bonitron M3575T User manual

Model M3575T

Standard Duty Braking Transistor

Customer Reference Manual

Bonitron, Inc.

2

Bonitron, Inc.

Nashville, TN

An industry leader in providing solutions for AC drives.

ABOUT BONITRON

Bonitron designs and manufactures quality industrial electronics that improve the reliability of

processes and variable frequency drives worldwide. With products in numerous industries, and

an educated and experienced team of engineers, Bonitron has seen thousands of products

engineered since 1962 and welcomes custom applications.

With engineering, production, and testing all in the same facility, Bonitron is able to ensure its

products are of the utmost quality and ready to be applied to your application.

The Bonitron engineering team has the background and expertise necessary to design, develop,

and manufacture the quality industrial electronic systems demanded in today’s market. A strong

academic background supported by continuing education is complemented by many years of

hands-on field experience. A clear advantage Bonitron has over many competitors is combined

on-site engineering labs and manufacturing facilities, which allows the engineering team to have

immediate access to testing and manufacturing. This not only saves time during prototype

development, but also is essential to providing only the highest quality products.

The sales and marketing teams work closely with engineering to provide up-to-date information

and provide remarkable customer support to make sure you receive the best solution for your

application. Thanks to this combination of quality products and superior customer support,

Bonitron has products installed in critical applications worldwide.

Bonitron, Inc.

3

AC DRIVE OPTIONS

In 1975, Bonitron began working with AC inverter drive specialists at synthetic fiber plants to

develop speed control systems that could be interfaced with their plant process computers. Ever

since, Bonitron has developed AC drive options that solve application issues associated with

modern AC variable frequency drives and aid in reducing drive faults. Below is a sampling of

Bonitron’s current product offering.

WORLD CLASS PRODUCTS

Undervoltage Solutions

Overvoltage Solutions

Uninterruptible Power for Drives

(DC Bus Ride-Thru)

Voltage Regulators

Chargers and Dischargers

Energy Storage

Braking Transistors

Braking Resistors

Transistor/Resistor Combo

Line Regeneration

Dynamic Braking for Servo Drives

Common Bus Solutions

Portable Maintenance Solutions

Single Phase Power Supplies

3-Phase Power Supplies

Common Bus Diodes

Capacitor Formers

Capacitor Testers

Power Quality Solutions

Green Solutions

12 and 18 Pulse Kits

Line Regeneration

M3575T

4

1. INTRODUCTION............................................................................................................. 7

1.1. Who Should Use...........................................................................................................7

1.2. Purpose and Scope......................................................................................................7

1.3. Manual Version and Change Record............................................................................7

Figure 1-1: Typical M3575T Module..........................................................................................7

1.4. Symbol Conventions Used in this Manual and on Equipment.......................................8

2. PRODUCT DESCRIPTION................................................................................................ 9

2.1. Related Products..........................................................................................................9

2.2. Part Number Breakdown ..............................................................................................9

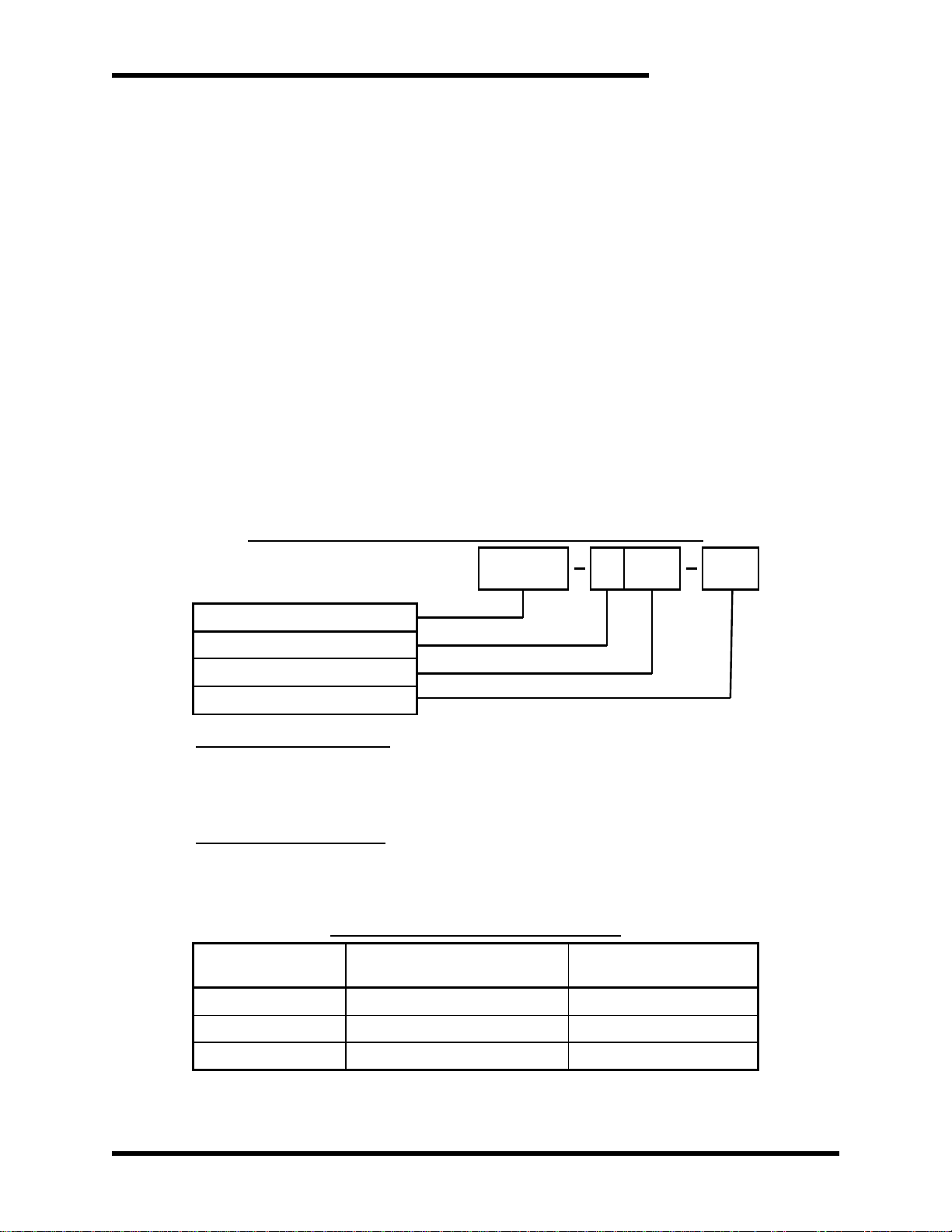

Figure 2-1: Example of M3575T Part Number Breakdown .......................................................9

Table 2-1: AC Voltage Rating Codes ........................................................................................9

Table 2-2: Chassis Determination...........................................................................................10

Table 2-3: Special Options ......................................................................................................11

2.3. General Specifications................................................................................................11

Table 2-4: General Specifications Table .................................................................................11

2.4. General Precautions and Safety Warnings.................................................................12

3. INSTALLATION INSTRUCTIONS...................................................................................... 13

3.1. Environment...............................................................................................................13

3.2. Unpacking ..................................................................................................................13

3.3. Mounting.....................................................................................................................13

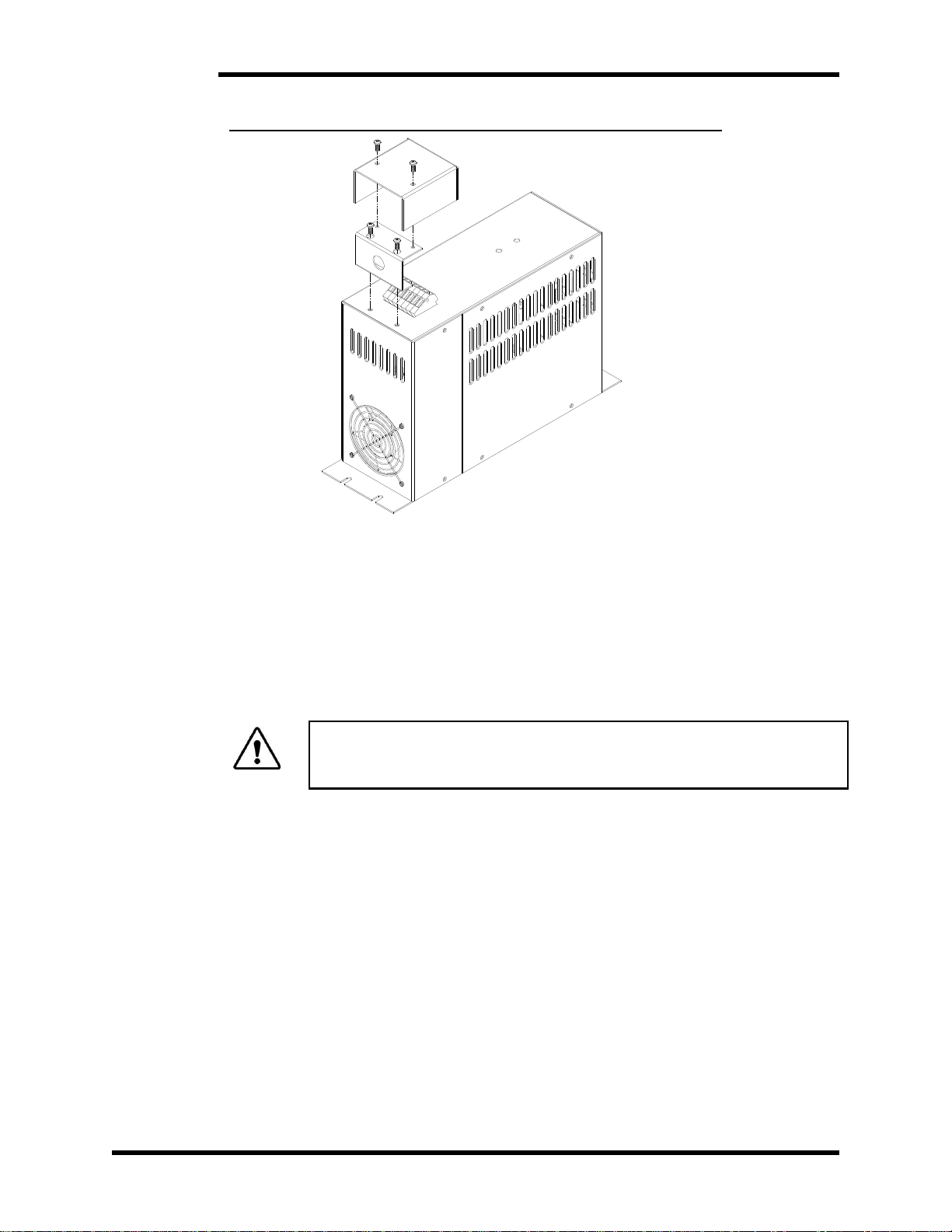

3.4. Conduit Cover Installation for M3 and M4 Chassis .....................................................13

Figure 3-1: Conduit Cover Installation for M3 and M4 chassis ...............................................14

3.5. Wiring and Customer Connections.............................................................................14

3.5.1. Power Wiring ................................................................................................................14

Table 3-1: Power Wiring Specifications...................................................................................15

3.5.2. Control Interface Wiring................................................................................................16

Table 3-2: Control Interface Wiring Specifications..................................................................16

3.6. Typical Configurations................................................................................................17

Figure 3-2: Typical Power Interconnection Diagram...............................................................17

Figure 3-3: Customer Connections .........................................................................................18

4. OPERATION ............................................................................................................... 19

4.1. Functional Description................................................................................................19

4.2. Features.....................................................................................................................19

4.2.1. Indicators ......................................................................................................................19

4.2.2. Terminal Strip I/O..........................................................................................................19

4.3. Pre-Power Checks......................................................................................................20

4.4. Startup Procedure and Checks...................................................................................20

4.5. Operational Adjustments ............................................................................................20

5. MAINTENANCE AND TROUBLESHOOTING ...................................................................... 21

5.1. Periodic Testing..........................................................................................................21

5.2. Maintenance Items.....................................................................................................21

5.3. Troubleshooting..........................................................................................................21

5.3.1. DC bus light not illuminated..........................................................................................21

5.3.2. Blown DC bus fuse.......................................................................................................22

5.3.3. Fan runs constantly ......................................................................................................22

5.3.4. Fan doesn’t run .............................................................................................................22

5.3.5. Control Ready contacts won’t close .............................................................................23

5.3.6. Module over-temp, or module seems too hot...............................................................23

5.3.7. Drive trips on overvoltage.............................................................................................23

5.3.8. Braking light flickers......................................................................................................23

5.3.9. Active braking light stays on all the time.......................................................................24

Table of Contents

5

5.3.10. Attached Drive Will Not Precharge...............................................................................24

5.4. Technical Help –Before you call ................................................................................24

6. ENGINEERING DATA ................................................................................................... 25

6.1. Ratings Charts............................................................................................................25

Table 6-1: Module Ratings ......................................................................................................25

6.2. Watt Loss ...................................................................................................................26

Table 6-2: Watt Loss ...............................................................................................................26

6.3. Certifications...............................................................................................................27

6.4. UL 508A Short Circuit Current Rating.........................................................................27

6.5. Fuse Sizing and Rating...............................................................................................27

Table 6-3: Recommended Fuses............................................................................................27

6.6. DC Bus Length Limits.................................................................................................27

Table 6-4: Maximum Inductance for DC Link Cable ...............................................................28

6.7. Dimensions and Mechanical Drawings .......................................................................29

Figure 6-1: M3 Chassis Dimensional Outline Drawing............................................................29

Figure 6-2: M4 Chassis Dimensional Outline Drawing............................................................30

Figure 6-3: B5 Chassis Dimensional Outline Drawing ............................................................31

Figure 6-4: B7 Chassis Dimensional Outline Drawing ............................................................32

Figure 6-5: MTW 3575-CVR-30U Conduit Cover Dimensional Outline ..................................33

Figure 6-6: MTW 3575-CVR-30 Conduit Cover Dimensional Outline.....................................33

6.8. Block Diagram............................................................................................................34

Figure 6-7: Block Diagram.......................................................................................................34

7. APPENDIX.................................................................................................................. 35

7.1. Application Notes........................................................................................................35

7.1.1. Sizing Your Braking Requirements...............................................................................35

7.1.2. Status Contact Connection Notes ................................................................................36

Figure 7-1: Typical Status Contact Wiring with Input Contactor..............................................38

Figure 7-2: Typical Status Contact Wiring with Drive Interlock Control ..................................39

7.1.3. Common Bus Notes......................................................................................................40

M3575T

6

This page is intentionally left blank.

User’s Manual

7

1. INTRODUCTION

1.1. WHO SHOULD USE

This manual is intendedfor use by anyone who is responsiblefor integrating, installing,

maintaining, troubleshooting, or using this equipment with any AC drive system.

Please keep this manual for future reference.

1.2. PURPOSE AND SCOPE

This manual is a user’s guide for the M3575T standard duty braking transistor. It will

provide the user with the necessary information to successfully install, integrate, and

use the M3575T.

In the event of any conflict between this document and any publication and/or

documentation related to the AC drive system, the latter shall have precedence.

1.3. MANUAL VERSION AND CHANGE RECORD

Additional models were added in rev 07 of this manual.

A new setpoint option and additional dimensional outlines were added in rev 07a.

Connection drawings were updated in rev 07b.

Wiring specifications were updated in rev 07c.

Updates to the Indicators were made in rev 07d.

The manual template was updated in rev 07e.

Table 6-1 and Figure 6-4 were updated in rev 07f.

Table 6-1 and Section 7.1.1.3 were updated in rev 07g.

Tables 2-2 and 3-1 and Figure 6-3 were updated in rev 07h.

Section 4.2.21 Status Contacts was updated in rev 07i.

Information regarding conduit cover installation was added in rev 07j.

Figure 1-1: Typical M3575T Module

M3575T

8

1.4. SYMBOL CONVENTIONS USED IN THIS MANUAL AND ON

EQUIPMENT

Earth Ground or Protective Earth

AC Voltage

DC Voltage

DANGER!

Electrical Hazard - Identifies a statement that indicates a shock

or electrocution hazard that must be avoided.

DANGER!

DANGER: Identifies information about practices or

circumstances that can lead to personal injury or death,

property damage, or economic loss.

CAUTION!

CAUTION: Identifies information about practices or

circumstances that can lead to property damage, or economic

loss. Attentions help you identify a potential hazard, avoid a

hazard, and recognize the consequences.

CAUTION!

Heat or burn hazard - Identifies a statement regarding heat

production or a burn hazard that should be avoided.

User’s Manual

9

2. PRODUCT DESCRIPTION

The need for regenerated voltage control occurs in applications where the frequency of

an AC motor at times exceeds that of its adjustable speed drive. In this case, the motor

acts as a generator. The energy generated by the motor must be dissipated as heat, or

returned to the power line. If this energy is not controlled, the motor may run with high

peak voltages, the energy may be dissipated as heat in the motor, or the drive may trip on

an over-voltage condition.

For applications where this condition occurs infrequently, dissipating the energy as heat

through resistive braking control can be the most cost-effective solution.

2.1. RELATED PRODUCTS

The model M3575T series of braking products is designed to provide resistive braking

control for applications utilizing a standard AC drive with a fixed DC bus. These

modules have been designed for use with remotely mounted resistive loads such as

the model M3575R or M3775RK resistive load modules.

For higher duty cycle applications, consider the M3452 series of braking transistor

modules.

2.2. PART NUMBER BREAKDOWN

Figure 2-1: Example of M3575T Part Number Breakdown

BASE MODEL NUMBER

The Base Model Number M3575T indicates that the unit incorporates the braking

transistor and its control circuitry only. An external resistive load is required for proper

function of the braking module.

AC VOLTAGE RATING

The AC voltage rating of the braking unit should match the input AC line voltage to the

AC drive used with the braking module. This rating is represented by a letter code as

shown in Table 2-1.

Table 2-1: AC Voltage Rating Codes

AC VOLTAGE

RATING CODE

AC VOLTAGE

NOMINAL AC LINE

DC BUS

TRIGGER LEVEL

L

230VAC

375VDC

E

400VAC

620VDC

H

460VAC

750VDC

BASE MODEL NUMBER

AC VOLTAGE RATING

DC CURRENT RATING

SPECIAL OPTIONS

M3575T

H

200

Nxxx

M3575T

10

DC CURRENT RATING

The DC current rating indicates the maximum DC current level safely handled by the

braking unit. This rating is represented numerically such that a value of “15” would

indicate that the braking unit has a peak current rating of 15 amps DC. The RMS

current rating of the unit depends on the application of the braking module. RMS

current ratings have been calculated for braking as well as for overhauling

applications. See Section 7.1.1 for application sizing assistance.

CHASSIS INFORMATION

Chassis size is determined by the module rating. For additional information, please

see Table 6-1 for ratings charts and Table 6-4 for chassis dimensions.

Table 2-2: Chassis Determination

230VAC

MODEL NUMBER

CHASSIS

DIMENSIONS H” X W” X D”

M3575T-L15

M3

12.75 x 3.00 x 8.70

M3575T-L30

M3

12.75 x 3.00 x 8.70

M3575T-L60

M4

12.75 x 4.00 x 8.70

M3575T-L125

B5

17.75 x 5.50 x 8.00

M3575T-L150

B5

17.75 x 5.50 x 8.00

M3575T-L200

B7

17.75 x 7.00 x 8.00

M3575T-L300

B7

17.75 x 7.00 x 8.00

M3575T-L600

B7

17.75 x 7.00 x 8.00

400VAC

MODEL NUMBER

CHASSIS

DIMENSIONS H” X W” X D”

M3575T-E15

M3

12.75 x 3.00 x 8.70

M3575T-E30

M3

12.75 x 3.00 x 8.70

M3575T-E75

M4

12.75 x 4.00 x 8.70

M3575T-E125

B5

17.75 x 5.50 x 8.00

M3575T-E150

B5

17.75 x 5.50 x 8.00

M3575T-E200

B7

17.75 x 7.00 x 8.00

M3575T-E300

B7

17.75 x 7.00 x 8.00

M3575T-E600

B7

17.75 x 7.00 x 8.00

460VAC

MODEL NUMBER

CHASSIS

DIMENSIONS H” X W” X D”

M3575T-H15

M3

12.75 x 3.00 x 8.70

M3575T-H30

M3

12.75 x 3.00 x 8.70

M3575T-H75

M4

12.75 x 4.00 x 8.70

M3575T-H125

B5

17.75 x 5.50 x 8.00

M3575T-H150

B5

17.75 x 5.50 x 8.00

M3575T-H200

B7

17.75 x 7.00 x 8.00

M3575T-H300

B7

17.75 x 7.00 x 8.00

M3575T-H600

B7

17.75 x 7.00 x 8.00

User’s Manual

11

SPECIAL OPTIONS

Table 2-3: Special Options

CODE

DESCRIPTION

Nxxx

A 3 digit setpoint is entered when a non-standard setpoint is required

C

Optional conduit cover for M3 and M4 chassis only.

2.3. GENERAL SPECIFICATIONS

Table 2-4: General Specifications Table

PARAMETER

SPECIFICATION

Adjustments

Factory calibrated - no field adjustments necessary

Connections

Drive DC bus

Resistors

Fault contact

Enclosure

Type 1

Status Output

Form-C contact rated at 1.0 Amp at 24VDC

or 0.5 Amp at 120VAC –Normally closed

Status Output opens on:

Open load

Over temperature

Transistor failure

Panel Indicators

DC Bus

Active Braking

Drive Voltage

For use with 230VAC, 400VAC, and 460VAC drive systems

Control Power

Derived from DC bus voltage:

100-400VDC required for 230VAC drives

320-800VDC required for 400VAC drives

450-800VDC required for 460VAC drives

Braking Current

15 –600A

(Use Bonitron M3452 for applications requiring 600+ Amps)

Turn-on Voltage

375VDC (for 230VAC drives)

620VDC (for 400VAC drives)

750VDC (for 460VAC drives)

Maximum On-Time

60 seconds

Duty Cycle

20% maximum for braking applications

6.67% maximum for overhauling applications

(Use Bonitron M3452 for applications requiring higher duty

cycles)

UL Approval

Units rated up to and including 75 amps peak are UL approved

Refer to UL file number E204386

Operating Temp

0ºC to 40º C

Storage Temp

-20 ºC to +65ºC

Humidity

Below 90% non-condensing

Atmosphere

Free of corrosive gas and conductive dust

M3575T

12

2.4. GENERAL PRECAUTIONS AND SAFETY WARNINGS

DANGER!

HIGH VOLTAGES M AY BE PRESENT!

NEVER ATTEMPT TO OPERATE THIS PRODUCT WITH THE

ENCLOSURE COVER REMO VED!

FAILURE TO HEED THESE WARNINGS MAY RESULT IN

SERIOUS BODILY INJURY OR DEATH!

CAUTION!

THIS PRODUCT WILL GENERATE HIGH AMBIE NT

TEMPERATURES DURING OPE RATION.

THIS PRODUCT SHOULD BE INST ALLED ACCORDINGL Y ON

NON-FLAMMABLE SURFACES W ITH CLEARANCES OF AT

LEAST TW O INCHES IN ALL DIRECTI ONS.

ALWAYS ALLOW AMPLE TIME FOR THE UNIT TO C OOL

BEFORE ATTEMPTING SE RVICE ON THIS PRODUC T.

NO USER-SERVICE ABLE PARTS AR E CONTAINED WI THIN THIS

PRODUCT.INOPERABLE UNITS SHOULD BE REPLACED OR

RETURNED F OR EVAL UATION AND/OR REPAIR BY QUALIFIED

TECHNICIANS.

BEFORE ATTEMPTING INS TALLATION OR REM OVAL OF THIS

PRODUCT,BE SURE TO REVIEW ALL DRIVE AND/OR

RESISTIVE LOAD DOCUM ENTATION FOR PERTINENT SAFETY

PRECAUTIONS .

INSTALLATION AND/OR REMOVAL OF THIS PRODUCT SHOULD

ONLY BE ACCOM PLISHED BY A QUALIFIED ELECTRICIAN IN

ACCORDANCE WITH NATIONAL ELECTRICAL CODE OR

EQUIVALENT REGULATIO NS.

ATTENTION!

A

T

T

E

N

T

I

O

N

!

Important Notice about drives with DC link chokes!

DURING BRAKING S ITUATIONS,ENERGY STORED IN A

DRIVE’S DC LINK CHOKES CAN CREATE EXTREME OVER-

VOLTAGE CONDITIONS F OR BRAKING TRANSISTOR

MODULES.TO AVOID THESE CONDIT IONS,DC CONNECTIONS

FROM BRAKING TRANSISTOR MODULES T O THE DRIVE

SYSTEM SHOULD ALWAYS BE MADE DIRECTLY IN PARAL LEL

WIT H T HE DRIVE’S FI LTER CAPACITORS.THESE MODULES

SHOULD NEVER BE CONNECTED IN SERIES WITH A DRIVE’S

DC LINK CHOKES.

BE SURE TO REV IEW ALL PERTINENT AC DRIVE

DOCUMENTATION TO ENSURE THAT THE PROPER

CONNECTIONS ARE USED.

CONT ACT THE DRIVE MANUFACT URER OR EQUIPMENT

SUPPLIER FOR ASSI ST ANCE WITH DRIVE CONNECTIONS.

ANY QUESTIONS AS TO APPLICATION, INSTALLATION, OR SERVICE

SAFETY SHOULD BE DIRECTED TO THE EQUIPMENT SUPPLIER.

User’s Manual

13

3. INSTALLATION INSTRUCTIONS

3.1. ENVIRONMENT

The installation site for the module should be chosen with several considerations in

mind.

The mounting surface must be non-flammable, as the unit will generate high

ambient temperatures during typical operation.

The unit will require a minimum clearance of two inches in all directions around it.

The unit will require adequate protection from the elements.

3.2. UNPACKING

Prior to installation, please verify that the product received matches the product that

was ordered and that there is no physical damage to the unit. If the wrong product

was received or is damaged in any way, please contact the supplier from which it was

purchased.

3.3. MOUNTING

WARNING!

Installation and/or removal of this product should only be

accomplished by a qualified electrician in accordance with National

Electrical Code or equivalent regulations.

Proper installation of the Model M3575T standard duty braking transistor module

should be accomplished following the steps outlined below. Be sure to refer to your

AC drive’s instruction manual as you perform these steps. Please direct all installation

inquiries that may arise during the installation and startup of this braking product to

your supplier or system integrator.

Once the installation site has been selected as outlined in Section 3.1, the unit should

be mounted in place using two or four ¼ inch diameter bolts or studs. Mounting

dimensions vary by unit chassis size. Refer to Table 2-2 and Section 6.7 for unit and

mounting dimensions.

3.4. CONDUIT COVER INSTALLATION FOR M3 AND M4 CHASSIS

The conduit cover is an optional cover for the M3575T with current ratings 15, 30, 60,

and 75A. The conduit cover option is designated by Cin the part number. See

Section 6.4 for conduit cover dimensions.

1. Inspect the chassis and conduit cover metalwork, MTW 3575-CVR-30 and MTW

3575-CVR-30U.

2. Install MTW 3575-CVR-30U below terminal strip. Rout wires through the circular

opening.

3. Install MTW 3575-CVR-30 according to Figure 3-2.

M3575T

14

Figure 3-1: Conduit Cover Installation for M3 and M4 chassis

3.5. WIRING AND CUSTOMER CONNECTIONS

3.5.1. POWER WIRING

This section provides information pertaining to the field connection of the DC

bus inputs to the M3575T and M3575R resistive braking modules. Actual

connection points andterminal numbers for the AC drive module will be found

in the documentation provided with the drive. Be sure to review all pertinent

drive and system documentation as well as the power connection notes listed

below before proceeding.

WARNING!

Only qualified electricians should perform and maintain the

interconnection wiring of this product. All wiring should be done in

accordance with local codes.

User’s Manual

15

Table 3-1: Power Wiring Specifications

MODEL NUMBER

CHASSIS

TERMINAL

MIN WIRE

AWG

MAX WIRE

AWG

TORQUE

M3575T-L15

M3575T-L30

M3575T-L60

M3575T-E15

M3575T-E30

M3575T-E75

M3575T-H15

M3575T-H30

M3575T-H75

M3, M4

DC+, DC-,

RES+, RES-

16 AWG

12 AWG

0.4-0.6 Nm

3.5-5.3 lb-in

M3575T-L125

M3575T-L150

M3575T-E125

M3575T-E150

M3575T-H125

M3575T-H150

B5

DC+, DC-,

RES+, RES-

12 AWG

8 AWG

0.8-1.6 Nm

7-14 lb-in

M3575T-L200

M3575T-L300

M3575T-E200

M3575T-E300

M3575T-H200

M3575T-H300

B7

(200A, 300A)

DC+, DC-,

RES+, RES-

6 AWG

2 AWG

2.5-5.0 Nm

22-44 lb-in

M3575T-L600

M3575T-E600

M3575T-H600

B7

(600A)

DC+, DC-,

RES+, RES-

4 AWG

2/0 AWG

14 Nm

120 lb-in

Attention!

The braking kit is rated in peak amperage. The wiring only needs to be

sized to handle the RMS current value which can be found in Table 6-1 in

Section 6 of this manual.

3.5.1.1. DC BUS CONNECTION

WARNING!

DC bus polarity must be correct! Connecting the DC bus with the

polarity reversed will cause damage to the equipment!

As a general rule, 30 feet (10m) is the maximum total buswork or

cable thatthe choppershould be mountedfrom the drive. This means

that the actual installation distance should be 15 feet (5m), as the

cable must go out and back. If you must connect the choppers farther

away, see Section 6.6 DC Bus Length Limits.

The braking transistor must be connected directly to the DC bus filter

capacitors of the drive.

Figure 3-2 is an example of the terminals that may be available in

your installation. Not all of the terminals may be on your drive. Refer

to the drive manufacturer's manual or technical documents to locate

the proper terminals. Your drive will have different terminal markings

depending on manufacturer and drive series.

M3575T

16

Ensure that the polarity of the connection is correct. Incorrect polarity

will effectively short the DC bus of the drive, and can cause severe

damage to the drive, load resistor, and the braking transistor.

The proper terminals to attach the braking transistor are marked +

and - on Figure 3-2.

The terminals marked BR+ and BR- are intended for the internal

braking transistor. If the Bonitron external braking transistor is

hooked to the terminals, the braking transistor will not operate

properly. In some cases, it may cause drive failure.

The terminals marked X and Y are intended for connection of a DC

link choke. If the Bonitron braking transistor is connected to the

terminals marked X and Y in Figure 3-2, switching resonances

caused by the DC link choke will destroy the braking transistor. If the

Bonitron braking transistor is connected between X and Y, the drive

will not operate.

If the braking transistor is connected to the terminals marked A and

B in Figure 3-2, switching resonances caused by the lack of filter

capacitance during precharge will destroy the braking transistor.

3.5.1.2. RESISTOR CONNECTION

The polarity of the resistor connections is not critical; however, it is critical

that the resistor be connected to the proper terminals. Improper hookup

can lead to the resistor being connected directly across the DC bus, which

will cause severe overheating and drive stress.

Minimum load resistance requirements listed in Table 6-1: Module

Ratings in Section 6 of this manual MUST be followed when selecting a

resistive load for use with the M3575T unit.

3.5.1.3. GROUNDING REQUIREMENTS

All units come equipped with either a ground terminal or ground stud that

is connected to the module chassis. Ground the chassis in accordance

with local codes. Typically, the wire gauge will be the same as is used to

ground the attached drive.

3.5.2. CONTROL INTERFACE WIRING

Table 3-2: Control Interface Wiring Specifications

TERMINAL

FUNCTION

ELECTRICAL

SPECIFICATIONS

MIN WIRE

AWG

MAX WIRE

AWG

TORQUE

TS 5-6

Status

Contacts

1.0 A at 24 VDC

0.5 A at 120 VAC

16 AWG

12 AWG

0.4-0.6 Nm

3.5-5.3 lb-in

User’s Manual

17

3.6. TYPICAL CONFIGURATIONS

Figure 3-2: Typical Power Interconnection Diagram

M3575T

18

Figure 3-3: Customer Connections

MOTOR

Input Rectifier

ØA

ØB

ØC

Precharge (2)

+

X Y

DC Link Choke (1)

BR+ BR-

Internal Brake

Transistor

connection

(Not Used)

-

Load Bank

Resistor

Bonitron Braking

Transistor

DC+

RES

DC-

RES

Notes:

(1) Precharge connections may not be external

(2) Choke may be internal to drive

A B

DC Bus Filter

Capacitors

Output

Inverter

User’s Manual

19

4. OPERATION

4.1. FUNCTIONAL DESCRIPTION

The M3575T module controls the bus voltage of a variable frequency drive by

transferring energy to a resistor.

When the drive’s DC bus voltage exceeds a fixed setpoint, the dynamic braking

transistor module’s control electronics turns on an IGBT transistor connecting a

resistive load across the DC bus. When the DC bus drops below another threshold,

the IGBT turns off.

The standard turn on setpoint for the M3575T is 375VDC for 230VAC systems,

620VDC for 400VAC systems, and 750VDC for 460VAC systems. See Section 2.2

Special Options for non-standard turn on voltages.

4.2. FEATURES

4.2.1. INDICATORS

4.2.1.1. DC BUS

The green DC Bus indicator illuminates when the voltage between the

DC+ and DC- terminals is greater than 40VDC.

CAUTION!

Do not use this light as an indication that the DC Bus is safe to work

on! Always check the DC bus with a working voltmeter before

servicing equipment, as the DC bus light may be broken!

4.2.1.2. ACTIVE BRAKING

The red indicator illuminates when the chopper IGBT is on. When the

drive is idle, this light should not be on. During braking, this light will be

on or flashing, depending on the amount of braking energy.

4.2.2. TERMINAL STRIP I/O

See Figure 3-1.

4.2.2.1. STATUS CONTACTS

The Status Contacts TS 5&6 will be closed unless there is a fault.

These contacts OPEN on the following conditions:

Failed IGBT (power transistor)

Open Load

Overtemperature in module

If one of these conditions exists, the module will not operate, and the DC

bus will not be regulated through the braking resistor.

CAUTION!

Bonitron braking transistor modules are designed to be used with

stand-alone or common DC bus drive/inverter systems with bus

capacitors. When using the Bonitron modules on common bus

systems, special considerations may apply. Refer to and review the

Application Notes found in Section 7.1.3 prior to energizing this type

of system!

M3575T

20

4.3. PRE-POWER CHECKS

Ensure that all connections are tight, DC bus polarity is correct, and that all customer

wiring is of the proper size for operational requirements. Check for exposed

conductors that may lead to inadvertent contact. Verify the load bank is properly sized

for the application. The ohmic value and wattage rating of the load bank are important

for proper and reliable system operation! Remember; do not operate the module

with less than its minimum ohmsvalue rating! See Section 7for sizing information.

4.4. STARTUP PROCEDURE AND CHECKS

Apply AC power to the drive system and the dynamic braking transistor module. Do

not start the motors on the system.

On the dynamic braking transistor module, verify the following:

Green DC Bus indicator is ON.

Red Active Braking indicator is OFF!Immediately turn off all power if the

indicator is ON to avoid possible load bank overheating and/or other equipment

damage

Verify the drive system DC bus voltage, and make sure it is within tolerance for the

drive system.

Verify the DC current flow through the load bank is zero amps. Even though the

Red Active Braking indicator is OFF, any significant current flow could indicate

incorrect connections or damaged equipment. Immediately turn off all power to

avoid possible load bank overheating and/or other equipment damage if current

flow is indicated!

Note: Depending on the type of measuring equipment used, small currents

could just be noise pickup and could be ignored.

Check status contacts to ensure they are all closed. This indicates that the module

does not have a fault.

If any of the above conditions are not as indicated, turn off all power and allow ample

time for all system energy sources to discharge. Verify that all voltages are below

40V with a meter! Check all wiring connections and jumper configurations. Refer to

the Section 5 of this manual for more information. For further assistance, contact

Bonitron.

Once the pre-checks are complete, the drive system can be enabled. Once the drive

system is operational, run themotors with light deceleration, and decrease the braking

time until the red Active Braking indicator lights.

4.5. OPERATIONAL ADJUSTMENTS

No adjustments are necessary for this module. All regulation points are factory

adjusted, and should not be changed in the field. If your module is not functioning

properly, refer to troubleshooting in Section 5 of this manual or contact Bonitron for

assistance.

Table of contents

Other bonitron Circuit Breaker manuals

Popular Circuit Breaker manuals by other brands

Siemens

Siemens Sentron 3VA9157-0FK Series operating instructions

Siemens

Siemens SION operating instructions

Schrack

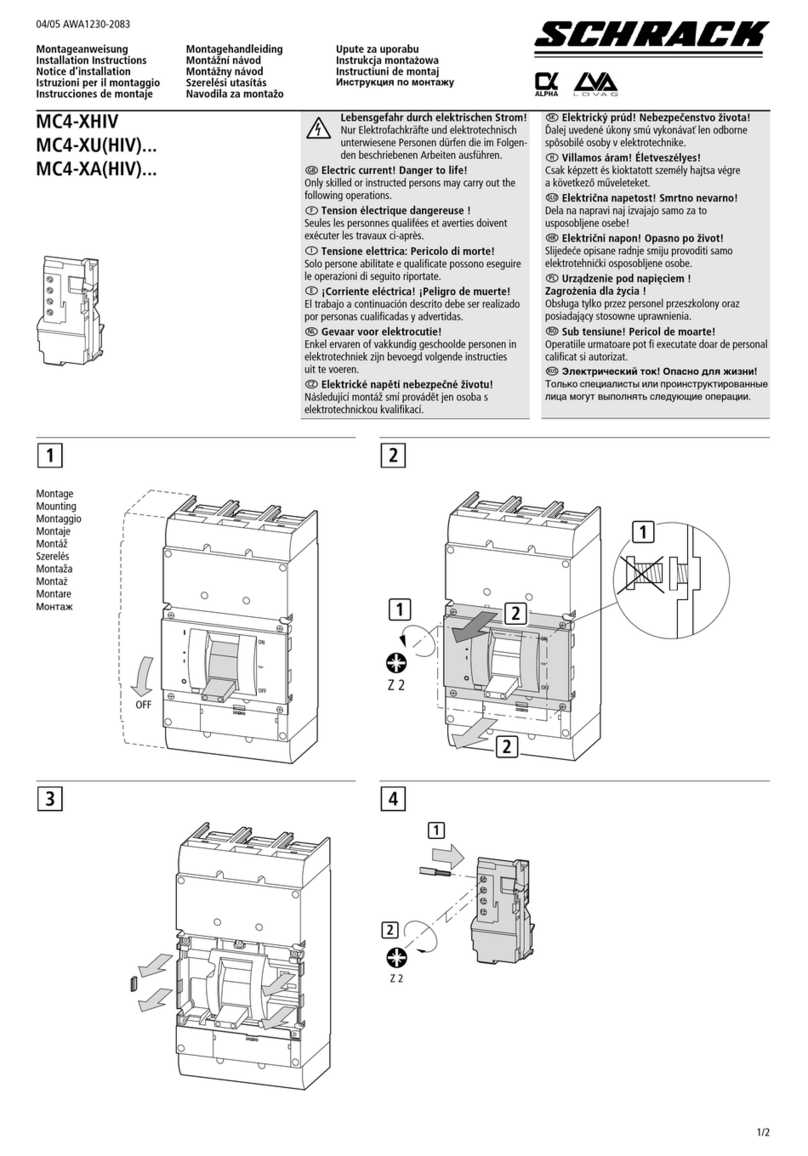

Schrack MC4-XU Series installation instructions

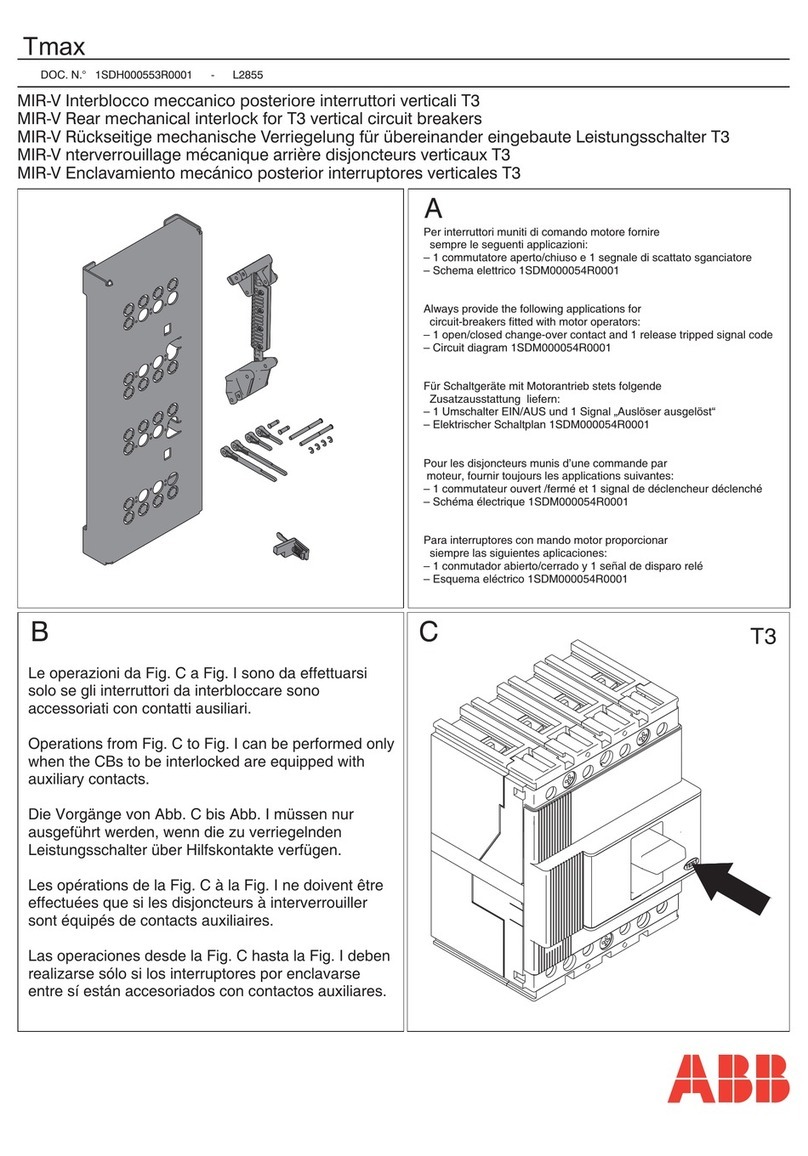

ABB

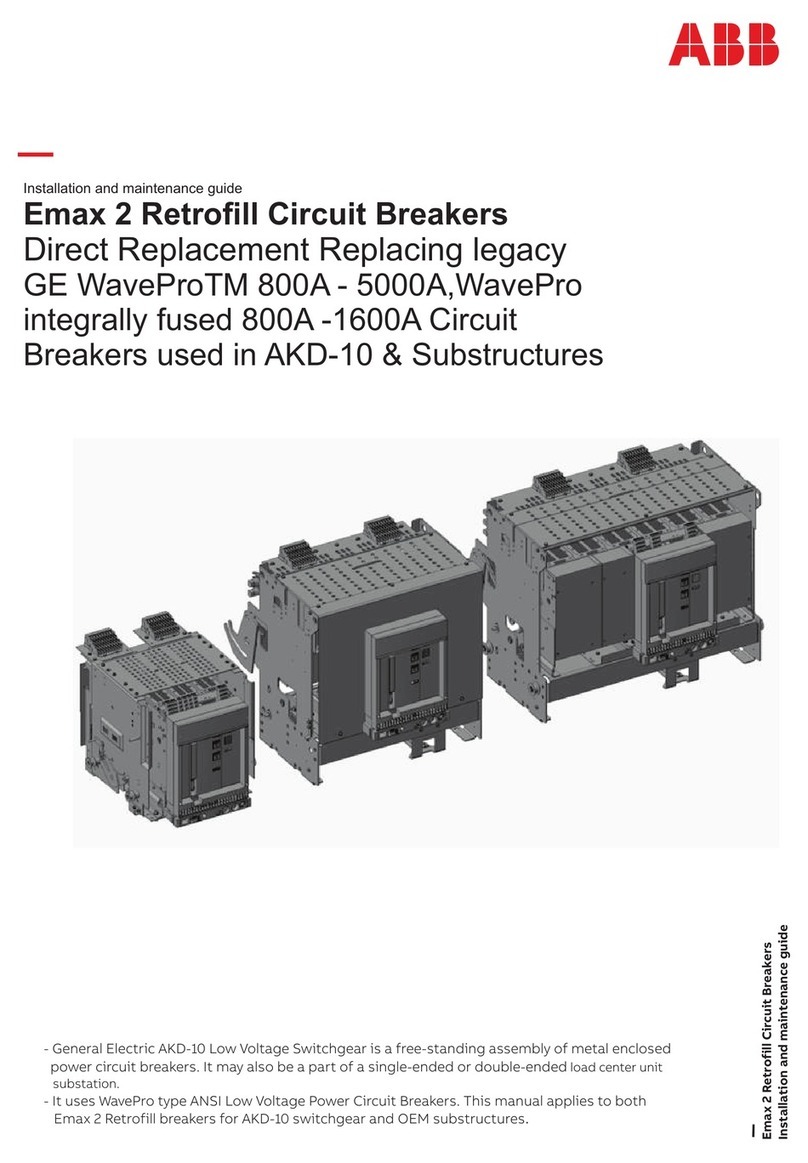

ABB Emax 2 Retrofill Installation and maintenance guide

OEZ

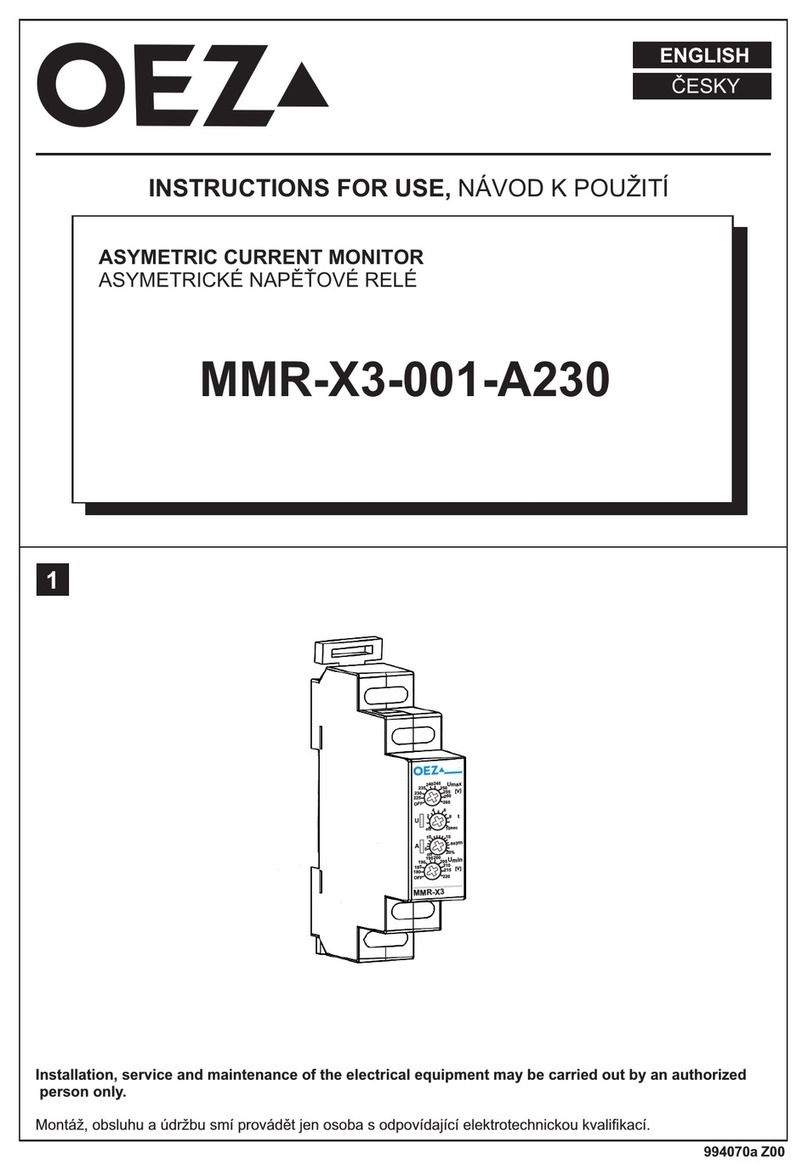

OEZ MINIA MMR-X3-001-A230 Instructions for use

ABB

ABB SACE Emax 2 Instructions for use