BODYTONE HOME User manual

PREVENTATIVE MAINTENANCE

TREADMILLS

PREVENTATIVE MAINTENANCE OF TREADMILLS

1. TENSING THE BELT

It is necessary to follow a few simple steps to allow the treadmill to perform perfectly and so that

it can provide all the features available.

We try to ensure that the belt is always kept in its ideal state of tension, as this will make it easier

to run on it. This way we can avoid dangerous sliding or involuntary braking that could cause damage to

the user or deteriorate the machine's running surface. For the tensioning, proceed in the following way:

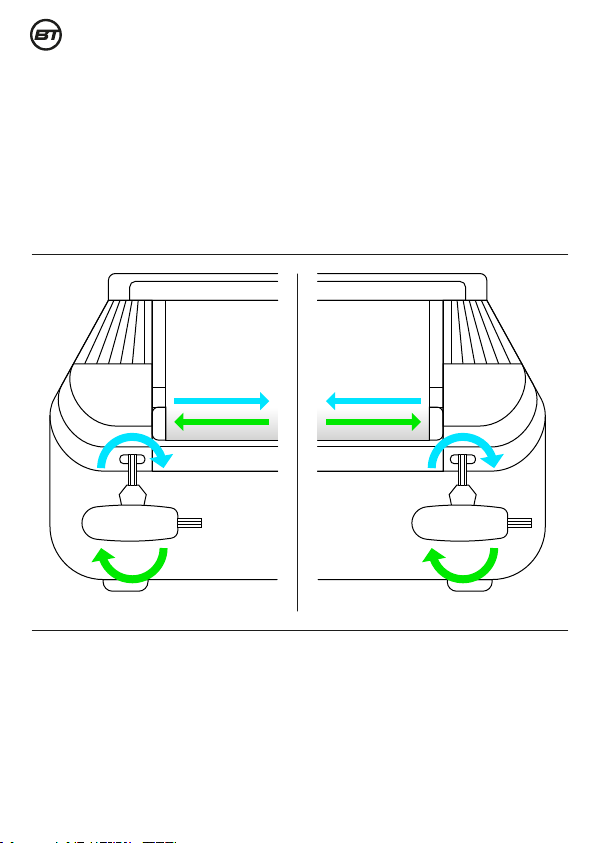

Left side

Opening A Opening B

Belt Belt

Right side

With the machine running and a speed of over 10km:

> Insert a 6 or 8 mm allen key (depending on the model of tape purchased) into the holes in

figures A and B.

> If you turn the screw A in a clockwise direction (blue circular arrow) the belt moves to the right,

as indicated by the blue arrow.

> If you turn the screw A counter-clockwise (green circular arrow) the belt moves to the left

as indicated by the green arrow.

BA

bodytone.eu

The procedure with screw B is exactly the same as with A except that it changes the direction of the

belt (follow the arrows).

Therefore, if we have a conveyor belt displaced to the left, we must turn the screw A in a clockwise

direction until we see that the belt is displaced towards the centre of the cylinder. If it goes beyond the

centre of the cylinder, loosen screw A again or turn screw B a little bit in a clockwise direction. To avoid

leaving one side of the belt tenser than the other, it is recommended that you play with screws A and B

by tightening one while loosening the other (never more than a quarter turn of tightening or loosening

for each screw and each time) until you reach the proper tension on both sides of the belt and that the

belt remains centered on the cylinder as shown in the illustration.

To know if it is the belt or the surface that skids:

1. Remove the motor cover

2. Run the belt between 2 and 4 km per hour.

3. Try to stop the belt with your foot

4. If you manage to stop the conveyor belt and with the motor cover removed, observe the following:

> If you stop the belt and the front cylinder moves, the belt needs tension.

> If by stopping the belt, the front cylinder is stopped, but the engine belt is turning or the

engine pulley is turning, the belt needs to be adjusted.

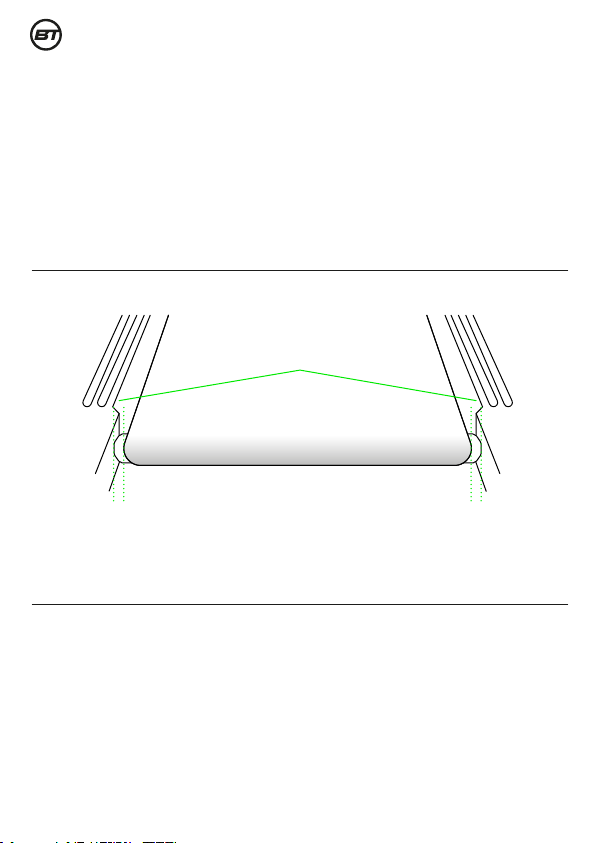

Perfect Centering

The distance between the belt and the machine (delimited by the green dotted lines) must be the

same on both sides.

Same distance

bodytone.eu

PREVENTATIVE MAINTENANCE OF TREADMILLS

2. LUBRICATION AND MAINTENANCE OF THE BELT

2.1. MACHINES WITH MANUAL LUBRICATION

The maintenance and lubrication of the belt should be a constant task to be done once every two weeks

or when intensive use of the machine requires it.

We begin by lifting, with one hand, one side of the belt. With rubbing alcohol or grease remover, we will

clean the accumulated dirt on the board and the remains of previous lubrication. Use a solvent-free,

silicone-based spray on the surface of the board in a wave-like motion (as shown in the illustration).

This will ensure that the liquid reaches all corners for the subsequent distribution process. We will

repeat the same step on the other side of the machine.

Once the previous processes have been carried out, we must start the machine and walk on it for about

4 km at a slow speed that will gradually increase to 10 km/hour.

We will try to move all over the surface of the belt, to ensure a uniform distribution of the liquid.

bodytone.eu

PREVENTATIVE MAINTENANCE OF TREADMILLS

Tapisserie

Tapisserie

With daily use, it is normal for the belt to accumulate dirt on its surface. The most notable evidence

of this dirt is the appearance of a whitish layer covering the area of greatest tread on the belt.

To clean it, it is advisable to use any rejuvenating liquid made of plastic or rubber that nourishes and

restores the colour to the dry rubber. For its application, proceed to spray the product on a sponge or

non-abrasive pad, start the machine at the lowest possible speed and rub, with circular movements

over the whole surface.

Remove the remains of the non-absorbed product with tissue paper and let it dry for 30 minutes

to 1 hour, depending on the markings. This treatment will only be carried out on the surface of the belt

and never underneath it or on the board; because the improper use of the product could damage these

components.

ATTENTION

If you try to disable the unit while the drying process is in progress, the belt may become slippery and its

use may result in injury to users or damage to machinery. Once dry, the belt recovers

its initial grip.

You can use this same product to clean, nourish and polish all plastic parts of the machine.

If you find that with time and daily use, the roughness of the surface disappears until it is smooth to

touch, it is time to replace the belt.

THINGS TO KEEP IN MIND

BodyTone strongly recommends the use of its Bodytone lubricant for the good maintenance of your

machinery or, failing that, similar products whose base lubricant is silicone and not a solvent.

The use of spray lubricants with oil bases (see 3in1, WD40 or similar) would drastically reduce the life of

the treadmill and even destroy it as well as the board where it is supported.

Problems arising from the improper use of these products on the machinery, which are not

recommended by the manufacturer, will immediately void the warranty.

You can clean the rest of the areas of the machine with a cloth moistened in soapy water or general

multi-purpose cleaner.

We recommend that you keep the area where the machine is located clean, as its operation generates

static electricity that attracts dust and deposits it underneath the machine.

To do this, once every two weeks, coinciding with the lubrication of the carpet, vacuum and clean all the

dirt accumulated on the floor or underneath. Open the engine cover, using a brush to release the

particles that have adhered best to it and access the most difficult corners, and vacuum all the dust

accumulated inside.

bodytone.eu

PREVENTATIVE MAINTENANCE OF TREADMILLS

bodytone.eu

2.2. SELF-LUBRICATING MACHINES

All BodyTone tapes that form part of the DT series (except the DT12) are self-lubricating.

Before the first use, the bottle must be emptied into the lubricant tank through the spigot provided

for this purpose (it can be on the side or on top of the engine cover

Some lubricant should be left in the bottle (up to the level of the lower blue strip).

With this excess lubricant, and before the first use of the machine, we recommend applying it on the

board (lifting the mat) as indicated in the maintenance manual

This procedure will only be done before the first use, after which the tape will automatically lubricate

when it detects that this is appropriate. On the DT20 and DT22W models it is possible to modify the

lubrication time and the frequency of pump activation from the Settings panel.

We recommend checking the lubricant level in the tank once a month. It is located inside the motor bay.

Take advantage of this operation to vacuum and clean the interior of the compartment to avoid future

dust incidents.

If you need to replace the lubricant in the tank, you can request this via our website.

PREVENTATIVE MAINTENANCE OF TREADMILLS

bodytone.eu

Carrying out and maintaining a programme of weekly checks and cleaning will ensure that you can enjoy

your equipment for many years at the lowest possible cost, with concern only for those parts that need

to be replaced due to the wear and tear they have been subjected to over the years.

Bodytone insists that maintaining your equipment in an optimum state of cleanliness and service

ennobles the image of the sports facility and the confidence of the user towards the correct functioning

of the equipment.

We wish you, without further ado, the full enjoyment of our products for many years to come.

The Bodytone Team

FINAL MESSAGE FOR OUR CLIENTS

PREVENTATIVE MAINTENANCE OF TREADMILLS

Table of contents

Other BODYTONE Treadmill manuals