03 SZ-81145

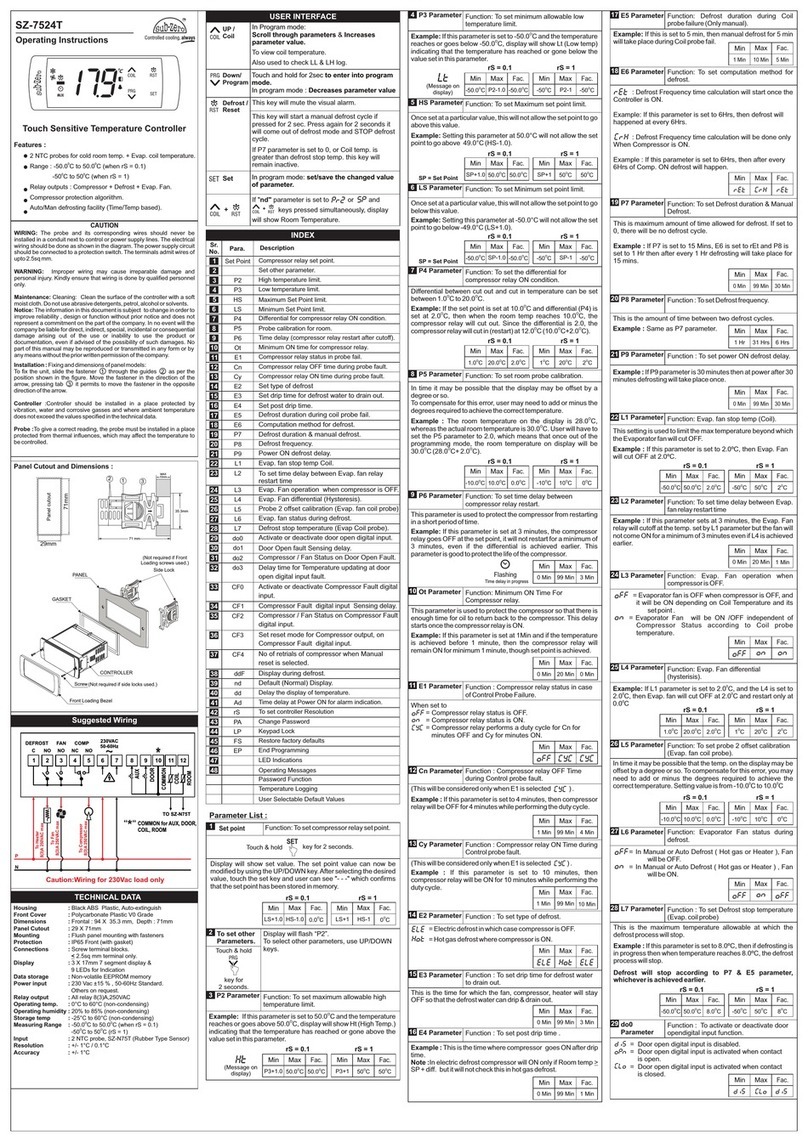

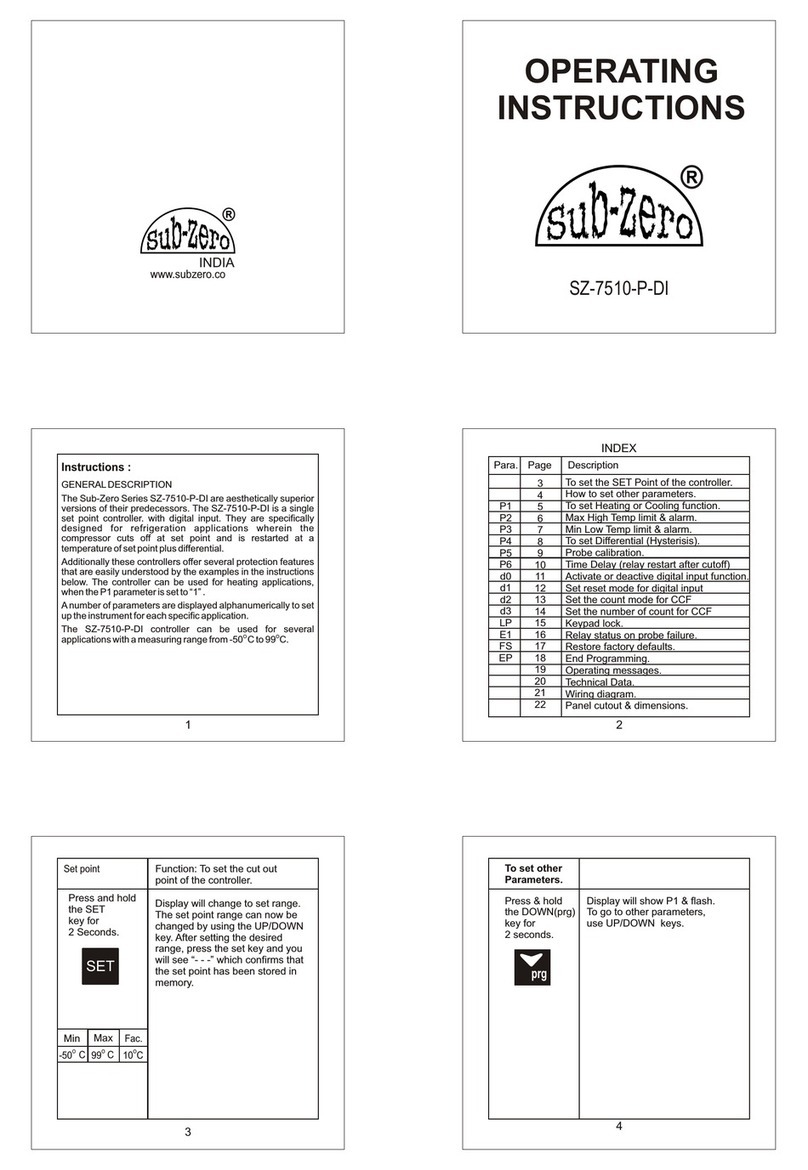

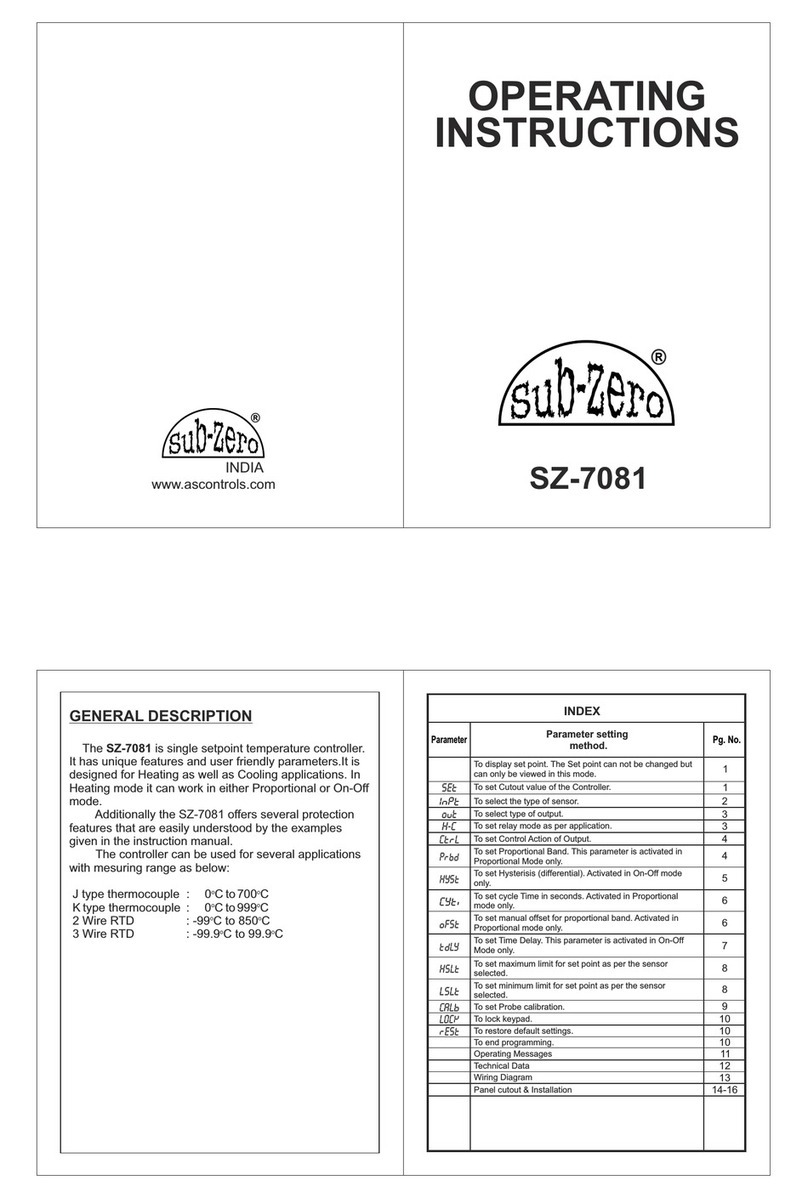

Sr.No.

Description of parameters and functions.

Parameter setting

method.

Parameter

Parameter List

Min : MINIMUM Max : MAXIMUM

Fact. Set : FACTORY SETTING(DEFAULT)

Use Down/Prg key to enter program mode,

Use Up, down, set keys to change values of parameters.

P2

01

press set key.

To change the parameter value, Use UP/DOWN keys to set desired

range.

Range

Min Max Fact. Set

P3+1.0 0

99.9 C 0

99.9 C

Function: To set maximum allowable high

temperature limit and alarm.

Example: Setting this parameter at

0

99.9 C will not allow the set point to go

0

above 99.9 C. Also if the temperature

0

reaches or goes above 99.9 C.the display

will show High Temp. Alarm & at this point

the alarm will activate.

Once set at a particular range, this will

not allow the set point to go above this

range.

P3

02

press set key.

To change the parameter value, Use UP/DOWN keys to set desired

range.

Range

Min Max Fact. Set

0

-50 C P2-1.0 0

-50 C

Function: To set minimum allowable low

temperature limit and alarm.

0

-50 C. Also, if the temperature reaches or

0

goes below -50 C the display will show

Low Temp. Alarm and at this point the

alarm will activate.

Once set at a particular range, this will not

allow the set point to go above this range.

0

Example: Setting this parameter at -50 C

will not allow the set point to go below

O

Note : Below -9.9 C, resolution automatically

O

change to 1 C .

04

SZ-81145

Use UP/DOWN keys to set desired

range.

0

Example: If the set point is set at 10.0 C

0

and differential is set as 2.0 C, then when

0

the s y stem r each e s 10. 0 C,th e

compressor will cutout. Since differential

0

is 2.0 C, the compressor will cut in(restart)

0 0 0

at 12.0 C (10.0 C + 2.0 C).

press set key.

To change the parameter value,

03

0.5ºC 20.0ºC 2.0ºC

Range

Min Max Fact. Set

P4 Function: To set differential for

temperature.

Use UP/DOWN keys to set desired

value.

Function: To set temperature probe

calibration.

P5

press set key.

To change the parameter value,

04

Range

Min Max Fact. Set

-9.9ºC 10.0ºC 0.0ºC

Example: If the actual temperature is

20.0ºC and the temperature on the

controller shows 22.0ºC set this

O

parameter to -2.0 C and once out of this

mode, the temperature will display

20.0ºC. (22.0ºC-2.0ºC).

H2

05

To change the parameter value,

press set key.

Use UP/DOWN keys to set desired

range.

Range

Min Max Fact. Set

H3+1 100% 100%

Function: To set maximum allowable high

alarm limit relative Humidity.

Once set at a particular range, this will not

allow the set point to go above this range.

Example: Setting this parameter at 100%

will not allow the set point to go above

100%.Also if the humidity reaches or goes

above 100%. the display will show High

humidity Alarm & at this point the alarm

will activate.

Sr.No.

Description of parameters and functions.

Parameter setting

method.

Parameter