CORPORACIÓN BOIA DOMENICO C.A.

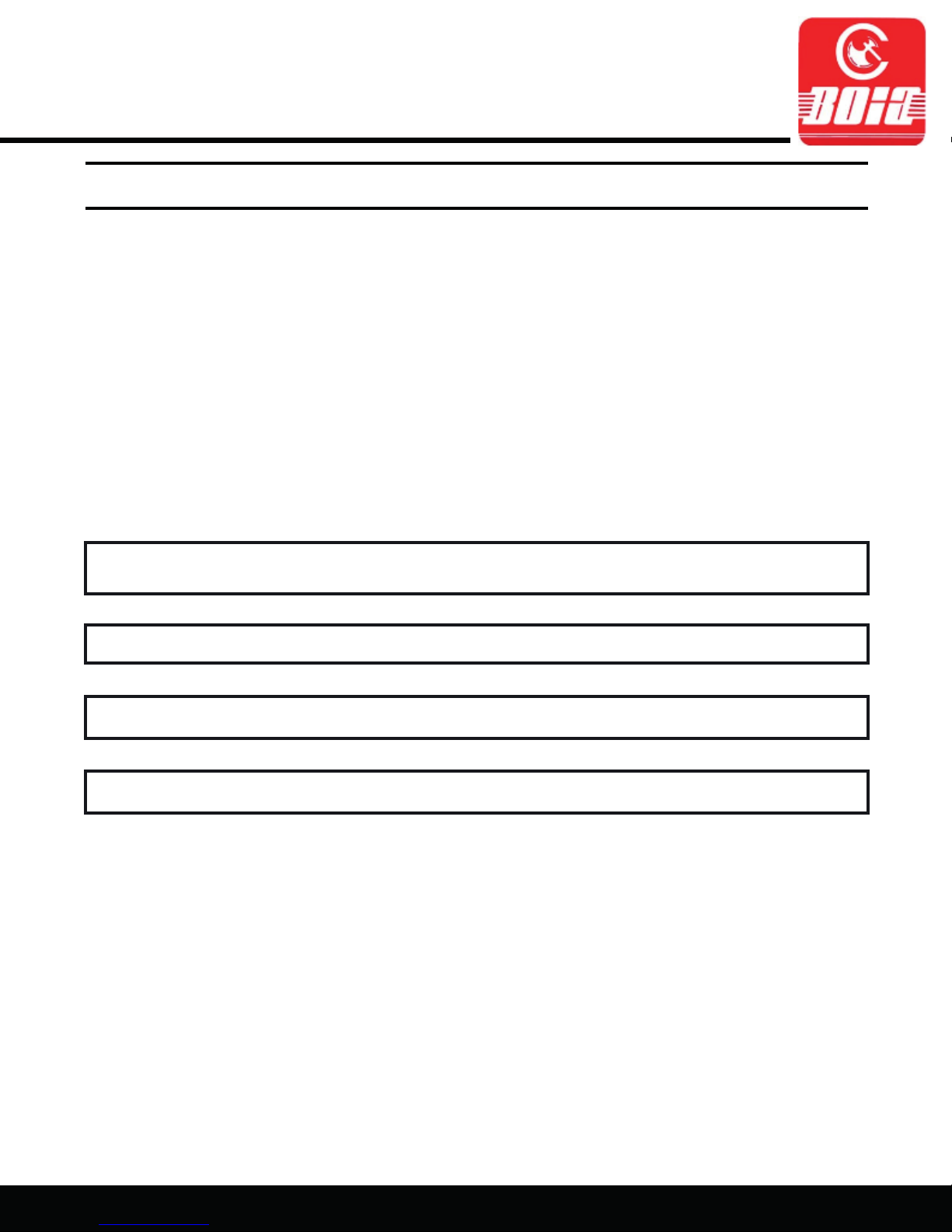

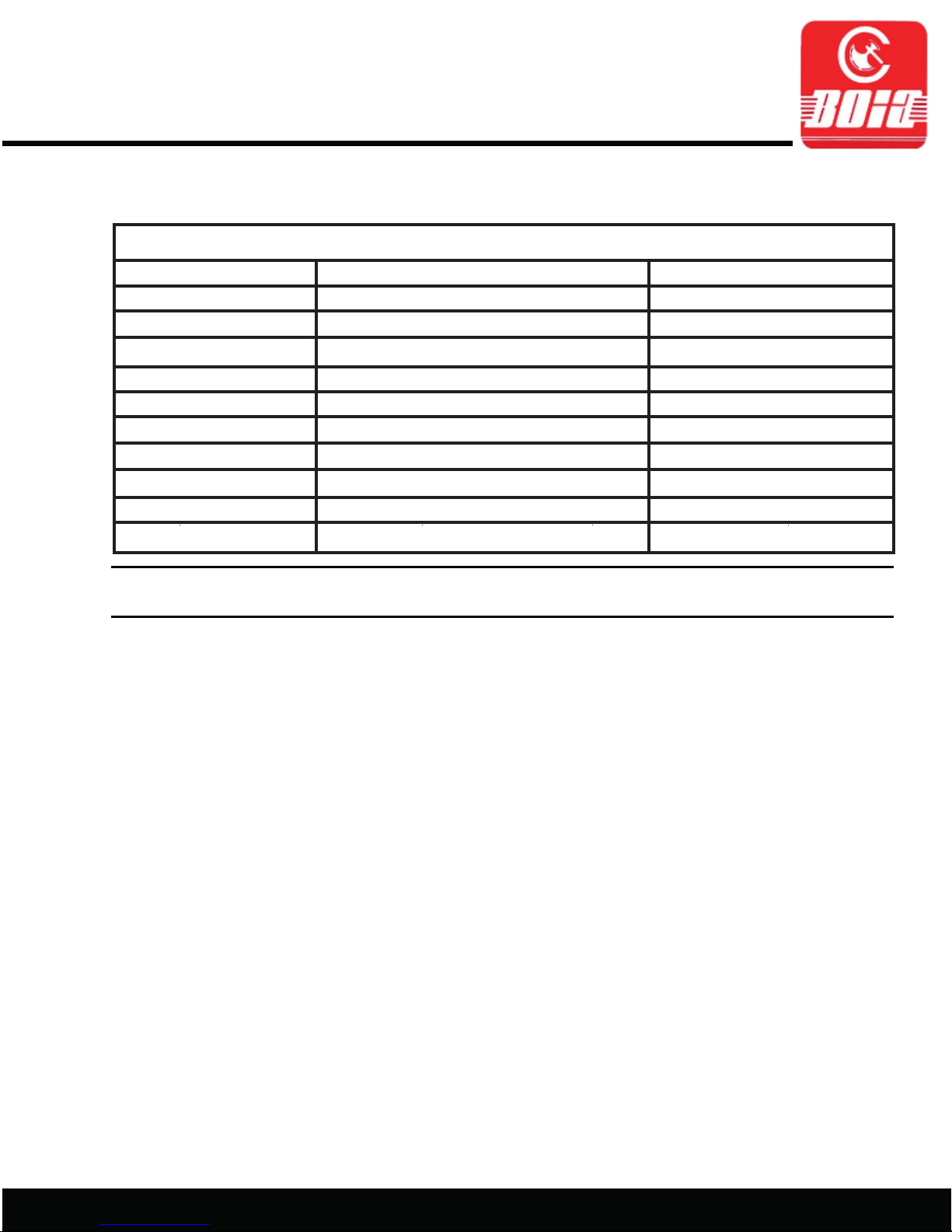

1.3. Technical Characteristics

The Band Saw is equipped with a single-phase motor.

Table 1: Main Characteristics

2.Installation and Pre-Operation

2.1. Installation

2.2. Pre-Operation

9

Characteristic

VOLTAGE

POWER

FREQUENCY

WIDHT

HEIGHT

DEPHT

NET WEIGHT

GROSS WEIGHT

MAX. CUT WIDTH

MAX. CUT HEIGHT

Unit.

VOLT

HP

HZ

cm.

M.

cm.

kg.

kg.

cm.

cm.

Quantity

220

2

60

80

1.7

1

155

165

29

35

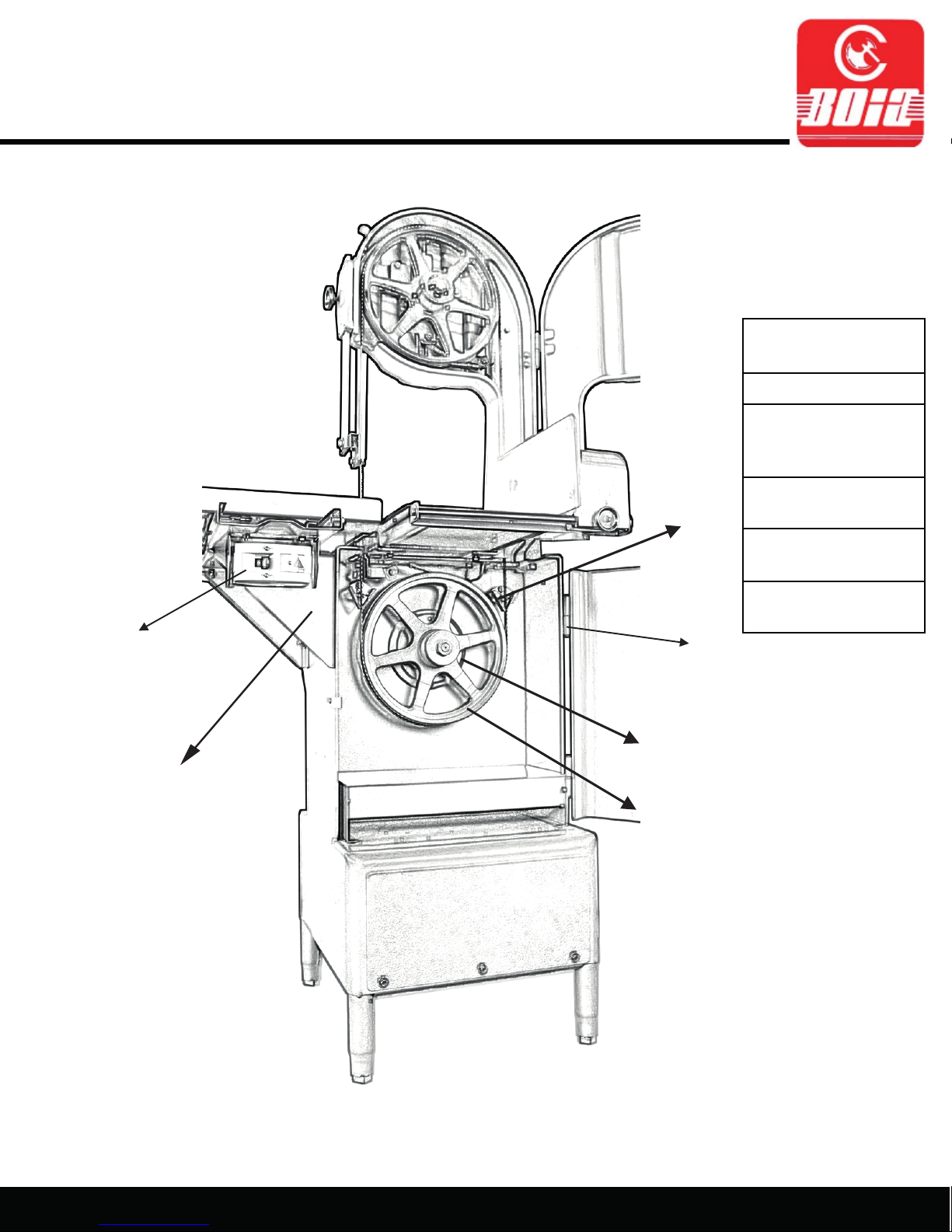

- Immediately after receiving a Band Saw BOIA Clasica, the machine must be inspected before

unpackaging it to see if there are any damages from shipping. After inspection, the machine can

be placed in a safe area in order to be operated.

- The band saw must be installed in a place with a flat surface in order to obtain the best stability

and performance during the operation.

- Before switching on the band saw, it must be connected to a power supply.

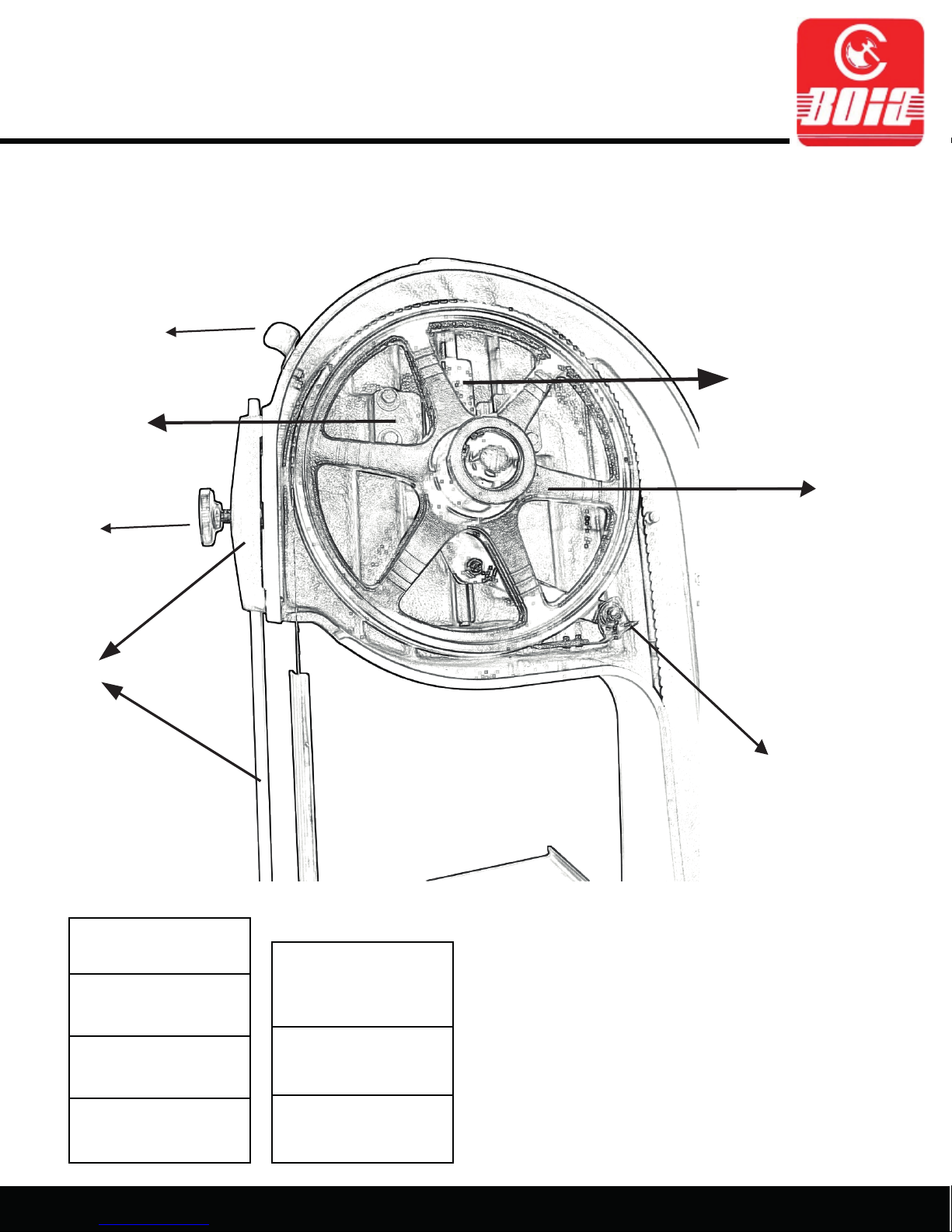

- Blade Installation: Open the upper and lower door of the band saw on the right side and loosen

the handle that tightens the previous blade. Slide the sliding plate all the way to left, loosen the

aluminum guide and lift it up. Next place the blade on the wheels and inside the wheel/blade

cleaners carefully. Finally, tighten the blade by turning the handle clockwise until it can freely

rotate around the wheels.

- Aluminum Guide Installation: Place the new aluminum guide in its position. Rotate manually

the upper wheel downward so the blade can fit inside the guide itself and then tighten it.

- The band saw blade must be calibrated before turning it on. Turn the handle clockwise in order to

tighten the blade.

- Before turning on the band saw make sure it is balanced and stable on its surface. The four band

saw legs allow themselves to be adjusted in order to obtain the best balance of the weight with

respect to the surface.

- Make sure that the motor and the power source have the same voltage, cycle, phase, and current.

For your best convenience contact your electrical technician.