17

Chapter 4 0041-46De121211_g.docx hu-gm

© Copyright by GEDORE Automotive GmbH, Germany

Product Information

6. Accessories

KL-0215-35 M25 Hydraulic Hand Pump

The hydraulic hand pump KL-0215-35 M25 is used to drive the hydraulic

cylinder KL-0040-2500.

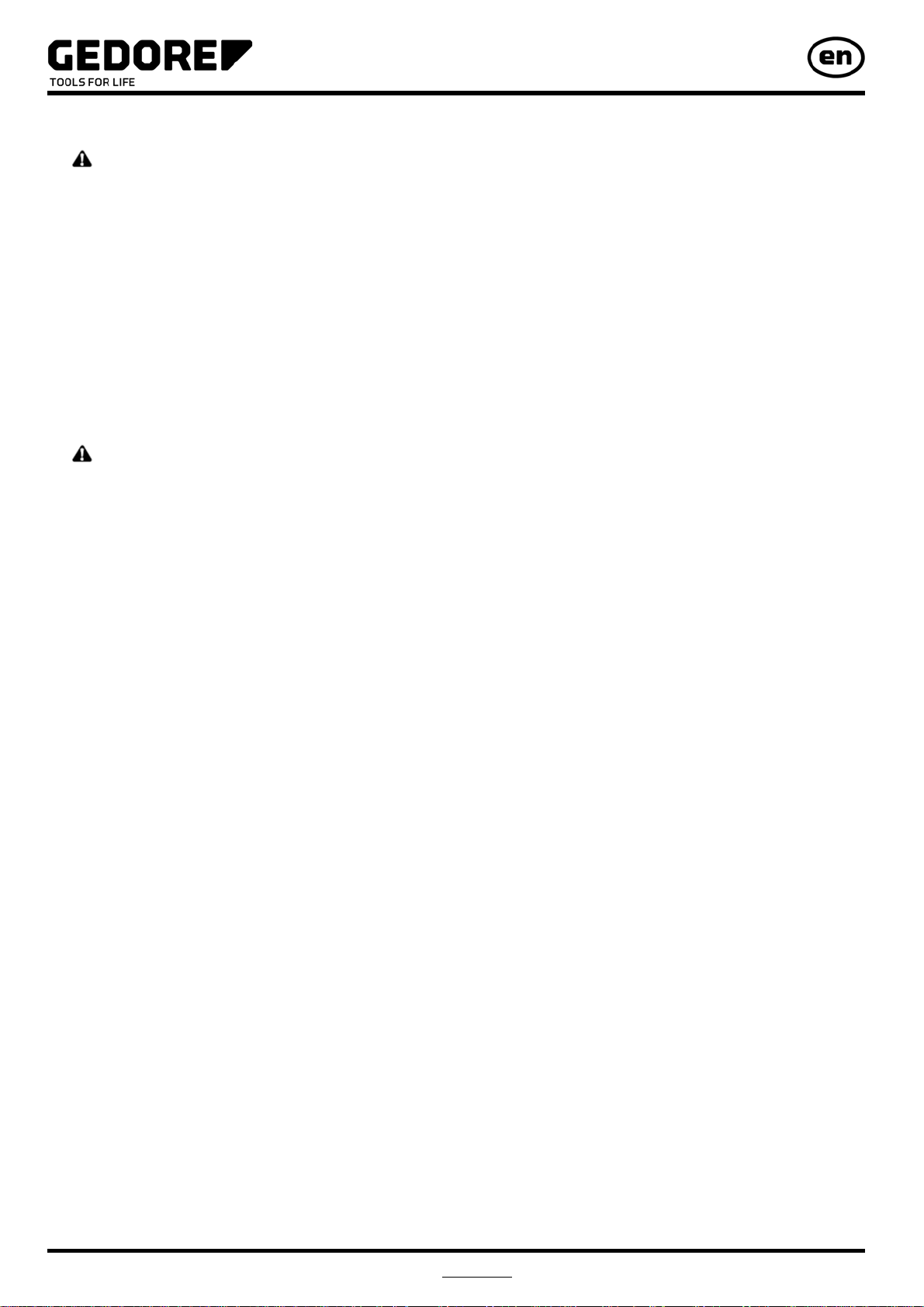

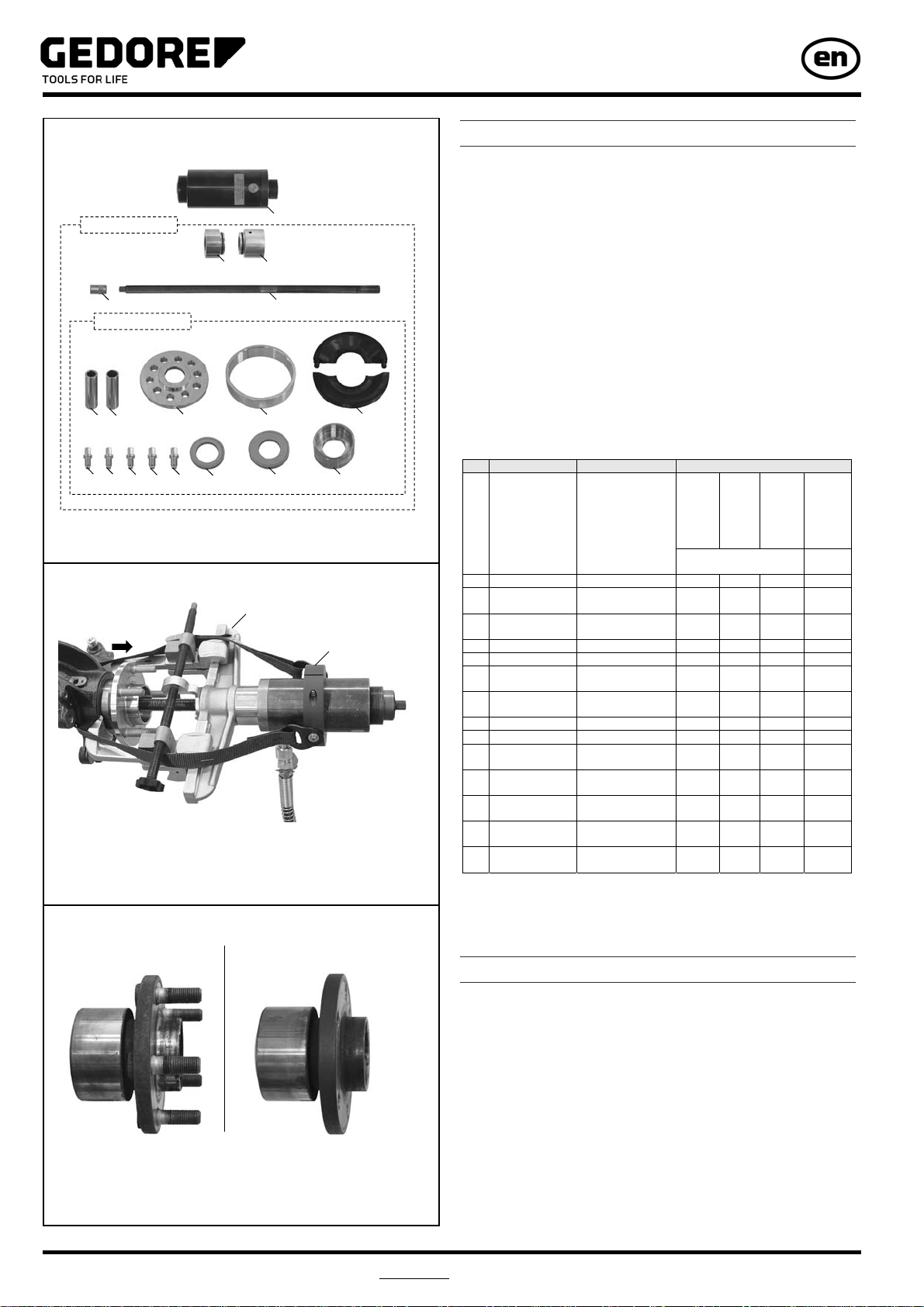

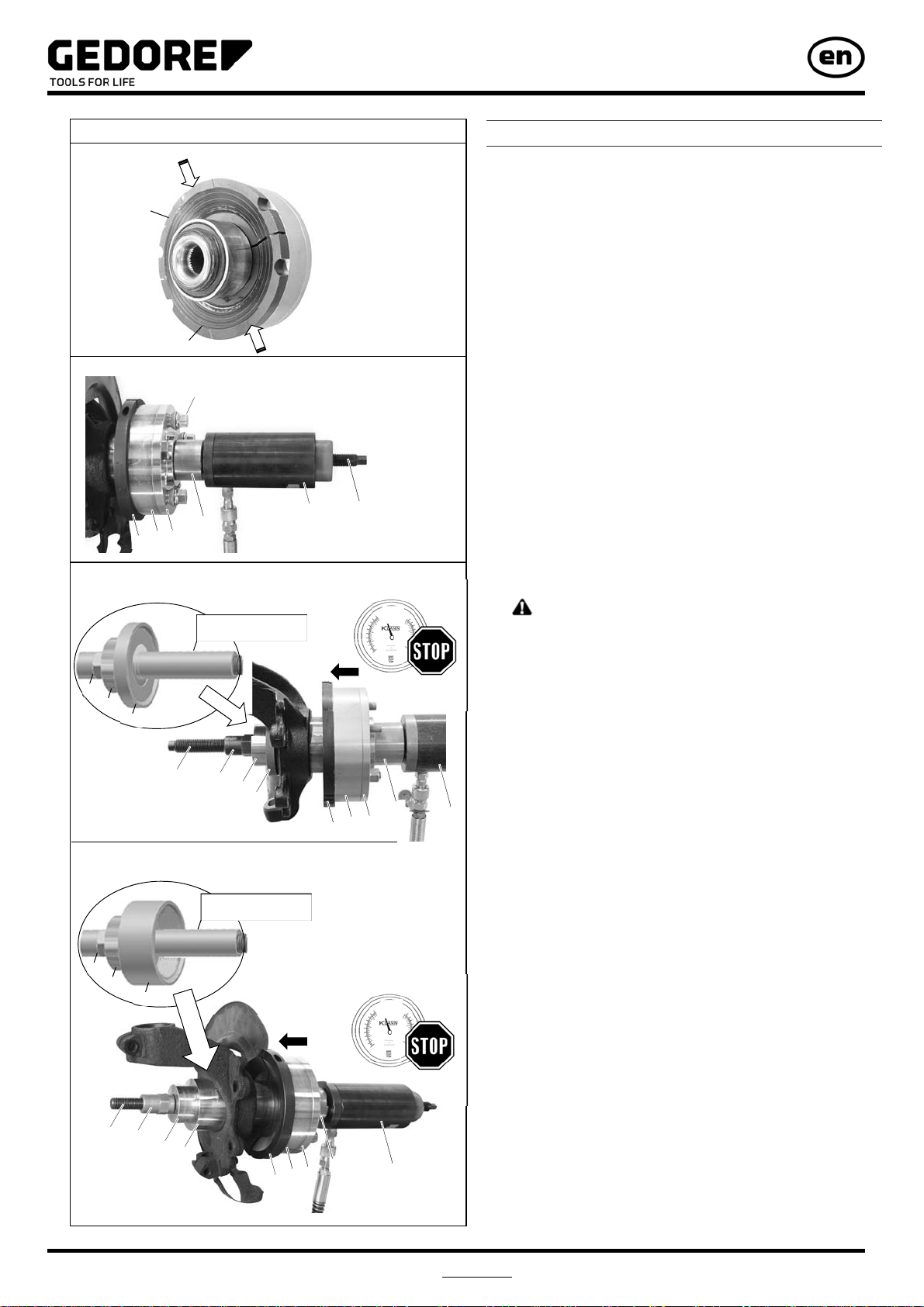

KL-0041-380 Wheel Hub Puller with Adjusting

Spindle,

without Hydraulic Cylinder (German Utility Model)

The wheel hub puller: KL-0041-380 enables the quick, safe, and

accurate extraction of wheel hub bearing units or wheel hubs. For this,

the hydraulic cylinder KL-0040-2500 and pull spindle M20 x 550 mm

KL-0039-1920-1 are necessary. Even bonded, seized or corroded

wheel hub bearing units or wheel hubs are no longer an issue thanks to

this tool.

Due to its special design, the wheel hub puller allows the extraction of a

wide range of different wheel hubs equipped with diameters of up to 250

mm.

Note: The plates KL-0041-3821 and KL-0041-3822 are used as

distance adjustment plates. They are needed if during the removal of a

wheel hub it is necessary to support on the rear side of the hooks and if

the supporting surface is not even.

KL-0040-2590 Safety Belt

By fastening the safety belt KL-0040-2590 to the vehicle and to the

hydraulic cylinder KL-0040-2500, the latter is prevented from falling.

7. Maintenance and Repair by the

GEDORE AUTOMOTIVE Service Centre

For safety reasons, as soon as damage is noticed on the wheel bearing

tool, immediate steps must be taken to prevent it from being used. For

professional checking and repair of the tool, please contact the

GEDORE AUTOMOTIVE Service Centre.

Address:

GEDORE AUTOMOTIVE GmbH

Breslauerstr. 41

DE-78166 Donaueschingen

Phone: +49 (0)771 83 22 371

For additional information concerning the use of our wheel bearing tool,

please contact the GEDORE AUTOMOTIVE Service Centre.

8. Spare Parts List

Pos. Part No. Description Qty.

KL-0041-46 D Wheel bearing tool with hydr. cyl. 1

bestehend aus:

KL-0041-460 D Wheel bearing tool without hydr. cyl. 1

1 KL-0040-2500 Hydraulic cylinder 17 t 1

Pos. Part No. Description Qty.

KL-0041-460 D Wheel bearing tool without hydr. cyl. 1

bestehend aus:

KL-0041-461 D Upgrade Kit Volvo, Ford, Mazda 1

2 KL-0039-1003 Retainer adaptor for hydraulic cylinder 1

3 KL-0039-1002 Retainer adaptor for clamping nut 1

4 KL-0040-3009 Clamping nut, M20 1

5 KL-0039-1920-1 Pull spindle M20 1

Pos. Part No. Description Qty.

KL-0041-461 D Upgrade Kit Volvo 1

bestehend aus:

6 KL-0041-4602 Guide sleeve Ø26.3 mm 1

7 KL-0041-4601 Guide sleeve Ø29.5 mm 1

8 KL-0041-4608 D Cover 1

9 KL-0041-4607 Housing 1

10 KL-0041-4600 D Clamping jaws (pair) Ø78 mm 1

11 KL-0041-3931 Pressure screw M14x1.5 5

12 KL-0039-1272 Pressure ring Ø72 mm 1

13 KL-0039-1288 Pressure ring Ø88 mm 1

14 KL-0039-1682 Pressure-/support sleeve (short) Ø82 mm 1

9. Environmentally Safe Disposal

Dispose of the wheel bearing tool and its packaging material in

compliance with the legal rules and regulations in force.

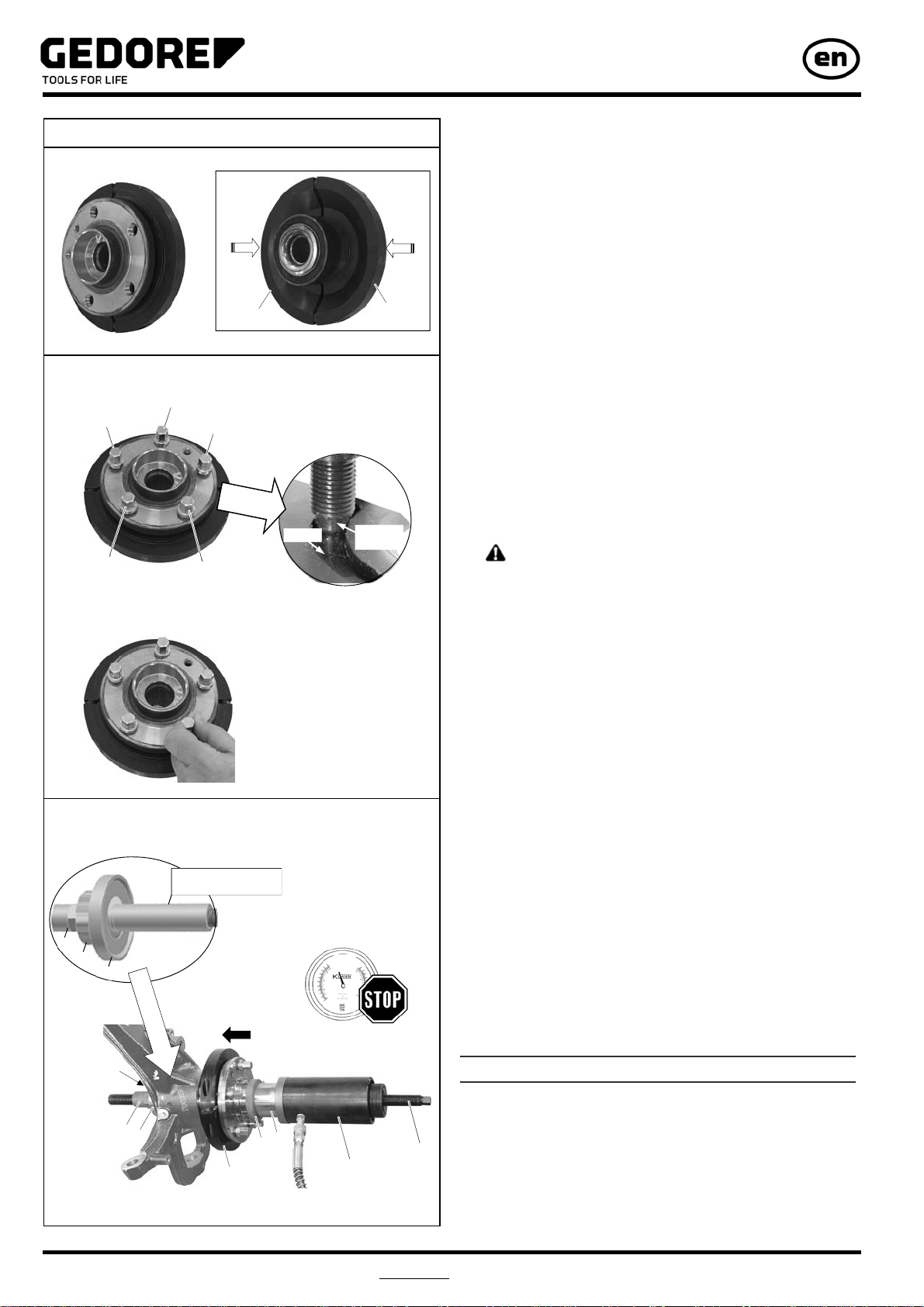

Fig. 10: Accessory: KL-0215-35 M25

Fig. 11: Accessory: KL-0041-380

Fig. 12: Accessory: KL-0040-2590

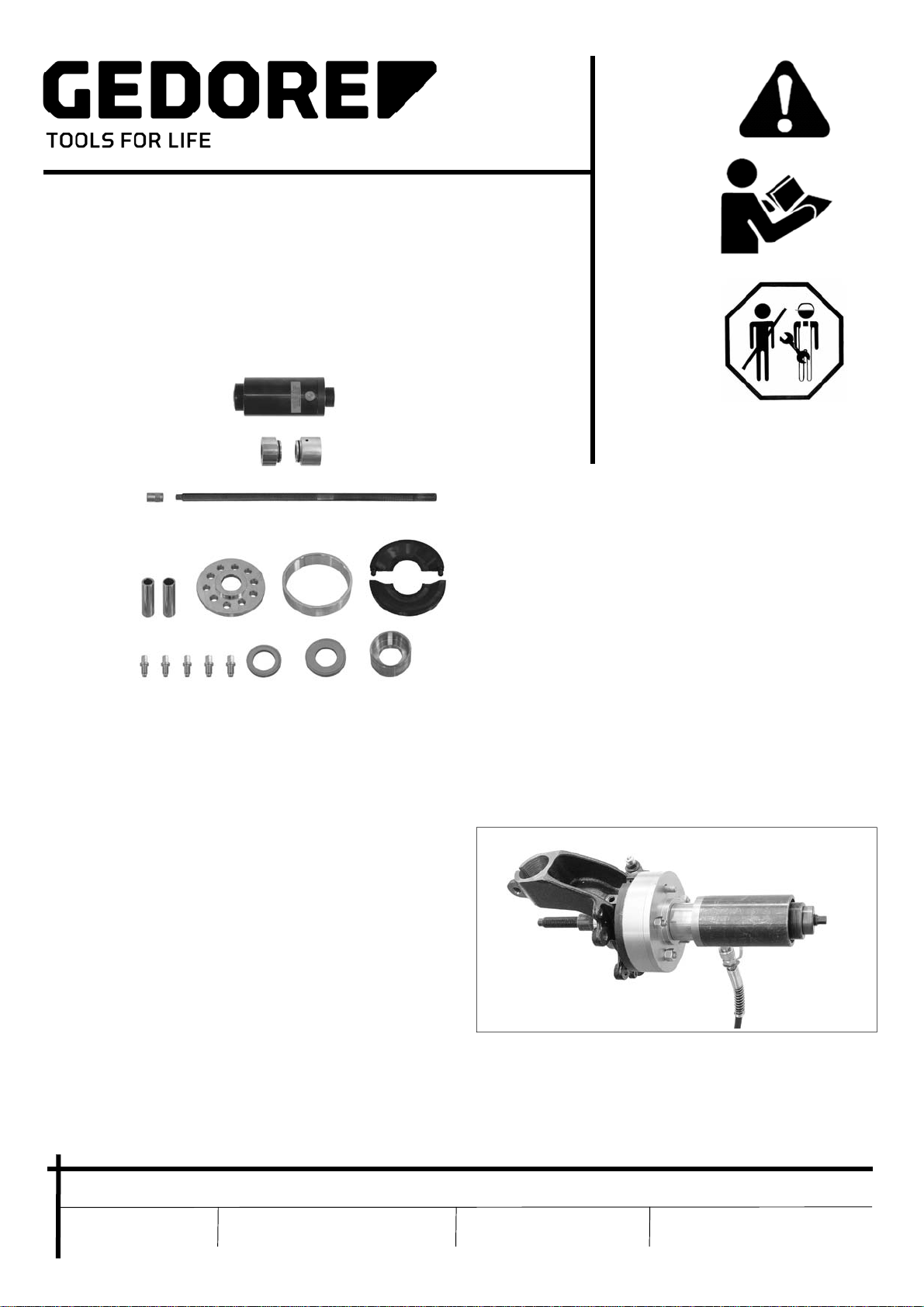

Fig. 13: Spare parts: KL-0041-46 D

KL-0041-461 D

KL-0041-460 D 1

2 3

4 5

6 7 8 9 10

11 12 13 14

11

11 11 11