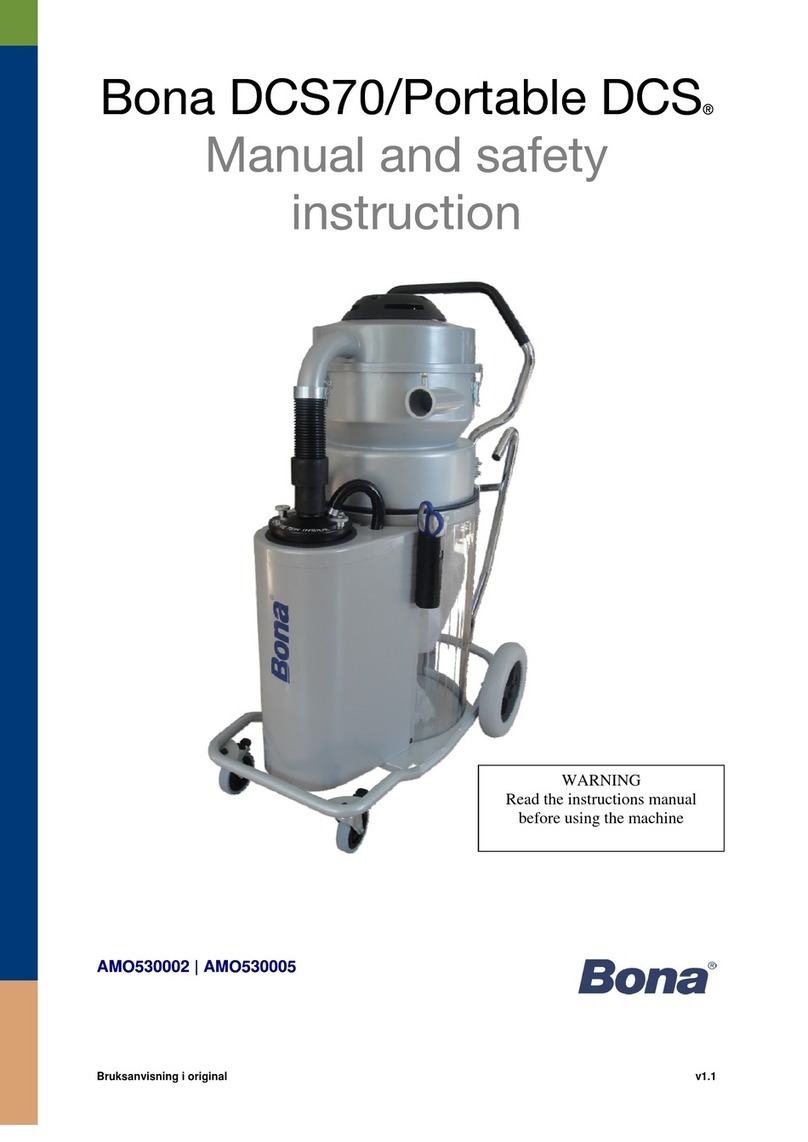

Bona DCS70 Operator's manual

Translation of manual in originals v1.4

Bona DCS70

Manual and safety

instruction

AMO530005

WARNING

Read the manual before

using the machine

Bona DCS70

2

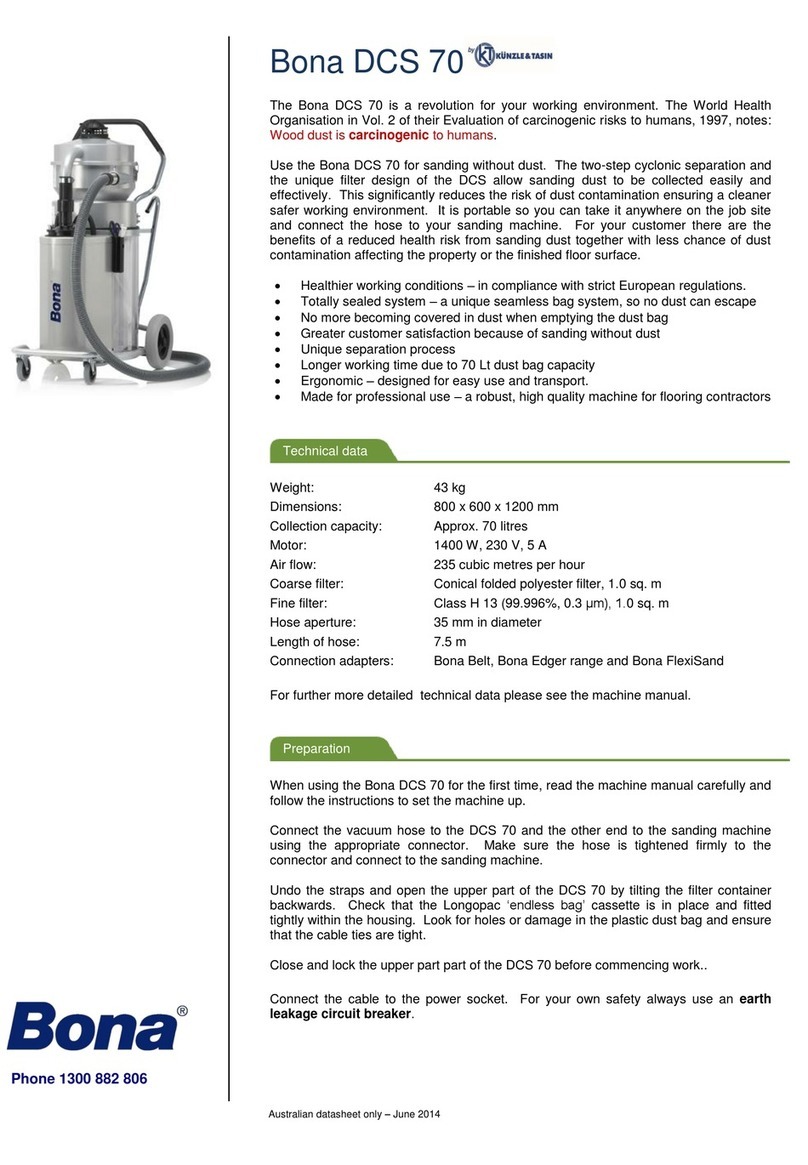

TECHNICAL DATA

Model:

DCS70

Article

num

b

er:

AMO530005

Motor type:

1

-

phase, 1400 W

Voltage (+/

-

10%):

230 VAC

Frequency:

50/60 Hz

Fuses:

10

slow

-

blow

Max Flow:

260m3/h

Max Vacuum:

28kpa

Hose:

7,5m x

∅

38mm

Coarse filter:

Folded 1,2m

2

HEPA filter:

H13 1,5m

2

Noise level:

80

dB(A)

Bag system:

Longopac® 20 m

Length/Wide/Height:

78x60x115cm

Weight:

43kg

Dust capacity:

70l

Hour meter:

99 999 hrs

We congratulate you on your choice of a new Bona DCS70.

Read the complete user instructions carefully before starting to use the

machine. If anything is not clear, you can obtain help from your dealer or from

Bona. You can also visit our web site, www.bona.com , where you can find

manuals, schematics and spare parts.

Important!

This Operator’s Manual only concerns Bona DCS70

Bona DCS70 may only be used for handling dry non explosive, materials.

Bona DCS70 is designed to handle wood dust when sanding floors and vacuuming with Bona’s

equipment. Bona AB disclaims all responsibility if the Bona DCS70 is used for other purposes

or is handled differently than described in this Operator’s Manual.

Pay special attention to the Safety Instructions.

Read the Operator’s Manual before starting to use Bona DCS70.

Spare parts used on the Bona DCS70 must be approved by Bona AB.

Bona DCS70

3

Unpacking

When unpacking the machine, please check that following items are included:

•Suction hose including hose end

•Cleaning equipment

•Connection cable

•Extra Longopac

•Operators Manual

•Cleaning kit, including:

oHose connector (38-50mm)

oHose lock 60mm

oHose lock 45-50mm

oLongopac sealer 60 Pcs

oWand 38mm, 3-parted

oFloor tool (dia 38X300mm)

oCrevice tool-rubber (dia 38X200mm)

oScissors

oBent tube 38-45mm

oBent tube 38-35mm

oAdapter belt

oVelcro one wrap strap (10-pcs)

If anything is missing of the above items, contact your dealer right away.

R

DANGER means: Severe bodily injury or death can occur to you or other personnel if the DANGER

STATEMENTS FOUND ON THIS MACHINE OR IN THIS Owner’s Manual are ignored or are not

adhered to. Read this entire manual before operating this machine.

WARNING means: Injury can occur to you or to other personnel if the WARNING statements found on

your machine or in this Owner’s Manual are ignored or are not adhered to. Damage to the machine or

to other property may occur as well, if the WARNING is ignored.

R

A mixture of dust and air can under unfortunate circumstances be explosive. Sanding/Vacuuming wood

floors can create an environment that can be explosive. The following safety procedures must be

adhered to.

Bona DCS70

4

SAFETY INSTRUCTIONS

Handling

•

Cables damaged through crushing or cracking can be dangerous if used and

should be replaced immediately. Risk of personal injury.

•Do not connect the machine to an unearthed socket. Risk of personal injury.

•

Make sure that the foundation is solid so the Bona DCS 70 doesn’t tip over.

Risk of personal injury and property damage.

•

Risk of pinch injuries when handling the toggle fasteners, cleaning unit and

cyclone.

•

Do not vacuum burning or smoldering particles as the machine can catch fire.

If a fire should break out, pull out the plug from the socket and extinguish

using the available firefighting equipment.

•

The machine must not be used in environments where explosive gas can

occur. Large risk for explosions.

•

Do not look into the suction pipe or suction hose if blocked. Large risk of

injury to the eyes.

•

Do not point the suction hose towards body parts when the machine is

running.

Avoid placing your hand or other parts of the body against the suction inlet if

the suction hose is not fitted. Risk of personal injury.

•Do not vacuum water, oil or any other liquids.

•

While lifting the machine, make sure that the dust container is emptied and

that no person is under the lifted machine. Risk of person injury and property

damage.

Service

•

Remove the plug from the wall socket when carrying out maintenance work.

Reassemble all guards on the motor and fan components once servicing is

complete. Risk for person injury.

•

Health impairing dust can be spread when cleaning the coarse filter and

during filter and bag replacement. Accordingly, the user should wear tight

fitting clothing, protective glasses, protective gloves and a breathing mask

conforming to protection class P2.

•

Do not make holes in any filter. Risk of dust dispersion.

Bona DCS70

5

Handling

Connect the power cable to the right wall outlet. Assemble the hose to the sanding machine or to the

suction pipe together with the floor nozzle. Start the Bona DCS70 by using the push switch.

The dust extractor separates material in three stages:

•The first stage consists of a cyclone separator, where all coarse material is separated before

reaching a filter.

•The second stage consists of a folded coarse filter that filters out the fine visible dust.

•The third stage, final filtering, uses a HEPA13 filter, which separates the health-impairing dust

which is not visible to the eye.

Coarse filter characteristics

The coarse filter is strong and very stable. Low pressure drop with extremely good separation.

In order to attain maximum capacity from the dust extractor it is important that the filter is cleaned, look

at “Cleaning the coarse filter”, or replaced as soon as the suction effect starts to drop. It is

recommended to change the filter 2 – 3 times per year.

HEPA13 filters operating characteristics

The Hepa13 filter is dimensioned for fine, dry dust and should be preceded by a pre-filter

Caution

•HEPA13 filter cannot be cleaned and must be replaced when spent.

Caution

•The operating stability of the HEPA13 filter drop and can be completely destroyed if exposed to

water.

Caution

•It is recommended to change the HEPA filter 1 – 2 times per year.

Motor and vacuum pump

The dust extractor is equipped with a 1 phase motor with a direct mounted vacuum pump.

The motor is cooled by a separate cooling fan

Auto start function

Start button: 0: Machine OFF

I: Machine ON

II: Auto start function

There is an outlet on the Bona DCS70 which can be used when running a sanding machine. If the

start button is set to 2, the DCS70 will start automatically when starting the connected machine. When

the connected machine is turned off the DCS70 will run for about 10 seconds this to make sure that all

dust in the hose will disappear.

Bona DCS70

6

Collection

Particles and dust falls down into a transparent dust container under the cyclone separator.

Inside the dust container is a Longopac bag hose system which should be replaced when full.

The system consists of an approximately 20 mlong plastic hose, which gives about 20 dust free bag

changes.

1. Seal the bag with two

cable ties.

2. Cut between the

cable ties.

3. Pull out a new bag from the

Longopac.

Bona DCS70

7

Replacing the Longopac magazine

Start off with locking the wheel brakes.

1. Cut the bag open

2. Loosen the straps

3. Pull out the

magazine

4. Remove the

gasket and discard

the Longopac rest

5. Place a new

Longopac magazine

and check the

opening according to

the picture

6. Cut off

the sealers

7. Fold the inner

Longopac over the

edge

8. Mount the gasket

9. Turn the magazine

over and pull out a

new bag

10. Put the magazine

in place

11. Attach the

straps

12. Seal the bag with

a sealer and cut off

any rest

NOTE: Always clean the tank from all the particles before you start the machine again!

Otherwise, the HEPA filter will be damaged or clogged.

(does not cover warranty)

Bona DCS70

8

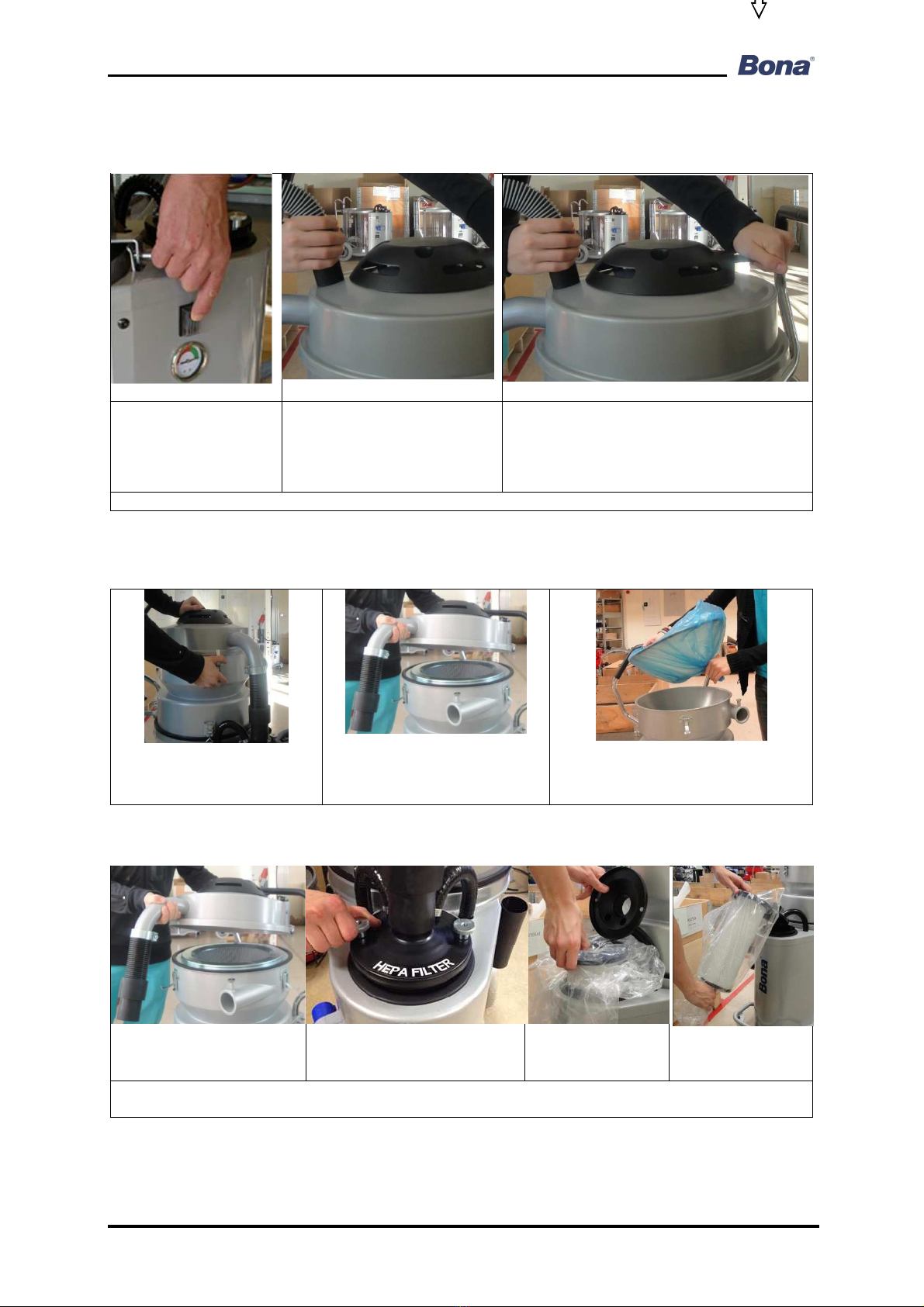

Cleaning the coarse filter through cleaning valve

In order to get maximum suction capacity is the dust extractor equipped with a cleaning valve which

effortlessly cleans the coarse filter.

1. Start the machine

Start button is

set to “I”

(Machine ON)

2. Block the suction hose

by the work place. Wait

about 7-10 sec. while the

machine builds up a

vacuum.

3. Press the filter cleaning valve hard

Repeat the whole process 3 times.

N.B. Clean the filter every time youstart and before you stop the machine.

Replacing the coarse filter

1. Open the cyclone lid 2. Remove the lid

3.

Replace the coarse filter and

place the old filter in a plastic

bag

Replacing the HEPA13 filter

1. Remove lid

2. Loosen the nuts

3. Remove filter

in a plastic bag

4. Seal the bag

and place a new

filter

5.

Place the

HEPA

filter

in

a plastic bag

to

prevent

harmful

particles

spread into the

environment!

Warning

Health impairing dust can be spread when cleaning the coarse filter and during filter and bag

replacement. Accordingly, the user should wear tight fitting clothing, protective glasses, protective

gloves and a breathing mask conforming to protection class PFF3 or NIOSH approved N95 Dust

Respirator Mask.

Bona DCS70

9

CONSUMABLES

To order spare parts, see schematics with article list,

This is available at: http://www.bona.com/spareparts/

Trouble shooting

The machine is constructed and adjusted to a demanding environment and task, but the user may

notice that the machine contains precision made components which should be protected against hard

blows and jolts. Filter, seals, fasteners and connections are thoroughly adjusted and chosen for the

operators working environment. That is why it is of great importance that the operator and service

personnel treat the machine with insight and knowledge in order for the machine to work perfectly for

its purpose.

Problem

Cause/Fault

Action

The motor is not running

No power

Broken cable

The switch is broken

Connect to the wall socket

Change the cable

Change switch

The motor stops right after

start

Wrong fuse

Replace the fuse

The motor is running but there

is no suction

The hose is not connected

The hose is blocked

Connect the hose

Suck out the blockage

backwards

The motor is running but there

is inadequate suction

Hole on the hose

Clogged filter

Worn seals

Replace the hose

Clean or change filter

Check/replace wornseals

The machine is leaking dust

The filter has loosen or is

damaged

Check and change if necessary

Abnormal machinery sounds

Order service

Dust in the HEPA filter

Leak

ing

Longopac,

Longopac-holder cyclone

Check

that

Longopac

bag

is sealed properly and have

no holes. Also check the seal

between Longopac-

holder and cyclone.

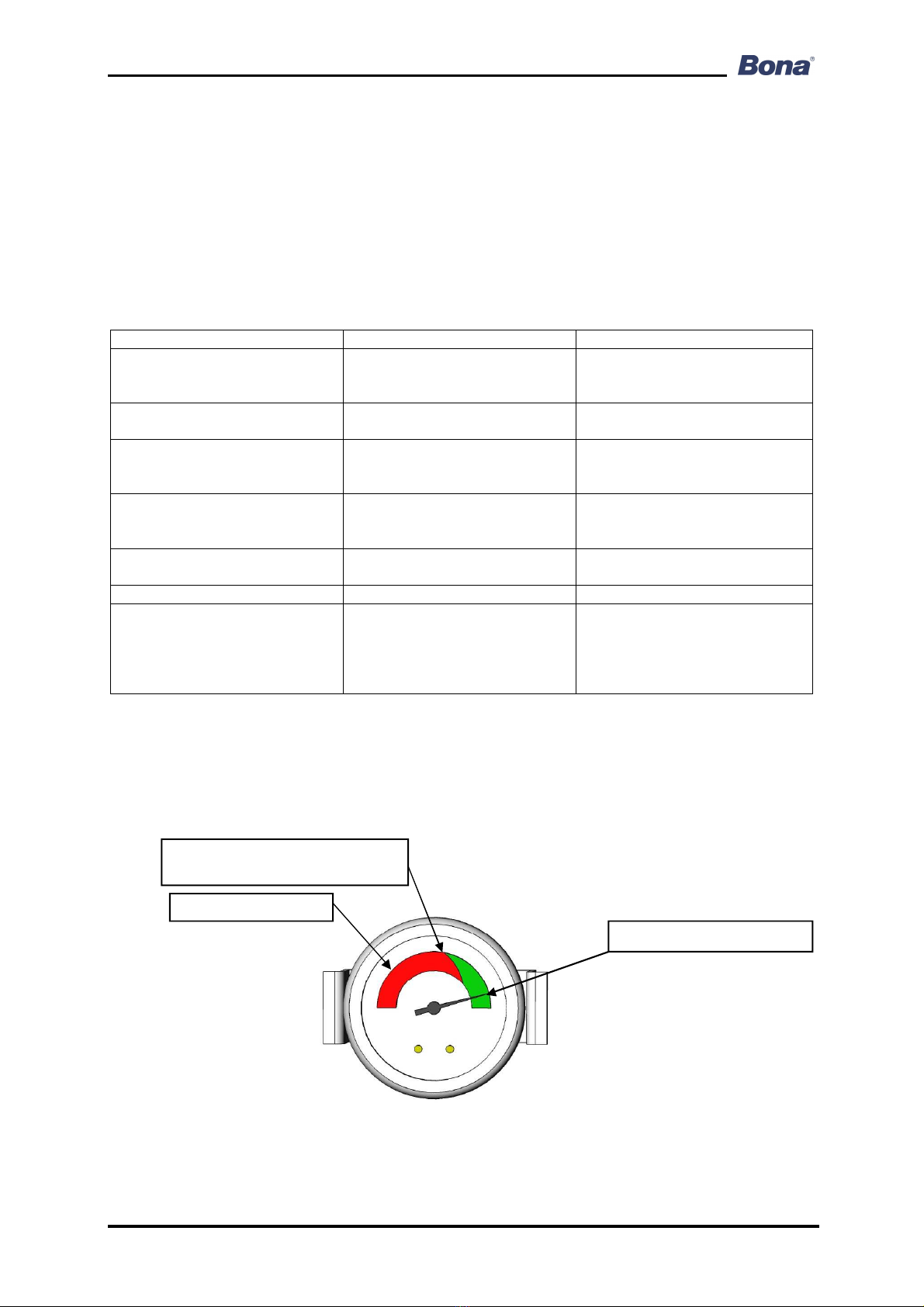

Manometer function

Bona DCS70 is equipped with a manometer for monitoring the filter conditions. The meter is checking

the machines filter status but it will also react on outside added hoses etc. Due to this the machine will

respond to the total load. This will not affect the function of the machine with added load. This means

that the meter will be allowed into the red area as shown below.

Max vacuum (0m/s)

Level for need of Fil

t

er cleaning

with 38mm hose (25m/s)

Level without load

Bona DCS70

10

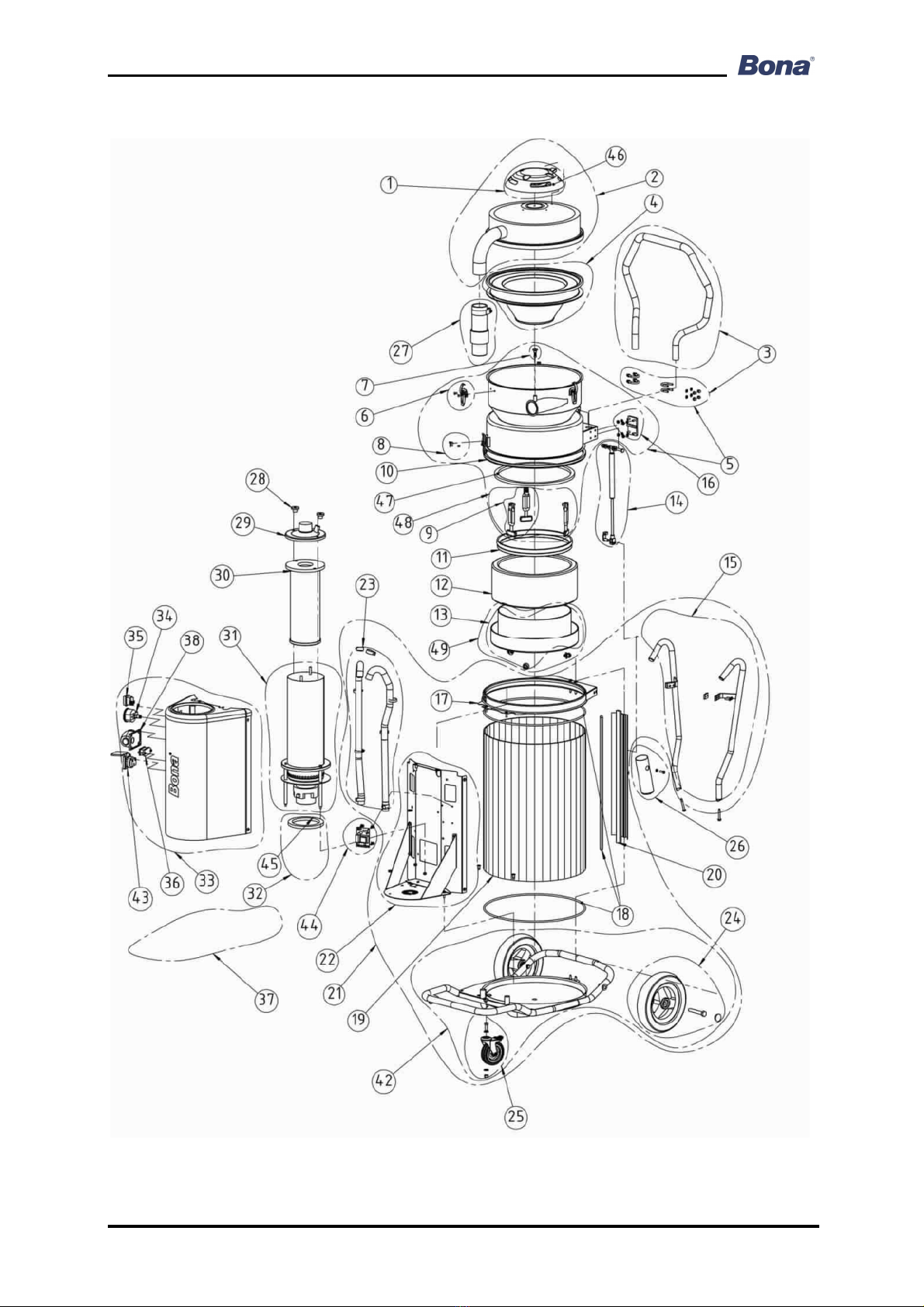

DCS70

Bona DCS70

11

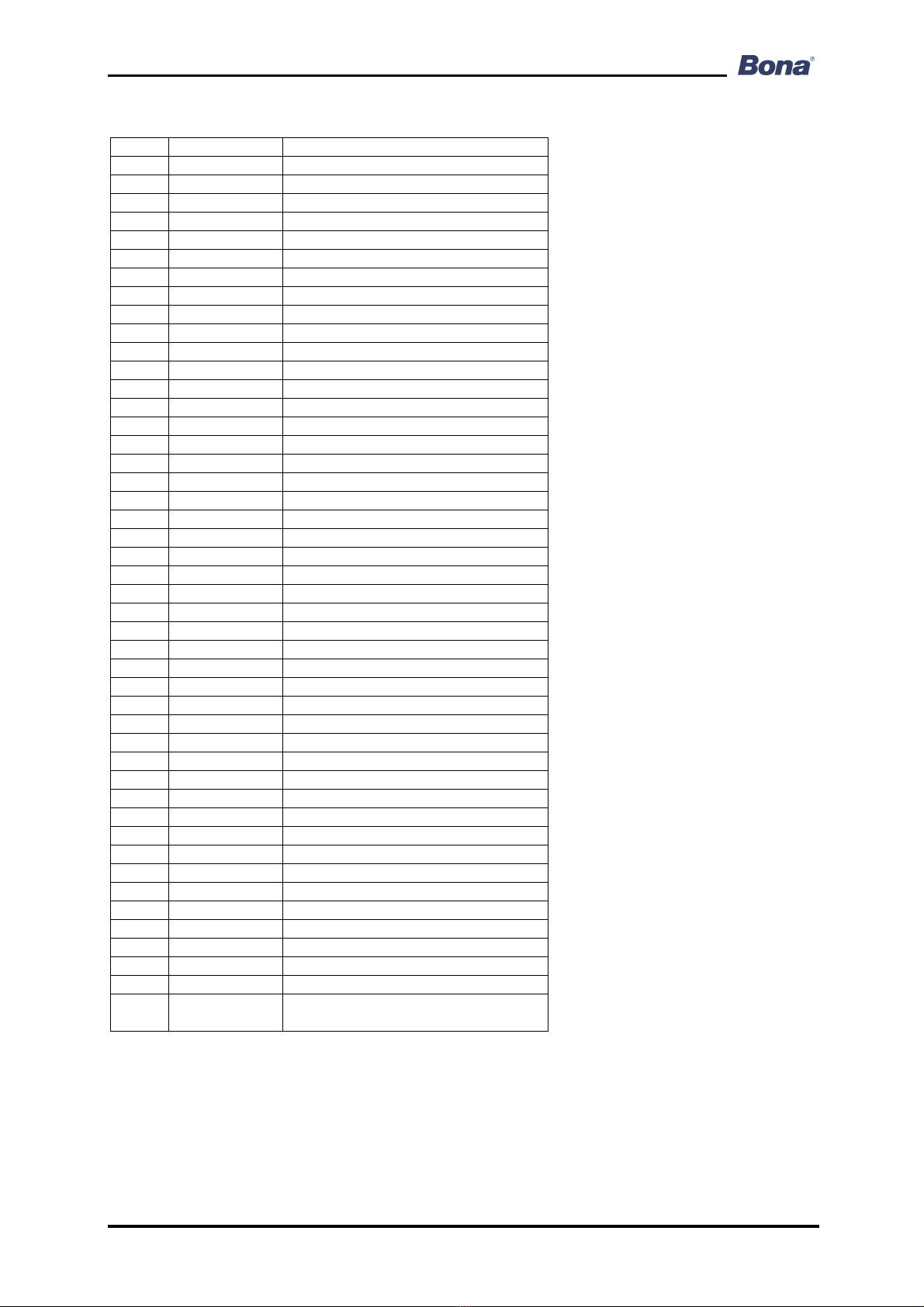

DCS70

Pos

Item

Description

01

ASO539127

Clean Unit

02

ASO539827

Cover Complete

03

ASO539148

Handle Complete

04

ASO539032

Folded Course Filter DCS II

05

ASO539080

Cyclone Complete

06

ASO539799

Tensi

on Set Complete (3 pcs)

07

ASO539745

Hose Locking

08

ASO539372

Hook Clamp 118

-

G3

09

ASO539144

Rubber straps (2 pcs)

10

ASO539451

Gasket L=1270mm

11

ASO539108

Gasket Ring

12

ASO539001

Longopac box 4

-

pack

13

ASO539145

Longopac Bracket 2

-

Attachment

14

ASO539146

Gas Spring Complete

15

ASO539147

Slide Protection Set

16

ASO539155

Hinge Set (2 pcs)

17

ASO539887

Container Bracket Over

18

ASO539149

Screw/Sealing Set to Container

19

ASO539560

Container

20

ASO539438

Back Rail

21

ASO53907

7

Cart complete incl. container 230 V

22

ASO539048

Motor Plate DCSII

23

ASO539150

Vacuum Hose

24

ASO539151

Rear wheel set (2 pcs)

25

ASO539152

Front wheel set

26

ASO539153

Strips bracket cpl

27

ASO539154

Hose connector

28

ASO539289

Easy row cap

nut (2 pcs)

29

ASO539747

Cover to

Filter tube DCS II

30

ASO539033

HEPA Filter to DCS II

31

ASO539084

Motor tube complete

32

ASO539367

Motor 230V 1400W DCS70

33

ASO539164

Motor cover DCS70 230V compl.

34

ASO539452

Vacuum

meter

35

ASO539511

Switch DCS70

36

ASO903888

Hour meter

(counter)

37

ASO539573

Cable kit DCS70 230V

38

ASO539093

Power inlet DCS70 230V

42

ASO539157

Chassis cart incl. wheels

43

ASO539202

Outlet

44

ASO539369

Autostart DCS 230V

45

ASO539169

Motor gasket DCS70

46

ASO539081

Top cover kit ex. clean

unit

47

ASO539158

Extra gas

ket cyclone/L

ongopac

48

ASO539134

Rubber straps (3 pcs)

49

ASO539135

Longopac Bracket 3

-

Attachment

Bona DCS70

12

Warranty

24 month factory warranty (from the date of invoice) against material and manufacturing faults.

In the event of a warranty claim, the machine or the agreed part must be returned to us or our dealer

with paid freight for warranty testing and for potential warranty repair or replacement.

During the factory warranty period, repairs may only be carried by staff at Bona AB or staff approved

by Bona AB.

We do not undertake any other form of compensation or liability to damages.

THE WARRANTY DOES NOT COVER:

• Consumable materials such as wheels, electric cables, coal brushes, vacuumhose, etc.

• Indirect damage, damage and errors that occur due to external damage, accidents, repairs

performed outside of our knowledge and approval, or damages for another reason outside of our

control.

• Transport damage or transport costs will not be compensated. In the event of transport damage it

is up to the receiver to contact the relevant transport company for compensation.

• Case of incorrect use, overloading, carelessness or poor maintenance

•

With the use of parts produced by another company outside of our control.

• Electrical components, if the voltage variations are beyond those set out in the technical

specification

• If payment for the machine is not made according to agreement

Vallgatan 45, SE-716 31 Fjugesta, Sweden

Tel.: +46 (0)40 38 73 90 Fax: +46 (0)585 204

Bona DCS70

13

According to Directive 2006/42/EC, Annex 2A

Other manuals for DCS70

4

This manual suits for next models

1

Table of contents

Other Bona Vacuum Cleaner manuals

Popular Vacuum Cleaner manuals by other brands

Elettro C.F.

Elettro C.F. A00802.S operating instructions

Concept2

Concept2 VP 8050 manual

Silvercrest

Silvercrest SAS 7.4 LI A2 operating instructions

EUROPRO

EUROPRO Hepa Shark quick start guide

Micromark

Micromark 90533 instruction manual

Silvercrest

Silvercrest SMS 300 B2 Operating instructions and safety instructions