Bodmer Ton SE 9-6 User manual

Bodmer Ton AG

Holzrüti 1

CH-8840 Einsiedeln

Phone +41 55 418 28 58

E-Mail info@bodmer-ton.ch

Website www.bodmer-ton.ch

1

Instruction Manual

Temperature Controller SE 9-6

1. Introduction.............................................................................................................................................................................2

2. The first start..........................................................................................................................................................................2

3. Working with the SE 9-6....................................................................................................................................................3

3.1. Control elements on displays.................................................................................................................................3

3.2. Choosing and starting saved programmes.......................................................................................................4

3.2.1. Factory set programmes .........................................................................................................................................5

3.3. Changing the programmes .....................................................................................................................................5

3.3.1. Meaning of the LED’s................................................................................................................................................7

4. The firing process: ................................................................................................................................................................7

5. Error messages .....................................................................................................................................................................8

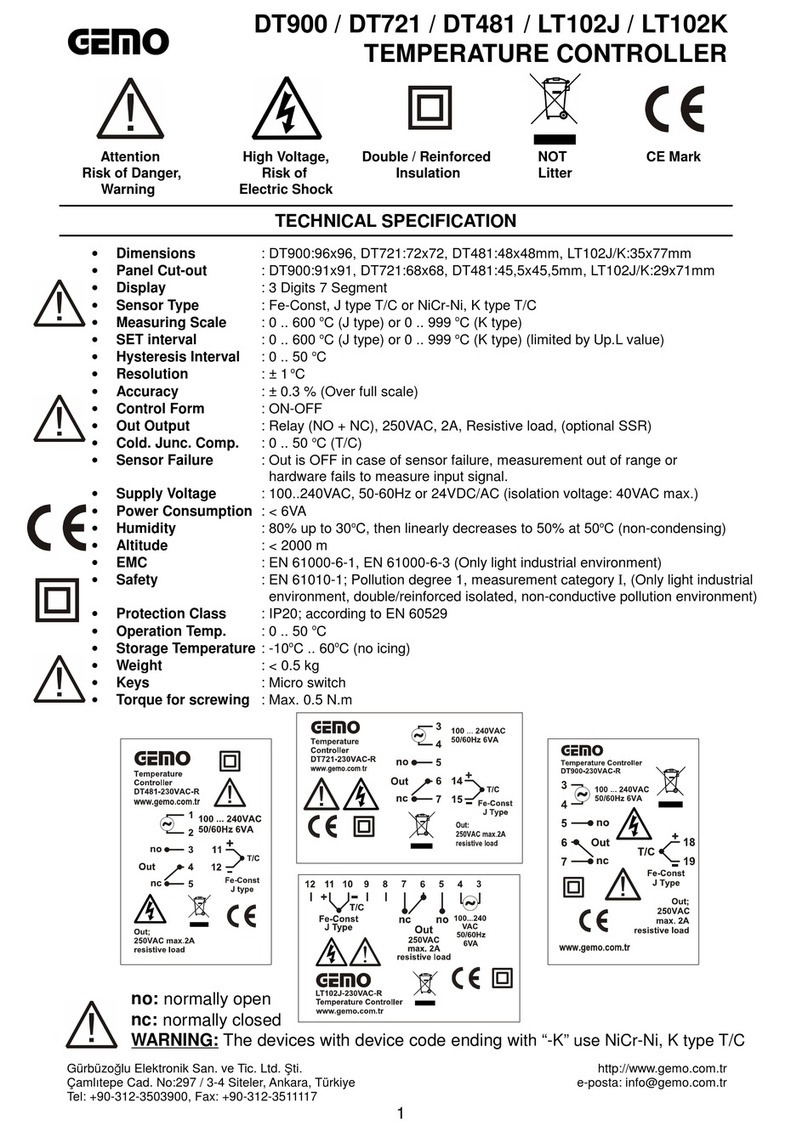

6. Technical Data........................................................................................................................................................................9

6.1. Data.................................................................................................................................................................................9

6.2. Connecting of the controller...................................................................................................................................9

Bodmer Ton AG

Holzrüti 1

CH-8840 Einsiedeln

Phone +41 55 418 28 58

E-Mail info@bodmer-ton.ch

Website www.bodmer-ton.ch

2

1. Introduction

The controller SE-96 enables you to exactly control your furnace. Three of the nine available

programmes are already pre-set for the most common uses. You can always alter and save any of

these programmes to fit your individual needs. The controller is fixed to the side of the furnace by a

mount that is delivered along whit the controller. You can easily take the controller out of the mount

to set up a programme and put it back after the programme has been started.

Important note:

-Do not put the controller on the top of the furnace during the firing process.

-

Do not alter the length of the cable connecting the controller to the furnace in any way

).

All of our controllers are checked and tested intensively in our company. But if there is a

malfunction, please try to find out the problem using chapter 5 of this manual. If the problem

cannot be solved this way, please contact us

.

2. The first start

The controller is connected to the furnace by the controller’s cable with a connector. This connector

fits only in one position, and therefore cannot be hooked up wrong. At the bottom of the controller is

the main power switch. When you switch on the controller, the current furnace temperature will be

displayed. The controller is now ready to be programmed.

Bodmer Ton AG

Holzrüti 1

CH-8840 Einsiedeln

Phone +41 55 418 28 58

E-Mail info@bodmer-ton.ch

Website www.bodmer-ton.ch

3

3. Working with the SE 9-6

3.1. Control elements on displays

.

Bodmer Ton AG

Holzrüti 1

CH-8840 Einsiedeln

Phone +41 55 418 28 58

E-Mail info@bodmer-ton.ch

Website www.bodmer-ton.ch

4

3.2. Choosing and starting saved programmes

The SE 9-6 has 9 programmes. They are individually altered and saved.

Starting a saved programme

Push the button to call up the programme mode. The display will show P= .

Use the keypad to choose your desired programme. Then push the button to start firing,

using the previously chosen programme.

For example:

To choose and start programme number 3, push the following button:

If you push the button again, the programme will be stopped.

Bodmer Ton AG

Holzrüti 1

CH-8840 Einsiedeln

Phone +41 55 418 28 58

E-Mail info@bodmer-ton.ch

Website www.bodmer-ton.ch

5

3.2.1. Factory set programmes

The programmes 1-3 are pre-set by the factory, and work for the most common uses.

These programmes can by changed as well.

Programme

Nr

t1

Temp 1

t2

Temp 2

t3

Temp 3

t4

Temp 4

t5

Temp 5

Drying

1

5:00 h

150 °C

3:00 h

150 °C

Onglaze fire

2

6:40 h

450 °C

0 min

750°C

15 min

750°C

Once-fire

980°C

3

9:00 h

720 °C

0 min

980°C

20 min

980°C

Glaze firing

1020°C

4

6:00 h

650°C

0 min

1020°C

20 min

1020°C

Glaze firing

1280°C

5

6:00 h

650°C

0 min

1260°C*

20 min

1260°C*

Drying +

Once-fire

6

5:00 h

150 °C

3:00 h

150 °C

4:30 h

650°C

0 min

980°C

20 min

980°C

*With the programmed final temperature of 1260°C and retention time of 20 minutes 1280°C

can be reached.

3.3. Changing the programmes

To change the controller’s programmes, first choose a programme as described earlier in

chapter 3.2.

Entering the time segments

Push the button once. The LED t1 will start blinking. You are now in the altering mode for

“time”. You can now change the value that is displayed using the keypad. Use the buttons

and to move back and forth through the time segments scale.

Entering the temperatures

Push the button once. The first temperature LED will start blinking. You are now in the

altering mode for “temperature”. You can now change the value that is displayed using the

keypad. Use the buttons and to move back and forth through the temperature segments

scale.

Bodmer Ton AG

Holzrüti 1

CH-8840 Einsiedeln

Phone +41 55 418 28 58

E-Mail info@bodmer-ton.ch

Website www.bodmer-ton.ch

6

When finished setting up the program, you can start it any time by pressing the button.

During the time firing process, the time segments will be counted backwards. In case you would

like to restart your program, you can either reload it in case you have it stored, to set the time

segments back to their original time, are you can re-enter the time segments.

Clearing a program

You can set all current time and temperature data to zero by choosing the programme number

(see chapter 3.2). This is useful if you want to set up a completely new program.

Note:

Saved programmes will not be affected by this

.

Saving a program

You can save up to nine programmes for your most common uses. To save a programme, follow

these instructions:

First set up a programme as you wish. Then push the button twice. The display will now

show “S=“. Now enter your desired programme number and then push the button. The

programme will now be saved.

Example:

We now want to enter and save programme number 4 with the following specifications:

Programme

Number

t 1

Temp 1

t 2

Temp 2

MyProg

4

30 min

250°C

60 min

1100 °C

To do this, follow these instructions:

Clear the old programme:

Enter the time segments:

Bodmer Ton AG

Holzrüti 1

CH-8840 Einsiedeln

Phone +41 55 418 28 58

E-Mail info@bodmer-ton.ch

Website www.bodmer-ton.ch

7

Enter the temperature segments:

Save the programme:

3.3.1. Meaning of the LED’s

The blinking of the LED's will have following meanings:

t0: Delay time

The firing process will be delayed after pushing the button by the set amount

of time.

Note:

The delay time cannot be saved to a programme.

t1 - t6: heat-up, soak, cool-off times

Here you can enter heat-up, soak and cool-off times.

Note:

When entering a cool-off time, you cannot cool-off the furnace faster than its

natural cooling.

end: This LED shows that the firing process has been finished and the heating has

been switched off. The furnace will now cool off.

The LED's above the time LED's show the currently set temperature of the segment.

4. The firing process:

After choosing a program (see chapter 3.1), and pressing the button, the firing process will be

started. In case that you have entered a delay time, the delay time will be displayed and counted

backwards after starting the programme. As soon as the time reaches zero, the actual firing process

will be started. The delay time is especially useful for furnaces that use night power which is cheaper.

The controller will start to carefully heat up the furnace in segment t1 to the temperature of the first

segment. As soon as the temperature has been reached, the controller will start with the next

Bodmer Ton AG

Holzrüti 1

CH-8840 Einsiedeln

Phone +41 55 418 28 58

E-Mail info@bodmer-ton.ch

Website www.bodmer-ton.ch

8

segment. After the controller has finished all the segments, the 'end'-LED will light up and display,

during the cooling-off process.

5. Error messages

The controller will permanently supervise all important processes. In case of a malfunction, the

controller will abort the firing process and display one of the following error messages:

Error message

Problem

Possible reason

F1

When the furnace is heated with

maximum power output, the

temperature has to increase at

least 1°C in 20 min. lf this is not

the case, FI will be displayed.

- Heating elements are too old or

defective

- On a 3 phase system: one phase

missing (check house-fuse)

- Thermocouple short cut

- Door contact switch not closed

F2

This error massage will be shown

whenever the furnace heats for

more than 18 hours with

maximum power.

- Heating elements are too old or

defective

-On a 3 phase system: one phase

missing (check house-fuse)

F3

lf the measured temperature is

too high, F3 will be displayed.

- Thermocouple defective

- Wiring of the thermocouple

defective

F4

lf the measured temperature has

a negative value F will be

displayed

- Thermocouple is connected wrong

(wiring for the thermocouple is

connected wrong)

F5

F5 will be displayed whenever the

controller has detected an internal

error

- The controller is defective. To

check this, switch off and on the

controller. lf the error occurs please

call us

F6

F6 will be displayed whenever the

controller has detected an internal

error.

- The controller is defective. To

check this, switch off and on the

controller. lf the error occurs please

call us

F7

F7 will be displayed if the

temperature of the furnace is

above 20°C over the programmed

temperature.

- Power-Relay of the furnace is

defective

Bodmer Ton AG

Holzrüti 1

CH-8840 Einsiedeln

Phone +41 55 418 28 58

E-Mail info@bodmer-ton.ch

Website www.bodmer-ton.ch

9

6. Technical Data

6.1. Data

Power

200 bis 250 Volt

50 / 60 Hz

Fuse

32 mA träge

Consumption

2 VA

Output

2 Contacts

230V max. 4 A

Input

Thermoelement Typ S

Pt10Rh / Pt

Accurate

1°C

Resolution

0.3%, +/- 1 Digit

Measures

200 * 100 * 45 mm

Weight

0.6 kg

Ambient temperature

0 to 50°C

6.2. Connecting of the controller

Wire Nr.

Harting 7D Pin-Nr.

Name

+ red (orange)

- white (white)

3

4

Wire of thermocouple

Type S

1

5

Input L1

2

2

Input N

3

6

Output Heating-Relay

4

1

Output N

7

7

Output Safety-Relay

Bodmer Ton AG

Holzrüti 1

CH-8840 Einsiedeln

Phone +41 55 418 28 58

E-Mail info@bodmer-ton.ch

Website www.bodmer-ton.ch

10

Table of contents

Popular Temperature Controllers manuals by other brands

IntelliSense

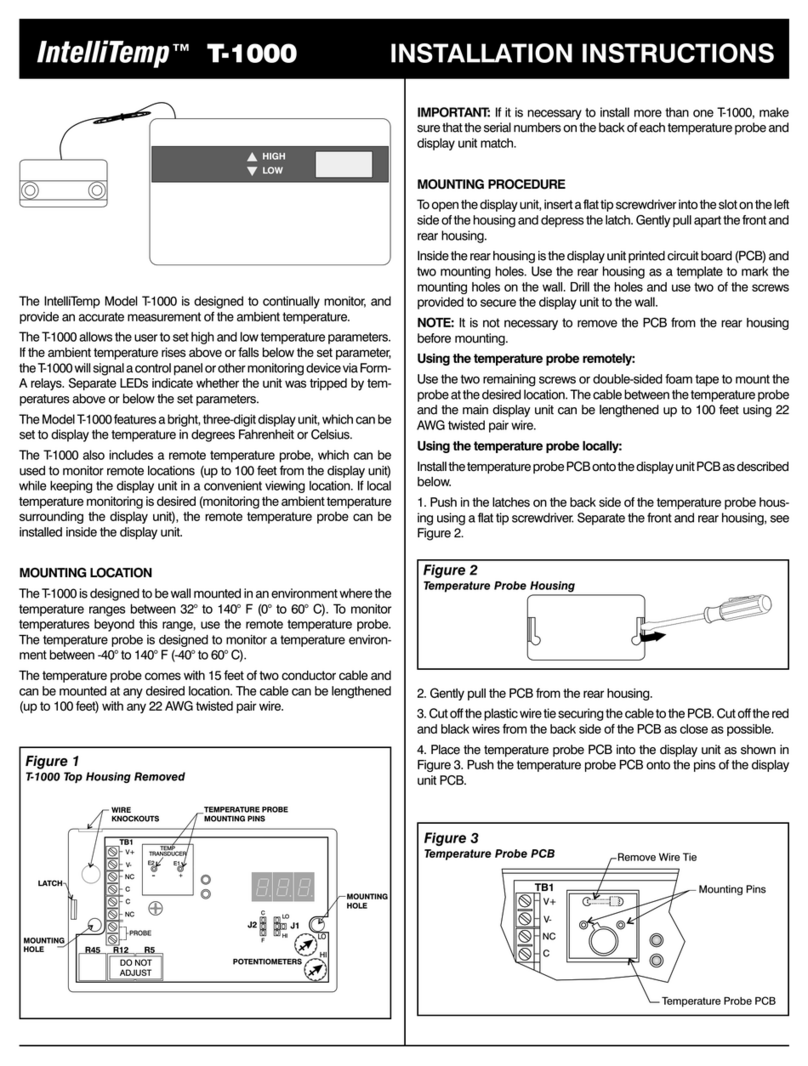

IntelliSense Intellitemp T-1000 installation instructions

ISG INFRASYS

ISG INFRASYS E380 operating manual

La Crosse Technology

La Crosse Technology TX4 instruction manual

Campbell

Campbell TEMPERATURE PROBE 109SS instruction manual

RF Code

RF Code R151 installation guide

Emerson

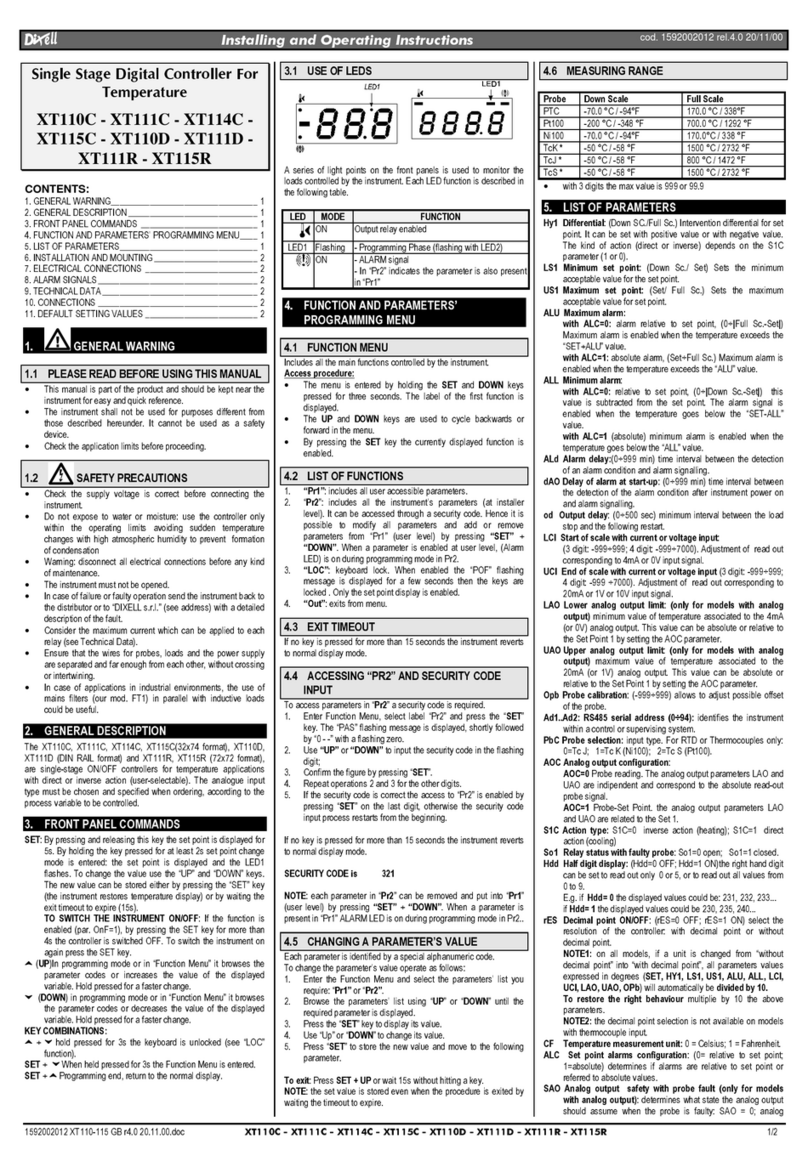

Emerson XT110C Installation and operating instructions