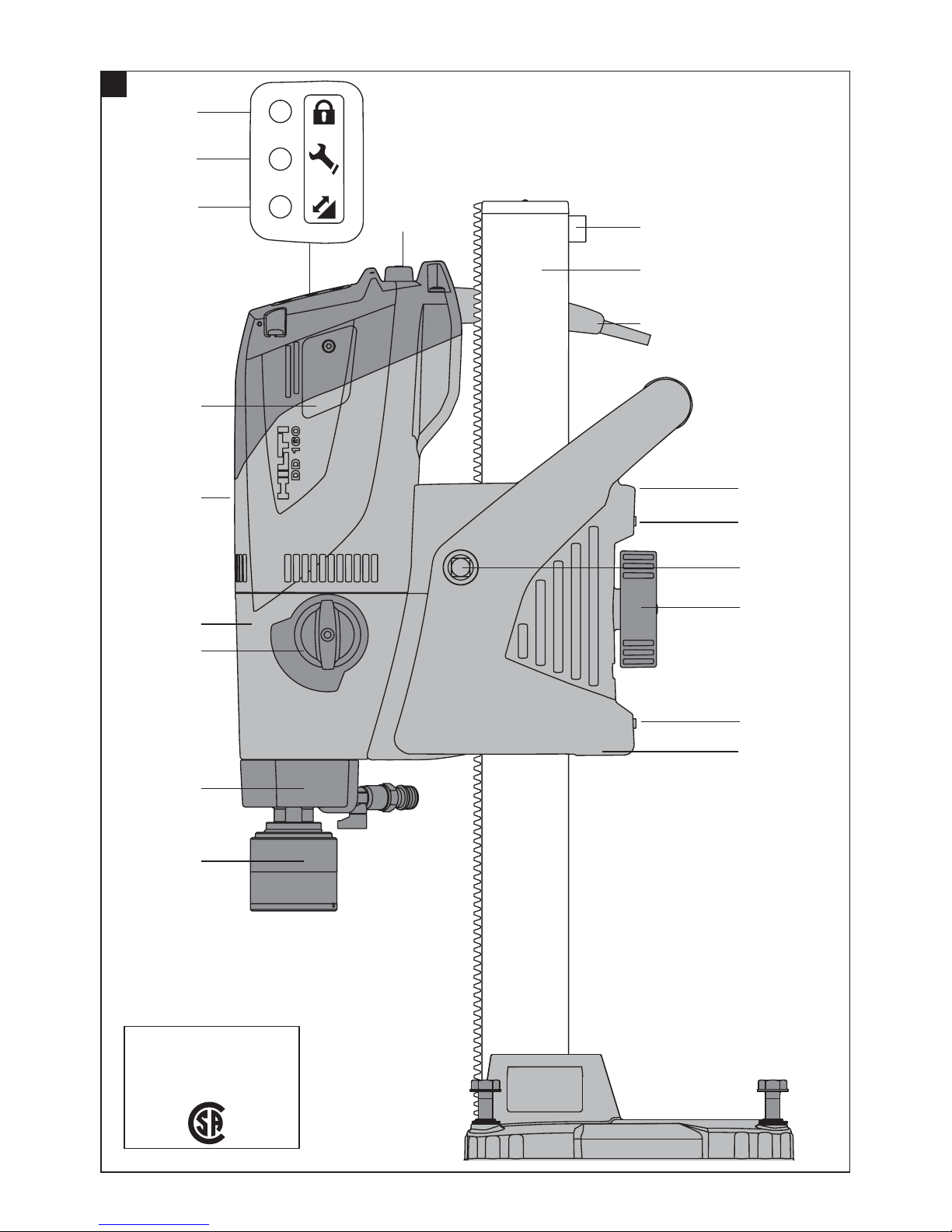

2 Description

2.1 Use of the product as directed

The DD 160 is an electrically-powered, rig-type diamond core drilling machine for drilling through-holes and blind

holes in (reinforced) mineral materials using diamond core bits and the wet drilling technique (hand-held use is not

permissible).

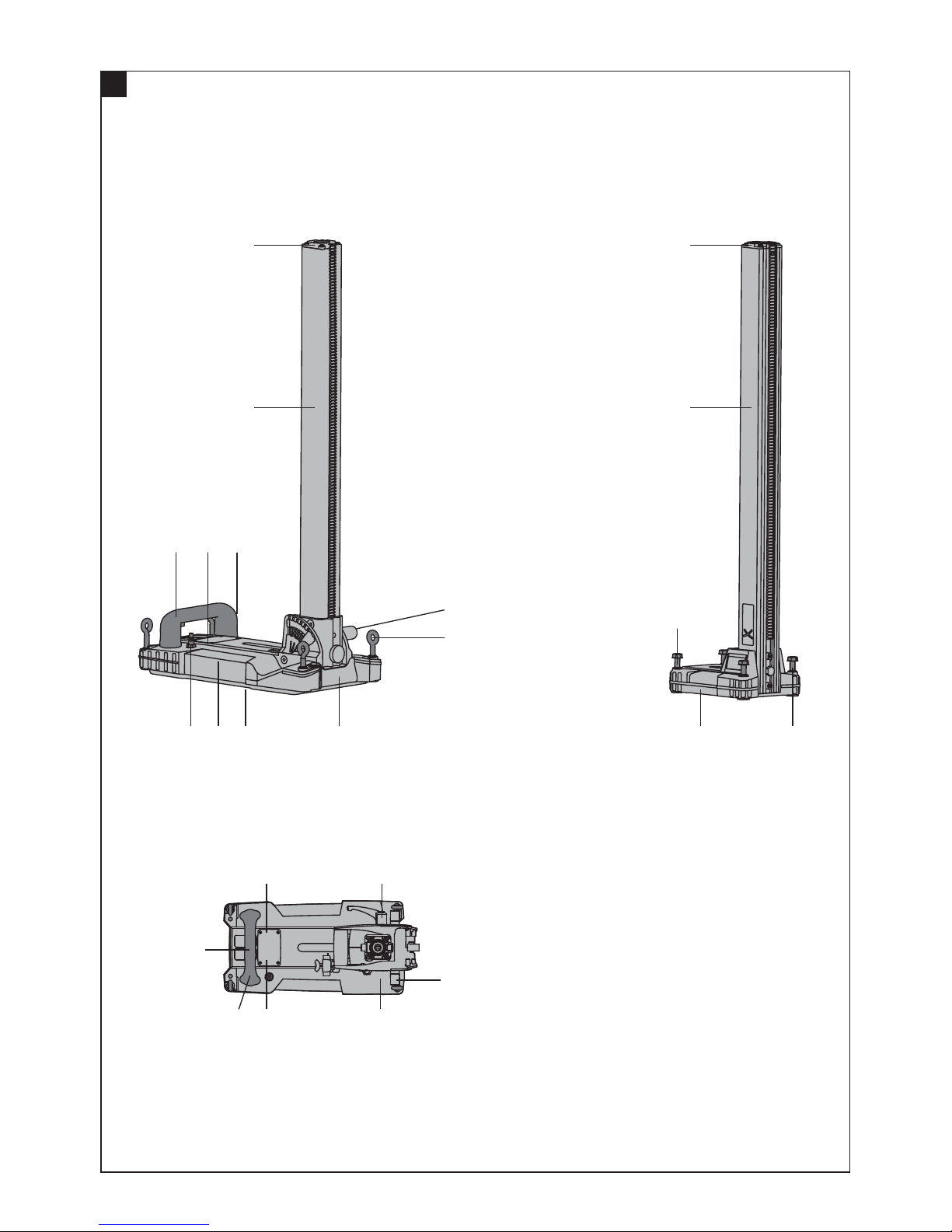

The machine must be adequately secured to the working surface with an anchor or vacuum base plate before use.

To avoid injury, use only genuine Hilti core bits and DD 160 accessories.

Observe the safety rules and operating instructions for the accessories used.

Observe the information printed in the operating instructions concerning operation, care and maintenance.

Nationally applicable industrial safety regulations must be observed.

The machine, accessories and cutting tools may present hazards when handled incorrectly by untrained personnel or

when used not as directed.

Use of the water collection system in conjunction with a wet-type industrial vacuum cleaner is a mandatory requirement

for working overhead.

An additional means of securing the drill stand must be employed when the machine is secured with the vacuum base

plate (accessory) for horizontal drilling.

Do not strike the base plate with a hammer or other heavy object when making adjustments to it.

Tampering with or modification of the machine, drill stand and accessoriesisstrictlyprohibited.

WARNING

The machine may be operated only when connected to an adequately-rated electric supply equipped with an

earth (ground) conductor.

WARNING

Drilling into materials hazardous to the health (e.g. asbestos) is not permissible.

DANGER

Use only the genuine Hilti accessories or ancillary equipment listed in the operating instructions. Use of

accessories or ancillary equipment not listed in the operating instructions may present a risk of personal injury.

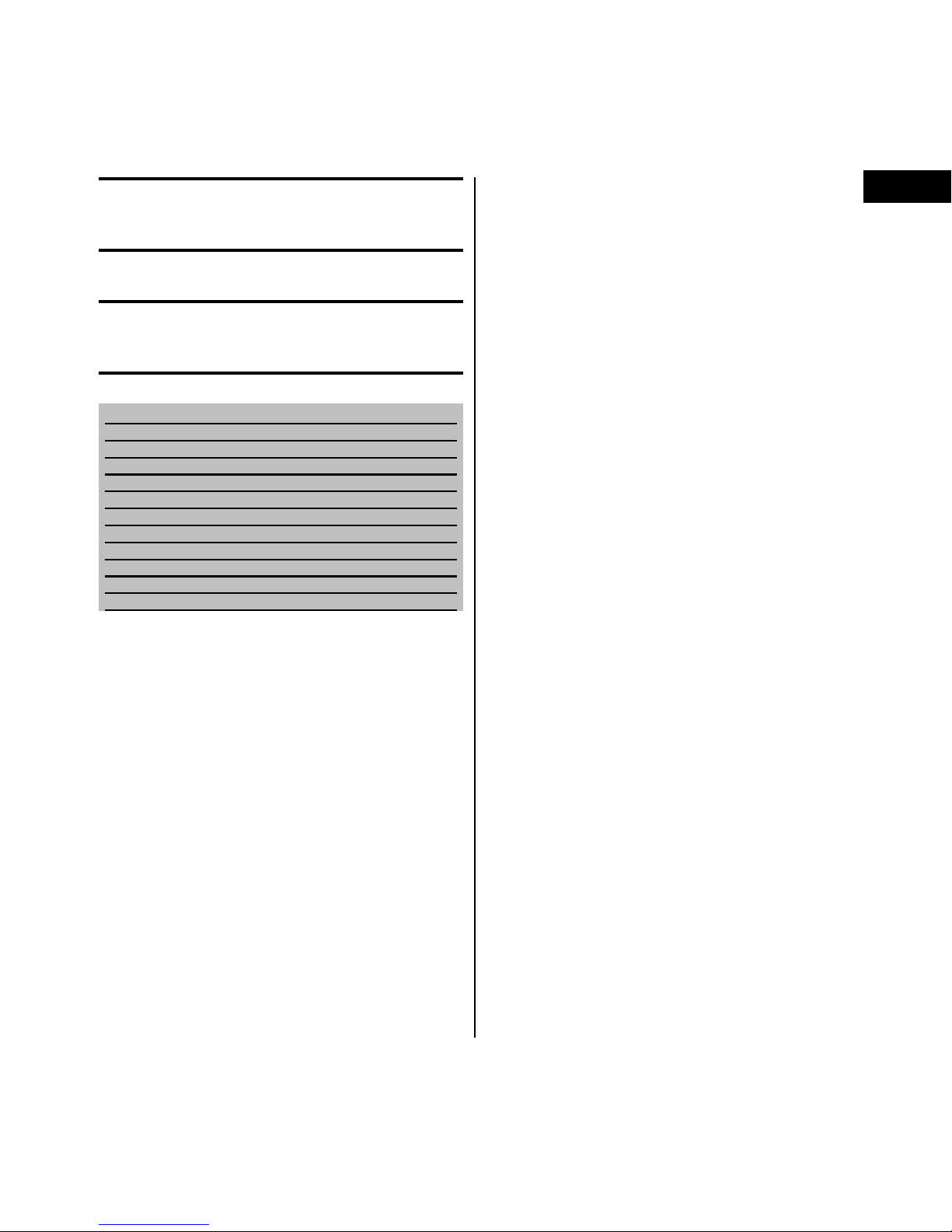

2.2 Use of the machine with various items of equipment

Equipment Core bit diameters Drilling direction

Without water collection system and wet-type

industrial vacuum cleaner

25…202 mm (1" to 8") Not upwards

With water collection system 25…162 mm (1" to 6¼") Not upwards

With water collection system and wet-type in-

dustrial vacuum cleaner

25…162 mm (1" to 6¼") All directions

2.3 Gears and corresponding core bit diameters

Gear Core bit diameters

(mm)

Core bit diameters

(inches) No-load speed /min

1 152…202 6…8 420

2 72…142 2³⁄₄…5¹⁄₂ 700

3 25…67 1…2¹⁄₂ 1,570

en

4

Printed: 08.07.2013 | Doc-Nr: PUB / 5069572 / 000 / 03