Bolecki SKN User manual

User’s manual for distillation column controller

“SKN” from version 2.07

Please read this manual carefully before first o eration of the

controller.

Firma Bolecki Tel. 503-064-713 (8 – 21)

32-650 Kęty forum.bolecki.pl

INFORMATION FOR THE CONSUMER

The symbol resented on roducts or in documentation enclosed with

them informs the non-o erational electrical or electronic a liances

shall not be dis osed together with munici al wastes. When dis osal,

recycling of recovery of subassemblies is necessary, the right

roceeding is to give over the a liance to a s ecialized collection oint,

where it will be taken over free of charge.

1. INSTALLATION RECOMENDATIONS.........................................................................1

1.1. HIGH-VOLTAGE PART...........................................................................................2

1.2. LOW-VOLTAGE PART............................................................................................3

2. FIRST TURN ON AND CONFIGURATION...................................................................4

3. SERVICE MENU...............................................................................................................4

3.1. SEMI-AUTOMATIC MODE.....................................................................................4

3.2. INPUT/OUTPUT TEST.............................................................................................5

3.3. RESET........................................................................................................................5

3.4. ADDITIONAL SETTINGS........................................................................................5

3.4.1 DISPLAY SETTINGS.........................................................................................6

3.4.2 OUTPUT SETTINGS..........................................................................................6

3.4.3 SENSORS SETTINGS........................................................................................8

4. PROCESS SETTINGS MENU.........................................................................................8

4.1. HEATING...................................................................................................................

4.2. ENFORCED WATERING.........................................................................................

4.3. COLUMN STABILIZATION....................................................................................

4.4. HEADS COLLECTION.............................................................................................

4.5. HEART COLLECTION.............................................................................................

4.6. TAILS COLLECTION...............................................................................................

4.7. PROCESS ENDING.................................................................................................10

5. THE APPLIANCE OPERATION...................................................................................10

6. MEMORY CARD...........................................................................................................10

6.1. OPERATION PARAMETERS REGISTER............................................................10

6.2. SOFTWARE UPDATE............................................................................................11

The SKN controller is designed to control the rocess in LM/VM distillation columns.

Functions of the controller make the column o eration much easier. Main features of the

controller:

- Two inde endent out uts 16A 230/400V.

- Cooling water electrovalve (NO relay out ut)

- LM electrovalve (max 12V 1,5A NO/NC)

- VM motorized valve (max 12V 40mA)

- Four thermometers with resolution of 0.01oC, including one of two sensors, which

could control the VM valve

- Gra hic dis lay with high contrast

1. INSTALLATION RECOMENDATIONS

It is recommended to install the actuator in the area of heaters, in an enclosure rotecting it

against accidental flooding (having in mind such cases like leaking water connections, etc.).

At the same time, the enclosure must rovide free air flow that is necessary for cooling the

SSR relay controlling the heaters. The late should be fixed to the enclosure with lastic

s acers rovided in the kit. Using metal s acers may lead to a short-circuit, damage of the

a liance or even electric shock of the user.

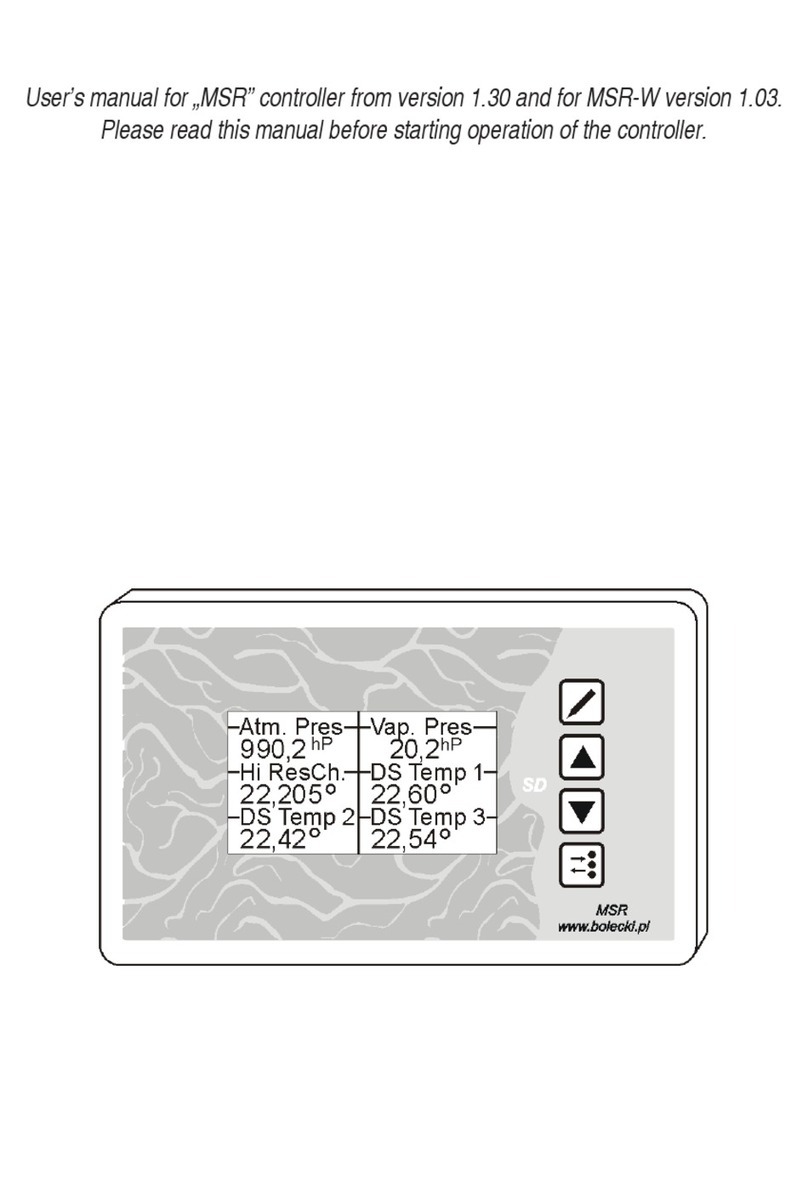

The control anel should be installed in a

convenient lace, having in mind there is

a slot for memory card at the to of the

anel – flooding the a liance from this

side for sure would cause the electronic to

be flooded. The anel is rovided with its

dedicated bracket. Put the anel on the

bracket and then ull it down.

- Remember, the a liance is su lied

with a dangerous voltage. Its electrical

connection should be entrusted to a

erson with suitable knowledge and

authorization. It is forbidden to use the

a liance when its enclosure or wiring

is damaged, also if there is only

sus icion of malfunction of the system.

- The a liance may activate its out ut

at any time without signaling this

event, even if does not result from its

o eration cycle. It is forbidden to make

any mani ulation on the electrical art

of the system when it is connected to

the mains. It a lies also to the low-

voltage elements.

- Do not turn the a liance ON when

the heaters are not covered with liquid

– in case of unex ected turning ON

they could be damaged. It should be

considered to install additional

(mechanical) heaters switch.

- The SKN controller has incor orated

electronic relay (SSR) controlling the

heaters, however it does not ensure

reliable, mechanical heaters

disconnection. Moreover, in case of its

failure (overloading, short-circuit, etc.),

most likely it will su ly the heaters

with full voltage.

- The su ly connection should be

easily accessible. It must ensure quick

and trouble-free disconnection of the

system form the mains at any time.

- The wires and connectors used should

be suitable for the a liance ower. It

is recommended to install a ro riate

terminal box with a ro riate breakers

and differential rotection.

1

- Perform eriodical maintenance of the

a liance. After first few cycles of

o eration, check es ecially the

connections o erating under

significant load, retightening might be

necessary.

- It is forbidden to use the system in

laces that can catch fire from the

wires used, it is forbidden to store

flammable materials in the

neighborhood of the system o eration.

-

- Metal elements of the a liance

must be grounded. Please kee in

mind the fluids are erfect

conductors, therefore each

element must be grounded even

though a arently it is isolated

(e.g. with hose) from the other

elements.

- It is forbidden to leave the system

connected to the mains without

su ervision of a erson with suitable

knowledge and skills.

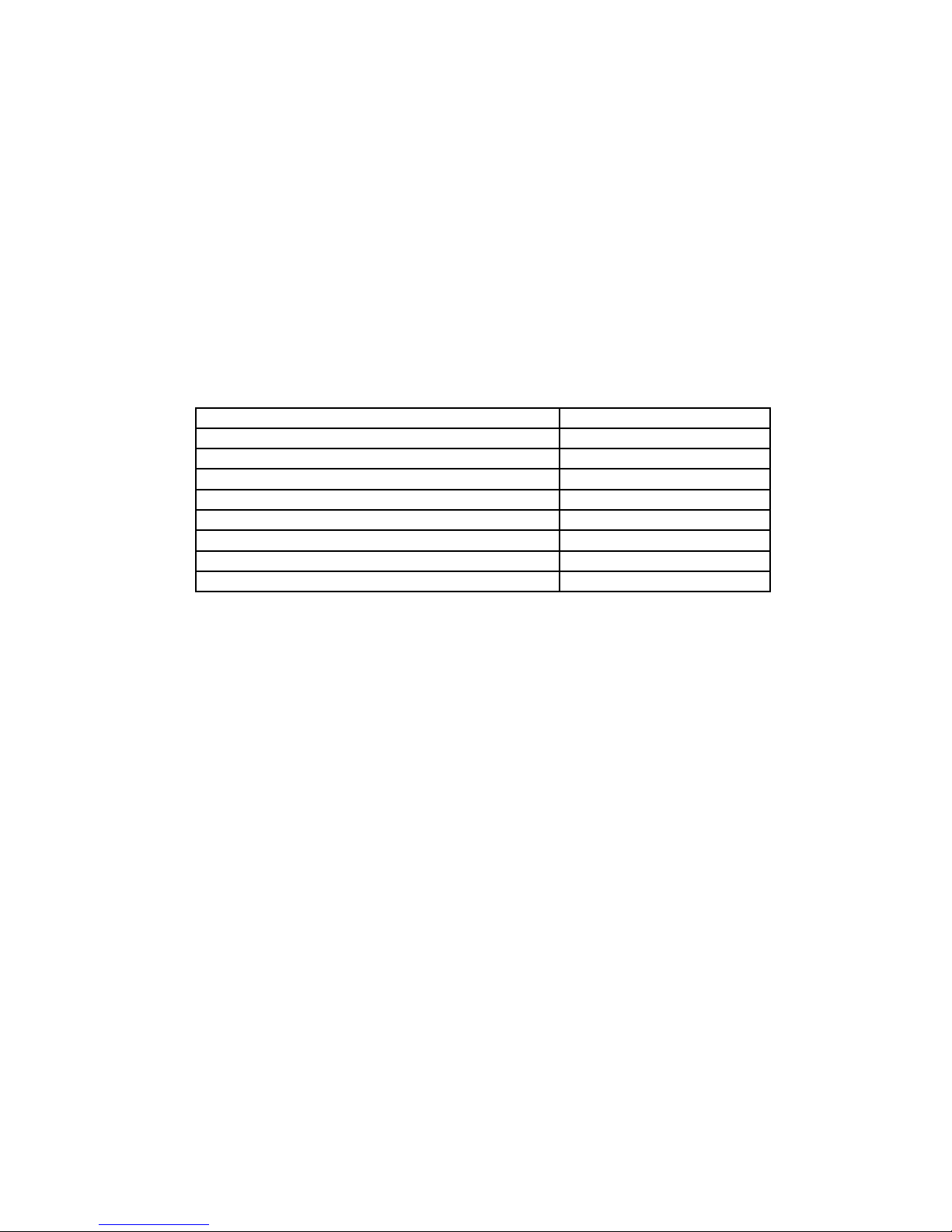

Electronic su ly voltage 230V AC +/-30%

Electronic ower consum tion Max 18W

Heaters su ly voltage Max 400V AC

G1 & G2 out ut current Max 16A each

Water valve max current 1A

LM valve max current 1.5A

VM valve max current 40MA

Tem . measurement resolution 0.01oC

Tem . measurement accuracy +/-3oC (0 – 100oC range)

1.1. HIGH-VOLTAGE PART

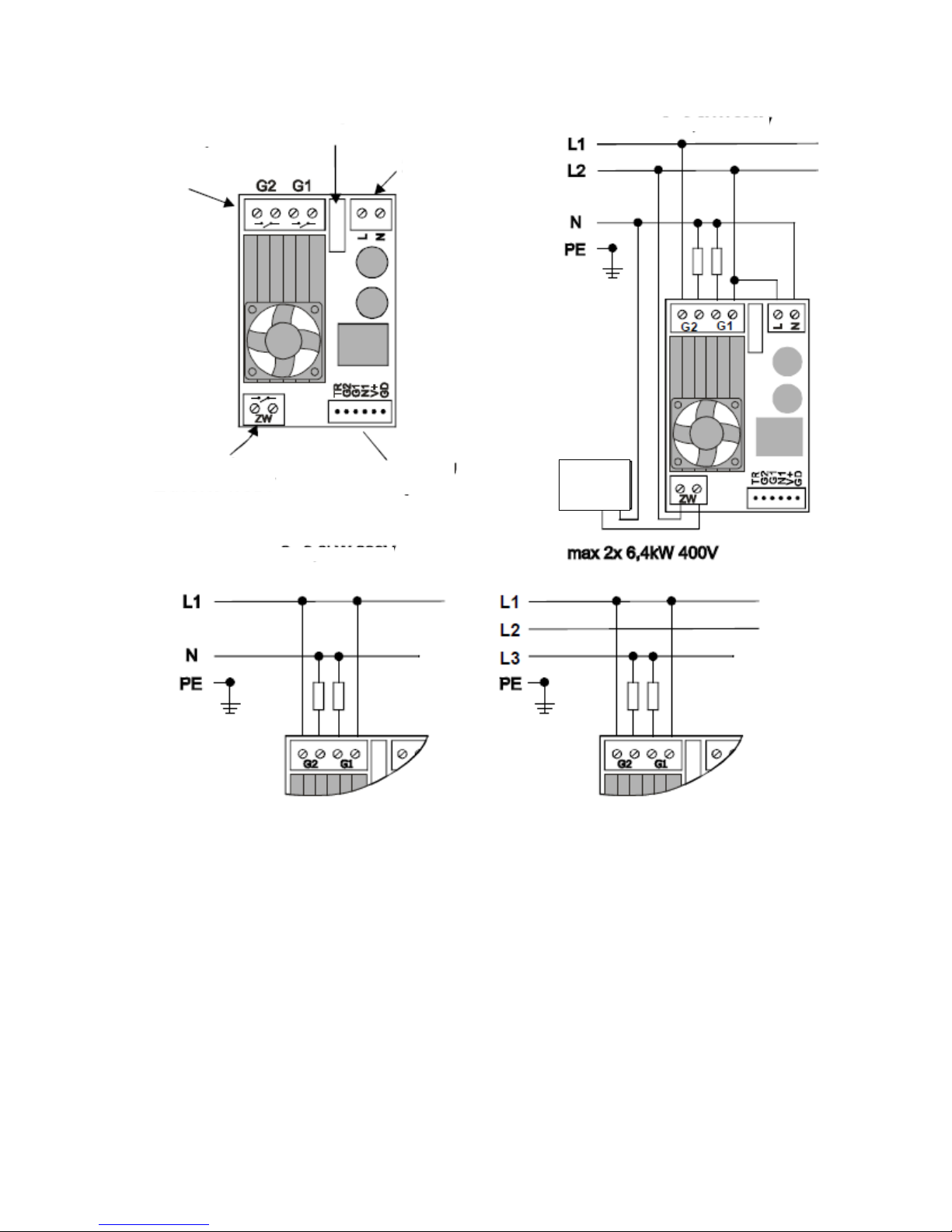

The following diagrams show the exam les of connection of this art of the a liance. The

mains voltage that is necessary for the electronics shall be connected to L N terminals,

aying attention the hase wire should be connected to “L”.

2

Water valve. The SKN controller is not designed to su ly the water valve from its own

ower su ly. The water valve should be su lied from the mains 230V or se arate ower

su ly. The ZW connector should be sim ly considered as a switch, which will close its

contacts when the controller wants to activate the water circulation. It enables to use only

NC valves.

The heaters, de ending on their o eration voltage, should be connected according to one of

the diagrams, considering GH1 and G2 out uts as the serial switches. If the heaters (or their

sections) are of different ower, remember the ower connected to the articular out ut – it

will be needed for further configuration of the a liance.

ATTENTION! The “ rey” factory enclosure of the execution part ensures proper

coolin for current sup to 10A (for each G1 and G2). If the excepted current is to be

hi her, it should be considered to place the execution part in different enclosure

providin adequately better ventilation.

3

FUSE

HEATRES

RELAY

230V

SUPPLY

WATER VALVE

RELAY

CONTROL PANEL

CONNECTOR

WATER

VALVE

max 2 x 3.6kW 230V

max 2 x 3.6kW 230V

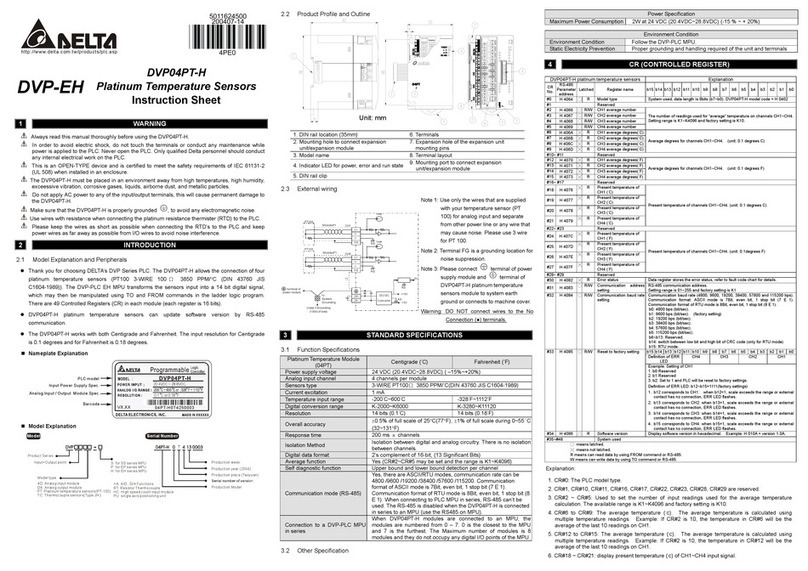

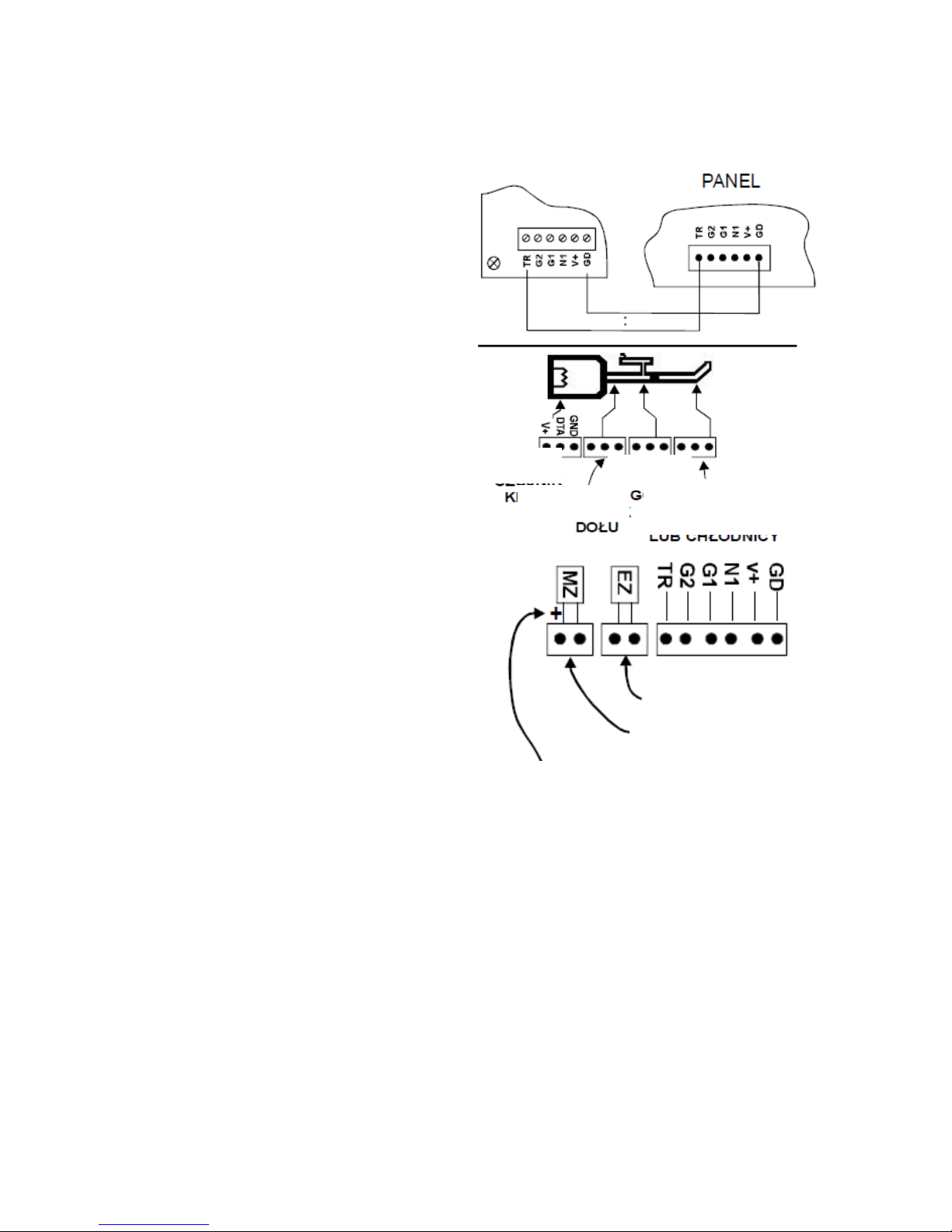

1.2. LOW-VOLTAGE PART

The control anel and the execution art

should be connected with the cable

enclosed. The res ective terminals should

be connected at both ends (i.e. GD-GD, V+-

V+, etc.). There is a connector at the anel

that could be easily detached.

The temperature sensor should be

installed in the column according to its

manufacturer recommendations, leaving

circa 1 cm of the metal art rotruding, if it

would be necessary to remove it ( ossibility

to hold it with liers, etc.). The measurement

oint of the column should be connected

with res ective terminal of the anel.

DS18B20 circuits, o erating in “normal” or

arasite ower, are used as the tem erature

sensors, the wire colors are im ortant.

Ground (GND) is brown, Data line (viewed

from the connectors and label side) (DTA) is

white, su ly is green. Mistake could

damage the sensor.

The LM electrovalve should be connected to

the EZ connector. Polarization (+/-) is not

im ortant. The electrovalve cable, due to

interferences created in it, should be shielded

and ossibly short, should not be ut in harness

with other cables. The controller enables control

of both NO and NC valves, a ro riate

configuration to be done in menu.

VM valve has an incor orated drive, thanks to

which, the controller may control its o ening

rate inde endently. It should be connected to

the MZ connector. Connecting here not

recommended element may lead to the out ut

failure. Polarization is im ortant, one of the wires is always red and it should be connected

to “+”. In case of inverted connection, the valve would o erate in o osite direction making

the column correct o eration im ossible. Correct installation could be check by means of

in ut/out ut test ( oint 3.2), where the symbol “+” visible on the dis lay means o ening and

“-” – closing.

2. FIRST TURN ON AND CONFIGURATION

After making sure that everything is installed correctly, fill u the tank or disconnect the

heaters and turn on the su ly. After a few seconds, the a liance should dis lay the main

screen with the column diagram and tem erature values in its articular elements. It is

recommended to erform a few o erations in the service menu.

1. Restore factory settings (o eration described in oint 3.3).

4

EXECUTION

BOARD

KEG’S

SENSOR

BOTTOM

SENSOR

COLUMN

OR COOLER

SENSOR

TOP

SENSOR

LM ELECTRTOVALVE

VM MOTORIZED VALVE

Here to connect the red motorized

valve wire

2. Check o eration of articular out uts, select o eration oints of VM and LM Valves

(3.2).

3. Configure initially the controller ( oint 3.4)

3. SERVICE MENU

This menu includes essential arameters of the controller. To enter this menu, ress and

hold for e few seconds the button, when the logo screen a ears ress the button

and wait for e few seconds. Navigation within this menu is done with the buttons,

select a ro riate function with . To exit this menu ress and hold for e few seconds the

button or turn ON the su ly again.

3.1. SEMI-AUTOMATIC MODE

This function makes it ossible to control the rocess with significant artici ation of the

user without alarms signalization. The user may, at any time, change the ower and turn the

cooling water valve ON/OFF. The only automatic function is VM valve control on the basis of

tem eratures entered by the user. The to value is an OFF tem erature, and the bottom

value is an ON tem erature. To sensor or bottom sensor is used to control this valve,

according to settings in menu 4.5. Setting of the VM valve o ening rate is done same way

as in the automatic mode.

T1…T4 designations refer to successive tem erature sensors (T1 is the head, T2 – bottom,

etc.). When entering this function, the clock visible in the u er art of the screen is

activated. It does not control the rocess, it is only to hel the user.

In this mode, data logging into SD card is also active. Holding for a few seconds the

button de ressed would cause the controller restarting. To acce t the new valve osition,

ress the button (editing this arameter) or sim ly move to edit next arameter ( ress

the button).

3.2. INPUT/OUTPUT TEST

In this menu, each out ut can be activated manually. The button activates the out ut,

the button deactivates the out ut. Transition between arameters is loo ed and it is

done with the button. To exit this menu ress and hold for e few seconds the

button or turn ON the su ly again.

Control of the VM valve, designated as MZ is done with the buttons. The visible “+’

symbol should cause the valve o ening and “-“ its closing, 0 means the valve is sto ed.

Control of the LM valve, designated as EZ is done with changing the values – above some

threshold the valve “engages” and below “releases”. To find the o timal value controlling the

valve, carefully increase the value and note when the valve o erates. Increase this value

further by circa 10...15%, then disconnect and reconnect the valve connector aying

attention if this o eration has roduced next and unequivocal vale o eration within 30 s.

Then enter the value obtained as Dt arameter value in out ut settings ( oint 3.4.2).

Setting too high values could cause the ower su ly overload and its shut-down (controller

restart). If such effect occurs without the valve o eration, it means this valve is not suitable

5

for this controller. Quite squealing or delayed o eration of the valve after disconnection of its

connector is a natural behavior.

3.3. RESET

Hold the button de ressed for a few seconds – the controller will restart. At the moment

when the logo screen a ears, ress the button, shortly after instead of main screen

the menu with a list of o erations will a ear. With the button move to “reset” and ress

the button. The controller will restart with factory settings. This function does not “cure”

the controller wonderfully and it is not a solution for all the roblems with its o eration that

usually might arise from not understanding its rinci al of work and wrong settings. Instead,

it causes necessity of resetting all the arameters.

3.4. ADDITIONAL SETTINGS

Hold the button de ressed for a few seconds – the controller will restart. At the moment

when the logo screen a ears, ress the button, shortly after instead of main screen

the menu with a list of o erations will a ear. With the button move to “additional

settings” and ress the button, first arameters – dis lay contrast – will come u .

Change the value with the buttons, confirm the value and move to next arameter

with the button. It is not ossible to move back to revious arameter. To save the

changes move across all the arameters. The controller will restart.

3.4.1 DISPLAY SETTINGS

Here you can select the LCD screen contrast.

3.4.2 OUTPUT SETTINGS

Here you can select the LCD screen contrast.

LM TYPE – s ecify the valve ty e (NO – normally o en or NC – normally closed)

Dt – arameter controlling the valve. The SKN controller controls the electrovalve in

so histicated way, in order to reduce heating of the valve and make it ossible to use valves

form a wide range of valves, which would not be suitable for direct o eration with this

a liance (e.g. excessive coil ower, o eration voltage different then 12V). Correct value of

this arameter should be obtained testing the valve o eration, available in the menu

“In ut/Out ut test” ( oint 3.2).

Then you could define how the heaters will work.

G1 modulated, G2 continuous – Heater connected to G2 out ut will o erate continuously,

even if set at minimum ower. Essential ower adjustment will be done with G1 heater.

G1 and G2 modulated. Both heaters will be turned On and Off at the same time.

G1/G1 power – the controller shows absolute ower in kilowatts (kW), not relative in

ercents. Therefore, to obtain correct value it is necessary to enter nominal ower of

articular heaters. Both the above ways of control have one common feature, the controller

realizes so called grou control with a few seconds eriod. Contrary to hase control, it

eliminates the necessity to use ex ensive noise filters, ensures good quality of control,

however it may cause light dimming in ace of heaters o eration. Therefore, it is

6

recommended to work in mode of G1 modulated and G2 continuous, where the modulated

heater will be su lied form different hase then lighting.

Max VM openin – defines the maximum valve o ening. When running the rocess it will

be im ossible to select higher valve o ening, reducing the ossibility to select higher

ca acity then the column can rovide and frequent rocess destabilization at beginning

hase of collecting the heart.

Min VM openin – means minimum o ening. When running the rocess it will be

im ossible to select lower o ening. Also the controller itself will no go below this vale if the

o ening correction o tion is active. Use a value at which the rate of collection is still

reasonable. Setting too low value or even total closing would cause the controller to

encounter a roblem with transferring to tails when the close time rinci le is selected, or

would case unnecessarily long collection of the heart and energy consum tion.

7

8

3.4.3 SENSORS SETTINGS

This menu consists of two screens. In the first of them you can define what sensors will be

connected the controller, and therefore their correct o eration should be checked.

Sensor alarm – leaving the sensor crossed out informs the controller that give sensor will

not be connected. The selected sensors are being checked only during rocess running

(before you can disconnect them freely). If during rocess running the controller detects a

roblem, a ro riate message will be dis layed and acoustic signal will sound.

From this moment, the user has a minute to confirm/cancel the error by ressing any button,

otherwise after indicated time the controller will sto the rocess.

The error will be cancelled automatically if the sensor comes back to its normal o eration.

Next error from the same sensor would a ear only if even for a moment correct signal from

this sensor rea ear, it means ermanently defected sensor would be signaled only once.

Such method of roceeding ensures determined reaction to an error, however excludes

immediate and not necessary column shut down e.g. due to accidental sensor

disconnection. It gives the user ossibility to make ro er decision without needless stress.

Head sensor as – to select head or cooler.

This function brings also changes in the main screen or rocess menu. Setting the sensor

as a head sensor would add to menu an additional o tion of rocess ending after obtaining

at it the s ecified tem erature (without it, still the other sensors will be selectable).

Setting the sensor as a cooler sensor would add an additional o tion of the cooler

tem erature control.

Readin correction. This o tion enables correction of the tem erature sensors readings.

Value in arenthesis shows an actual tem erature taking into account the correction

entered. Please remember the DS18b20 sensors are quite good thermometers and

ractically offers much smaller error then described in the s ecifications. Small difference

from the actual tem erature is meaningless for the controller, so this correction is urely a

cosmetic function. Differences exceeding a few degrees might indicate sensor defect.

4. PROCESS SETTINGS MENU

Here you can configure the entire rocess. To enter this menu, ress the button at the

moment when main screen is visible and no arameters are being changed. To exit this

menu, res the same button again. The buttons rewind the menu or change

arameters values after entering the editing menu.

Entering the editing of a given screen, moving to next arameters, and exiting the editing is

ossible with the button.

Turning Off and long holding of the button de ressed when making changes would not

save them (saving into memory is done with exiting the editing).

Princi les of the rocess might be also changed during its running. Remember, however,

such changes have immediate im act so unex ected rocess interru tion or move to next

hase may ha en. The entire distillation rocess runs according to subsequent, below

listed rinci les.

4.1. HEATING

First rocess stage. Here you can define the ower of heating, at what tem erature of the

column bottom the electrovalve of cooling water should be activated and what tem erature

of the column to should start the watering stage.

4.2. ENFORCED WATERING

Consists of three attem ts of watering with auses the ur ose of which is better wetting of

the column acking. This o tion is aimed at controlled filling of the column with water. When

not sure how to set u these arameters, it is recommended to set u much longer time

then exce ted (even tens of minutes) and control the watering rocess with self-contained

changes of ower form the main screen. And then enforce transition to a next stage

(described in oint 5). Such method ensures comfortable work without a ressure of time

and necessity of restarting the rocess in case of its omitting.

4.3. COLUMN STABILIZATION

This rinci le determines the ower and time of stabilization.

4.4. HEADS COLLECTION

Fourth stage. This rinci le defines the ower effective from this moment and a time for

which the user can collect so called kindling and heads. During this stage the LM valve is

being o en, and the VM valve is still closed.

4.5. HEART COLLECTION

Fifth stage. This rinci le defines how the main roduct will be collected, the user decides

what jum from the tem erature of the day is to cause the end of collection. Which sensor

(column to or bottom) will control the VM valve. Beginning value of the VM valve o ening

and a ste decreasing each next valve o ening. The tem erature of the day is to be defined

automatically by the controller during its o eration. From the moment of starting this stage,

the user may at any time, from the main screen, change the o ening/closing tem erature

and the current valve o ening level. For the time of heart collection, the LM valve is being

closed.

4.6. TAILS COLLECTION

Sixth stage. The VM valve is being closed, the LM valve is being reo ened. This stage can

be induced if the selected rinci le is met. You can select the ty e of sensor (keg, bottom or

to ) and tem erature value to be obtained at this sensor, or maximum time of the VM being

closed. In order to use the tem eratures in articular column oints, first it is recommended

to erform the column test and find out these values (s read of the sensor arameters, the

column o eration conditions, etc.).

10

A better solution might be the rinci le of VM closing time. When the column is good (and

the accessories set correctly), the valve will start to close in the very ending hase of

collection and each next closing will be longer and longer. The so far observations indicate

the time of a level of 10 min. should be enough.

4.7. PROCESS ENDING

With ro er arameters setting, in this rinci le the controller may end the rocess directly

from the heart collection (ski ing the tails). The user defines how long the cooling shall be

active after the heaters are turned off, and how to detect the end of rocess. It could be in

result of exceeding the tem erature in the KEG or the column bottom or to .

5. THE APPLIANCE OPERATION

The main screen with the column view enables a few functions such as beginning and end

of rocess, transition to next stage or modification of arameters during o eration. Enter the

functions selection by ressing the button. When the rocess is sto ed, it is ossible

only to restart the rocess ( ressing the button). During rocess running you can move

to a next stage, quickly change the VM valve tem erature, change the ower currently used

or end the entire rocess. In case of changing the valve o ening rate, after changing the

value ress the button, or sim ly move to another arameter ressing the button

(changing the valve o ening is effective only when the valve is o ened). The second screen

dis lays information on the VM valve o eration, it means the current or revious times the

valve was closed. This information enables to make a decision on the ossible settings

corrections, ending the rocess or to be familiar with the rocess status in general. Here you

can also see the tem erature of the cooler located in the execution art. Navigation between

these screen is ossible by ressing the buttons.

It is possible to enter the menu and change the process principles during process running,

however remember the modification of the current stage may cause its unexpected ending

and transition to a subsequent stage.

6. MEMORY CARD

The a liance makes it ossible to record the significant o eration arameters into memory

card, or to u dates the controller software quickly.

Only SD/MicroSD cards of u to 32GB can be used with this a liance. There is no

guarantee the a liance will function correctly with all ty es of cards meeting these

requirements.

6.1. OPERATION PARAMETERS REGISTER

Each start of rocess in automatic or semiautomatic mode causes the controller to generate

a new .csv file, where the data will be regularly registered. Active registering into the card is

being signaled with regular flashing of the SD icon in the front of the controller. Such a file

could be im orted into calculation sheet. Each next file has an ascending number in its

name, the file creation date is random. It is forbidden to move or remove the card from the

a liance when the rocess is started. It could cause the file to be damaged or the rocess

to be interru ted.

11

6.2. SOFTWARE UPDATE

U dating rocess is sim le, however the a liance not covered with warranty could be

damaged. Each u date attem t is recorded in the controller together with a file fragment. Do

not load a software other then designed for this a liance. During u dating is could ha en

the controller will cease its correct o eration and e.g. activate its out uts (a risk of heaters

damage, etc.)

It is natural that after updatin the controller will si nal an error of the settin s

recorded in the memory. Even if the controller does not display such messa e, reset

it to factory settin s.

U dating shall be always done in the following sequence:

- Save the file with a software to be loaded into the controller into the card.

- Check and ossible modify the file name to S_SKN (or S_SKN.hex if your system shows

file extensions).

- Insert the card into the controller with the su ly turned off.

- Turn the controller on with the button de ressed.

The SD icon will flash a few times, then during a few seconds it will flash quickly, then

slowly. If the u date is successful, the controller will start u automatically with the new

software. If instead, the SD icon will flash regularly it means u date failure. Number of

flashes informs the cause of failure:

2 flashes: roblem with the card, try to format it or use another card

3 flashes: the ex ected file not detected

4-6 flashes: roblem with the file content (e.g. damaged)

If there is any roblem with the memory card, first o eration should be its formatting for

FAT32 file system. Correct u dating rocess (software u loading) takes about 10 seconds.

The appliance does not react to supply application, the panel does not li ht, the fan

does not rotate.

Check the su ly connections, check the fuse.

The appliance does not react to supply application, the panel does not li ht, the fan

rotates.

Check correct connection of the low- and high-voltage arts, disconnect the electrovalve

and the tem erature sensors.

One of the heaters works, its control lamp on the execution panel does not li ht.

If the connection is correct (the out ut used to work), the most likely the out ut is damaged

due to short-circuit.

12

One of the heaters works, its control

lamp on the execution panel does not

li ht.

Check the connection between the low-

and high-voltage arts.

One of the heaters works, its control

lamp on the execution panel li hts.

Check the heater connection and its

efficiency.

The panel resets at the moment of LM

valve operation, or it does it in cycles

tryin to turn on.

Disconnect the VM valve, it is an

excessive load for the controller. Check

the VM valve for the ossible short-circuit,

check the valve ty e (NO/NC),

check/reduce the Dt arameter.

The controller displays a memory error.

Such situation can ha en after software

u dating or s oradically due to

disturbances (e.g. shut-down during

settings modifications).

One of the heaters work when it should

not, its control lamp on the execution

panel li hts.

Check the connection between the low-

and high-voltage arts.

One of the heaters does not work, its

control lamp on the execution panel

li hts.

Check the connection between the low-

and high-voltage arts.

One of the heaters does not work, its

control lamp on the execution panel

li hts.

Check the connection between the low-

and high-voltage arts.

Immediately after process start, there

is an error of cooler overheatin .

Sensor on the execution anel damaged

(service is necessary) or incorrect

connection between the low- and high-

voltage arts.

Cooler overheatin error appears some

time after the process start.

Cooling of the execution art is ineffective,

ventilation holes are obstructed, the

execution art heats u from the tank, the

heaters connected are of excessive

ower.

The controller displays error for a

sensor that is not connected.

Configure correctly the sensors used.

The panel resets at the moment of LM

valve operation, or it does it in cycles

tryin to turn on.

Disconnect the VM valve, it is an

excessive load for the controller. Check

the VM valve for the ossible short-circuit,

check the valve ty e (NO/NC),

check/reduce the Dt arameter.

The controller displays a memory error.

Such situation can ha en after software

u dating or s oradically due to

disturbances (e.g. shut-down during

settings modifications).

If the above su estions do not solve the problem, contact the manufacturer.

13

Serial number ……………………

Date of sale and stam

WARRANTY CARD

- The manufacturer warrants correct o eration of the a liance for a eriod of 24 months

from the date of sale.

- Factory defects revealed within the above eriod will be eliminated free-of-charge within

14 working days from the date of receiving it to the service. Before sending the

a liance back, contact the manufacturer.

- Return the a liance cleaned directly to the manufacturer (it will significantly shorten the

re air time) at your cost, in a ackage ensuring its ro er rotection, enclosing the roof

of urchase and the warranty card correctly filled in. Enclose also contact data of the

claiming erson (shi ing address, tele hone number) and recise failure descri tion.

- Warranty is void if the seal or the label with serial number is not intact.

- Warranty does not cover failures not resulting from the manufacturer errors, e.g. not

a roved design modification, im ro er installation or use, overloads, atmos heric

discharges, mains overvoltages, fouling or flooding, mechanical damages.

- Warranty card that is illegible, not fully filled out, or with traces of unauthorized

corrections is invalid!

- This warranty card doe not exclude nor limit the consumer rights resulting from the

regulations of the laws.

14

Table of contents

Other Bolecki Controllers manuals