BOLIY PRO3600SI User manual

DIGITAL GENERATOR

BOLIY

BOLIY POWER

Pro3600Si

GENERATOR SHOP MANUAL

BOLIY POWER

©2010-2011

www.boliypower.com

Pro3600SiE (electric start)

Preface

This manual covers the construction, function and servicing procedure of the BOLIY

Pro3600Si/E model generators. This manual is principally concerned with the generator

specifications, function, troubleshooting and repair. There is a separate manual to

cover engine overhaul which includes the starting systems.

Careful observance of the instructions contained in this manual will result in safe and

quality service work.

All information, illustrations, directions and specifications included in this publication

are based on the latest product information available at the time of approval for

printing.

BOLIY POWER, reserves the right to make changes without incurring any obligation

whatever. No part of this publication may be reproduced without written permission.

Table of Contents

1. Specifications ..................................................................................................................3

1.1 Specifications.................................................................................................................3

2. Service information ..........................................................................................................6

2.1 The importance of proper service ..................................................................................6

2.2 Important safety precautions .........................................................................................6

2.3 Service rules ..................................................................................................................7

2.4 Electrical Precautions ....................................................................................................7

2.5 Serial number location...................................................................................................8

2.6 Maintenance standards .................................................................................................9

3. Maintenance .....................................................................................................................11

3.1 Regular inspection schedule .........................................................................................11

3.2 Engine oil .......................................................................................................................12

3.3 Fule leak........................................................................................................................13

3.4 Air filter maintenance.....................................................................................................14

3.5 Exhuast .........................................................................................................................15

3.6 Adjusting of valve clearance..........................................................................................16

3.7 Compress pressure ...................................................................................................17

3.8 Rating speed ...............................................................................................................18

4.0 Spark plug ......................................................................................................................19

4.1 Check engine switch..................................................................................................19

4.2 ECON switch..................................................................................................................20

4.3. Check electric components.....................................................................................20

4.4 Troubleshooting .........................................................................................................21

Section 1- Fuel related problems..................................................................................22

Section 2-Generator won't start.....................................................................................23

Section 3-No Start, no spark..........................................................................................23

Section 4-No AC Output (Inverter series) ...................................................................24

Section 5-ECON Switch failurel.....................................................................................24

1.1 SPECIFICATIONS

DIMENSIONS & WEIGHT

OVERALL LENGTH ( mm / in ) 585 / 23

OVERALL WIDTH ( mm / in ) 420 / 16.5

OVERALL HEIGHT ( mm / in ) 470 /18.5

DRY WEIGHT ( kg / lb. ) 31/ 68

GROSS WEIGHT ( kg / lb. ) 35.5 / 78

FUEL TANK CAPACITY ( L / US gal. ) 7.4 / 1.9

FUEL CONSUMPTION AT RATED OUTPUT 0.55 L/kwh

NOISE LEVEL ( at 7m ) 53-58 dB

ENGINE

TYPE 166F, OHV, AIR-COOLED, 4 * STROKE

STARTING SYSTEM RECOIL START

CYLINDER ARRANGEMENT INCLINED,SINGLE CYLINDER

BORE * STROKE ( mm/in) 66(2.6) * 50(1.97)

IGNITION SYSTEM CDI

SPARK PLUG TYPE BPR4ES(NGK)/F7RTC

GAP ( mm/in) 0.7-0.8(0.028-0.031)

DISPLACEMENT ( cc ) 171CC

RATED OUTPUT KW(HP)r/min 3.6(4.9)/3,600

FUEL UNLEADED GASOLINE

ENGINE OIL QUANTITY( L / US qt, ) 0.6(0.63)

3

GENERATOR

TYPE AC OUTPUT, Multistage

permanent-magnet generator

RATED OUTPUT ( WATTS ) 3,000

MAX OUTPUT ( WATTS ) 3,300

FULL TANK OUTPUT ( WATTS ) 13,500

RUN TIME AT 1/2 RATED LOAD 8.3 hours

RUN TIME AT RATED LOAD 4.5 hours

POWER CONVERSION RATE 85%*92%

RATED VOLTAGE ( V ) 120 & 230

RATED CURRENT ( A ) 25 & 13

DC OUTPUT( 12V / 8 A ) YES

CHARACTERISTIC

AUTOMATIC RELEASE PRESSURE YES

ELECTRO-BREAKER YES

FUEL LEVEL GAUGE YES

ENGINE Oil WARNING LIGHT YES

OVERLOAD INDICATOR LIGHT NO

AC INDICATOR LIGHT YES

ENERGY CONSERVATION CURRENT IDLING YES

INSULATION CLASS E

THE FLUCTUATION OF VOLTAGE & FREQUENCY

INSTANTANEOUS 25%

STABLE STATE ?2%

STABLE TIME ( second ) 3 sec. max.

FREQUENCY stability ?.01%

4

5

Color code

B - Black

G - Green

L - Blue

O - Orange

R - Red

W - White

Y - Yellow

P - Pink

B/W - Black/White

G/Y - Green/Yellow

W/L - White/Blue

1 - Main coil

2 - Sub coil

3 - Control unit

4 - AC indicator light/

Overload indicator light

5 - AC receptacle

6 - Ground (Earth) terminal

7 - Economy Control Switch

8 - Step Motor controller

9 - Engine switch

10 - Oil warning light

11 - Oil warning unit

12 - Oil level gauge

13 - Ignition coil

14 - Spark plug

15 - AC-CDI unit

16 - Pulsar coil

17 - Stepping motor

18 - Charge coil

19 - DC receptacle

20 - Ballast

BOLIY Pro 3600Si & 3600Si/E DSP INVERTER GENERATOR WIRING DIAGRAM

2. Service information

2.1 The importance of proper servicing

Proper servicing is essential to the safety of the operator and the reliability of the generator.

Any error or oversight made by the technician while servicing can easily result in faulty

operation and/or damage to the equipment or injury to the operator.

WARNING

* Improper servicing can cause an unsafe condition that can lead to serious injury or death.

* Follow the procedures and precautions in this shop manual carefully.

Some of the most important precautions are stated below.

2.2 Important safety precautions

Be sure you have a clear understanding of all basic shop safety practices and that you are

wearing appropriate clothing and safety equipment. When performing maintenance or repairs,

be especially careful of the following:

*Read the instructions before you begin, and be sure you have the tools and skills required

to perform the tasks safely.

*Be sure that the engine is off before you begin any maintenance or repairs. This will reduce

the possibility of several hazards:

- Carbon monoxide poisoning from engine exhaust.

- Burns from hot parts.

- Injury from moving parts.

*Do not run the engine unless the instructions tell you to do so. Keep your hands and clothing

away from rotating parts.

*To reduce the possibility of fire or explosion, exercise extreme caution when working around

gasoline. Use only a nonflammable solvent, not gasoline, to clean parts. Keep cigarettes,

sparks and flames away from all fuel-related parts.

6

2.3 Service rules

*Use genuine BOLIY or BOLIY-recommended parts and lubricants or their

equivalents. Parts that do not meet BOLIY design specifications may damage

the engine.

*Use the special tools designed for the product.

*Always install new gaskets, O-rings, etc. when reassembling components.

*Clean parts in cleaning solvent upon disassembly. Lubricate any sliding surfaces

before reassembly. After reassembly, check all parts for proper installation and

operation.

*Many screws used in this machine are self-tapping. Be aware that cross-

threading or over tightening these screws will strip the threads and ruin the

hole.

*Use only metric tools when servicing this engine. Metric bolts, nuts and screws

are not interchangeable with non metric fasteners. The use of incorrect tools

and fasteners will damage the engine.

2.4 Electrical precautions

*Hold the connector body to disconnect the connector. Do not disconnect by

pulling the wire harness. To disconnect the locking connector, be sure to unlock

first, and then disconnect.

*Check the connector terminals for bend, excessive extrusion, missing terminals,

or other abnormalities before connecting the connector.

*To connect, insert the connector as far as it goes. If the connector is a locking

type, be sure that it is locked securely.

*Check the connector cover for breakage and check whether the connector

female terminal is not opened excessively. Then, connect the connector securely.

Check the connector terminal for rust. Remove the rust using an emery paper

or equivalent material before connecting the connector.

*Set the harness clips in the specified places of the frame securely, and secure

the wire harnesses.

*Clamp the cables securely.

7

*Clamp the wire harnesses securely so that they do not interfere with the

rotating parts, moving parts and hot parts.

*Route and connect the wire harnesses properly. Be sure that the harnesses

are not slack, twisted or pulled overly taut.

*Route the wire harnesses properly so that they do not contact sharp edges

and corners and the end of the bolts and screws on the body.

*If a wire harness must contact the end of the bolts or screws or sharp edges

and corners, protect the contact part of the harness with a loom or by winding

with electrical insulating tape. If the wire harness has a grommet, set the

grommet securely.

*Take care not to pinch the wire harnesses during installation of a part. If a

wire harness has damaged insulation, repair by winding with electrical insulating

tape.

*When using an electrical tester like a volt/ohm meter or clamp on meter, read

the manufacturer抯operating instructions carefully before operating the tester.

Be sure that the tester battery is fully charged and the meter is functioning

properly

2.5 Serial number location

The engine serial number is stamped at the underside of engine side cover.

Refer to this number when ordering or making technical inquiries.

One engine serial number-one machine bar serial number

Engine serial number

Machine bar serial number

Engine serial number Machine bar serial number

8

xxxxxxxx

2.6 Maintenance standards

Engine

Part Item Standard(mm) Service limit

Cylinder Sleeve I.D. 66.02~66.04 66.15

Piston Skirt O.D 67.97~67.99 66.67

Piston-to-cylinder clearance 0.040~0.060 0.12

Piston pin O.D 15.990~16.000 .15.95

Pin-to-piston clearance 0.002~0.018 0.080

Piston ring Ring width Top 1.420~1.440 1.32

Second 1.420~1.440 1.32

Ring side clearance Top/second 0.02~0.06 0.15

Connecting rodSmall end I.D 6.006~18.017 16.07

Big end I.D 28.015~28.025 28.07

Big end oil clearance 0.046~0.060 0.12

Crankshaft Crank pin O.D. 27.960~27.975 27.90

Valve Valve clearance Intake 0.1?.2

Exhaust 0.15?.2

Stem OD Intake 5.46~5.48 5.35

Exhaust 5.45~5.47 5.35

Vessel I.D Intake/Exhaust 5.500~5.518 5.56

Clearance of valve and vessel Intake 0.020~0.058 0.1

Valve spring Free Length Intake/Exhaust 26.8 25.5

Camshaft O.D 14.966~14.984 14.92

Crankcase cover Camshaft Bearing I.D. 15.000~15.027 15.05

Cylinder block Valve lifter I.D. 8.000-8.015 8.06

Camshaft Bearing I.D. 15.000*15.02 15.05

Spark plug Clearance 0.6~0.8

Ignition coil Resistance Primary side 0.6~1.1ohm

Second side 15~19ohm

Starting relay Resistance 0.25~0.5

9

Generator

Part Item Ty p e S ta n d a r d Service

120V Limit

Ignition coil Resistance Ye l l o w / G r e e n - R e d 0 . 7 ~ 0 . 8 5 ~

Outer charging winding coil Resistance Yellow-Yellow 0.35~0.45 ~

ECON feedback winding coil Resistance White-White 0.2~0.3 ~

Control feedback Resistance Yellow-Yellow 0.4~0.45 ~

Main winding coil Resistance Blue-Blue 0.8~1.0 ~

10

3 MAINTENANCE

3.1 Maintenance schedule

Item Attention Each First month Every 3 months Every 6 months Every year or

use or 20 Hrs. or 50Hrs. or 100 Hrs. 300 Hrs.

Spark Clean-Adjust *

plug

Valve Check-Adjust *

clearance

Crankshaft Check *

System

Idile Check-Ajust *

Speed

Exhaust Check Replace *

System

Engine oil Check *

Replace * *

Air cleaner Check-Replace *

Fuel clearner Check *

Fuel pipe Check Replace *

Chock Check *

Cooling Check *

System

Start Check *

system

Clean Clean *

engine

carbon

Generator Check light *

Assembly Check *

Part

11

3.2 Engine Oil

Check Engine Oil leak

Check the engine whether or not have leak oil.

If leak replace gasket, or oil seal or O ring.

A. Checking Oil Level

Engine should be shut off and generator be on level ground when checking the oil level.

1. Check engine oil level and

oil warning light

When start whether or not the

light ray.

Light ray- add oil

No light ray- ok

2. Remove the oil dipstick,Add the proper viscosity engine oil

to the upper limit if oil level is low. Be careful to over fill.

B. Changing engine oil

(1) Remove the bottom oil screw and unscrew oil drain plug to drain used

oil.

(2) Replace the drain plug and secure tightly.

(3) Add the proper viscosity oil to the upper oil limit level.

(4) Reinstall the dipstick and screw it tightly

17Nm(1.7 m.kg ,12 ft.ib)

Enginine

A SAE#30 or 10W-30

B SAE#20 or 10W-30

C SAE10W or 10W-30

0.6L (0.53imp qt 0.63 US qt)

12

ON

OFF

AC

1

1

a

2

5

B SAE#20 or 10W-30

C SAE10W or 10W-30

0C25 C

32 80 F

F

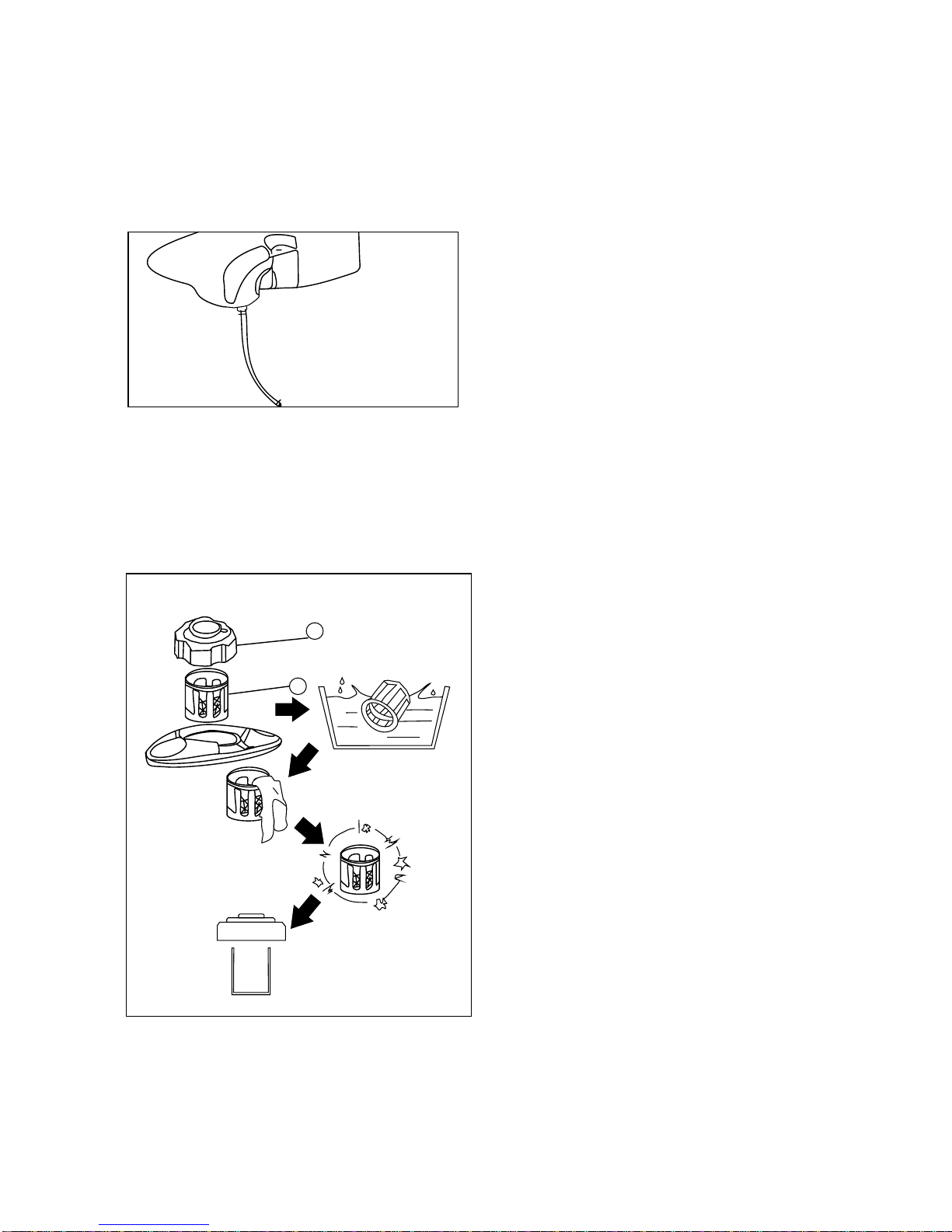

3.3 Fuel leak

1 Check

Check fuel tank, fuel switch,fuel pipe

and carburetor.

Caution:

Every 2 years replace the fuel pipe and

fuel filter.

Caution:

No fire when you clean it.

1. Take off hat.

2. get the strainer

Check strainer

Damage-replace

If ok-Clean it.

Remark: You'd better use impregnant clean it

then for dry.

13

1

2

3.4 Air Filter Maintenance

(1) Open the service door.

(2) Open the cover of air filter and take out the filter

element.

(3) Blow the inner side of filter element using compressed

air or lightly knock it to remove dirt. If any dirt remains,

change the element. Be sure to use a genuine Kipor element

to maintain a proper seal and avoid engine damage.

(4) Reinstall the filter element and close the service door.

14

Oil

3.5 Exhaust

1. Take off

Wire netting, collar clamp,and bolt etc.

2. remove carbon dust.

The exhaust as picture method to knock.

3. Clean the wire netting.

Waring: Don't use metal silk for clean. That will damage the material.

15

3.6 Adjusting valve clearance

Attention

Valve adjustment should only be performed on a cool engine.

(1) Remove back case, then take off valve cover.

(2) Pull the starter rope gently and set the piston in top dead

center (Use a stick in the spark plug hole measure the depth).

(3) Insert a feeler gauge into the gap between rocker and valve to

measure the valve clearance.

Valve Clearance

Intake: 0.1mm(0.004 in)

Exhaust:. 0.1mm (0.004in)

(4) If adjustment is necessary, proceed as follows:

a. Hold rocker axis using the wrench and loosen the lock nut.

b. Loosen the lock nut of rocker axis to gain the specified intake

and exhaust valve clearance.

c. Hold rocker axis using a wrench and tighten the lock nut.

d. Check the clearance of valve after adjustment.

16

3.7 compress pressure

Remark:

When finish adjust Valve Clearance, then measure the

compress pressure.

1. For running few mins.

2. Remove spark plug.

3. Use manometer and adapter for measure.

Manometer

Adapter

Measure:

Measure pressure you need pull the starter when the pressure finger stop, read the NO..

The standard:400-600kpa(4-6kg/cm3,57-85 psi )

Waring:

When start engine, spark plug need connect for ground, that no spark.

Measure step(At lowest level):

dripping little engine oil for cylinder, then mesure the compress pressure.

Reading Estimate

Low than no oil Cylinder,piston or piston rings are wear and tear.

The same with no oil Piston, piston rings, valve,Cylinder gasket fail.

Or need adjust valve clearance.

Measure step(At high level):

Check cylinder, valve and piston whether or not have carbon dirty.

Build in the spark plug:

18Nm(18M.kg, 13ft.ib)

17

1

3.8 Rating speed

Frist connect the speed meter

Accord with standard speed = right

If not right please check chapter3. for repair.

Check step:

1) Start engine (0% load)

2) Turn to off ECON switch.

3)Measure the speed.

3800-3950r/min

3.9 Hose

1.Check:

Hose

Crack/- Replace.

No good connect- Adjust

18

A

B

ON

OFF

Attention

Check the cylinder position should only be performed on a cool

engine.

When you take off the spark plug must keep no durity into engine.

4.0 Spark plug

1. Take off the spark plug and spark cap.

take off the spark plug.

2. Check electrode

Bad-replace

dielectric- color

3. Measure

Spark plug clearance

Ues thickness tool.

No standard- Adjust

Spark plug clearance 0.7-0.8mm

If need for clean, please use cleaner for clean

Standard spark plug BPR4ES(NSK or F7RTC)

4.1 Check engine switch.

Turn to witch for "ON" If start that's ok.

Turn "off" , the engine stop -ok.

19

a

a

b

ON

STOP

Other manuals for PRO3600SI

2

This manual suits for next models

1

Table of contents

Other BOLIY Portable Generator manuals

Popular Portable Generator manuals by other brands

Champion

Champion 40026 Owner's manual & operating instructions

Generac Power Systems

Generac Power Systems 5500XL owner's manual

Zendure

Zendure SuperBase V6400 user manual

Mosa

Mosa GE 10 YSXC Use and maintenance manual

Briggs & Stratton

Briggs & Stratton 030670-00 manual

North Star

North Star M165923V.1 owner's manual