Bona OptiSpread UX User manual

EN

DE

FR

ES

SE

Operating manual

Bedienungsanleitung

Manuel d’utilisation

Manual de funcionamiento

Instruktionsbok

Bona OptiSpread UX

Operating manual

2

Table of contents

1. Preface 3

2. Important information 4

2.1. Declaration of Conformity 5

2.2. What you need to know about this instruction manual 6

2.3. Labelling in the instruction manual 6

3. Warranty 6

4. Safety instructions 7

4.1. General Power Tool Safety Warnings 7

4.2. Work area safety 7

4.3. Electrical safety 7

4.4. Personal safety 8

4.5. Power tool use and care 8

4.6. Battery tool use and care 9

4.7. Service 10

4.8. Safety Instructions for Cordless Caulking Guns 10

4.9. ProductDescriptionandSpecications 11

4.10 Intended use 11

5. Technical Data 12

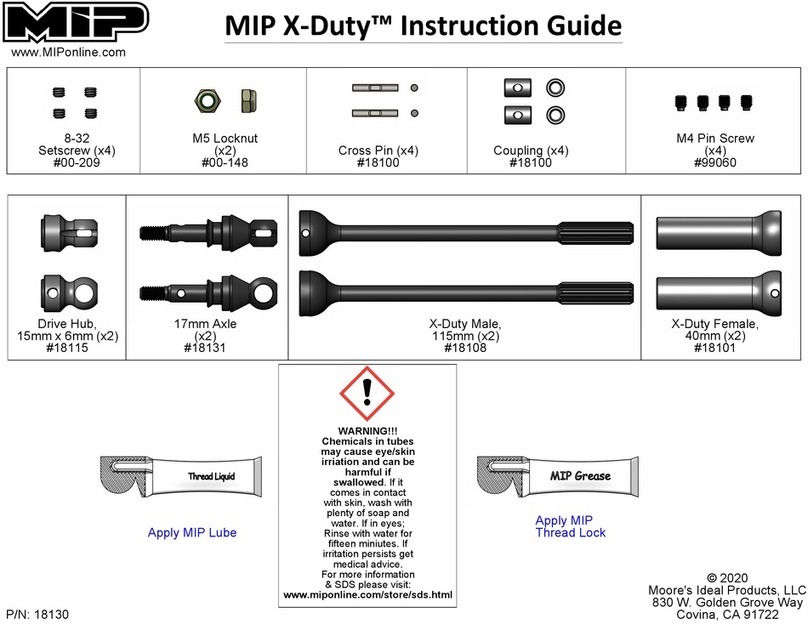

6. Scope of delivery and operation 12

6.1. Scope of delivery 12

6.2. Operation 13

6.2.1. Charging the battery 13

6.2.2. Removing the Battery 13

6.2.3. Battery Charge Indicator 14

6.2.4. Filling/changing the tubular bag 14

6.3. Adhesive application 16

6.3.1. Notes 16

6.3.2. Working instructions 17

6.3.3. Changing the nozzle 18

6.3.4. Substrate condition 18

7. Maintenance and cleaning 18

7.1. Maintenance 18

7.2. Cleaning 18

7.3. Cleaning the glue nozzle 19

8. Storage and Transportation 20

8.1. Proper Storage 20

8.2. Transportation 20

9. Defect detection 21

10. Technical drawings 22

11. Service address (customer service and application advice) 23

12. Disposal 23

Operating manual

3

EN

1. Preface

Thank you for purchasing our Bona OptiSpread UX. The Bona OptiSpread system allows

you to apply Bona parquet adhesives easily and ergonomically in 9 kg tubular bags.

We kindly ask you to read this instructions manual carefully and attentively before using your

newBonaOptiSpreadUXforthersttimetoensureoptimalandsafeuse.Pleasestorethis

instructions manual with care, preferably together with the proof of purchase.

We hope you enjoy your new Bona OptiSpread UX.

This instructions manual has been compiled with the greatest possible care. Nevertheless,

we reserve the right to optimize and technically adapt these instructions at any time.

Illustrations may differ from the original. Version: September 2022

Operating manual

4

2. Important information

2.1 Declaration of Conformity

We hereby declare that the machine described below, in its design and construction

and in the version placed on the market by us, complies with the essential health and

safety requirements of EC Directive 2006/42/EC. In the event of a change to the machine

not agreed with us, this declaration shall lose its validity. EC manufacturer‘s declaration

according to the Machinery Directive 2006/42/EC, Annex II A.

Manufacturer / Distributor:

Bona AB Germany

Auf dem Aurain 6

65549 Limburg

GB Importer

8 Thornton Chase

Linford Wood

Milton Keynes

MK14 6FD

Description and identification of the machine:

Product designations: Bona OptiSpread UX

Manufacturing year: From September 2022

Item number: AT32046061

Series/type designation: Bona OptiSpread UX

The following harmonized standards were applied:

EN 61310-2:1995 Safety of machinery – Indication, marking and actuation –

Part 2: Requirements for marking (IEC 1310-2:1995)

EN 61310-3:1999 Safety of machinery – Indication, marking and actuation –

Part 3: Requirements for the location and operation of actuators (IEC 61310-3:1999)

EN 614-2:2000 Safety of machinery – Ergonomic design principles –

Part 2: Interactions between the design of machinery and work tasks

EN 55014-1: Electromagnetic compatibility. Requirements for household appliances, electric

tools and similar apparatus – Part 1: Emission

EN 55014-2: Electromagnetic compatibility. Requirements for household appliances, electric

tools and similar apparatus – Part 2: Immunity

EN 60745: Hand-held motor-operated electric tools – Safety – Part 1: General requirements

Björn Saalbach

Senior Vice President – Product Management

Operating manual

5

EN

The design of the machine:

Manufacturer: Bona AB Deutschland Auf dem Aurain 6 65549 Limburg

Type designation: Bona OptiSpread UX

Article-Nr.: AT32046061

has been developed, designed and manufactured on sole responsibility of:

Manufacturer: Bona AB Deutschland, Auf dem Aurain 6, 65549 Limburg

General Agent in the UK:

BONA LIMITED

8 Thornton Chase, Linford Wood

Milton Keynes, MK14 6FD

The design of the machine complies with the following guidelines and standards applying to it:

UK SI 2008 No. 1597 and amendments: Supply of Machinery (Safety) Regulations 2008

UK SI 2016 No. 1091 and amendments: Electromagnetic Compatibility Regulations 2016

Guideline / Standard Title

UK SI 2008 No. 1597 Supply of Machinery (Safety) Regulations 2008

BS EN 61310-2:2009-02-28 Safety of machinery. Indication, marking and

actuation. Requirements for marking

BS EN 61310-3:2009-02-28 Safety of machinery - Indication, marking and

actuation - Requirements for the location and

operation of actuators

BS EN 614-2:2000+A1:2008 Safety of machinery. Ergonomic design principles

Interactions between the design of machinery and

work tasks

UK SI 2016 No. 1091 Electromagnetic Compatibility Regulations 2016

BS EN IEC 55014-1:2021-03-31 Electromagnetic compatibility - Requirements for

household appliances, electric tools and similar

apparatus. Part 1: Emission

BS EN IEC 55014-2:2021-04-01 Electromagnetic compatibility. Requirements for

household appliances, electric tools and similar

apparatus. Immunity. Product family standard

BS EN 60745-1+A11:2010-02-28 Hand-held motor-operated electric tools. Safety.

General requirements

Modicationsorextensionstothemachinethatwerenotcarriedoutbytheabove-mentioned

manufacturer or by his authorized representatives will void this declaration of conformity.

Björn Saalbach

Senior Vice President – Product Management

Operating manual

6

2.2. What you need to know about this instruction manual

Pay special attention to the instructions in bold in this manual, which are very important for

the use of the Bona OptiSpread UX. The information in brackets is general and serves for

better understanding.

Significance of the instruction manual

Theinstructionsmanualispartoftheproduct,readitcarefullybeforerstusetofamiliarize

yourself with the Bona OptiSpread UX and to be able to work optimally with this tool. The

instructions manual must be retained throughout the service life of the Bona OptiSpread UX

and passed on to subsequent owners and users.

Operating instructions

Parts of this instruction manual correspond to operating instructions. In particular, the use

and protective measures described under points 4 – 8.

2.3. Labelling in the instruction manual

Attention danger! The safety instructions marked with this symbol must be

observed. Failure to comply can cause serious and far-reaching damage to health

as well as immense damage to property.

3. Warranty

Bona AB Germany gives a 24-month warranty on this product. During this period, Bona will

repair any defects in materials or workmanship found in the device free of charge.

Excluded from the warranty are errors that are not based on material or production errors, e.g. B.

• Transport damage of any kind

• Errors due to improper installation

• Errors as a result of improper use

• Errors resulting from improper handling

• Defects resulting from improperly executed or repair attempts by persons

and/or companies not authorized by Bona

• Normal operational wear (e.g. glue nozzles)

• Cleaning components

• Furthermore, we assume no liability for devices whose serial number

hasbeenfalsied,changedorremoved.

Operating manual

7

EN

A warranty claim is also void if parts are installed in the device that are not approved by

Bona AB. Claims that go beyond free troubleshooting, such as B. Claims for damages are

not part of the scope of warranty.

Write down the serial number of your Bona OptiSpread UX which is located on the bottom

cover of the device:

Purchase date__________________________________________________________________

Serialnumber(pleasellin)_______________________________________________________

4. Safety instructions

4.1. General Power Tool Safety Warnings

Readallsafetywarnings,instructions,illustrationsandspecicationsprovided

with this power tool. Failure to follow all instructions listed below may result in

electricshock,reand/orseriousinjury.

Save all warnings and instructions for future reference. The term „power tool“

in the warnings refers to your mains operated (corded) power tool or battery-

operated (cordless) power tool.

4.2. Work area safety

• Keep work area clean and well lit. Cluttered or dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

ammableliquids,gasesordust.Powertoolscreatesparkswhichmayignitethe

dust or fumes.

• Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

4.3. Electrical safety

• Power tool plugs must match the outlet. Never modify the plug in any way. Do not use

anyadapterplugswithearthed(grounded)powertools.Unmodiedplugsandmatching

outlets will reduce risk of electric shock.

• Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges

and refrigerators. There is an increased risk of electric shock if your body is earthed or

grounded.

• Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

Operating manual

8

• Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

• When operating a power tool outdoors, use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

• If operating a power tool in a damp location is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces the risk of electric shock.

4.4. Personal safety

• Stay alert, watch what you are doing and use common sense when operating a power

tool.Donotuseapowertoolwhileyouaretiredorundertheinuenceofdrugs,alcohol

or medication. A moment of inattention while operating power tools may result in serious

personal injury.

• Use personal protective equipment. Always wear eye protection. Protective equipment

such as a dust mask, non-skid safety shoes, hard hat or hearing protection used for

appropriate conditions will reduce personal injuries.

• Prevent unintentional starting. Ensure the switch is in the off-position before connecting to

power source and/or battery pack, picking up or carrying the tool. Carrying power tools

withyourngerontheswitchorenergizingpowertoolsthathavetheswitchoninvites

accidents.

• Remove any adjusting key or wrench before turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool may result in personal injury.

• Do not overreach. Always keep proper footing and balance. This enables better control of

the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or jewelry. Keep your hair and clothing away

from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

• If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of dust collection can reduce dust-

related hazards.

• Do not let familiarity gained from frequent use of tools allow you to become complacent

and ignore tool safety principles. A careless action can cause severe injury within a

fraction of a second.

4.5. Power tool use and care

• Do not force the power tool. Use the correct power tool for your application. The correct

power tool will do the job better and safer at the rate for which it was designed.

• Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

Operating manual

9

EN

• Disconnect the plug from the power source and/or remove the battery pack, if

detachable, from the power tool before making any adjustments, changing accessories,

or storing power tools. Such preventive safety measures reduce the risk of starting the

power tool accidentally.

• Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate the power tool. Power tools are dangerous

in the hands of untrained users.

• Maintain power tools and accessories. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s operation. If

damaged, have the power tool repaired before use. Many accidents are caused by poorly

maintained power tools.

• Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

• Use the power tool, accessories and tool bits etc. in accordance with these instructions,

taking into account the working conditions and the work to be performed. Use of the

power tool for operations different from those intended could result in a hazardous

situation.

• Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery

handles and grasping surfaces do not allow for safe handling and control of the tool in

unexpected situations.

4.6. Battery tool use and care

Rechargeonlywiththechargerspeciedbythemanufacturer.Achargerthatissuitablefor

onetypeofbatterypackmaycreateariskofrewhenusedwithanotherbatterypack.

Usepowertoolsonlywithspecicallydesignatedbatterypacks.Useofanyotherbattery

packsmaycreateariskofinjuryandre.

When battery pack is not in use, keep it away from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal objects, that can make a connection from one

terminaltoanother.Shortingthebatteryterminalstogethermaycauseburnsorare.

Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact

accidentallyoccurs,ushwithwater.Ifliquidcontactseyes,additionallyseekmedicalhelp.

Liquid ejected from the battery may cause irritation or burns.

Donotuseabatterypackortoolthatisdamagedormodied.Damagedormodied

batteriesmayexhibitunpredictablebehaviourresultinginre,explosionorriskofinjury.

Donotexposeabatterypackortooltoreorexcessivetemperature.Exposuretoreor

temperature above 130°C may cause explosion.

Operating manual

10

Follow all charging instructions and do not charge the battery pack or tool outside the

temperaturerangespeciedintheinstructions.Chargingimproperlyorattemperatures

outsidethespeciedrangemaydamagethebatteryandincreasetheriskofre.

4.7. Service

• Haveyourpowertoolservicedbyaqualiedrepairpersonusingonlyidentical

replacement parts. This will ensure that the safety of the power tool is maintained.

• Never service damaged battery packs. Service of battery packs should only be performed

by the manufacturer or authorized service providers.

4.8. Safety Instructions for Cordless Caulking Guns

• Remove the battery from the power tool before carrying out work on the power tool (e.g.

maintenance, changing tool, etc.). The battery should also be removed for transport and

storage. There is risk of injury from unintentionally pressing the on/off switch.

• In case of damage and improper use of the battery, vapours may be emitted. The battery

can set alight or explode. Ensure the area is well ventilated and seek medical attention

should you experience any adverse effects. The vapours may irritate the respiratory

system.

• Do not open the battery. There is a risk of short-circuiting.

• The battery can be damaged by pointed objects such as nails or screwdrivers or by force

applied externally. An internal short circuit may occur, causing the battery to burn, smoke,

explode or overheat.

• Only use the battery with products from the manufacturer. This is the only way in which

you can protect the battery against dangerous overload.

•Protectthebatteryagainstheat,e.g.againstcontinuousintensesunlight,re,

dirt,water and moisture. There is a risk of explosion and short-circuiting.

•Do not continue to press the On/Off switch after the caulking gun has been

automatically switched off. This can damage the battery.

•When working with the cordless caulking gun, use the personal protective

equipmentrecommendedbythemanufactureroftheconsumable.Youcannd

information about this in the safety data sheet for the consumable. Always wear

safety goggles and gloves that are suitable for handling chemical substances.

Depending on the material, further protective measures may be necessary.

• This power tool may only be used to dispense sealants and adhesives from standard

sachets (foil bags) and cartridges. Dispensing other types of materials or using customer-

specicpackagingsystemsisstrictlyprohibited.

• When working with volatile or hazardous substances, ensure that the workplace is

sufcientlyventilated,andthatsuitablebreathingapparatusiswornifnecessary.

Operating manual

11

EN

• Ensure that the sachets (foil bags) and cartridges are the right size for this power tool.

Ensurethatthesachets(foilbags)andcartridgestwellinthebarrelforsachets(foil

bags)/cartridges and that this barrel is securely attached to the power tool. Only then

should you begin to dispense material.

• Never try to dispense material from an incorrectly aligned or blocked cartridge.

• Topreventhazardscausedbypartsyingaround,ensurethatthepowertoolisnever

operated with loose front barrel caps. If the dispensing nozzle becomes blocked during

use, you must replace it.

• Never point the power tool at yourself or anyone else during use.

4.9. Product Description and Specifications

Read all the safety and general instructions. Failure to observe the safety and

generalinstructionsmayresultinelectricshock,reand/orseriousinjury.Please

observe the illustrations at the beginning of this operating manual.

4.10. Intended use

The Bona OptiSpread UX is a parquet adhesive applicator, specially developed for applying

the high-viscosity adhesives Bona R848T or Bona Quantum T to dry, dust- and grease-free

substrates. In principle, other adhesives manufactured by Bona GmbH Germany can also

be squeezed out in the 9 kg foil bag. The device should enable you to do your work faster,

easier and, above all, more ergonomically.

By pressing the on/off switch, the adhesive is pressed out of the nozzle and can thus be

appliedquicklyandevenlytothesuboor.

The drive used presses the adhesive out of the adhesive nozzle easily and evenly. The

amount of adhesive applied can be individually adjusted for each work process by means of

the different notches, the application speed and/or the feed speed.

Operating manual

12

5. Technische Daten

Length: 1030 mm [Toothed rack retracted)

2300 mm [Toothed rack extended]

Weight (empty): 12Kg[lledapprox.21Kg]

Innerdiameterllingtube: 100 mm

Tubular bag size: 9 Kg

Nozzle: PVC adhesive nozzle with teeth 1250 F [TKB B12

(optionally available 850 F [TKB B6] or 1500 F/G)

Material piston POM-DELRIN

Application width: 500 mm

Adhesives: Bona Silane-based adhesives in 9 Kg tubular foil bag

Typ: Battery Li

Voltage: 18 Volt 2 A

Mains voltage: 100-240 V 50-60 HZ 60 Watt

Charging time: ca. 35 – 45 minutes

Coverage: ca. 60-80 m²

6. Scope of delivery and operation

6.1. Scope of delivery

Beforetherstcommissioning,thedeliverymustrstbecheckedforcompletenessin

accordance with the scope of delivery below. If, contrary to expectations, parts are missing,

please report this immediately to your responsible Bona system consultant/Bona branch or

contact your direct contractual partner.

12

Operating manual

13

EN

Quantity Part

1 Bona OptiSpread UX

1 Battery charger BOSCH GAL 18V-40

2 18.8 V Li battery blocks BOSCH Pro Core 18V 4.0 Ah

3 Nozzles 1250 F [B12] (optionally available 850F or 1500 F/G)

1 Nozzle head

1 Support stand

1 Hool spanner

1 Screwdriver PZ 1/80

1 Screw set for nozzle assembly

1 Transport bag

To open the tubular bags, we recommend using a pair of pliers, which are not included in

the scope of delivery.

6.2. Operation

6.2.1. Charging the battery

Use only the chargers listed in the technical data. Only these chargers are matched to the

lithium-ion battery of your power tool.

Note: The battery is supplied partially charged. To ensure full battery capacity, fully charge

thebatteryinthechargerbeforeusingyourpowertoolforthersttime.

The lithium-ion battery can be charged at any time without reducing its service life.

Interrupting the charging process does not damage the battery.

The lithium-ion battery is protected against deep discharge by the „Electronic Cell Protection

(ECP)“. When the battery is discharged, the power tool is switched off by means of a

protective circuit: The application tool no longer rotates.

6.2.2. Removing the Battery

The battery is equipped with two locking levels to prevent the battery from falling out when

pushing the battery release button unintentionally. As long as the battery is inserted in the

power tool, it is held in position by means of a spring. To remove the battery, press the

release button and pull the battery back and out of the power tool. Do not use force to do

this.

Operating manual

14

6.2.3. Battery Charge Indicator

The three green LEDs of the battery charge indicator indicate the state of charge of the

battery. For safety reasons, it is only possible to check the state of charge when the power

tool is at a standstill. Press the button to show the state of charge. This is also possible

when the battery is removed.

LED Capacity

Continuous lighting 3 x green ≥2/3

Continuous lighting 2 x green ≥1/3

Continuous lighting 1 x green < 1/3

Flashing light 3 x green Reserve

If no LED lights up after pressing the button, then the battery is defective and must be

replaced.

6.2.4. Filling/changing the tubular bag

Before doing any work on the Bona Optispread UX, remove the battery.

TolltheBonaOptiSpreadUXandtochangeanemptytubularbag,placethemachineon

the support provided. Secure the machine at the head end with the rubber strap. ➊

NEVER PLACE THE BONA OPTISPREAD UX ON THE TOOTHED RACK.

THIS CAN LEAD TO MALFUNCTIONS!!

1.Unscrewthenozzlehead,whichisattachedtothellingtubewithaunionnutand

put it aside.

2. Remove the empty tubular bag

3. Unlock the toothed rack and pull it out again completely using the hook handle ➋

4. Insert the new tubular bag horizontally and remove the clip. When inserting, please

makesurethatthebagdoesnotkink!Tubularbagsthatdonottintothelling

tube due to their larger diameter must not be used! Do not try to force the bag into

thellingtube!➌➍

5. Screw the nozzle head back on and carefully push the unlocked toothed rack forwards

until the squeezing disc touches the tubular bag. When attaching the nozzles, make sure

that the pointed end of the teeth is pointing upwards.

6. Loosen the rubber strap and take the machine off the support.

Operating manual

15

EN

➊

➋➌

➍

Operating manual

16

6.3. Adhesive application

SimplyplacethelledBonaOptiSpreadUXonthenozzlehead,presstheon/offbuttonand

walk backwards. ➎

The amount of adhesive applied depends largely on your walking speed, the nozzle size and

thefeed,whichisinnitelyadjustablefrom1-9.➏

Youcanpresetthemaximumfeedoftherackwiththevolumeowlimiter.Highvaluesmean

highfeed,smallvaluesmeanlowfeed.Themaximumvolumeowcanalsobereadjusted

during operation.

➎➏

6.3.1. Notes

Whensqueezingoutofanewnozzleforthersttime,ittakesamomentfortheadhesiveto

emerge from the openings.

If the on/off switch is released, the adhesive application is stopped immediately. To do this,

the piston is moved back slightly (audible). This ensures that no more adhesive is dispensed

after the on/off switch is released. This enables precise and dosed adhesive application.

Tubular bag: If possible, you should try to completely empty the adhesive bag. If this is

not possible, the opened tubular bag can remain in the machine for up to 12 hours. The

machine must be stored horizontally.

If work is interrupted for a longer period of time, the opened bag should be removed and

sealed with a cable tie. The bag sealed in this way can then be used again if required.

Operating manual

17

EN

Depending on the age of the foil bag, gas pressure can build up inside, causing the foil to

swell.Thismaymakeinsertiondifcult.Hereitisadvisabletopiercethefoilneartheclip

with a needle. This allows the excess pressure to escape. However, this has no effect on the

corresponding adhesive.

Nozzle: In the event of longer work interruptions (up to 12 hours), the adhesive that has

escaped from the nozzle teeth will harden. Here we recommend removing excess adhesive

with Bona Cleaning Wipes and covering the outlet openings with adhesive tape. In the case

of longer interruptions, the nozzle must be cleaned or, if necessary, replaced with a new one.

Cured adhesive should not be squeezed out by squeezing the following adhesives. This can

lead to damage to the drive or severe contamination.

Feed: The toothed rack is set at the factory so that it does not exceed that marked with a

red arrow marked marking drives out. When the point is reached, the adhesive application is

interrupted.

Temperature-dependent Overload Protection

If the permissible temperature is exceeded, the caulking gun switches off. Let the caulking

gun cool down and then switch the caulking gun back on.

6.3.2. Working instructions

• Observe the technical data sheets for the adhesives to be applied!

• Donotopenthetubularbaguntilitissecurelyinthellingtube

• Adjustthevolumeowratetoensureasmoothandconsistentapplicationofmaterialin

one application.

Operating manual

18

6.3.3. Changing the nozzle

1. Loosen the fastening screws on the underside, remove the nozzle and dispose of it

2.Putonthenewnozzleandxitwiththefasteningscrews

If there is hardened adhesive in the feed channel and inside the nozzle base, it

must be removed manually. Liquid adhesive does not need to be removed.

6.3.4. Substrate condition

The substrate must in general be even, dry, clean, free from cracks and physically sound.

The surface should also be slightly textured. Thoroughly vacuum off loose material and dust.

If applicable, it must meet the requirements of local standards or codes of practice.

7. Maintenance and cleaning

7.1. Maintenance

The Bona OptiSpread UX is maintenance-free if used properly and carefully in accordance

with the user manual.

7.2. Cleaning

TheBonaOptiSpreadUXisfactoryttedwithaPTFEworkingpiston.Theuseofany

lubricants, fats, oils or similar is not permitted. If necessary, clean the inside of the tube only

with compressed air or a clean, lint-free cotton cloth or Bona Cleaning Wipes.

Theupperpartofthellingtubeandtheouterthreadtendtobeexposedtothemost

contaminationfromfreshadhesive,whichcangetontothethreadandtheinsideofthelling

tube in very small quantities when the tubular bag is changed. This fresh adhesive soiling

should be removed immediately with Bona Cleaning Wipes, as adhesive build-up on the

threads or the inside of the pipe can lead to unwanted adhesive leakage.

Regular cleaning of the affected parts of the machine guarantees a long-lasting function of

theBonaOptiSpreadUXandevenlesscleaningeffortafteryouhavenishedyourwork!

Operating manual

19

EN

7.3. Cleaning the nozzle

Basically, the adhesive nozzle is designed as a disposable nozzle that can be disposed of

after completion of the construction project. However, the nozzle is suitable for multiple use

inanycase.However,nospecicrangeneedstobespecied,asthenozzleitselfhasalong

service life thanks to the resistant material and regular cleaning and correct handling.

However, it is possible to use the nozzle several times after thorough cleaning.

Cleaning should be done as follows:

• First dismantle the nozzle as described under item 6.3.3.

• Remove nozzle side caps and remove uncured fresh adhesive. This is done very easily

with the help of a round rod or rag drawn through the tube.

• Then clean the inside with several Bona Cleaning Wipes by pulling them through the

nozzle.

• Adhesive residues in the serrations are easiest to remove when they have hardened. Be

careful not to damage the tooth form unnecessarily with pointed and sharp objects in

order to ensure a permanently even adhesive discharge.

• The glue outlet on the nozzle shoe should also be cleaned with Bona Cleaning Wipes.

Operating manual

20

8. Storage and Transportation

8.1. Proper Storage

Always store the device horizontally in the original packaging. The Bona OptiSpread UX

nozzle can remain on the machine during longer work breaks of up to 12 hours. Adhesive

lmbagsthatarenotcompletelyemptiedcanalsoremaininthemachine.Todothis,clean

the nozzle from the outside with Bona Cleaning Wipes. In particular, the area where the

adhesive exits should be cleaned thoroughly. The teeth must then be covered with adhesive

tape, or the entire nozzle sealed airtight.

The machine can be stored or transported horizontally for up to 24 hours without the risk of

it drying out.

For longer storage (> 24 hours), the nozzle must be removed from the pipe. If there is still a

lmbag,itmustrstbesqueezedoutorremoved.Theadhesivenozzleitselfisdesignedas

a disposable nozzle and can be disposed of after the construction site has been completed.

If necessary, the nozzle can also be used several times.

Avoid long-term storage in damp or permanently wet as well as dusty places. If the machine

hasbeenstoredpermanentlyorovernightatbelow+10°C,themachinemustrstbe

acclimatized to the room climate (from +15°C) to ensure safe functioning of the piston.

8.2. Transportation

Always transport Bona OptiSpread UX in the original packaging provided. When

transporting,makesurethatthemachineisnotdamagedandsecureitsufciently

to avoid transport damage.

The included Li-ion batteries are subject to the requirements of dangerous goods

legislation. The batteries can be transported on the road by the user without any

further restrictions. When shipping by third parties (e.g. air transport or forwarding

agency), special requirements for packaging and labeling must be observed.

Here, a dangerous goods expert must be consulted when preparing the package.

Only ship batteries if the housing is undamaged. Tape open contacts and pack the

battery so that it does not move in the packaging. Please also note any additional national

regulations.

This manual suits for next models

1

Table of contents

Languages: