Section 01 MAINTENANCE

Subsection 04 (STORAGE)

01-04-2

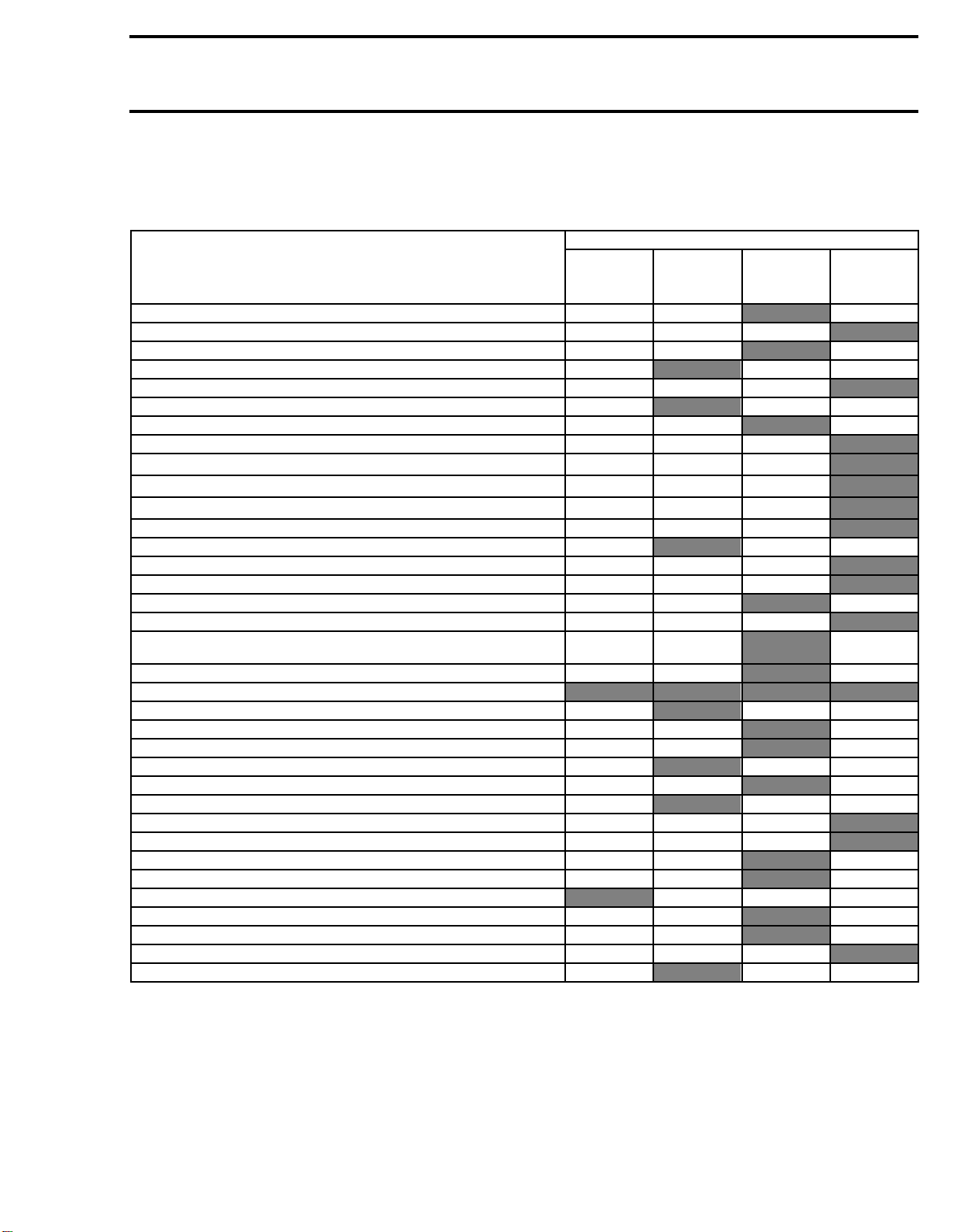

PTO FLYWHEEL

Lubricate PTO flywheel at grease fitting with syn-

thetic grease (P/N 293 550 010).

1. Grease PTO flywheel

Battery

For battery removal, cleaning and storage, refer to

the

1998 Sea-Doo Shop Manual

.

Watercraft Cleaning

Clean the bilge with hot water and mild detergent

or with bilge cleaner. Rinse thoroughly. Lift front

end of watercraft to completely drain bilge. If any

repairs are needed to body or to the hull, touch up

paint and Gelcote®repair kit are available. Replace

damaged labels/decals.

Wash the body with soap and water solution (only

use mild detergent). Rinse thoroughly with fresh

water. Remove marine organisms from the hull.

Apply a nonabrasive wax.

If the watercraft is to be stored outside, cover it

with an opaque tarpaulin to prevent sun rays and

grime from affecting the plastic components, wa-

tercraft finish as well as preventing dust accumu-

lation.

Anticorrosion Treatment

Wipe off any residual water in the engine com-

partment.

Spray BOMBARDIER LUBE lubricant over all me-

tallic components in engine compartment.

Lubricate the throttle cable with BOMBARDIER

LUBE lubricant.

The front seat should be partially left opened dur-

ing storage. This will avoid engine compartment

condensation and possible corrosion.

Additional Recommended Protection

In cool regions (where freezing point may be en-

countered), cooling system should be filled with

water and antifreeze solution.

-CAUTION

Do not lubricate excessively. Immediately

stop when a slight movement is noticed on

rubber boot.

-CAUTION

Never leave any clothing, tool or other ob-

jects near PTO flywheel and drive shaft.

F01I0BA

1

-CAUTION

Never clean fiberglass and plastic parts with

strong detergent, degreasing agent, paint

thinner, acetone, etc.

-CAUTION

The watercraft must never be Ieft in water for

storage. Never leave the watercraft stored in

direct sunlight.

-CAUTION

Always use ethylene-glycol antifreeze con-

taining corrosion inhibitors specifically rec-

ommended for aluminum engines.