Bomag BPR 30/38-3 Instructions for use

Operating instructions

Maintenance instructions

Catalogue number

008 156 55 02/2006

BPR 30/38-3 - BPR 35/38-3

S/N10168036....

Honda

Vibratory plate

For Parts go to Discount-Equipment.com

Discount-Equipment.com is your online resource for quality parts & equipment.

Florida: 561-964-4949 Outside Florida TOLL FREE: 877-690-3101

Need parts?

Click on this link: http://www.discount-equipment.com/category/5443-parts/ and

choose one of the options to help get the right parts and equipment you are looking

for. Please have the machine model and serial number available in order to help us

get you the correct parts. If you don’t find the part on the website or on once of the

online manuals, please fill out the request form and one of our experienced staff

members will get back to you with a quote for the right part that your machine needs.

We sell worldwide for the brands: Genie, Terex, JLG, MultiQuip, Mikasa, Essick, Whiteman,

Mayco, Toro Stone, Diamond Products, Generac Magnum, Airman, Haulotte, Barreto,

Power Blanket, Nifty Lift, Atlas Copco, Chicago Pneumatic, Allmand, Miller Curber, Skyjack,

Lull, Skytrak, Tsurumi, Husquvarna Target, , Stow, Wacker, Sakai, Mi-T- M, Sullair, Basic,

Dynapac, MBW, Weber, Bartell, Bennar Newman, Haulotte, Ditch Runner, Menegotti,

Morrison, Contec, Buddy, Crown, Edco, Wyco, Bomag, Laymor, Barreto, EZ Trench, Bil-

Jax, F.S. Curtis, Gehl Pavers, Heli, Honda, ICS/PowerGrit, IHI, Partner, Imer, Clipper, MMD,

Koshin, Rice, CH&E, General Equipment, ,AMida, Coleman, NAC, Gradall, Square Shooter,

Kent, Stanley, Tamco, Toku, Hatz, Kohler, Robin, Wisconsin, Northrock, Oztec, Toker TK,

Rol-Air, Small Line, Wanco, Yanmar

For Parts go to Discount-Equipment.com

For Parts go to Discount-Equipment.com

Foreword

BOMAG

3

BPR 30/38-3 / BPR 35/38-3

F oreword

The BOMAG - machines are products from the

wide range of BOMAG soil compaction ma-

chines. BOMAG's vast experience as well as

most up-to-date production and testing proce-

dures, such as lifetime tests of all important

components and highest quality demands,

guarantee maximum reliability of your ma-

chine.

Using this manual will

lhelp youto understand the machine.

lavoid malfunctions caused by faulty operation.

Refering to the maintenance instructions will

lincreasethe reliability of the machine on the

site,

lincreasethe service life of your machine,

lreducerepair costs and downtimes.

BOMAG shall not assume liability for safe func-

tioning of the machine

lif it is handled in a way which does not comply

with the usual modes of use,

lif it is used for purposes other than those men-

tioned in the instructions.

No warranty claims may be lodged in case of dam-

ages caused by

loperating mistakes,

linsufficient maintenance and

lwrong fuels and lubricants.

Please note!

This manual has been written to be used by oper-

ators and service personnel on the site.

You should only operate the machine if you are ful-

ly conversant with the contents of these instruc-

tions.

Please strictly observe the safety regulations.

Please observe also the guidelines of the civil en-

geneering liability association "Safety Rules for

the Operation of Road Rollers and soil Compac-

tors" and all relevant accident prevention instruc-

tions.

For your own safety you should only use

BOMAG spare parts.

We reserve the right for technical modifica-

tions without prior notification.

These operating and maintenance instructions are

also available in other languages.

You can also receive the spare parts catalogue

from your BOMAG dealer when giving the serial

number of your machine.

You can also obtain informations about the correct

use of our machines for soil- and asphalt compac-

tion from your BOMAG dealer.

The above mentioned notes do not constitute an

extension of the warranty and liability conditions

specified in the general terms of business of

BOMAG.

We wish you much success with your BOMAG

machine.

BOMAG GmbH

PrintedinGermany

Copyright by BOMAG

For Parts go to Discount-Equipment.com

Foreword

BOMAG

4

BPR 30/38-3 / BPR 35/38-3

Please fill in

............................

Machinetype(Fig.1)

............................

Serial No. (Fig. 1 and 2)

............................

Engine type (Fig. 3)

............................

Engine No. (Fig. 3)

i

Note

Fill in the above listed data when receiving the ma-

chine.

Upon receipt of the machine our organization will

instruct you about correct operation and mainte-

nance.

Please observe strictly all safety regulations and

notes on potential dangers!

Fig. 1

Fig. 2

Fig. 3

For Parts go to Discount-Equipment.com

Table of Contents

BOMAG

5

BPR 30/38-3 / BPR 35/38-3

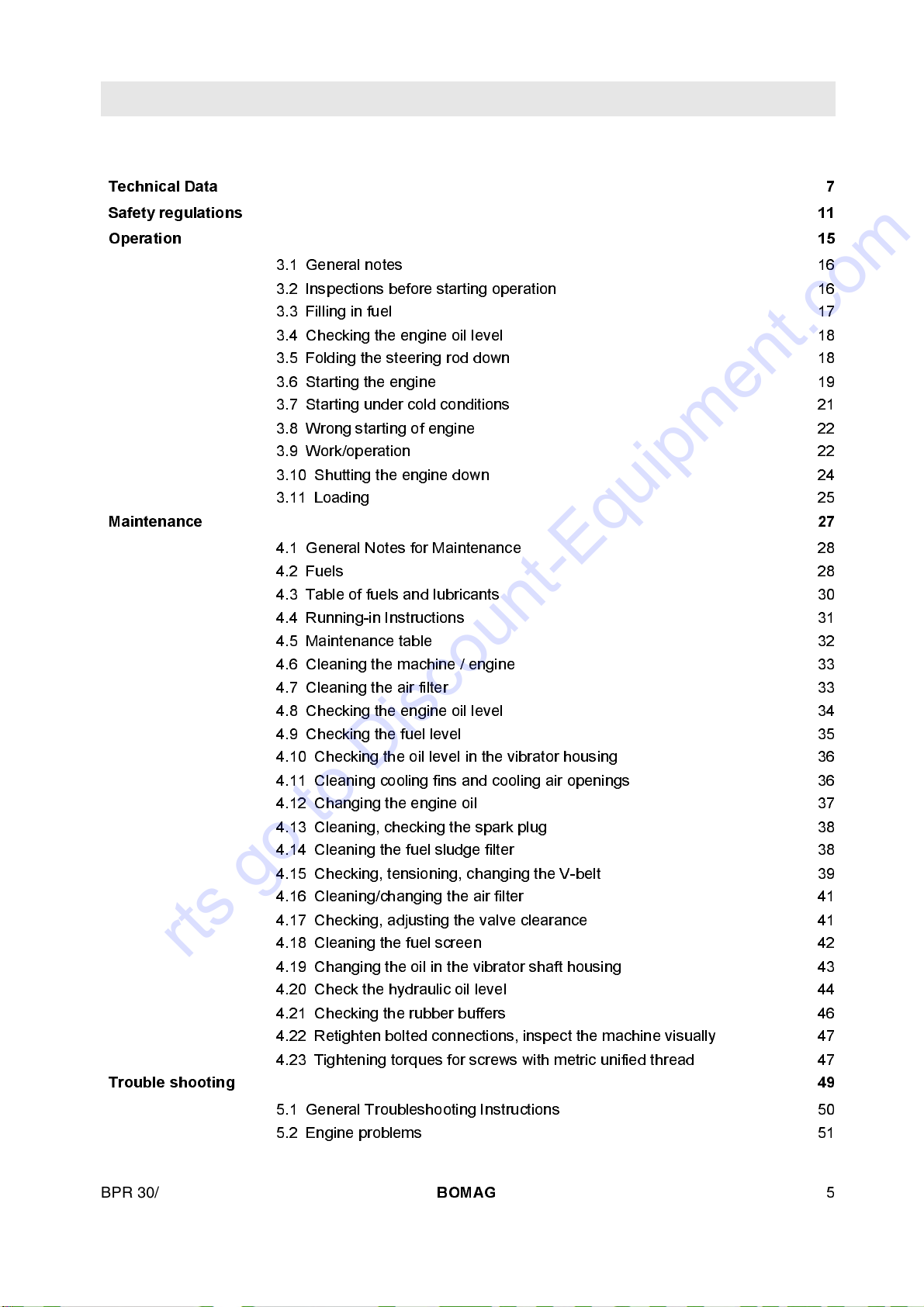

Technical Data 7

Safety regulations 11

Operation 15

3.1 General notes 16

3.2 Inspections before starting operation 16

3.3 Filling in fuel 17

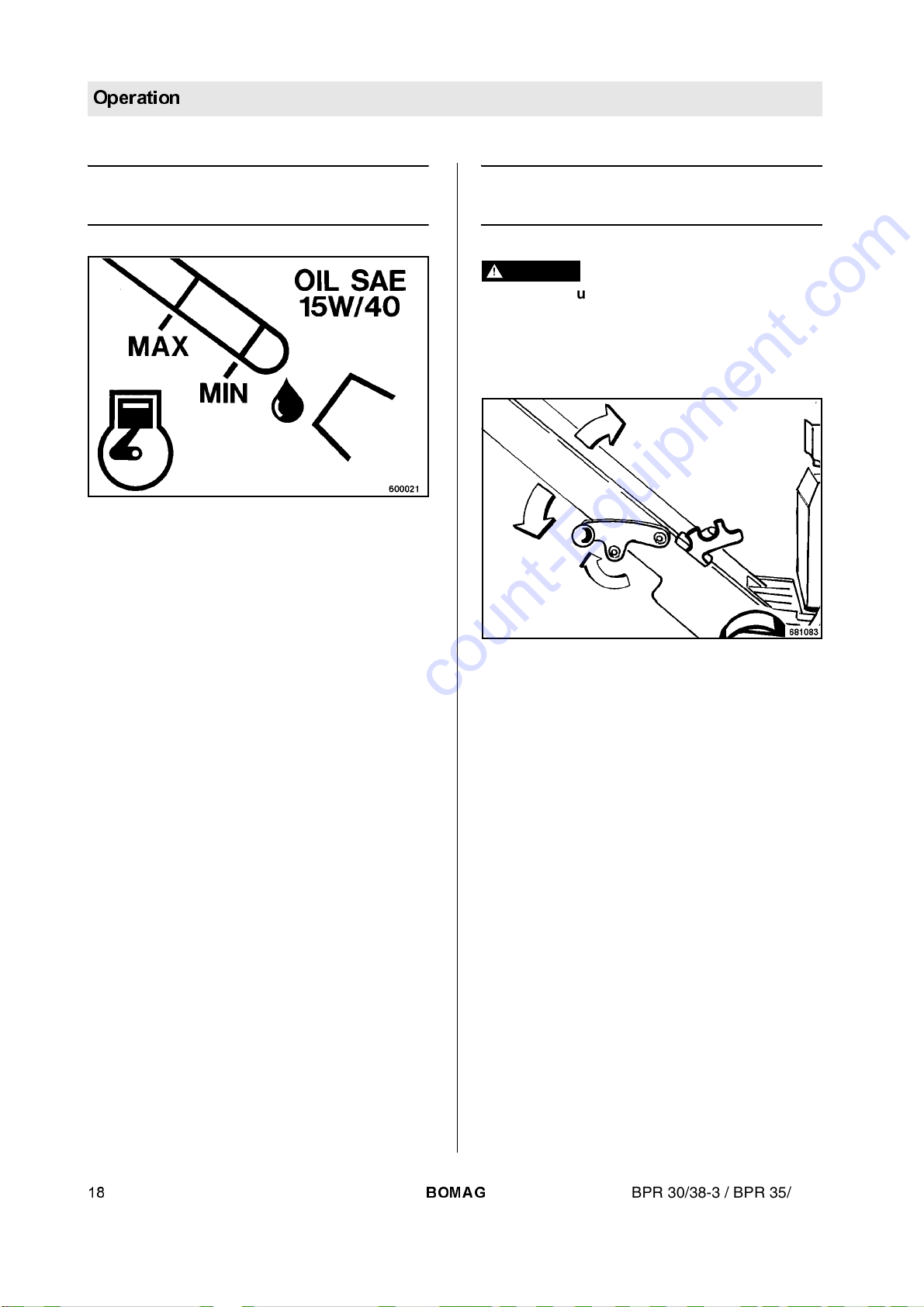

3.4 Checking the engine oil level 18

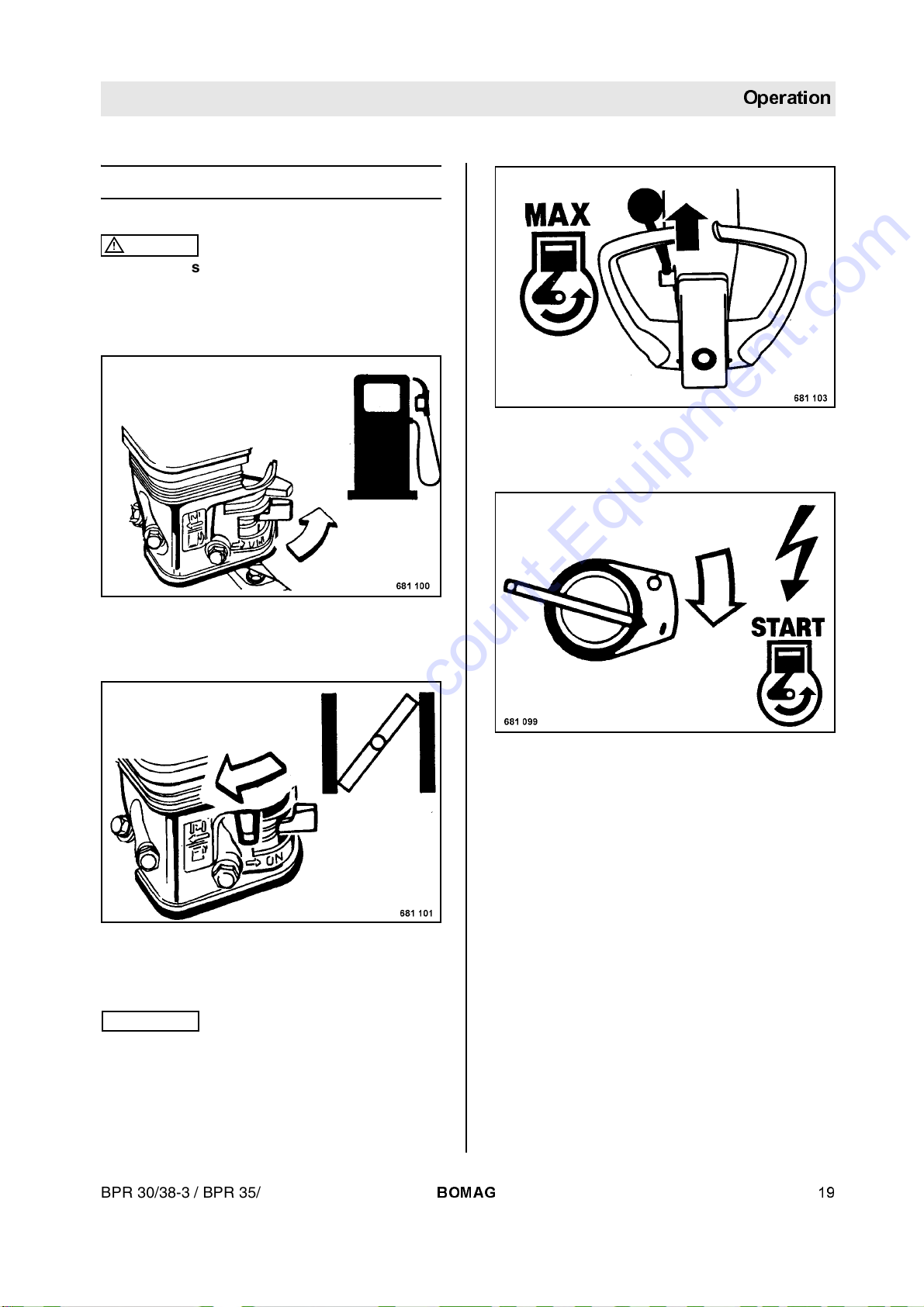

3.5 Folding the steering rod down 18

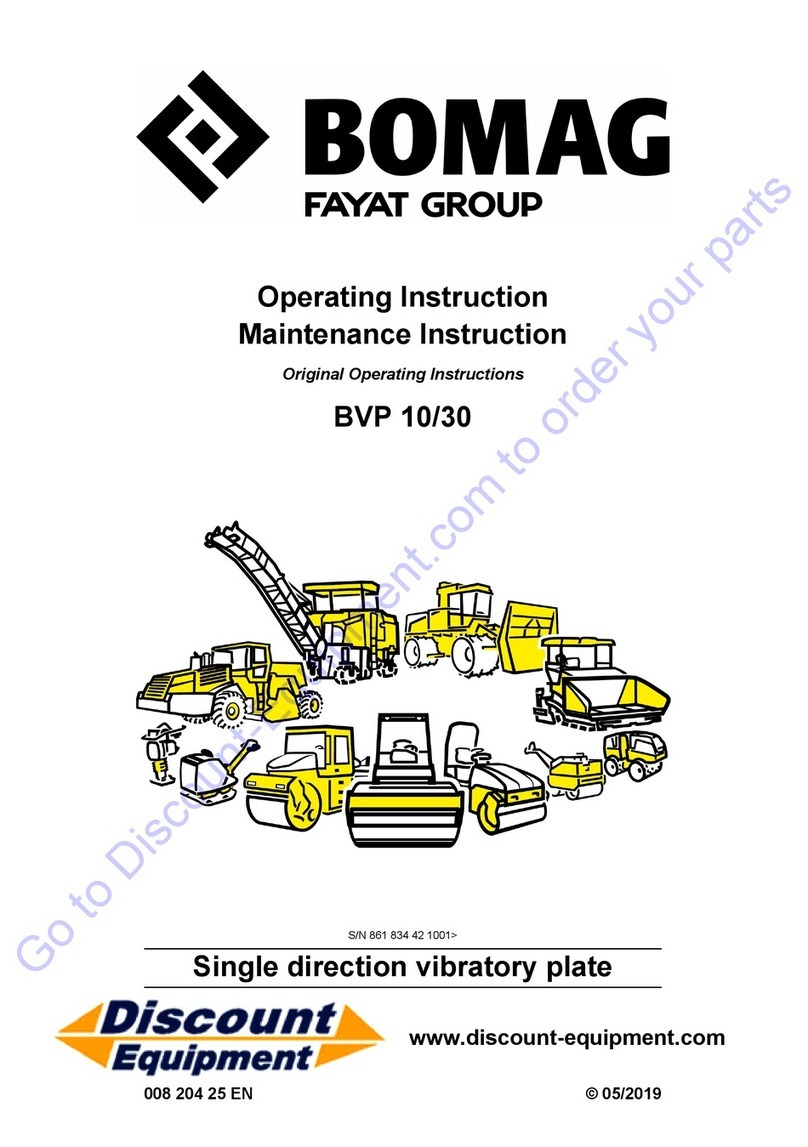

3.6 Starting the engine 19

3.7 Starting under cold conditions 21

3.8 Wrong starting of engine 22

3.9 Work/operation 22

3.10 Shutting the engine down 24

3.11 Loading 25

Maintenance 27

4.1 General Notes for Maintenance 28

4.2 Fuels 28

4.3 Table of fuels and lubricants 30

4.4 Running-in Instructions 31

4.5 Maintenance table 32

4.6 Cleaning the machine / engine 33

4.7 Cleaning the air filter 33

4.8 Checking the engine oil level 34

4.9 Checking the fuel level 35

4.10 Checking the oil level in the vibrator housing 36

4.11 Cleaning cooling fins and cooling air openings 36

4.12 Changing the engine oil 37

4.13 Cleaning, checking the spark plug 38

4.14 Cleaning the fuel sludge filter 38

4.15 Checking, tensioning, changing the V-belt 39

4.16 Cleaning/changing the air filter 41

4.17 Checking, adjusting the valve clearance 41

4.18 Cleaning the fuel screen 42

4.19 Changing the oil in the vibrator shaft housing 43

4.20 Check the hydraulic oil level 44

4.21 Checking the rubber buffers 46

4.22 Retighten bolted connections, inspect the machine visually 47

4.23 Tightening torques for screws with metric unified thread 47

Trouble shooting 49

5.1 General Troubleshooting Instructions 50

5.2 Engine problems 51

For Parts go to Discount-Equipment.com

Table of Contents

BOMAG

6

BPR 30/38-3 / BPR 35/38-3

For Parts go to Discount-Equipment.com

BOMAG

7

BPR 30/38-3 / BPR 35/38-3

1 Technical Data

For Parts go to Discount-Equipment.com

Technical Data

BOMAG

8

BPR 30/38-3 / BPR 35/38-3

Fig. 4

Dim. mm (inch) HH1 LL1 WW1 W2 W3

BPR 30/38-3 690 1070 1440 720 380 500 580 700

BPR 35/38-3 690 1070 1440 720 380 500 580 700

*BPR 30/38-3 BPR 35/38-3

Weights

Basic weight kg 198 198

Operating weight (CECE) kg 210 210

Operating weight (CECE)

with extension plates

kg 215 215

Drive

Engine manufacturer Honda Honda

Type GX160 GX160

Cooling air air

Working cycles 4 4

Number of cylinders 1 1

Rated power ISO 9249 kW (PS) 4 (5,4) 4 (5,4)

Rated speed rpm 3600 3600

Starting device Recoil starter Recoil starter

Fuel Standard gasoline Standard gasoline

Fuel tank capacity l 4 4

For Parts go to Discount-Equipment.com

Technical Data

BOMAG

9

BPR 30/38-3 / BPR 35/38-3

Drive system mechanical mechanical

Working speed m/min 0...22 0...22

max. gradability % 30 30

Vibration system

Frequency Hz 75 89

Amplitude mm 1,1 0,8

* Technical modifications reserved

*BPR 30/38-3 BPR 35/38-3

For Parts go to Discount-Equipment.com

Technical Data

BOMAG

10

BPR 30/38-3 / BPR 35/38-3

The following noise and vibration data acc. to

- EC Machine Regulation edition 98/37/EC and

- the noise regulation 2000/14/EC, noise protection guideline 2003/10/EC

- Vibration Protection Regulation 2002/44/EC

were determined during conditions typical for this type of equipment and by application of harmo-

nized standards.

During operation these values may vary because of the existing operating conditions.

Noise value

sound pressure level on the operator’s stand:

LpA = 91 dB(A), determined acc. to ISO 11204 and EN 500

Garanteed sound capacity level:

LWA = 105 dB(A), determined acc. to ISO 3744 and EN 500

!

Danger

Loss of hearing!

Wear your personal noise protection means (ear defenders) before starting operation.

Vibration value

Hand-arm vibration:

Vector total of the weighted effective acceleration in three orthogonal directions:

Weighted total vibration value

ahw = 11.6 m/sec2on crushed rock determined acc. to ISO 5349 and EN 500

!

Caution

Observe the daily vibration load (Industrial safety acc. to 2002/44/EC).

For Parts go to Discount-Equipment.com

BOMAG

11

BPR 30/38-3 / BPR 35/38-3

2 Safety regulations

For Parts go to Discount-Equipment.com

Safety regulations

BOMAG

12

BPR 30/38-3 / BPR 35/38-3

General

This BOMAG machine is built in accordance

with the latest technical standard and the valid

technical rules and regulations. There is, how-

ever, a risk of danger for persons and property

if:

lthe machine is used for purposes other than

those it is intended for

lthe machine is operated by untrained person-

nel

lthe machine is modified or converted in an un-

professional way

lthe applicable safety regulations are not ob-

served.

Each person involved in operation, mainte-

nance and repair of the machine must there-

fore read and apply these safety regulations.

This should be confirmed by obtaining the sig-

natures of the customer, if necessary.

Furthermore the following regulations and instruc-

tions are obviously also valid:

lapplicable accident prevention instructions

lgenerally acknowledged safety and road traffic

regulations

lcountry specific safety regulations. It is the

duty of the operator to know and observe

these regulations. This applies also for local

regulations and the regulations for various

types of manual work. If the recommendations

in this manual differ from the regulations valid

in your country, you must strictly observe the

regulations in your country.

Intended use

This machine must only be used for:

lthe compaction of all types of soil

lrepair work on all types of soil

lenforcement of paths and walkways

lwork in trenches

lbackfills and compaction of hard shoulders

lHave the machine inspected by an expert

once every year.

Unintended use

However, dangers may arise from this machine if

it is operated by untrained personnel or if it is sub-

ject of unintended use.

Who has permission to operate the ma-

chine?

Only trained and instructed persons of at least 18

years of age are permitted to drive and operate

this machine. For operation of the machine the re-

sponsibilities must be clearly specified and com-

plied with.

Persons under the influence of alcohol, medicine

or drugs are not allowed to operate, service or re-

pair the machine.

Maintenance and repair work requires specific

knowledge and must therefore only be performed

by trained specialists.

Conversions and alterations to the ma-

chine

Unauthorized conversions to the machine are pro-

hibited for safety reasons.

Original parts and accessories have been special-

ly designed for this machine. We wish to make ex-

pressly clear that we have not tested or authorized

any original parts or special equipment not sup-

plied by us. The installation and/or use of such

products can impair the active and/or passive driv-

ing safety. The manufacturer expressly excludes

any liability for damage resulting from the use of

non-original parts or accessories.

Safety notes in the operating and main-

tenance instructions:

!

Danger

Sections marked like this highlight possible

dangers for persons.

!

Caution

Sections marked like this highlight possible

dangers for the amchine or parts of the ma-

chine

For Parts go to Discount-Equipment.com

Safety regulations

BOMAG

13

BPR 30/38-3 / BPR 35/38-3

i

Note

Sections marked like this contain technical infor-

mation concerning the optimal economical use of

the machine.

Environment

Sections marked like this highlight activities

for the safe and environmental disposal of fu-

els, lubricants and exchanged parts.

Observeallregulationsfortheprotectionof

the environment.

Safety stickers on the machine

Do not destroy safety stickers (see spare parts

list), keep them legible and observe their meaning.

Replace damaged or illegible safety stickers.

Loading the machine

Secure the machine against tipping or slipping off.

Persons are highly endangered when

lstepping under loads being lifted or

lstanding under loads being lifted.

Secure the machine on the transport vehicle

against rolling, slipping and turning over.

Starting the machine

Before starting

Become acquainted with the equipment, the con-

trol elements, the working principle of the machine

and the working area.

Wear your personal protective outfit (hard hat,

safety boots, etc.). Wear ear defenders.

Before starting the machine check whether:

lthe machine shows any obvious faults

lall guards and safety elements are in place

lthe control elements are fully functional

lthe machine is free of oily and combustible

material

lall handles are free of grease, oils, fuel, dirt,

snow and ice.

Use only machines which are serviced at regular

intervals.

For starting move your feet out of the danger zone

of the base plate.

Starting in closed rooms

Exhaust gases are highly dangerous! Always en-

sure an adequate supply of fresh air when starting

in closed rooms!

Operation

The machine must only be operated with the steer-

ing rod folded down.

Guide the machine so that you to not hit your

hands against any hard obstacles. Danger of inju-

ry!

Stop the machine if you notice unusual noises and

the development of smoke, detect the cause and

have the fault corrected.

Operate the machine only at full engine speed, as

otherwise the centrifugal clutch will be damaged.

Never let the machine run unattented.

Parking the machine

If possible park the machine on level and firm

ground.

Before leaving the machine:

lsecure the machine against turning over,

lshut the engine down.

Mark parked machines, which could be in the way,

with noticeable means.

Refueling

Refuel only with the engine shut down.

Do not refuel in closed rooms.

Do not use open fire, do not smoke.

Do not spill any fuel. Catch running out fuel, do not

let it seep into the ground.

Do not inhale any fuel fumes.

Maintenance work

Maintenance work must only be performed by

qualified and authorized persons.

Keep unauthorized persons away from the ma-

chine.

Do not perform maintenance work on a running

engine.

For Parts go to Discount-Equipment.com

Safety regulations

BOMAG

14

BPR 30/38-3 / BPR 35/38-3

Park the machine on level and firm ground.

Working on the engine

Drain the engine oil at operating temperature -

danger of scalding!

Wipe off spilled oil, catch running out oil and dis-

pose of environmentally.

Store used filters and other oil contaminated ma-

terials in a separate, specially marked container

and dispose of environmentally.

Working on the fuel system

No open fire, do not smoke, do not spill any fuel.

Catch running out fuel, do not let it seep into the

ground and dispose of environmentally.

Cleaning work

Do not clean the machine while the engine is run-

ning.

Do not use gasoline or other inflammable sub-

stances for cleaning.

When using a steam cleaner for cleaning do not

subject electrical parts and insulation material to

the direct jet or cover these items beforehand.

Do not guide the water jet directly into the air filter

and into the air intake.

After maintenance work

After completion of maintenance work reinstall all

guards and safety features.

Repair

Repairs must only be carried out by qualified and

authorized personnel and by following our repair

instructions.

Exhaust gases are highly dangerous! Always en-

sure an adequate supply of fresh air when starting

the engine indoors!

Always mark defective machines by attaching a

sign to the steering rod.

For Parts go to Discount-Equipment.com

BOMAG

15

BPR 30/38-3 / BPR 35/38-3

3Operation

For Parts go to Discount-Equipment.com

Operation

BOMAG

16

BPR 30/38-3 / BPR 35/38-3

3.1 General notes

Please read section 3 Indicators and Control Ele-

ments thoroughly before operating the machine if

you are not yet fully familiar with the indicators and

control elements of the machine.

All indicators and control elements are described

in detail in this chapter.

3.2 Inspections before starting

operation

The following inspections must be carried out

before each working day or before a longer

working period.

i

Note

The running-in period for the vibratory plate is 20

operating hours.

lFill the fuel tank.

lCheck fuel tank and fuel lines for leaks.

lCheck the condition of the entire machine.

For Parts go to Discount-Equipment.com

Operation

BOMAG

17

BPR 30/38-3 / BPR 35/38-3

3.3 Filling in fuel

!

Danger

Refuel only with the engine shut down and the

fuel cock valve closed.

Do not spill any fuel!

No open fire, do not smoke!

lRun the engine only on standard grade gaso-

line (DIN 51600) and/or unleaded standard

grade gasoline (DIN 51607).

lUse a fuel screen when filling from a spare fuel

drum.

Fig. 5

i

Note

During refuelling the fuel cock valve (Fig. 5) must

be closed.

lClean the area around the fuel filler cap, un-

screw the filler cap.

Fig. 6

lFill in fuel (Fig. 6). Tank capacity max. 4 l.

lClose the filler cap again tightly after refuelling.

For Parts go to Discount-Equipment.com

Operation

BOMAG

18

BPR 30/38-3 / BPR 35/38-3

3.4 Checking the engine oil lev-

el

Fig. 7

lPark the machine on level ground so that the

engine is in horizontal position.

lCheck engine oil level, correct if necessary.

lThe oil level must reach up to the bottom edge

of the filler opening (Fig. 7).

3.5 Folding the steering rod

down

!

Danger

Danger of injury!

Shockbyspringforce!

The steering rod is elastically suspended in

operating position.

Fig. 8

lPush locking lever (Fig. 8) up and fold the rod

down, so that steering rod can swing freely.

For Parts go to Discount-Equipment.com

Operation

BOMAG

19

BPR 30/38-3 / BPR 35/38-3

3.6 Starting the engine

!

Caution

The engine is equipped with a low oil level

safety feature. If the oil level is too low, the en-

gine cannot be started or it goes out during op-

eration.

Fig. 9

lOpen the fuel cock valve (Fig. 9) completely by

turningindirectionofarrow.

Fig. 10

lClose the choke (Fig. 10) completely by shift-

ing the lever in direction of arrow.

i

Note

Do NOT operate the choke lever when the engine

is warm or at high ambient temperatures.

Also operation position.

Fig. 11

lShift the throttle lever (Fig. 11) to position

"MAX".

Fig. 12

lTurn ignition switch 1 (Fig. 12) to position

"ON".

For Parts go to Discount-Equipment.com

This manual suits for next models

1

Table of contents

Other Bomag Power Tools manuals

Bomag

Bomag BT 60/4 Instructions for use

Bomag

Bomag BPR 45/55 D User manual

Bomag

Bomag BVP 10/30 User manual

Bomag

Bomag BPH 80/65 Instructions for use

Bomag

Bomag BPR 35/42 D Instructions for use

Bomag

Bomag BPR 25/40 D Manual

Bomag

Bomag BPR 25/32 User manual

Bomag

Bomag BPR 70/70 D Manual

Bomag

Bomag BPR 50 User manual