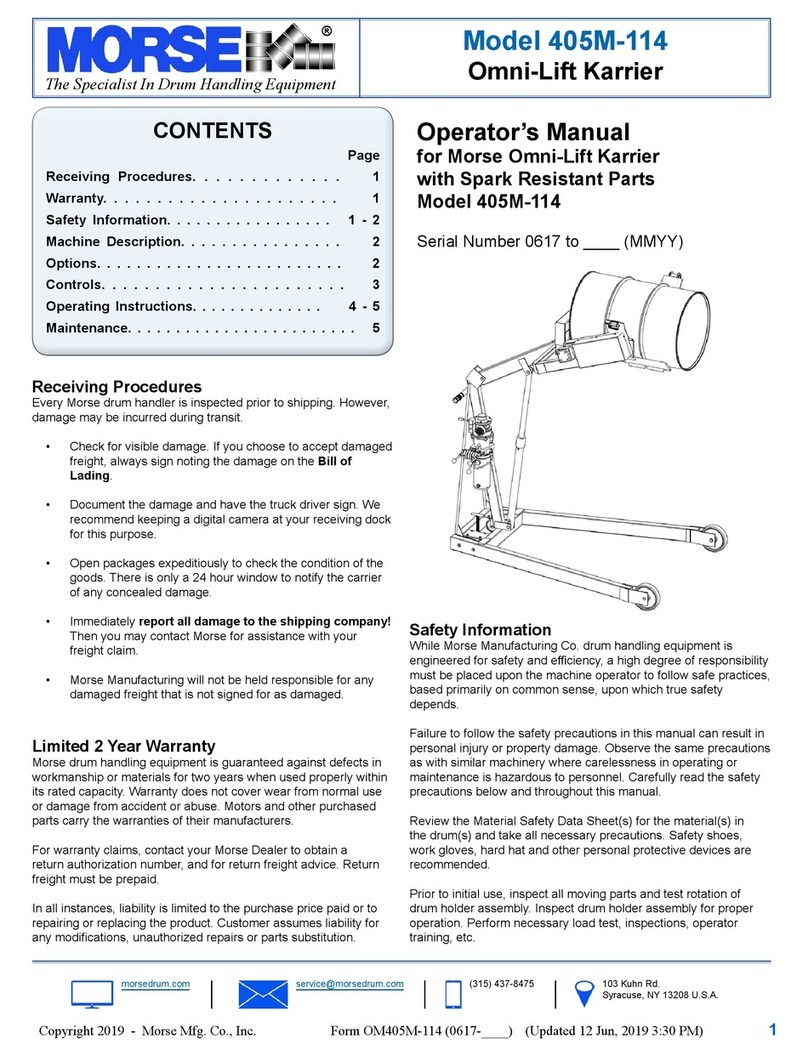

ATTENTION The oil level must be in

the visible part of the sight

glass; damage to the com-

pressor is possible if over-

filled or underfilled! Fig. 4

max.

min.

0,5 Ltr.

oil level ~

~

INFO Used refrigerant oils have to have a self-ignition temperature of

> 250 °C.

14

D

GB

F

E

I

09691-01.2021-DGbFEIRu

3|Areas of application

3.4 Limits of application

ATTENTION Compressor operation is possible within the operating limits.

These can be found in Bock compressor selection tool (VAP)

under vap.bock.de. Observe the information given there.

- Max. permissible discharge end temperature 140 °C.

-Max.permissibleswitchingfrequency8x/h.

- A minimum running time of 3 min. steady-state condition

(continuous operation) must be achieved.

Suction gas overheating ∆toh:

The correct setting of the suction gas overheating temperature

∆tohatthecompressorentranceisofdecisiveimportance:

Too low ∆toh =>dangerofliquidoperation

Too high ∆toh => danger of compressor overheating

∆toh min=7-10K,individualadjustmentrequired.

Permissibleambienttemperaturerange−20°Cto+60°C.

Avoid continuous operation near the limits.

Foroperationwithfrequencyconverter:

- the maximum current and power consumption may not

be exceeded.Duringoperationabovethe mainsfrequency

the application limit can be restricted.

Variablefrequencyrange:30-70Hz

During operation in the vacuum range, there is a danger of air

entering on the suction side. This can cause chemical reactions,

pressure rise in the condenser and an excessive pressure gas tem-

perature as well as shifting of the refrigerant ignition limit into the

critical range. Avoid absolutely operation in the vacuum range!

D

GB

F

E

I

15

09691-01.2021-DGbFEIRu

4|Compressor assembly

4.1 Ignition source control of the compressor

INFO • Newcompressorsarefactory-lledwithinertgas.Leavethisservice

charge in the compressor for as long as possible and prevent the

ingress of air.

•Check the compressor for transport damage before starting any

work.

•Before starting work, obtain written work release.

•Observe national regulations when setting up explosion-protected

systems(withintheEU:ATEXDirective1999/92/EG,EN60079-14,

EN 60079-17 a.o.).

• Use only tools permitted for explosion-protected systems (within

the EU, in accordance with EN 1127-1).

• Observe work safety rules (TRGS 727, e.g. protective shoes,

clothing etc.)!

To protect against an exceeding of temperature the protection type ignition source control "h" is

used at the compressor. Via sensors, the areas with the highest heat potential at every cylinder

cover are controlled. Additionally, the temperature of the motor winding is controlled by the safety

device INT69 EX2.

The permissible limit temperatures for normal operation of the compressor were set with 130 °C for

the motor and with 140 °C for the hot gas side of the cylinder cover. If one of those values is exceeded,

the compressor is shut down by the control device INT69 EX2. Besides the installation according to

wiring diagram, the operator/installer does not have to regard other parameters for the correct func-

tioning of the ignition protection system. A function check however has to be carried out before every

startup of the compressor according to section 5.7 of this assembly instruction.

For a safe function of the ignition source control the INT69 EX2 has to be installed according to the

wiringdiagramg.25,therestartinterlock(bridgeB2)mustnotberemovedinanycase.Checkthe

function of the ignition protection system according to section 5.8. Defective sensors or ignition pro-

tection systems have to be replaced before reconnection of the compressor.

Operation of the compressor without igintion source control is not permitted!

After shutdown by the INT69 EX2, precise error diagnostics and error correction is necessary.

The INT69 EX2 has a restart interlock that can only be interrupted by means of voltage inter-

ruption.

16

D

GB

F

E

I

09691-01.2021-DGbFEIRu

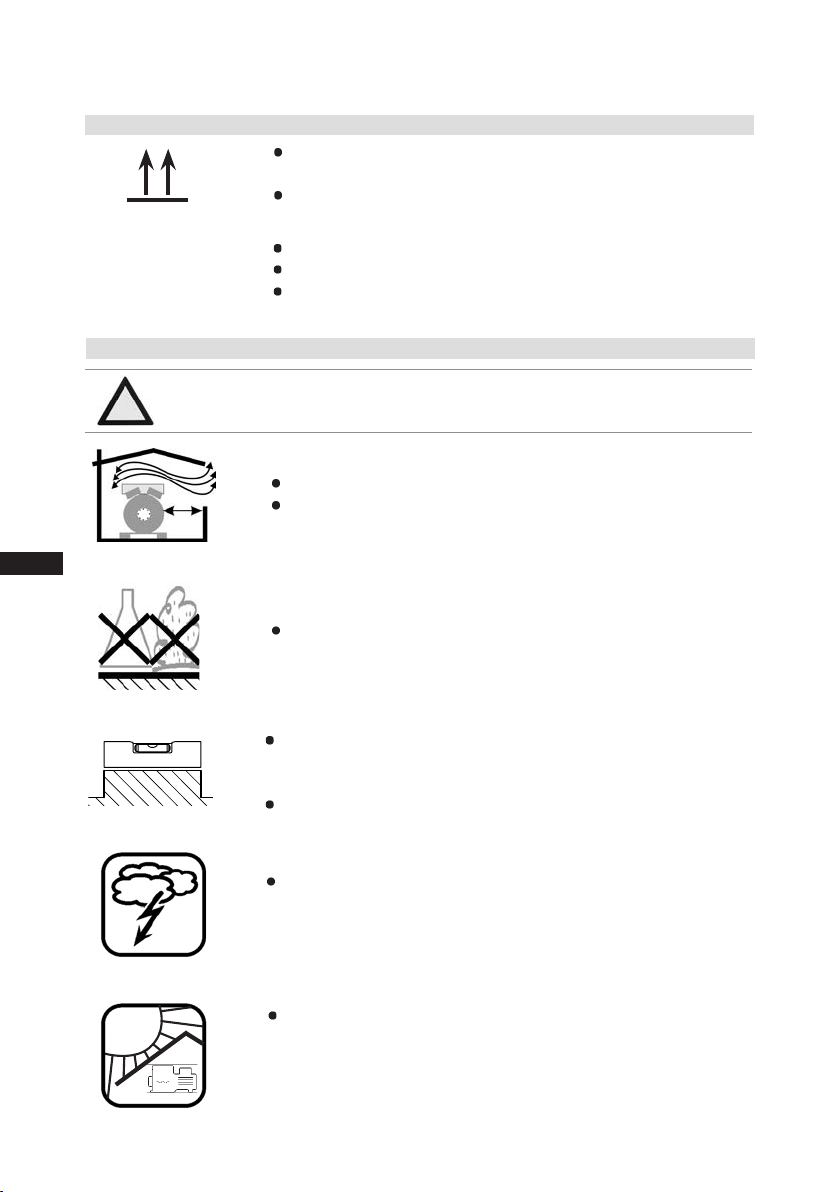

Setuponanevensurfaceorframewithsufcientload-

bearing capacity. Only set up on a slant after consulting

with the manufacturer.

Single compressor preferably on vibration damper.

Provideadequateclearanceformaintenancework.

Ensureadequatecompressorventilation.

Do not operate in an aggressive and/or corrosive atmosphere.

Fig. 7

Fig. 8

Fig. 9

F

E

D

C

B

A

1

2

3

4

F

E

D

C

4

3

2

1

A

B

Tol.-Ang. DIN ISO 2768-mK

Ra Rz

Maß

Passung

Freigabe

Alternativbezug:

Baumustergeprüft

Teil inaktiv

Lieferantenzeichnung

-

-

K.-Auftrag:

PL:

Zeichnung ungültig

Entwicklungsstand

Teil keine Serie

120

400

±0.5

über 0.5

bis 6

Benzstraße 7 - 72636 Frickenhausen - Germany - www.bock.de

-

-

Unbemaßte Radien:

-

Diese Zeichnung ist unser Eigentum!

Sie darf ohne unsere Genehmigung weder nach-

gebildet, vervielfältigt, oder Dritten Personen zu-

gänglich gemacht werden. Der Nachbau nach

dieser Zeichnung, oder an Hand der nach dieser

Zeichnung hergestellten Gegenstände durch den

Abnehmer oder Dritte ist nicht gestattet.

Wir behalten uns alle Rechte, gemäß DIN ISO 16016

an dieser Zeichnung vor.

Bearb.

Datum

Änderungs-Nr.

Werkstoff:

Ausgangsteil, bzw. Rohteil:

--

Gepr.

Name

Datum

19.04.

Werkstückkanten

DIN ISO 13715

Ersatz für:

Ersetzt durch:

Erstellt

2010

Geprüft

-

Kurz

Zone

1/x

Oberflächenbehandlung / Härte:

-

Blatt:

Änderungsbeschreibung

400

Benennung:

±0.8

1000

30

6

-

±0.3

120

30

±0.2

Zeichn.-Nr. Teile-Nr.

Oberflächenangaben ISO 1302

x.xxxx-xxxxx.x

Zust.

Gußtoleranzen:

Gewicht: (kg)

±0.1

Maßstab:

1:1

Wasserwaage

für Indesign

Der Lieferant muß sicherstellen, dass die Ware in

einwandfreiem Zustand angeliefert wird (Korrosions-

schutz, Verpackung für sicheren Transport).

Rz 25

Rz 160

s

25

z

y

x

w

u

t

0,05

Rz 1,6

0,3

0,7

1,6

2

Rz 16

6,3

Rz 63

Rz 6,3

Rz 12,5

F:\user\kurz\3D Sachen\3D Teile\Zeichnungen\Wasserwaage

4|Compressor assembly

Lightening protection: If the compressor is set up outdoors,

a lightening protection concept has to be integrated.

Sun protection: If the compressor is set up outdoors, it has

to be protected from direct sunlight.

Fig. 10

Fig. 11

4.3 Setting up

?

4.2 Storage and transport

Use transport eyelet.

Do not lift manually!

Use lifting gear!

Storageat(−30°C)-(+70°C),maximumpermissiblerelativehumi-

dity 10 % - 95 %, no condensation

Do not store in a corrosive, dusty, vaporous atmosphere or in a com-

bustible environment.

Fig. 6

Fig. 5

ATTENTION Fittings (e.g. pipe holders, additional units, mounting parts etc.)

on the compressor are not permissible!

D

GB

F

E

I

17

09691-01.2021-DGbFEIRu

Fig. 13

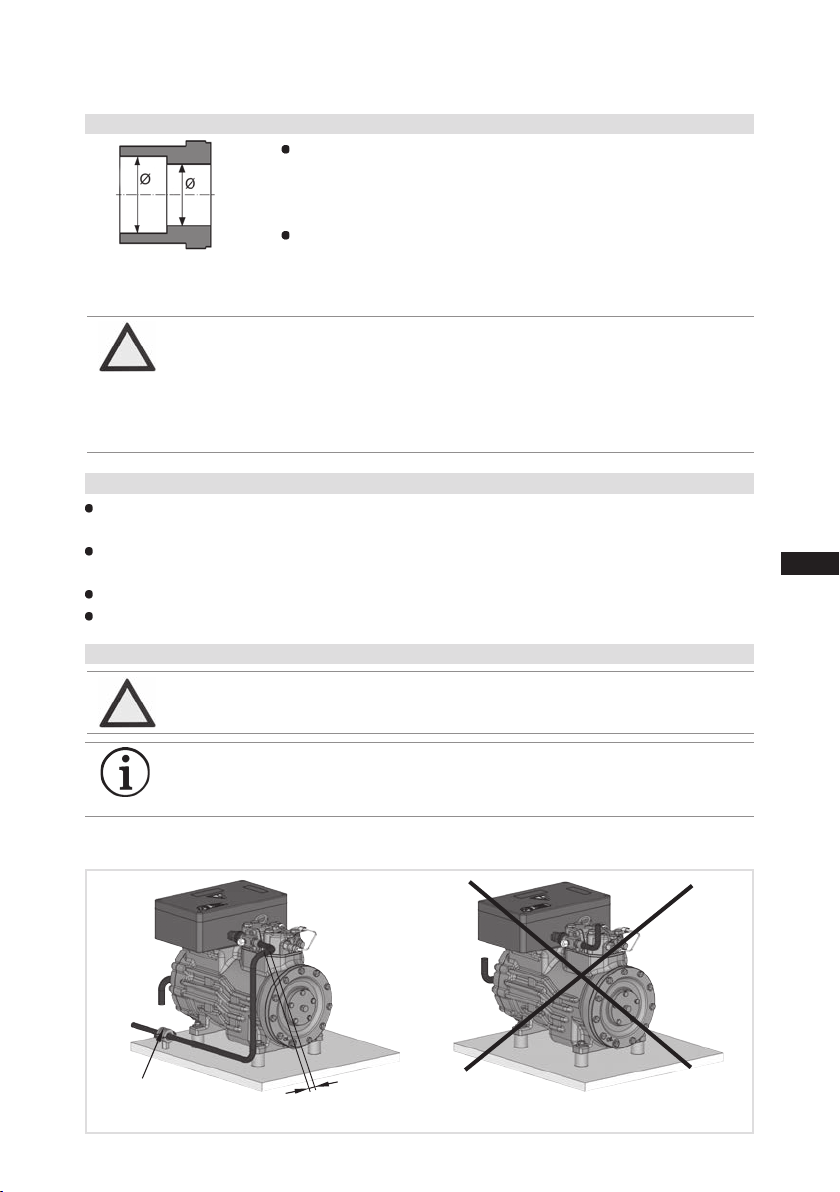

4.6 Laying suction and pressure lines

4|Compressor assembly

4.5 Pipes

The pressure and suction shut-off valves have graduated inside

diameters so that pipes in the common millimeter and inch dimensions

can be used. The pipe will be inserted more or less deep, depending on

the dimension.

The connection diameters of the shut-off valves are designed for

maximum compressor performance. Theactualrequiredpipecross

section must be matched to the output. The same applies for

non-return valves.

Fig.12: graduated

internal diameter

4.4 Pipe connections

ATTENTION An explosive atmosphere must not be present!

Do not solder as long as the compressor is under pressure.

Superheating can damage the valve. Remove the pipe supports

therefore from the valve for soldering and accordingly cool the

valve body during and after soldering.

Only solder using inert gas to inhibit oxidation products (scale).

Aruleofthumb:Alwayslaytherstpipesectionstartingfromtheshut-offvalvedownwards and

parallel to the drive shaft.

ATTENTION Improperly installed pipes can cause cracks and tears which can

result in a loss of refrigerant

INFO Proper layout of the suction and pressure lines directly after the com-

pressor is integral to the smooth running and vibration behaviour of

the system.

Pipes and system components must be clean and dry inside and free of scale, swarf and layers of

rust and phosphate. Only use air-tight parts.

Lay pipes correctly. Suitable vibration compensators must be provided to prevent pipes being

cracked and broken by severe vibrations.

Ensure a proper oil return.

Keep pressure losses to an absolute minimum.

As short

as possible Rigid fixed point

18

D

GB

F

E

I

09691-01.2021-DGbFEIRu

Fig. 14 Fig. 15

Valve spindle seal

Release

Tighten

4|Compressor assembly

4.7 Operating the shut-off valves

Before opening or closing the shut-off valve, release the valve spindle seal by approx. 1/4of a turn

counter-clockwise.

After activating the shut-off valve, re-tighten the adjustable valve spindle seal clockwise.

Pipe connection

Pipe connection

4.8 Operating mode of the lockable service connections

Fig. 16

Openingtheshut-offvalve:

Spindle: turn to the left (counter-clockwise) as far as it will go.

—> Shut-off valve completely opened / service connection closed.

Fig. 17

Opening the service connection

Spindle: Turn 1/2- 1 turn to the right clockwise.

—> Service connection opened / shut-off valve opened.

Connection

blocked

Spindle

Spindle Connection

open

Compressor

Compressor

Service connection

closed

Service connection

opened

Afteractivatingthespindle,generallytthespindleprotectioncapagainandtightenwith14-16Nm.

This serves as a second sealing feature during operation.

For systems with long pipes and higher degree of contamination, a lter on the suction-side is

recommended.Thelterhastobebereneweddependingonthedegreeofcontamination(reduced

pressure loss).

4.9Suctionpipelter

D

GB

F

E

I

19

09691-01.2021-DGbFEIRu

5|Electrical connection

DANGER Risk of electric shock! High voltage!

Only carry out work when the electrical system is disconnected

from the power supply!

INFO Connect the compressor motor according to the circuit diagram (s.

g. 19 or sticker inside the terminal box). Comply with local safety

regulations for electrical work, safety standards (within the EU:

EN 60204, EN 60335 among others) and regulations for setting up

electrical systems in explosion-endangered areas (within the EU: IEC/

EN 60079-14 among others).

Avoiddamagetocablettings,sinceotherwiseoperationalsafetycan

beimpaired.Laythecablesothatthettingtotheterminalboxwill

not loosen itself. If necessary (e.g. installation that is not twist free),

protection against loosening can be achieved through check nuts or

appropriate adhesive. Avoid abrasion points on cables.

For cable lead-through at the terminal box, use suitable Ex cable

screw connections in the correct protective version (see name plate).

Use strain relief. Avoid abrasion points on cables.

Install all switching devices outside the explosion-endangered area.

Motor contactors, feed lines and fuses are to be rated according to the

maximum operating current (see name plate). Recommendations for

contactor and motor protection selection are included in the table at

the end of the „Electrical system“ chapter 5.2.

Do not separate contacts 1 + 2 of the motor thermistors under voltage.

Comparethedetailsforvoltageandfrequencyonthenameplatewith

the details for the electricity mains supply. The motor may only be

connected if these details match.

Use a motor protector switch. It should be set to the rated motor current

and checked.

For the installation of phases L1, L2 and L3 to line-up terminals U1, V1

and W1, no solid wire may be used.

Cross section for connection of line-up terminals U1, V1 and W1

= 0,5 - 6,0 mm².

Cross section for connection of line-up terminals 1, 2, 3 and 4 =

max. 2,5 mm².

5 Electrical connection

ATTENTION When attaching accessories with an electrical cable, a minimum

bending radius of 3 x the cable diameter must be maintained for

laying the cable.

20

D

GB

F

E

I

09691-01.2021-DGbFEIRu

Potentialequalizationconnection

Fig. 18

5.2 Information for contactor and motor contactor selection

5|Electrical connection

5.1 Potentialequalization

Beforestart-up,thepotentialequalisationmustbeconnected(seeFig.18).

Allprotectiondevicesandswitchingormonitoringunitsmustbettedinaccordancewiththelocal

safetyregulationsandestablishedspecications(e.g.VDE)aswellaswiththemanufacturer’sinfor-

mation. Motorprotectionswitchesarerequired! Motor contactors, feed lines, fuses and motor

protection switches must be rated on the basis of the maximum working current (see name plate).

For motor protection use a current-dependent and time-delayed overload protection device for moni-

toring all three phases. Set the overload protection device so that it must be actuated within 2 hours,

if there is 1.2 times the max. working current.

INFO Specialattentionmustbepaidtosufcientconductivityofallcontact

points. There must be a large seat (e.g. with ring cable lug).

Theinstalledvoltageequalizationmustbesecuredagainstloosing

andrmlyconnectedtoearth

WARNING Always install all electrical peripheral devices in an external

control cabinet outside the explosion-endangered area!

This manual suits for next models

21

Table of contents

Other BOCK Industrial Equipment manuals