Bomag BPR 25/40 D Manual

Operating instructions

Maintenance instructions

Catalogue number

%35'

S/N 101 730 15 ....

9LEUDWRU\SODWH

www.discount-equipment.com

Go to Discount-Equipment.com to order your parts

Discount-Equipment.com is your online resource for quality parts & equipment.

Florida: 561-964-4949 Outside Florida TOLL FREE: 877-690-3101

Need parts?

Click on this link: http://www.discount-equipment.com/category/5443-parts/ and

choose one of the options to help get the right parts and equipment you are looking

for. Please have the machine model and serial number available in order to help us

get you the correct parts. If you don’t find the part on the website or on one of the

online manuals, please fill out the request form and one of our experienced staff

members will get back to you with a quote for the right part that your machine needs.

We sell worldwide for the brands: Genie, Terex, JLG, MultiQuip, Mikasa, Essick, Whiteman,

Mayco, Toro Stone, Diamond Products, Generac Magnum, Airman, Haulotte, Barreto,

Power Blanket, Nifty Lift, Atlas Copco, Chicago Pneumatic, Allmand, Miller Curber, Skyjack,

Lull, Skytrak, Tsurumi, Husquvarna Target, Stow, Wacker, Sakai, Mi-T-M, Sullair, Basic,

Dynapac, MBW, Weber, Bartell, Bennar Newman, Haulotte, Ditch Runner, Menegotti,

Morrison, Contec, Buddy, Crown, Edco, Wyco, Bomag, Laymor, EZ Trench, Bil-Jax, F.S.

Curtis, Gehl Pavers, Heli, Honda, ICS/PowerGrit, IHI, Partner, Imer, Clipper, MMD, Koshin,

Rice, CH&E, General Equipment ,Amida, Coleman, NAC, Gradall, Square Shooter, Kent,

Stanley, Tamco, Toku, Hatz, Kohler, Robin, Wisconsin, Northrock, Oztec, Toker TK, Rol-Air,

APT, Wylie, Ingersoll Rand / Doosan, Innovatech, Con X, Ammann, Mecalac, Makinex, Smith

Surface Prep,Small Line, Wanco, Yanmar

Go to Discount-Equipment.com to order your parts

Go to Discount-Equipment.com to order your parts

Go to Discount-Equipment.com to order your parts

)RUHZRUG

%20$*

5BPR 25/40 D

Foreword

These BOMAG - machines are products from

the wide product range of BOMAG compaction

equipment. BOMAG’s vast experience, cou-

pled with the most modern production and

testing methods, such as lifetime tests of all

important components and highest quality de-

mands, ensure highest reliability of your ma-

chine.

Using these instructions will

●help you to become acquainted with the ma-

chine.

●avoid faults caused by unprofessional opera-

tion.

Observing the maintenance instructions will

●increase the reliability of the machine during

use on site,

●prolong the lifetime of the machine,

●reduce repair costs and downtime.

BOMAG does not assume liability for the function

of the machine

●if the machine is handled in a way, which does

not comply with the use it is intended for,

●if it is used for purposes other then the ones

mentioned in these instructions.

No warranty claims can be lodged for damage re-

sulting from

●operating errors,

●insufficient maintenance and

●the use of wrong fuels and lubricants.

Please note!

This manual was written for operators and mainte-

nance personnel on construction sites.

You should only operate the machine after you

have been instructed to do so and by following

these instructions.

Please observe strictly the safety regulations.

Please observe also the guidelines of the civil en-

gineering liability association "safety rules for the

operation of road rollers and soil compaction

equipment", as well as the applicable instructions

for the prevention of accidents.

For your own safety you should only use gen-

uine BOMAG spare parts.

To comply with the technical development we

reserve the right of modifications without prior

notification.

Theseoperatingandmaintenance instructions are

also available in other languages.

In addition you can obtain a spare parts catalogue

from your BOMAG dealer by just stating the serial

number of your machine.

Information for the correct use of our machines in

earth and asphalt construction is also available

from your BOMAG-dealer.

The notes mentioned above do not constitute an

extension of the warranty and liability conditions,

which are part of the general terms of business of

BOMAG.

We wish you much success with your BOMAG

machine.

BOMAG GmbH & Co. OHG

Printed in Germany

Copyright by BOMAG

Go to Discount-Equipment.com to order your parts

)RUHZRUG

%20$*

6BPR 25/40 D

Please fill in

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Machine type (Fig. 1)

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial No. (Fig. 1 and 2)

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine type (Fig. 3)

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine No. (Fig. 3)

L

Note

Fill in the above listed data when receiving the ma-

chine.

Upon receipt of the machine our organization will

instruct you about correct operation and mainte-

nance.

Please observe strictly all safety regulations and

notes on potential dangers!

Fig. 1

Fig. 2

Fig. 3

Go to Discount-Equipment.com to order your parts

Table of Contents

%20$*

7BPR 25/40 D

7HFKQLFDO'DWD

6DIHW\UHJXODWLRQV

2SHUDWLRQ

3.1 General notes 18

3.2 Before starting work 18

3.3 Folding the steering rod down 19

3.4 Starting with recoil starter 19

3.5 Work/operation 21

3.6 Shutting the engine down 22

3.7 Loading 23

0DLQWHQDQFH

4.1 General notes on maintenance 26

4.2 Fuels and lubricants 27

4.3 Table of fuels and lubricants 29

4.4 Running-in instructions 30

4.5 Maintenance chart 31

4.6 Cleaning machine/engine 32

4.7 Checking the fuel level 32

4.8 Checking the engine oil level 33

4.9 Checking the air filter, cleaning if necessary 34

4.10 Checking the oil level in the vibrator housing 36

4.11 Changing the engine oil 36

4.12 Cleaning the engine oil filter 37

4.13 Checking, tensioning, changing the V-belt 38

4.14 Checking, adjusting the valve clearance 39

4.15 Cleaning cooling fins and cooling air intake opening 40

4.16 Cleaning the exhaust screen 41

4.17 Changing the dry air filter 42

4.18 Changing the fuel filter 43

4.19 Changing the oil in the vibrator housing 43

4.20 Checking the rubber buffers 44

4.21 Drawing the water out of the fuel tank 44

4.22 Retightening the bolted connections 45

7URXEOHVKRRWLQJ

5.1 General notes 48

5.2 Replacing the injection pump 49

5.3 Engine faults 53

Go to Discount-Equipment.com to order your parts

%20$*

9BPR 25/40 D

1 Technical Data

Go to Discount-Equipment.com to order your parts

7HFKQLFDO'DWD

%20$*

10 BPR 25/40 D

Fig. 4

*BPR 25/40 D

Dimensions

(L) Overall length mm (inch) 1440 (56.69)

(L1) Length with base

plate mm (inch) 760 (29.92)

(W) Overall width mm (inch) 400 (15.74)

(H)Lowestpassingheight mm (inch) 685 (26.97)

(H1) Max. height with

steering rod in upright po-

sition

mm (inch) 1070 (42.13)

Weights

Basic weight kg (lbs) 148 (326.27)

Operating weight (CECE) kg (lbs) 149 (328.48)

Go to Discount-Equipment.com to order your parts

7HFKQLFDO'DWD

%20$*

11BPR 25/40 D

Drive

Engine manufacturer Hatz

Type 1B20

Cooling air

Working cycles 4

Number of cylinders 1

Rated power ISO 9249 kW (PS) 3,1 (4,2)

Rated speed rpm 3000

Starting device recoil starter

Fuel diesel

Fuel tank capacity l (USgal) 3 (0.79)

Drive system mechanical (V-belt)

Working speed m/min 0...20

max. gradability % 30

Vibration system

Frequency Hz 78

Amplitude mm (inch) 1,05 (0,041)

* Technical modifications reserved

*BPR 25/40 D

Go to Discount-Equipment.com to order your parts

7HFKQLFDO'DWD

%20$*

12 BPR 25/40 D

The following noise and vibration data according to the EC-machine regulation, edition (93/68/EWG)

were determined at operating conditions, which are typical for the machine, with vibration and over

a pre-determined travel distance (DIN 45635).

During operation these values may vary because of the existing operating conditions.

Noise values

The noise measured according to enclosure 1, paragraph 1.7.4. f of the EC-machine regulation is for the

sound pressure level at the operator’s place:

LpA = 96,0

sound capacity level:

LpA = 106,6

These noise values were determined according to ISO 6081 for the sound pressure level (LpA)and ISO 3744,

DIN 45635 for the sound capacity level (LWA).

Vibration values

The vibration data according to enclosure 1, paragraph 2. 2 or 3. 6. 3. a of the EC-machine regulation are:

Hand-arm vibration values

The weighted effective acceleration value according to ISO 8662 Part 1, DIN 45675, part 9 is

BPR 25/40 D = 4,5 m/sec2

Danger

Risk of hearing damage!

Go to Discount-Equipment.com to order your parts

%20$*

13BPR 25/40 D

2 Safety regulations

Go to Discount-Equipment.com to order your parts

6DIHW\UHJXODWLRQV

%20$*

14 BPR 25/40 D

General

This BOMAG machine is built in accordance

with the latest technical standard and the valid

technical rules and regulations. There is, how-

ever, a risk of danger for persons and property

if:

●the machine is used for purposes other than

those it is intended for

●the machine is operated by untrained person-

nel

●the machine is modified or converted in an un-

professional way

●the applicable safety regulations are not ob-

served.

Each person involved in operation, mainte-

nance and repair of the machine must there-

fore read and apply these safety regulations.

This should be confirmed by obtaining the sig-

natures of the customer, if necessary.

Furthermore the following regulations and instruc-

tions are obviously also valid:

●applicable accident prevention instructions

●generallyacknowledged safetyandroadtraffic

regulations

●country specific safety regulations. It is the

duty of the operator to know and observe

these regulations. This applies also for local

regulations and the regulations for various

types of manual work. If the recommendations

in this manual differ from the regulations valid

in your country, you must strictly observe the

regulations in your country.

Intended use

This machine must only be used for:

●compaction of all types of soil,

●repair work on all types of soil,

●reinforcement of pedestrian walkways,

●work in trenches,

●filling and compaction of hard shoulders.

●The machine should be checked by an expert

once every year.

Unintended use

Dangers may, however, arise from the machine if

it is used by untrained personnel in an unprofes-

sional way or if it is used for purposes other than

those mentioned in these instructions.

Who is allowed to work with the ma-

chine?

The machine must only be operated by trained

and authorized persons who are at least 18 years

of age. The responsibilities for the operation of the

machine must be clearly specified and complied

with.

Persons under the influence of alcohol, medica-

tion or drugs must not operate, service or repair

the machine.

Maintenance and repair tasks require specific

knowledge and must therefore only be carried out

by trained and qualified personnel.

Conversions and alterations to the ma-

chine

Unauthorized conversions to the machine are pro-

hibited for safety reasons.

Original parts and accessories have been special-

ly designed for this machine. We wish to make ex-

pressly clear that we have not tested or authorized

any original parts or special equipment not sup-

plied by us. The installation and/or use of such

products can impair the active and/or passive driv-

ing safety. The manufacturer expressly excludes

any liability for damage resulting from the use of

non-original parts or accessories.

Safety notes in the operating and main-

tenance instructions:

Danger

Paragraphs marked like this highlight possible

dangers for persons.

Caution

Paragraphs marked this way highlight possi-

ble dangers for machines or parts of the ma-

chines.

Go to Discount-Equipment.com to order your parts

6DIHW\UHJXODWLRQV

%20$*

15BPR 25/40 D

L

Note

Sections marked like this provide technical infor-

mation concerning the optimal economical use of

the machine.

Environment

Sections marked like this highlight activities

for the safe and environmental disposal of fu-

els and lubricants as well as replaced parts.

Safety stickers on the machine

Keep safety stickers in good condition and legible

and follow their meaning.

Replace damaged and illegible safety stickers.

Loading the machine

Secure the machine against turning over or slip-

ping off.

Persons are highly endangered if they

●step under loads being lifted or

●stand under loads being lifted

Secure the machine on the transport vehicle

against rolling off, slipping and turning over.

Starting the machine

Before starting

Become acquainted with the equipment, the con-

trol elements, the working mode of the machine

and the area you will be working in.

Use your personal protective outfit (hard hat, safe-

ty boots etc.). Wear ear defenders.

Check before starting, whether:

●the machine shows any obvious defects

●all protective devices are properly secured in

their place

●the control elements are fully functional

●themachineisfreeof any oilyandcombustible

material

●all handles are free of grease, oils, fuels, dirt,

snow and ice.

Use only machines which have been serviced at

regular intervals.

Do not use any starting aids such as Startpilot or

ether.

Starting in closed rooms

Exhaust fumes are life threatening! Always ensure

an adequate supply of fresh air when starting in

closed rooms!

Operation

Guide the machine in such a way, that your hands

stay clear of any solid obstructions, risk of injury.

Watch out for unusual noises and development of

smoke. Detect the cause and have the fault cor-

rected.

Operatethe vibratoryplateonlywithfullthrottle,as

otherwise the centrifugal clutch may be damaged.

Never let the machine run unattended.

Parking the machine

If possible, park the machine on level ground.

Before leaving the machine:

●Park the machine so, that it cannot turn over.

●Shut the engine down and pull the ignition key

out.

Always secure parked machines, which could be

in the way, with appropriate measures.

Filling the fuel tank

Refuel only with the engine shut down.

Do not refuel in closed rooms.

No open fire, do not smoke.

Do not spill any fuel. Catch running out fuel, do not

let it seep into the ground.

Maintenance

Maintenance work must only be carried out by

qualified and authorized personnel.

Keep unauthorized persons away from the ma-

chine.

Do not perform service work while the engine is

running.

If possible, park the machine on level and firm

ground.

Go to Discount-Equipment.com to order your parts

6DIHW\UHJXODWLRQV

%20$*

16 BPR 25/40 D

Working on the engine

Drain the engine oil at operating temperature -

danger of scalding!

Wipe off spilled oil, catch running out oil and dis-

pose of environmentally.

Storeusedfiltersandotheroilcontainingmaterials

in a specially marked container and dispose of en-

vironmentally.

Working on electric components

Before starting to work on electric components dis-

connect the battery and cover it with insulating ma-

terial.

Working on the battery

When working on the battery do not smoke, do not

use open fire.

Do not let skin and clothes come in contact with

acid.

In case of injuries caused by acid flush the respec-

tive parts with clear water and consult a doctor for

medical advice.

Do not place any tools on the battery, danger of

short circuit.

When recharging the battery remove all plugs to

avoid an accumulation of explosive gases.

Dispose of old batteries environmentally.

Working on the fuel system

No open fire, do not smoke, do not spill any fuel.

Catch running out fuel, do not let it seep into the

ground and dispose of environmentally.

Cleaning

Do not clean the machine while the engine is run-

ning.

Do not use gasoline or other combustible sub-

stances for cleaning purposes.

When using steam cleaning equipment do not

subjectelectricpartstothe direct waterjetorcover

it beforehand.

Do not guide the water jet directly into the air filter

and into the air intake opening.

After maintenance work

Reinstall all protective devices after completing

the maintenance work.

Repair

Repairs must only be performed by qualified and

authorized personnel. Use our repair instructions

for this purpose.

Exhaust gases are a threat to life! Always ensure

an adequate supply of fresh air when starting in

closed rooms!

Ifthe machine isdefective, attach a warning tag on

the steering handle.

Test

Depending on the type of applicational and the op-

erating conditions vibratory equipment has to be

examined by a specialist whenever required, but

at least once every year.

Go to Discount-Equipment.com to order your parts

%20$*

17BPR 25/40 D

3Operation

Go to Discount-Equipment.com to order your parts

2SHUDWLRQ

%20$*

18 BPR 25/40 D

3.1 General notes

Please read section 3 Indicators and Control Ele-

ments thoroughly before operating the machine if

you are not yet fully familiar with the indicators and

control elements of the machine.

All indicators and control elements are described

in detail in this chapter.

3.2 Before starting work

Please observe strictly the safety regulations

in chapter 2 of these operating and mainte-

nance instructions.

Refer also to the detailed description in the

chapter "Maintenance".

Top up missing fuels and lubricants according to

the respective maintenance instruction.

●Stand the machine on level ground.

●Check fuel tank and lines for leaks.

●Check the engine oil level, if necessary top up

to the upper mark.

●Check the fuel level, if necessary top up.

●Check the dry air filter maintenance indicator.

●Check the condition of the entire machine and

check the screw connections for tight fit.

Danger

Loss of hearing!

Wear your personal noise protection equip-

ment (ear defenders) before starting operation.

Go to Discount-Equipment.com to order your parts

2SHUDWLRQ

%20$*

19BPR 25/40 D

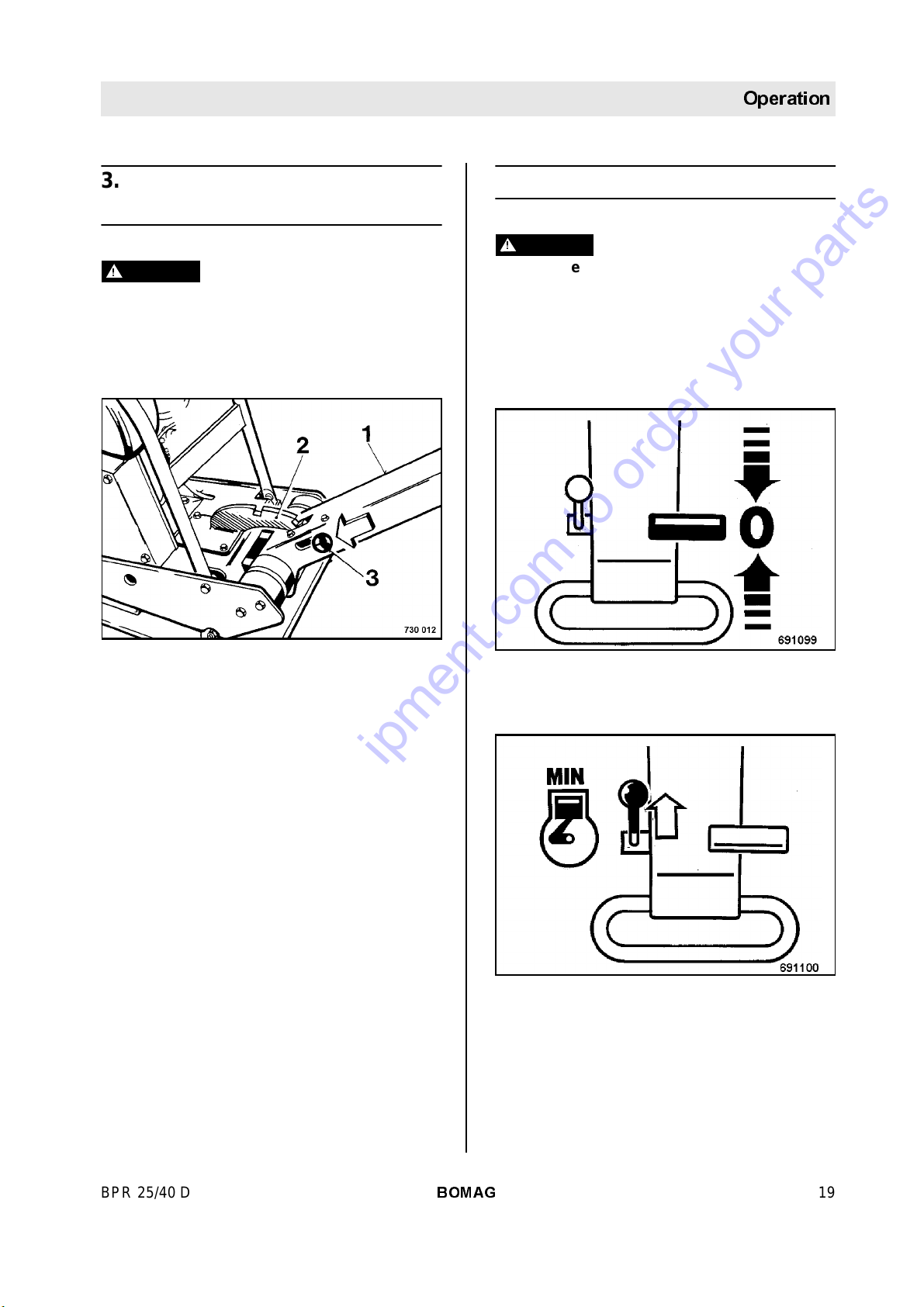

3.3 Folding the steering rod

down

Danger

Danger of injury!

Impact caused by spring force!

The steering rod is resilient in operating posi-

tion.

Fig. 5

●Press the locking lever 3 (Fig. 5) in direction

ofarrowandfoldthesteering rod down, sothat

it can move freely.

3.4 Starting with recoil starter

Danger

Danger of explosion!

Do not use any starting aid sprays.

Before starting make sure that no persons are

in the danger zone around the engine or the

machine and that all guards and safety instal-

lations are in place.

Fig. 6

●Set the travel lever (reversing lever) (Fig. 6) to

position "0".

Fig. 7

●Shiftthethrottlelever(Fig.7)toposition"MIN."

(idle speed).

Go to Discount-Equipment.com to order your parts

2SHUDWLRQ

%20$*

20 BPR 25/40 D

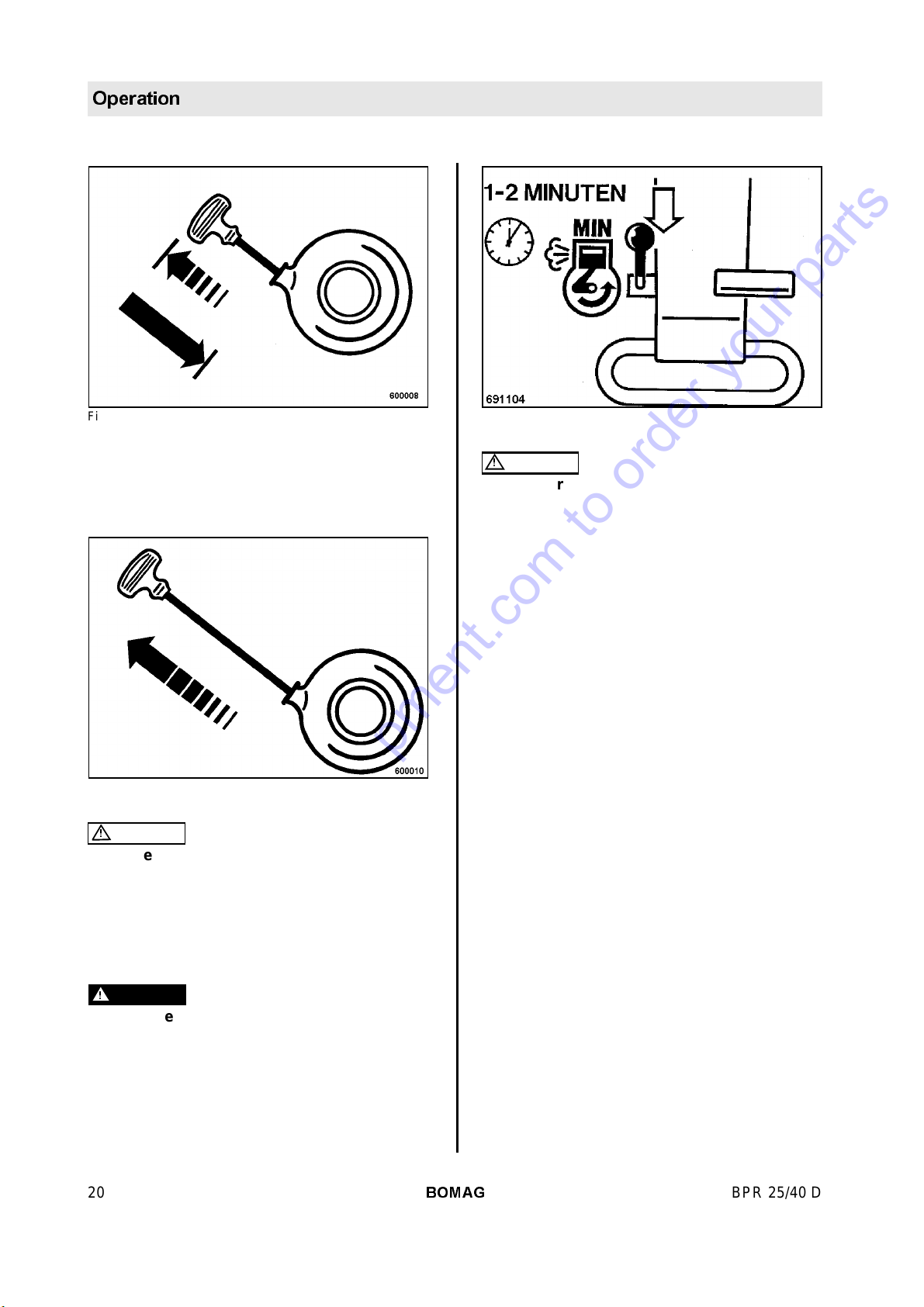

Fig. 8

●Pullthe rope with the starterhandle (Fig.8) out

until a noticeable resistance can be felt.

●Let the starter handle run back to initial posi-

tion.

Fig. 9

Caution

Do not let the starter handle run back after pull-

ing.

●Pull the starter handle (Fig. 9) powerfully.

●If the engine does not start the first time, re-

peat the starting procedure.

Danger

Danger of explosion!

Do not use spray-type starting aids or other in-

flammable liquids to assist the starting proc-

ess.

Fig. 10

Caution

Before starting work allow the engine to warm

up for a short while (Fig. 10).

Go to Discount-Equipment.com to order your parts

Table of contents

Other Bomag Power Tools manuals

Bomag

Bomag BPH 80/65 Instructions for use

Bomag

Bomag BT 60/4 Instructions for use

Bomag

Bomag BPR 35/42 D Instructions for use

Bomag

Bomag BPR 70/70 D Manual

Bomag

Bomag BVP 10/30 User manual

Bomag

Bomag BPR 45/55 D User manual

Bomag

Bomag BPR 25/32 User manual

Bomag

Bomag BPR 30/38-3 Instructions for use

Bomag

Bomag BPR 50 User manual