TABLE OF CONTENTS

IMPORTANT MANUAL INFORMATION................................................................................................3

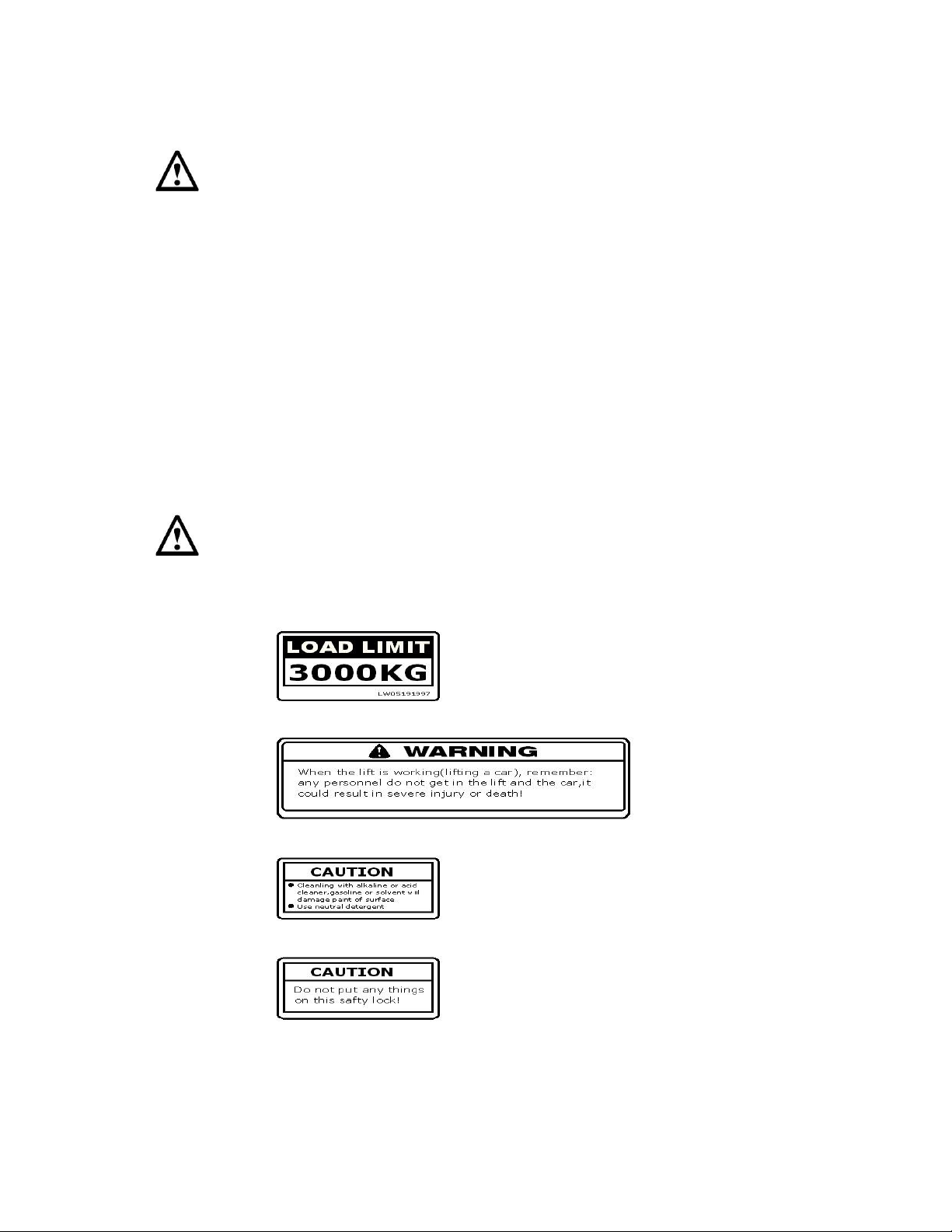

SAFETY INFORMATION.............................................................................................................................. 4

TRANSPORT & UNPACKING......................................................................................................................4

SPECIFICATIONS............................................................................................................................................5

WORKING PLACE........................................................................................................................................... 7

WORKPLACE REQUIREMENTS............................................................................................................... 7

DESCRIPTION.................................................................................................................................................. 8

INSTALLATION............................................................................................................................................. 10

OPERATION..................................................................................................................................................... 11

OPERATION.....................................................................................................................................................12

STORING...........................................................................................................................................................13

ELECTRIC SYSTEM...................................................................................................................................... 13

HYDRAULIC SYSTEM................................................................................................................................. 14

STRUCTURE DIAGRAM............................................................................................................................. 15

PACKING LIST................................................................................................................................................16