2

Palmgren Operating Manual & Parts List 9683122 & 9683123

GETTING STARTED

STRUCTURAL REQUIREMENTS

Make sure all supporting structures and load attaching devices are

strong enough to hold your intended loads. If in doubt, consult a

qualified structural engineer.

ELECTRICAL REQUIREMENTS

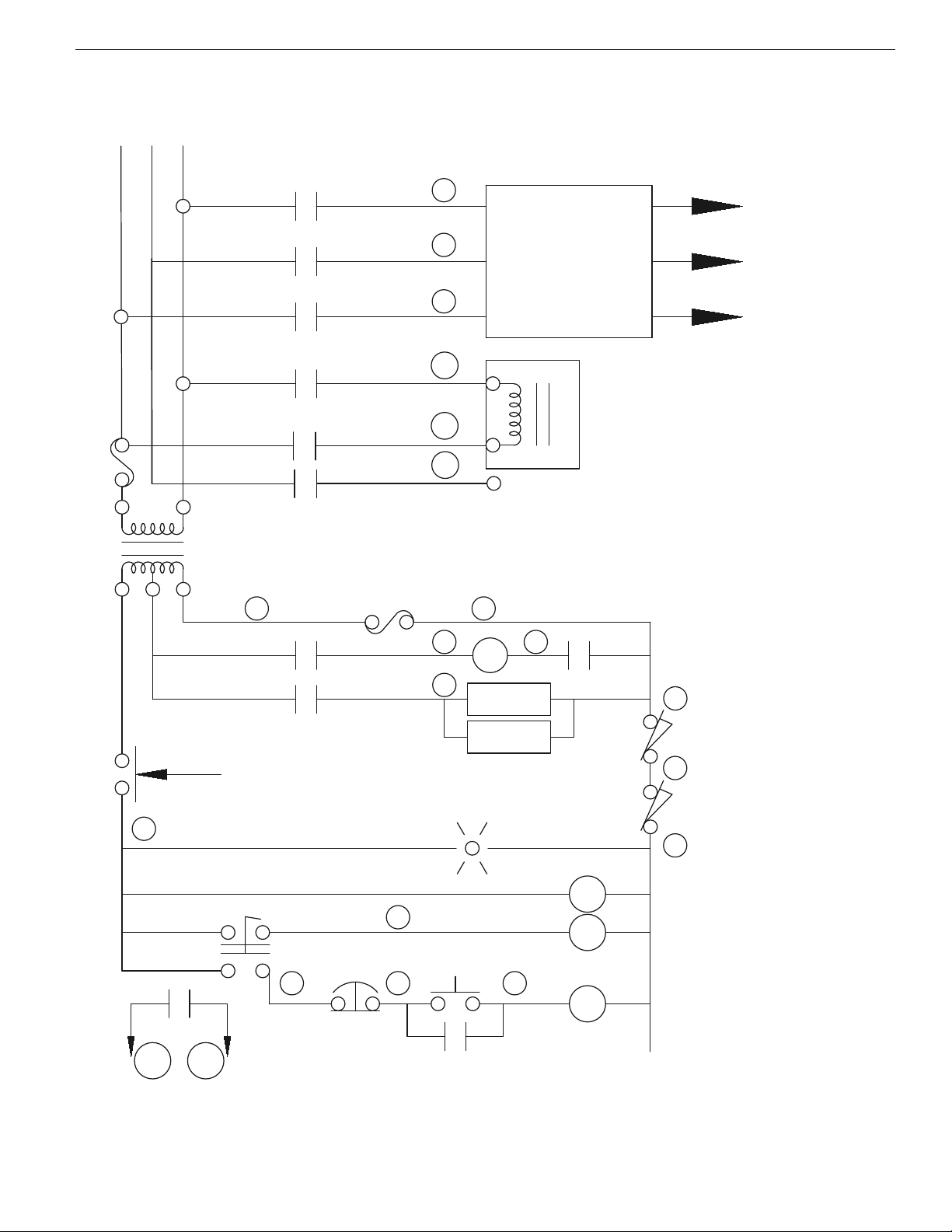

The power supply to Model 9683122 needs to be 220 volt/ 9.7 amp,

three phase,60 Hz.The standard allowable voltage variation is plus

or minus 10%.

The power supply to Model 9683123 needs to be 440 volt/ 4.9 amp,

three phase,60 Hz.The standard allowable voltage variation is plus

or minus 10%.

TOOLS NEEDED:

Standard mechanic’s hand tool set.

UNPACKING

Carton should be handled with care to avoid damage from drop-

ping,bumping,etc.Store and unpack carton with correct side up.

After unpacking Band Saw, inspect carefully for any damage that

may have occurred during transit. Check for loose,missing or dam-

aged parts. If any damage or loss has occurred, claim must be filed

with carrier immediately.Check for completeness.Immediately re-

port missing parts to dealer.

IMPORTANT: Table is coated with a protectant.To ensure proper fit

and operation, remove coating. Coating is easily removed with mild

solvents,such as mineral spirits,and a soft cloth. Avoid getting solu-

tion on paint or any of the rubber or plastic parts. Solvents may de-

teriorate these finishes.Use soap and water on paint,plastic or

rubber components.After cleaning,cover all exposed metal surfaces

with a light coating of oil.Paste wax is recommended for table top.

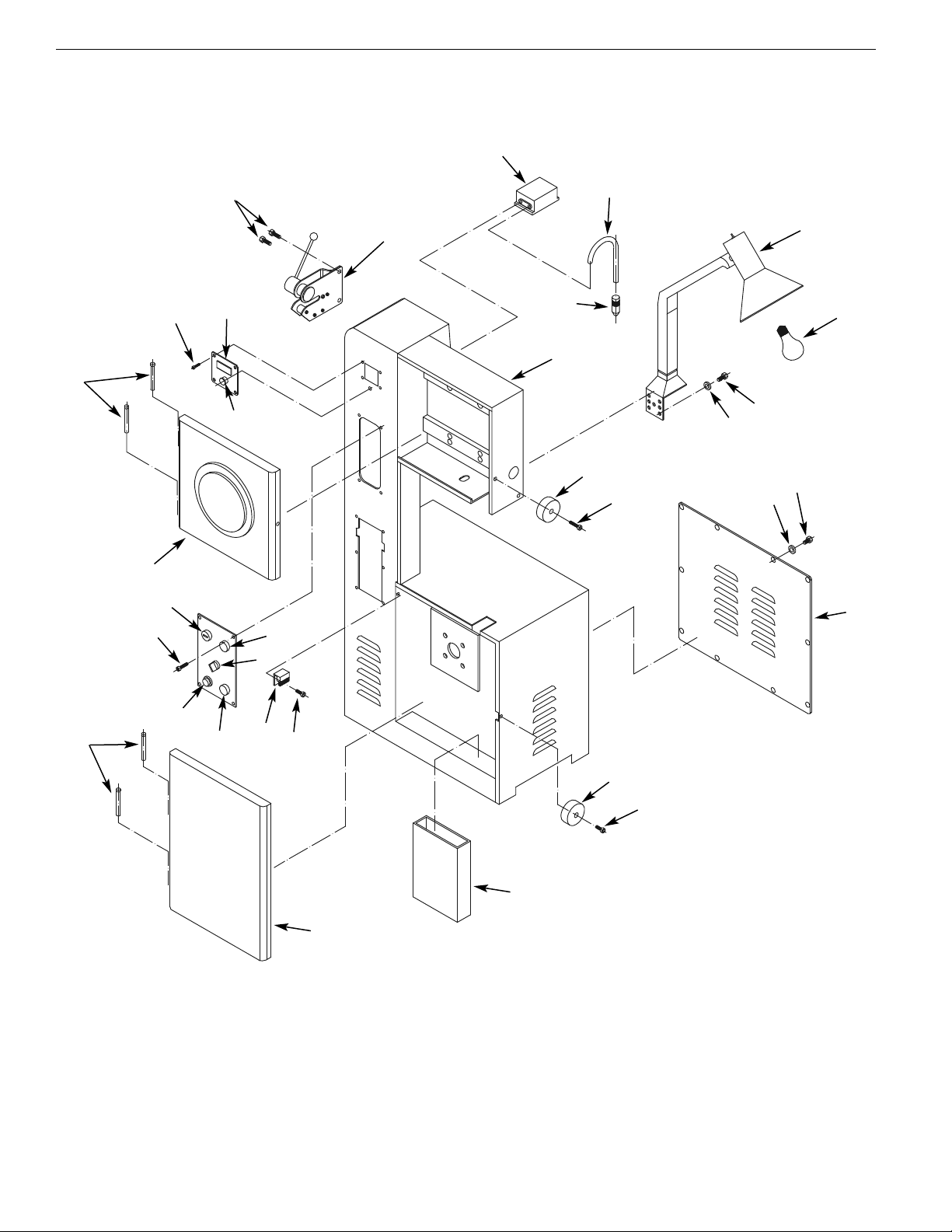

Band Saw is shipped partially assembled.End user will need to as-

semble loose parts to machine.

After unpacking the unit, carefully inspect for any damage that may

have occurred during transit. Check for loose, missing or damaged

parts. Shipping damage claims must be filed with the carrier.

All tools should be visually inspected before use, in addition to regu-

lar periodic maintenance inspections.

Be sure that the voltage labeled on the unit matches your power

supply.

UNPACK:

Do not discard packing materials until after machine has been in-

spected for damage and completeness.Locate loose parts and set

aside.

INSPECT:

After unpacking the unit, carefully inspect for any damage that may

have occurred during transit. Check for loose, missing or damaged

parts. Shipping damage claims must be filed with the carrier.

All tools should be visually inspected before use, in addition to regu-

lar periodic maintenance inspections.

Be sure that the voltage labeled on the unit matches your power

supply.

SPECIFICATIONS

9683122 9683123

Blade Length 167.75" - 169" 167.75" - 169"

Blade Width 1/4" - 3/4" 1/4" - 3/4"

Blade Thickness .035" .035"

HP 3 HP 3 HP

Voltage 220V 440V

Amperage 9.7A 4.9A

Phase 3 PH 3 PH

Cutting Capacity Rectangle 14" x 22" 14" x 22"

Cutting Capacity Round 14" 14"

Cutting Capacity Square 13-1/2" 13-1/2"

Table Height 36.5" 36.5"

Table Tilt 45° right; 15° left 45° right; 15° left

Blade to Frame 13-3/4" 13-3/4"

Electric Welder 4.2 kVA 4.2 kVA

Grinder Motor 1/8 HP 1/8 HP

Machine Dimensions 53" x 40" x 77.5" 53" x 40" x 77.5"

Weight 1500 lbs 1500 lbs

Speeds 0 - 1650 sfpm 0-1650 sfpm

Table Dimensions 24.25" x 24.25" 24.25" x 24.25"

Blade Wheels Diameter 24" 24"

SAFETY RULES

WARNING: For your own safety, read operating instructions

manual before operating tool.

PROPOSITION 65 WARNING: Some dust created by using

power tools contain chemicals known to the state of California to

cause cancer,birth defects or other reproductive harm.

Some examples of these chemicals are:

•Lead from lead-based paints

•Crystalline silica from bricks and cement and other masonry

products.

•Arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies,depending on how often you

do this type of work.To reduce your exposure to these chemicals;

work in a well ventilated area and work with approved safety equip-

ment. Always wear OSHA/NIOSH approved, properly fitting face

mask or respirator when using such tools

WARNING:Always follow proper operating procedures as defined

in this manual even if you are familiar with the use of this or similar

tools.Remember that being careless for even a fraction of a second

can result in severe personal injury.

BE PREPARED FOR JOB

•Wear proper apparel. Do not wear loose clothing,gloves,neck-

ties,rings, bracelets or other jewelry which may get caught in

moving parts of machine.

•Wear protective hair covering to contain long hair.

•Wear safety shoes with non-slip soles.

•Wear safety glasses complying with United States ANSI Z87.1.

Everyday glasses have only impact resistant lenses.They are NOT

safety glasses.

•Wear face mask or dust mask if operation is dusty.

•Be alert and think clearly.Never operate power tools when tired,

intoxicated or when taking medications that cause drowsiness.