18 www.bodine-electric.com

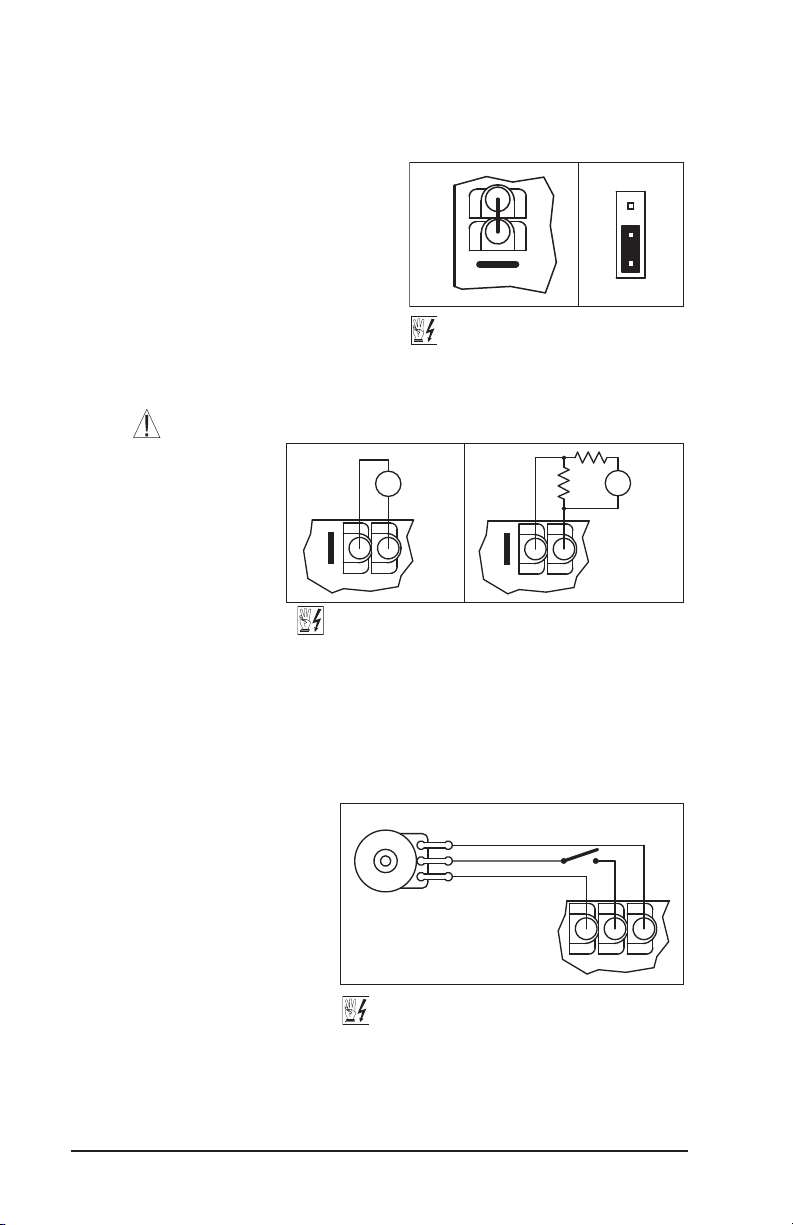

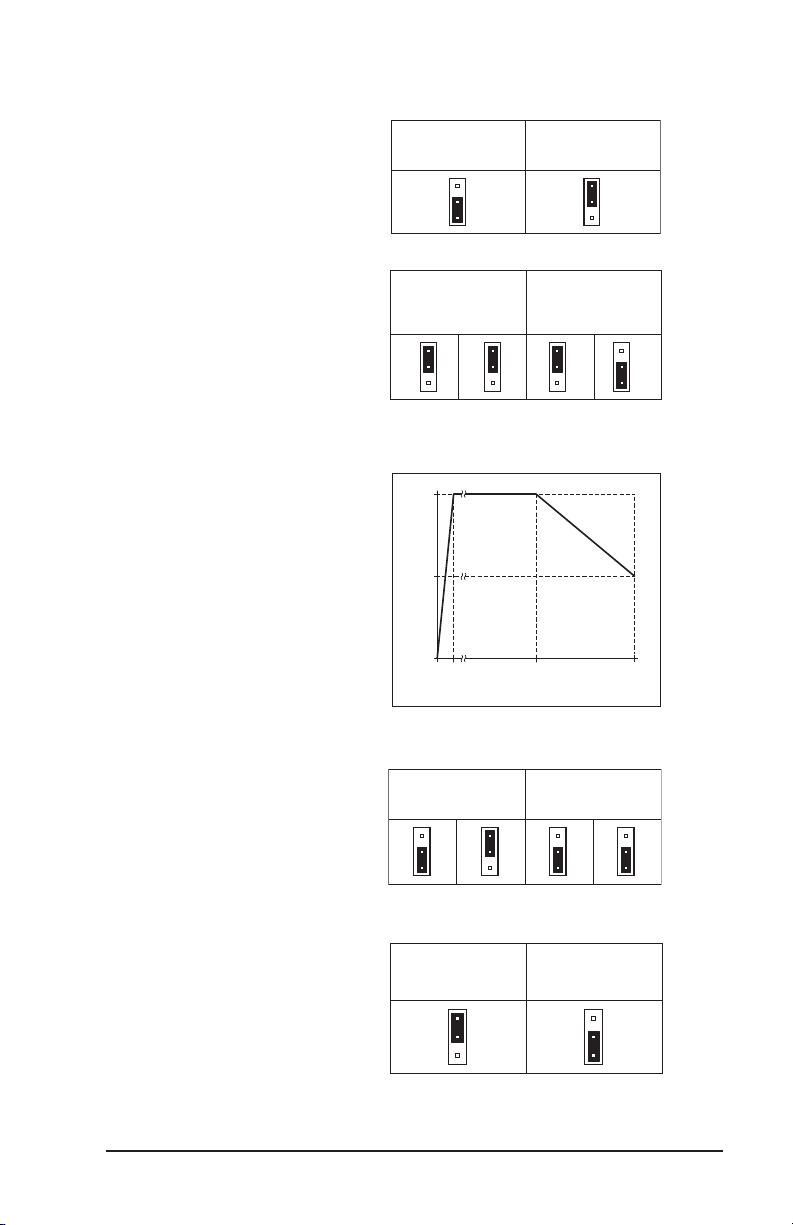

6.5 Boost Mode Selection (J6) –

Jumper J6 is factory set to the

“FIX” position for Fixed Boost.

For Adjustable Boost using the

BOOST Trimpot, set Jumper

J6 to the “ADJ” position. See

Figure 21. Also see Section

13.8 on page 25 for the BOOST

Trimpot range.

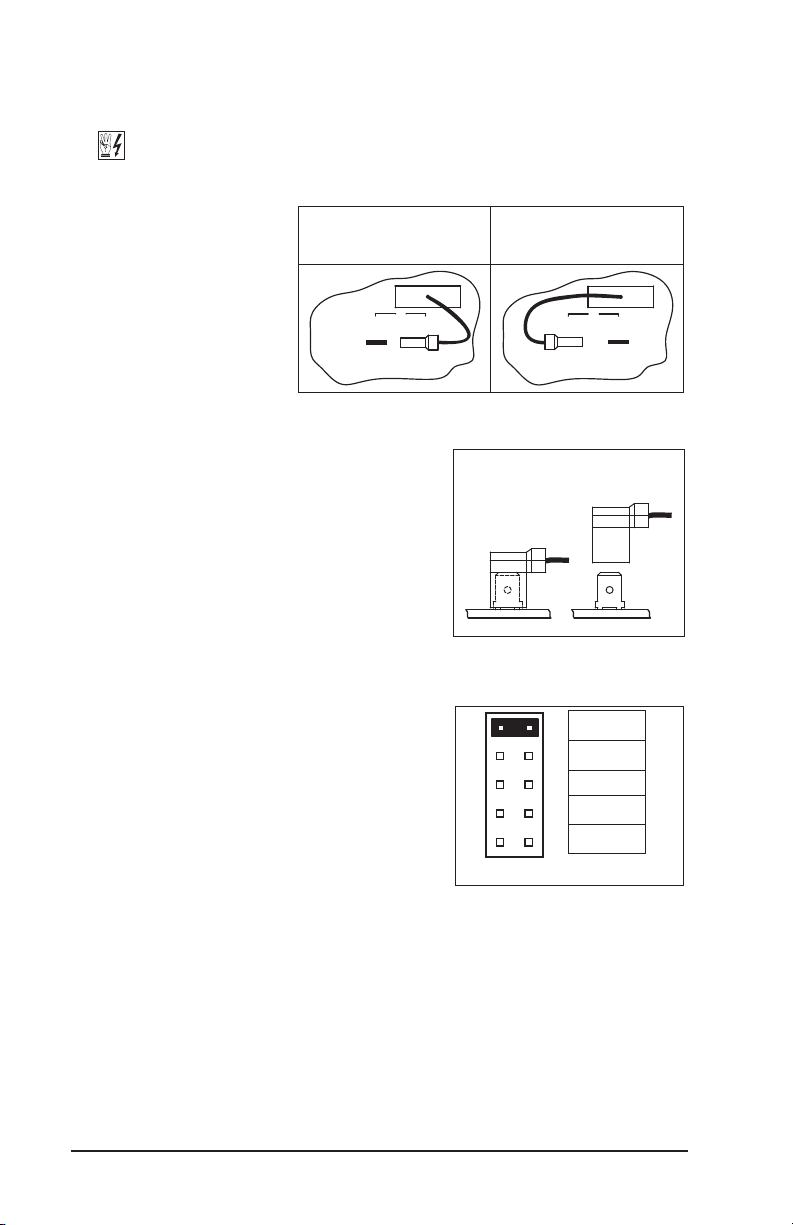

6.6 Braking Mode Selection (J7) –

Jumper J7 is factory set to the

“RG” position for Regenerative

Braking when the Start/Stop

Switch is set to the “STOP”

position. For DC Injection

Braking, set Jumper J7 to the

“INJ” position. See Figure 22

on page 19. Also see Section

13.5 on page 24.

When the Injection Brake

Mode is selected, the DECEL

Trimpot is used to adjust the

brake time and intensity.

6.7 Run/Fault Output Relay

Operation Selection (J8) –

Jumper J8 is factory set to

the “R” position for “Run”

operation of the Run/Fault

Relay. For “Fault” operation of

the Run/Fault Relay, set Jumper

J8 to the “F” position. See

Figure 23 on page 19.

For Run/Fault Relay output

contacts, see Section 5.8 on

page 15. The Run/Fault Relay

contact status for various drive

operating conditions is shown

in Table 5 on page 16.

6.8 Stop Contact Selection (J9) –

Jumper J9 is factory set to the

“NO” position for a normally

open stop contact. For remote

normally closed stop contact,

set Jumper J9 to the “NC”

position. See Figure 24 on page

19. For wiring information, see

Section 5.5 on page 14.

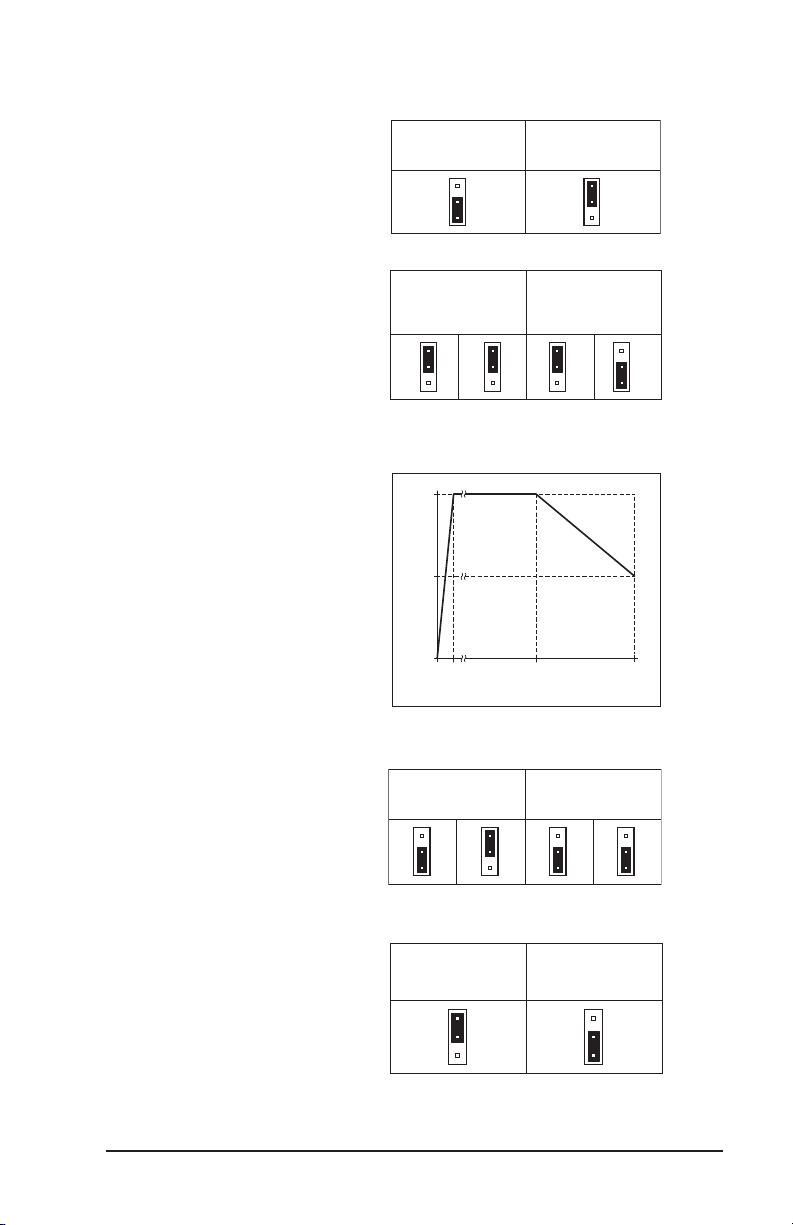

Automatic Ride-Through

(Factory Setting)

(J3 Installed in “A”Position)

Manual Start

(J3 Installed in “M”Position)

A

J3

M

A

J3

M

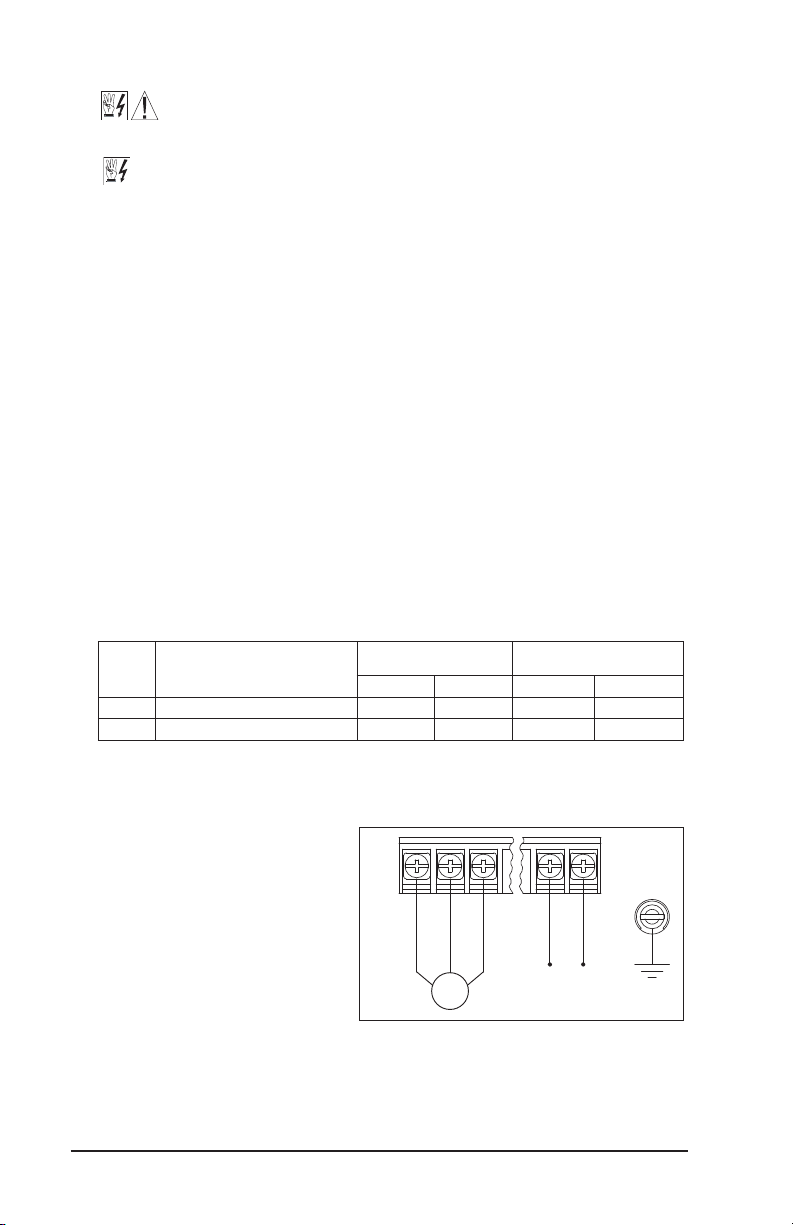

Figure 17 – Automatic Ride-Through

or Manual Start Selection*

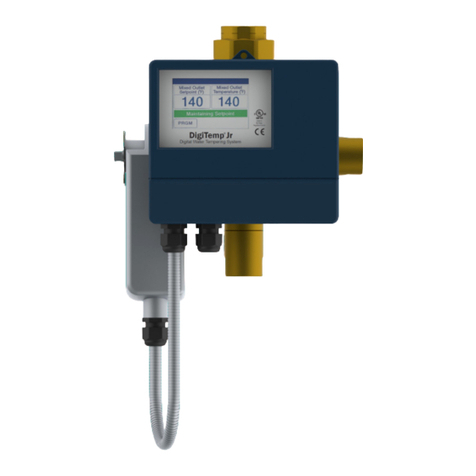

60 Hz Motor Operation

(Factory Setting)

(J4 Installed in “1X”Position)

(J5 Installed in “60Hz” Position)

50 Hz Motor Operation

(J4 Installed in “1X”Position)

(J5 Installed in “50Hz” Position)

50Hz

J5

60Hz

2X

J4

1X

50Hz

J5

60Hz

2X

J4

1X

Figure 18 – 60 Hz & 50 Hz Motor Selection

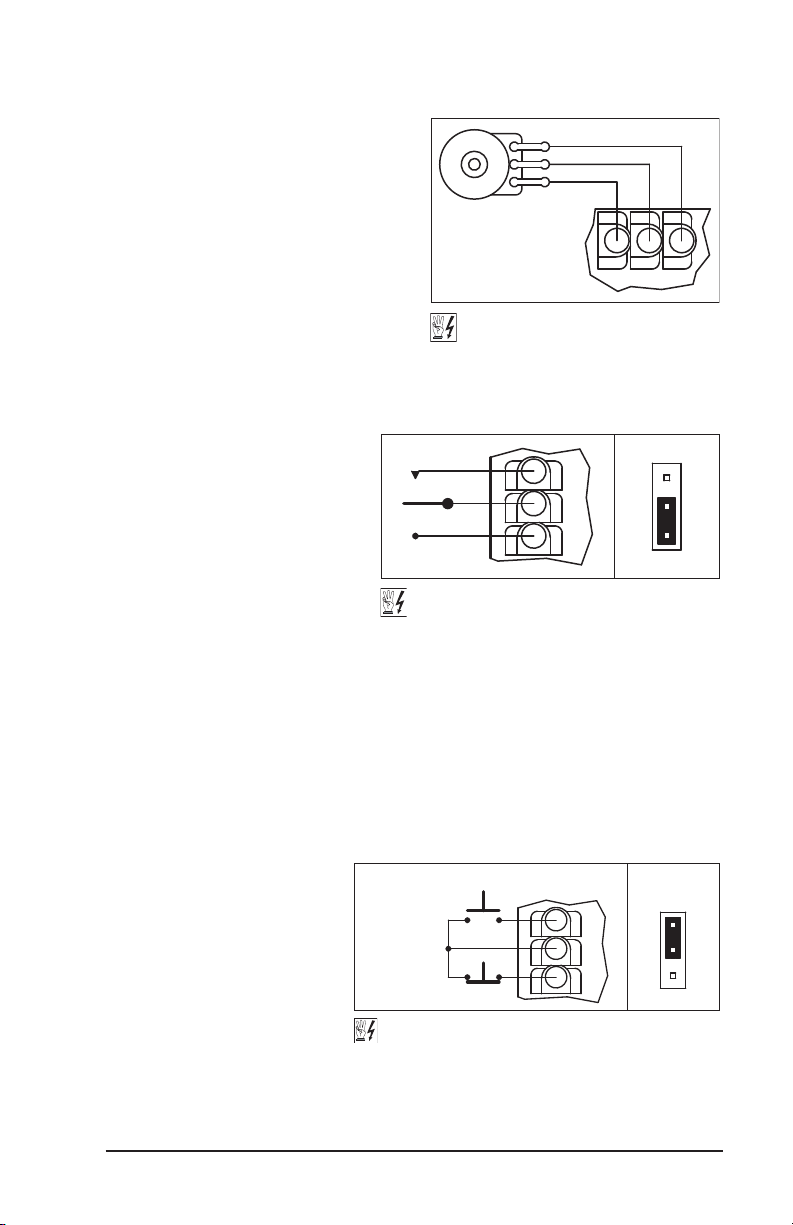

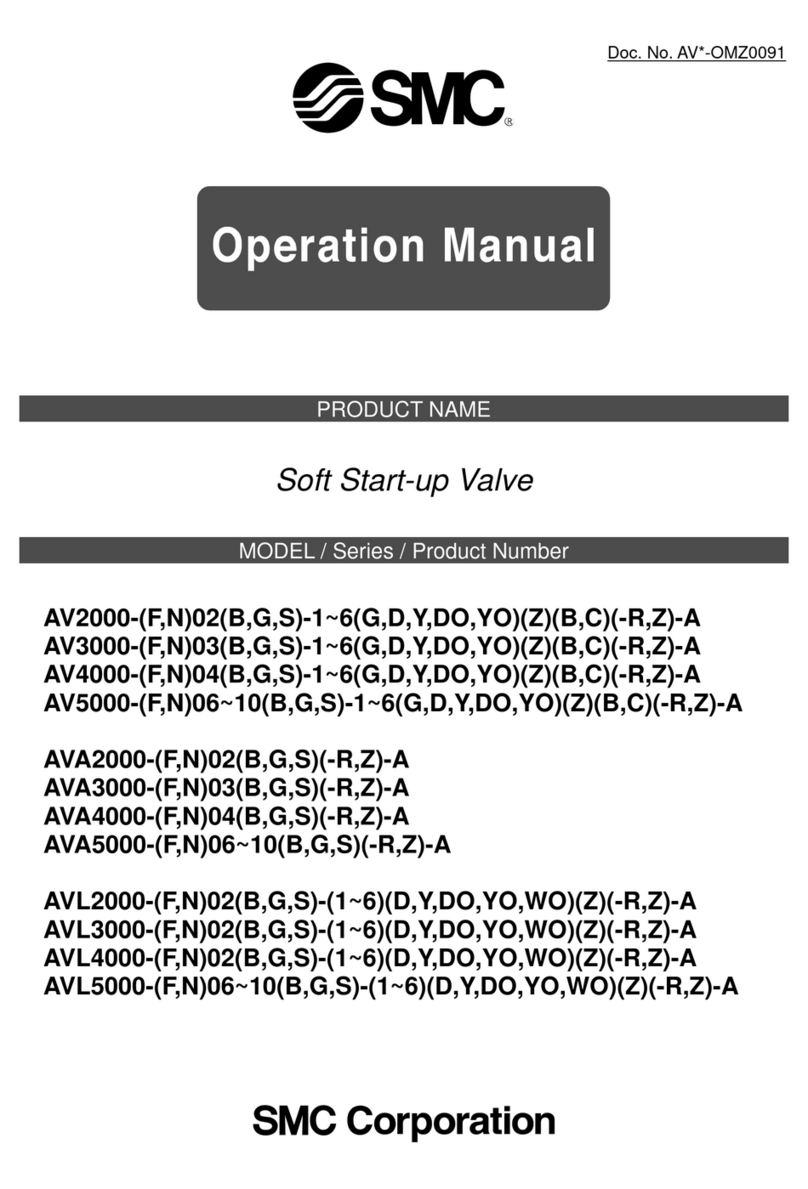

50/60

020

50

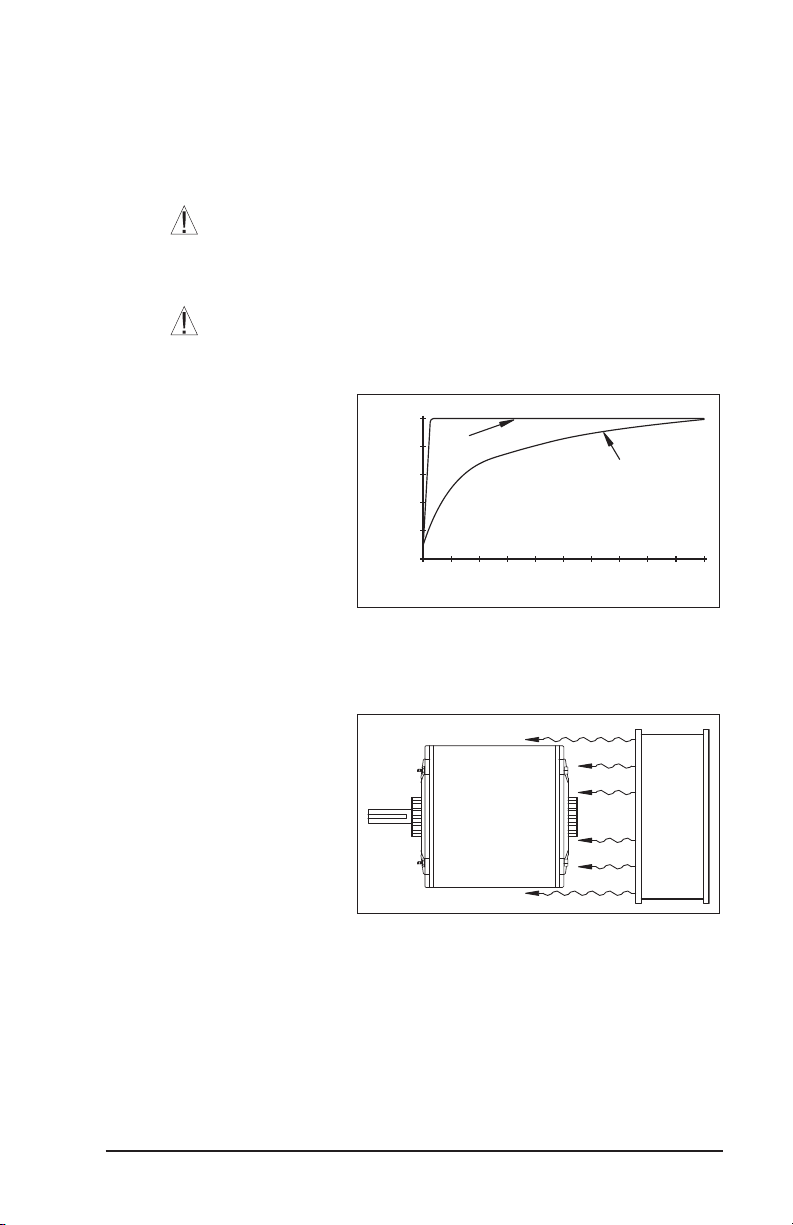

Figure 19 – Available Torque vs.

Output Frequency

120 Hz Output with 60 Hz Motor

(J4 Installed in “2X”Position)

(J5 Installed in “60Hz” Position)

100 Hz Output with 50 Hz Motor

(J4 Installed in “2X”Position)

(J5 Installed in “50Hz” Position)

50Hz

J5

60Hz

2X

J4

1X

50Hz

J5

60Hz

2X

J4

1X

Figure 20 – 120 Hz & 100 Hz Drive Output

Frequency Selection

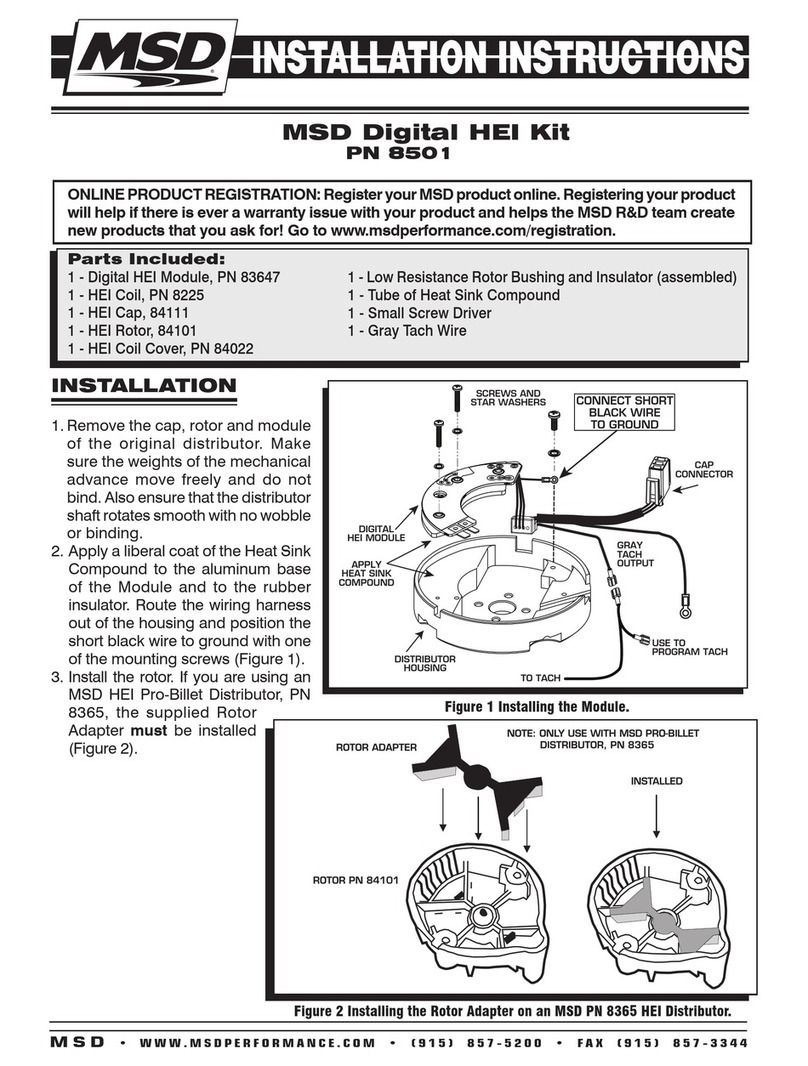

Fixed Boost

(Factory Setting)

(J6 Installed in “FIX”Position)

Adjustable Boost

(J6 Installed in “ADJ” Position)

ADJ

J6

FIX

ADJ

J6

FIX

Figure 21 –

Fixed or Adjustable Boost Selection