bonitron M3645 User manual

Customer Reference Manual

Bonitron, Inc.

2

Bonitron, Inc.

Nashville, TN

An industry leader in providing solutions for AC drives.

ABOUT BONITRON

Bonitron designs and manufactures quality industrial electronics that improve the reliability of

processes and variable frequency drives worldwide. With products in numerous industries, and

an educated and experienced team of engineers, Bonitron has seen thousands of products

engineered since 1962 and welcomes custom applications.

With engineering, production, and testing all in the same facility, Bonitron is able to ensure its

products are of the utmost quality and ready to be applied to your application.

The Bonitron engineering team has the background and expertise necessary to design, develop,

and manufacture the quality industrial electronic systems demanded in today’s market. A strong

academic background supported by continuing education is complemented by many years of

hands-on field experience. A clear advantage Bonitron has o

ver many competitors is combined on-site engineering labs and manufacturing facilities, which

allows the engineering team to have immediate access to testing and manufacturing. This not

only saves time during prototype development, but also is essential to providing only the highest

quality products.

The sales and marketing teams work closely with engineering to provide up-to-date information

and provide remarkable customer support to make sure you receive the best solution for your

application. Thanks to this combination of quality products and superior customer support,

Bonitron has products installed in critical applications worldwide.

Bonitron, Inc.

3

AC DRIVE OPTIONS

In 1975, Bonitron began working with AC inverter drive specialists at synthetic fiber plants to

develop speed control systems that could be interfaced with their plant process computers. Ever

since, Bonitron has developed AC drive options that solve application issues associated with

modern AC variable frequency drives and aid in reducing drive faults. Below is a sampling of

Bonitron’s current product offering.

WORLD CLASS PRODUCTS

Undervoltage Solutions

Overvoltage Solutions

Uninterruptible Power for Drives

(DC Bus Ride-Thru)

Voltage Regulators

Chargers and Dischargers

Energy Storage

Braking Transistors

Braking Resistors

Transistor/Resistor Combo

Line Regeneration

Dynamic Braking for Servo Drives

Common Bus Solutions

Portable Maintenance Solutions

Single Phase Power Supplies

3-Phase Power Supplies

Common Bus Diodes

Capacitor Formers

Capacitor Testers

Power Quality Solutions

Green Solutions

12 and 18 Pulse Kits

Line Regeneration

M3645

4

1. INTRODUCTION..........................................................................................................................7

1.1. Who should use ............................................................................................................................ 7

1.2. Purpose and Scope........................................................................................................................7

1.3. Manual version and change record...............................................................................................7

Figure 1-1: Typical M3645 Line Regen...................................................................................................7

1.4. Symbol Conventions Used in this Manual and on Equipment.....................................................8

2. PRODUCT DESCRIPTION............................................................................................................9

2.1. Related Products........................................................................................................................... 9

2.2. Part Number Breakdown ............................................................................................................10

Figure 2-1: Example of M3645 Part Number Breakdown .....................................................................10

Table 2-1: Voltage Ratings ....................................................................................................................10

Table 2-2: 300A Identifier......................................................................................................................10

Table 2-3: Chassis Styles .......................................................................................................................11

Table 2-4: Option Codes ........................................................................................................................11

2.3. General Specifications Chart......................................................................................................12

Table 2-5: General Specifications..........................................................................................................12

2.4. General Precautions and Safety Warnings .................................................................................13

3. INSTALLATION INSTRUCTIONS................................................................................................15

3.1. Environment ...............................................................................................................................15

3.2. Unpacking................................................................................................................................... 15

3.3. Mounting ....................................................................................................................................15

3.3.1. M3645 Line Regen Mounting...........................................................................................15

Figure 3-1: M3645 Mounting Orientation..............................................................................................16

3.3.2. M3645-x300R Line Reactor Mounting ............................................................................17

3.3.3. KIT 3645DD, External Display Mounting .......................................................................17

3.4. Wiring and Customer Connections.............................................................................................17

3.4.1. Power Wiring....................................................................................................................17

Table 3-1: Transformer Ratings.............................................................................................................18

Table 3-2: Power Terminal Specifications - 30 Amp Unit –M10 Chassis............................................19

Table 3-3: Power Terminal Specifications - 50 Amp Unit –M11 Chassis............................................19

Table 3-4: Power Terminal Specifications - 100 Amp Unit –M12 Chassis..........................................19

Figure 3-2: 30A, 50A, 100A Power Connections ..................................................................................20

Figure 3-3: 30A, 50A, 100A Connection Locations ..............................................................................20

Table 3-5: Power Terminal Specifications - 300 Amp Unit –M15 Chassis..........................................21

Figure 3-4: 300A Power Connections....................................................................................................21

Figure 3-5: 300A Connection Locations................................................................................................22

3.4.2. I/O Wiring.........................................................................................................................23

Table 3-6: M3645 30A, 50A, 100A User I/O Terminal Specifications .................................................23

Figure 3-6: M3645 30A, 50A, 100A User I/O Diagram ........................................................................23

Figure 3-7: M3645 Enable Input Using Internal Power Supply.............................................................24

Figure 3-8: M3645 Enable Input Using External Power Supply............................................................24

3.5 Typical Configurations...............................................................................................................25

Figure 3-9: M3645 30A, 50A, 100A Regen Power Wiring ...................................................................26

Figure 3-10: M3645 300A Regen Customer Power Wiring...................................................................27

Figure 3-11: M3645 Multiple Drives / Regens Field Wiring Diagram..................................................28

Figure 3-12: M3645 Connection with KIT 3645DD, External Panel Mounted Display........................29

4. OPERATION..............................................................................................................................31

4.1. Functional Description ...............................................................................................................31

4.2. Features....................................................................................................................................... 31

Table of Contents

5

4.2.1. Digital Display..................................................................................................................31

4.2.2. LEDs.................................................................................................................................31

4.2.3. Buttons.............................................................................................................................. 31

4.3. Digital Display Operation...........................................................................................................32

4.3.1. Metering Screen................................................................................................................32

4.3.2. Energy Records Screen..................................................................................................... 32

4.3.3. Reset Energy Records Screen...........................................................................................32

4.3.4. Faults Screen.....................................................................................................................32

4.3.5. Fault Records Screen........................................................................................................32

Figure 4-1: M3645 Screen Tree .............................................................................................................32

4.4. Faults ..........................................................................................................................................33

Table 4-1: Blink Codes ..........................................................................................................................33

4.4.1. Feedback Undervoltage ....................................................................................................33

4.4.2. Overtemperature ...............................................................................................................33

4.4.3. DC Overvoltage................................................................................................................33

4.4.4. Differential Overvoltage...................................................................................................33

4.4.5. Sync Loss..........................................................................................................................34

4.4.6. IGBT Driver......................................................................................................................34

4.4.7. Phase 1-3 Overcurrent ......................................................................................................34

4.4.8. Phase Loss.........................................................................................................................34

4.4.9. DC Undervoltage..............................................................................................................34

4.4.10. Regen Power-On/Precharge Not Complete......................................................................34

4.4.11. Frequency Detect Failure..................................................................................................34

4.5. Input / Output Connections.........................................................................................................35

4.5.1. Local I/O +24V Supply- TB2-1 & TB2-5 ........................................................................35

4.5.2. Enable Input - TB2-2........................................................................................................35

4.5.3. Fault Recall Input -TB2-3.................................................................................................35

4.5.4. Input COM -TB2-4...........................................................................................................35

4.5.5. Ready Output - TB2-6 ......................................................................................................35

4.5.6. Overtemperature Output - TB2-7......................................................................................35

4.5.7. Output COM - TB2-8 .......................................................................................................35

4.6. Startup......................................................................................................................................... 36

4.6.1. Pre-power Checks.............................................................................................................36

4.6.2. Startup Procedure and Checks..........................................................................................36

4.6.3. Cooling Fan.......................................................................................................................36

5. MAINTENANCE AND TROUBLESHOOTING...............................................................................37

5.1. Periodic Testing..........................................................................................................................37

5.2. Maintenance Items......................................................................................................................37

5.3. Troubleshooting..........................................................................................................................37

5.3.1. POWER LED is not on, or Digital Display is not active:.................................................37

5.3.2. READY output will not close...........................................................................................37

5.3.3. Unit will not respond to ENABLE command...................................................................37

5.3.4. Drive trips on DC Bus Overvoltage during braking.........................................................37

5.3.5. Feedback Undervoltage ....................................................................................................38

5.3.6. Overtemperature ...............................................................................................................38

5.3.7. DC overvoltage on Regen.................................................................................................38

5.3.8. Differential Overvoltage...................................................................................................39

5.3.9. Sync Loss..........................................................................................................................39

5.3.10. IGBT Driver......................................................................................................................39

5.3.11. Phase Overcurrent............................................................................................................. 39

M3645

6

5.3.12. Phase Loss.........................................................................................................................39

5.3.13. DC Undervoltage..............................................................................................................39

5.3.14. Regen Power-On/Precharge Not Complete......................................................................39

5.3.15. Frequency Detect Failure..................................................................................................40

5.3.16. Technical Help –Before you contact us...........................................................................40

6. ENGINEERING DATA................................................................................................................41

6.1. Ratings Charts.............................................................................................................................41

Table 6-1: Ratings and Specifications –230 - 240VAC ........................................................................41

Table 6-2: Ratings and Specifications –380 - 415VAC ........................................................................41

Table 6-3: Ratings and Specifications –460 - 480VAC ........................................................................41

Table 6-4: Ratings and Specifications –575 - 600VAC ........................................................................41

6.2. Derating Parallel Regens ............................................................................................................42

Table 6-5: Derating Regens in Parallel ..................................................................................................42

6.3. Watt Loss....................................................................................................................................42

6.4. Certifications and RoHS............................................................................................................. 42

6.5. Fuse Selection.............................................................................................................................43

Table 6-6: Fuse Current Rating Requirements.......................................................................................43

Table 6-7: Fuse Voltage Rating Requirements ......................................................................................43

6.6. Dimensions and Mechanical Drawings......................................................................................44

Figure 6-1: M3645 M10 Chassis Dimensional Outline..........................................................................44

Figure 6-2: M3645 M11 Chassis Dimensional Outline..........................................................................45

Figure 6-3: M3645 M12 Chassis Dimensional Outline..........................................................................46

Figure 6-4: M3645 M15 Dimensional Outline.......................................................................................47

Figure 6-5: M645-x300R Line Reactor Dimensional Outline................................................................48

Figure 6-6: KIT 3645DD, External Display Dimensional Outline.........................................................49

6.7. Block Diagram............................................................................................................................50

Figure 6-7: M3645 30A, 50A, 100A Functional Block Diagram...........................................................50

7. APPENDIX.................................................................................................................................51

7.1. Application Notes....................................................................................................................... 51

7.1.1. Sizing the Line Regeneration Unit....................................................................................51

7.1.2. Calculating Energy Savings..............................................................................................52

User’s Manual

7

1. INTRODUCTION

1.1. WHO SHOULD USE

This manual is intended for use by anyone who is responsible for integrating, installing,

maintaining, troubleshooting, or using this equipment with any AC drive system.

Please keep this manual for future reference.

1.2. PURPOSE AND SCOPE

This manual is a user’s guide for the Model M3645 line regen. It provides you with the

necessary information to successfully install and use the M3645 modules in your

application.

In the event of any conflict between this document and any publication and/or

documentation related to the application, the latter shall have precedence.

1.3. MANUAL VERSION AND CHANGE RECORD

Figure 3-8 and Table 6-5-were updated in Rev 01k.

Figures 3-7, 3-8, and 6-4 were updated in Rev 01l.

Figure 3-8 was updated in Rev 01m.

Table 2-2 was updated in Rev 01n.

Updates were made to Section 6.2 and Table 6-5 in Rev 02a.

Updates to Figures 3-7 and 6-4 were made in Rev 02b.

Updates to drawing numbers and chassis dimensional drawings in Rev 02c.

Updated to include KIT 3645DD and M15 frame size in Rev 02d.

Update to Figure 3-9, Sections 6.2, and 6.6 were made in Rev 02e.

Update to Table 6-1 in Rev 02f.

Figures 3-9 and 3-11 were updated in Rev 02g.

Figure 1-1: Typical M3645 Line Regen

M3645

8

1.4. SYMBOL CONVENTIONS USED IN THIS MANUAL AND ON

EQUIPMENT

Earth Ground or Protective Earth

AC Voltage

DC Voltage

DANGER!

DANGER: Electrical hazard - Identifies a statement that indicates

a shock or electrocution hazard that must be avoided.

DANGER!

DANGER: Identifies information about practices or circumstances

that can lead to personal injury or death, property damage, or

economic loss.

CAUTION!

CAUTION: Identifies information about practices or

circumstances that can lead to property damage, or economic

loss. Attentions help you identify a potential hazard, avoid a

hazard, and recognize the consequences.

CAUTION!

CAUTION: Heat or burn hazard - Identifies a statement regarding

heat production or a burn hazard that should be avoided.

User’s Manual

9

2. PRODUCT DESCRIPTION

Regenerated voltage occurs when the speed of the motor exceeds the set speed on the

drive. This can be due to braking or an overhauling load. In applications with extended

braking times, high horsepower, or where frequent regeneration occurs, the M3645 line

regen is the economical solution for controlling regenerative voltage. While resistor

solutions waste regenerated energy as heat, the Bonitron M3645 line regen returns the

regenerated energy back to the input AC line.

The M3645 line regen synchronizes to the frequency of the incoming power line, allowing

it to automatically adapt to 50Hz or 60Hz input. As the DC bus rises above the AC line

peak, the M3645 redirects current from the DC bus into the AC line to limit the rise in bus

voltage and prevent overvoltage faults. The M3645 is current limiting and will

automatically fold back or shut down in the event that unsafe conditions are detected.

With the optional digital display, the current status of the M3645 is shown and fault records

are stored along with a lifetime count of regenerative energy.

Up to two line regen units can be run in parallel for high-power applications.

2.1. RELATED PRODUCTS

LINE REGEN

M3545 Single Phase or Three Phase Line Regen (<15A)

REGENERATIVE POWER SUPPLY

M3645P Regenerative DC Bus Power Supply (<375A)

EXTERNAL PANEL MOUNTED DIGITAL DISPLAY

KIT 3645DD External Display Kit (compatible only with “L” M3645 regen)

COMMON BUS DIODES

M3345CBM Sharing Diode

BRAKING RESISTORS

M3575R Standard Duty Braking Resistors (<30A)

M3775R Various Duty Load Banks (<1600A)

BRAKING TRANSISTORS

M3452 Heavy Duty Braking Transistor (<1600A)

M3575T Standard Duty Braking Transistor (<600A)

M3675T Low HP Braking Transistor (<10A)

M3645

10

2.2. PART NUMBER BREAKDOWN

Figure 2-1: Example of M3645 Part Number Breakdown

Base Model Number

The base model number for all line regen units is M3645.

VOLTAGE RATING

A code letter represents the 3-phase AC line input voltage to the regen module. The

voltage rating must be selected for the system voltage that will be applied. See Table

2-1 for available voltage ratings.

Table 2-1: Voltage Ratings

RATING CODE

VOLTAGE

L

230 - 240VAC

E

380 - 415VAC

H

460 - 480VAC

C

575 - 600VAC

CURRENT RATING

A 3-digit number represents the maximum continuous DC Current (Amps) the regen

module can regenerate.

The M10, M11, M12 frame sizes are capable of handling a 50% overload above this

current rating for 60 seconds. The M15 frame size is capable ofa 25% overload above

this current rating for 60 seconds.

300A IDENTIFIER

This single letter code is omitted except for 300A models.

Both a line reactor module and a line regen module are required for 300A models. A

single letter code is used for 300A model line regens to designate the line reactor and

the line regen.

Table 2-2: 300A Identifier

CODE

MODEL

DESCRIPTION

R

M3645-x300R

Line Reactor Module

T

M3645-x300T-M15

Line Regen Module

T

300A IDENTIFIER

CURRENT RATING

OPTIONS

VOLTAGE RATING

BASE MODEL NUMBER

CHASSIS STYLE

M3645

H

300

M15

D

User’s Manual

11

CHASSIS STYLE

The chassis style is determined by the current rating, and is represented by an

alphanumeric code as defined in Table 2-2. See Section 6.5 for chassis mounting and

dimensional outlines.

Table 2-3: Chassis Styles

CHASSIS CODE

CURRENT

DESCRIPTION

SIZE (H X WX D)

M10

30A

Open Chassis

20.0”x 10.0”x 10.1”

M11

50A

Open Chassis

22.0”x 11.3”x 10.6”

M12

100A

Open Chassis

24.0”x 12.0”x 12.1”

M15

300A

Open Chassis

26.0” x 13.9” x 11.1”

M15 Reactor

300A

Open Chassis

17.9” x 18.8” x 15.2”

See Section 6.5 for chassis mounting and dimensional outlines.

OPTIONS

Two display options are available.

Table 2-4: Option Codes

OPTION CODE

DESCRIPTION

D

Digital Diagnostic Display

L

Basic LED Indicators

NOTE: The KIT 3645DD external display is only compatible with “L” versions of the

M3645 line regen. Only a single display can be used for each line regen. The line

regen is unable to power more than a single display.

M3645

12

2.3. GENERAL SPECIFICATIONS CHART

Table 2-5: General Specifications

PARAMETER

SPECIFICATION

AC Line Voltage

Voltage Rating

50 or 60 Hz

Voltage Min

Voltage Max

L

207 VAC

253 VAC

E

342 VAC

418 VAC

H

414 VAC

506 VAC

C

518 VAC

600 VAC

DC Input Current

30-300A, continuous

150% of rating, 60 second overload for M10,

M11, M12 chasses

125% of rating, 60 second overload for M15

chassis

Control Voltage

Internal

Indicators

Power

Regen

Fault

Optional 4 line character display

Inputs

Enable 24VDC - 5mA

Fault Recall 24VDC –5mA

Outputs

Ready 200VDC - 100 mA

Operating Temp

0 to +40OC

Storage Temp

-20Oto +65OC

Humidity

Below 90%, non-condensing

Atmosphere

Free of corrosive gas or conductive dust

User’s Manual

13

2.4. GENERAL PRECAUTIONS AND SAFETY WARNINGS

DANGER!

HIGH VOLTAGES MAY BE PRESENT!

NEVER ATTEMPT TO OPERATE THIS PRODUCT WITH THE ACCESS

DOORS OR COVERS OPENED!

NEVER ATTEMPT TO SERVICE THIS PRODUCT WITHOUT FIRST

DISCONNECTING POWER TO AND FROM THE UNIT!

FAILURE TO HEED THESE WARNINGS MAY RESULT IN

SERIOUS BODILY INJURY OR DEATH!

CAUTION!

THIS PRODUCT WILL GENERATE HIGH AMBIENT TEMPERATURES

DURING OPERATION.

THIS PRODUCT SHOULD BE INSTALLED ON A NON-FLAMMABLE

SURFACE WITH CLEARANCES OF AT LEAST TWO INCHES IN ALL

DIRECTIONS.

ALWAYS ALLOW AMPLE TIME FOR THE UNIT TO COOL BEFORE

ATTEMPTING SERVICE ON THIS PRODUCT.

BEFORE ATTEMPTING INSTALLATION OR REMOVAL OF THIS

PRODUCT,BE SURE TO REVIEW ALL DRIVE AND/OR RESISTIVE

LOAD DOCUMENTATION FOR PERTINENT SAFETY PRECAUTIONS.

INSTALLATION AND/OR REMOVAL OF THIS PRODUCT SHOULD

ONLY BE ACCOMPLISHED BY A QUALIFIED ELECTRICIAN IN

ACCORDANCE WITH NATIONAL ELECTRICAL CODE OR

EQUIVALENT REGULATIONS.

ANY QUESTIONS AS TO APPLICATION, INSTALLATION OR SERVICE

SAFETY SHOULD BE DIRECTED TO THE EQUIPMENT SUPPLIER.

M3645

14

This page intentionally left blank

User’s Manual

15

3. INSTALLATION INSTRUCTIONS

CAUTION!

Installation and/or removal of this product should only be performed by a

qualified electrician in accordance with National Electrical Code or local

codes and regulations.

Proper installation of the M3645regen modules should be accomplishedfollowing the steps

outlined below. Be sure to refer to the AC drive instruction manual as these steps are

performed. Please direct all installation inquiries that may arise during the installation and

start-up of this product to the equipment supplier or system integrator.

3.1. ENVIRONMENT

The module should be installed in an area protected from moisture and falling debris.

Buildup of dust or debris may cause poor performance and possibly a failure.

Operating in a wet environment can pose a shock hazard. The recommended

temperature range for operating this module is 0 to +40C.

Device shall be installed in a Pollution Degree 2 environment.

3.2. UNPACKING

Upon receipt of this product, please verify that the product received matches the

product that was ordered and that there is no obvious physical damage to the unit. If

the wrong product was received or the product is damaged in any way, please contact

the supplier from which the product was purchased.

3.3. MOUNTING

3.3.1. M3645 LINE REGEN MOUNTING

The installation site for the M3645 line regen should be chosen with several

considerations in mind:

When mounting regen units in an enclosure, power dissipation should be taken

into account. Refer to Section 6.3 Watt Loss for details.

The unit requires a minimum clearance of two (2) inches in all directions around it

when not mounted near a heat source. Heat sources may increase necessary

clearances.

Unit should not be exposed to falling debris or condensation.

Once the installation site has been selected as outlined above, the unit should be

mounted in place.

The M3645 must be properly oriented for proper heat flow through the unit. The M3645

must be mounted with the rear surface of the unit to the mounting surface. The unit

may be mounted vertically (Figure 3-1D), or with its backplane down and parallel to

the ground (Figure 3-1A).

Do Not mount the unit on the underside of a mounting surface as shown in Figure 3-

1B.

Do Not mount the unit in a horizontal position with its side parallel to the mounting

surface or floor as shown in Figure 3-1C.

Do Not mount the unit in an upside-down position, as shown in Figure 3-1E.

Refer to Table 2-3: Chassis Styles to determine the chassis for the unit. Mounting

dimensions and provisions vary by unit chassis. See Figure 3-1 for mounting

orientation information and Section 6.6 for dimensional drawings.

M3645

16

Figure 3-1: M3645 Mounting Orientation

Figure 3-1A

Figure 3-1D

HORIZONTAL SURFACE

UP

UP

BONITRON

Figure 3-1B

Figure 3-1E

UP

HANGING UNDERSIDE

Fig B

UP

BONITRON

Figure 3-1C

UP

PARALLEL TO FLOOR

BONITRON BONITRON

User’s Manual

17

3.3.2. M3645-X300R LINE REACTOR MOUNTING

The installation of the M3645-x300R line reactor should be chosen with several

considerations in mind:

The M3645-x300R line reactor is only required when using the 300A rated

M3645 in the M15 chassis.

When mounting the line reactor in an enclosure, power dissipation should be

taken into account. Refer to Section 6.3 Watt Loss for details.

The unit requires a minimum clearance of two inches (2”) in all directions around

it when not mounted near a heat source. Heat sources may increase necessary

clearances.

Unit should not be exposed to falling debris or condensation.

The unit can be mounted in any orientation.

Once the installation site has been selected as outlined above, the unit should be

mounted in place. See Section 6.6 for dimensional drawings.

3.3.3. KIT 3645DD, EXTERNAL DISPLAY MOUNTING

The KIT 3645DD external display is comprised of the display board assembly (ASM

3645D3) and a 12 foot long cable (CBL 3660DD4-DI12). The installation should be

chosen with several considerations in mind:

The external display requires a cutout from the front panel. See Figure 6-6 for the

dimensional requirements for the cutout.

The display will attach to the front of the panel. The display is secured to the

panel with a screw in each corner.

The unit requires a minimum clearance of one (1) inch in all directions around it.

The unit should not be exposed to falling debris or condensation.

The 12 foot cable provided with the display must be attached to TB5 on the

control board of the M3645 and to TB3 on the ASM 3645D3 on the rear of the

display. See Figure 3-12.

Once the installation site has been selected as outlined above, the unit should be

mounted in place. See Section 6.6 for dimensional drawings.

NOTE: The KIT 3645DD is only compatible with “L” versions of the M3645 line regen.

Only a single display can be used for each line regen. The line regen is unable to

power more than a single display.

3.4. WIRING AND CUSTOMER CONNECTIONS

Be sure to review all pertinent AC drive and system documentation as well as the

information listed below before proceeding. Connection points and terminal numbers

of the AC drive will be found in the documentation provided with those units. See

Tables 3-1 thru 3-6 and Figures 3-2 thru 3-8 for connection details.

3.4.1. POWER WIRING

CAUTION!

Only qualified electricians should perform and maintain the interconnection

wiring of this product. All wiring should be in accordance with local codes.

DANGER!

Do NOT daisy chain the AC, DC, or ground connections between multiple

regen units. Each regen should have separate power and ground

connections.

M3645

18

Where possible, minimize the wire length between the regen and the

drive. The wire length should not exceed 10 feet.

Avoid routing and bundling theregen AC/DC wire with the drive AC PWM

motor output wiring.

3.4.1.1. 3-PHASE AC INPUT

Do not installchokes or reactors between the regen and the power source

besides the M3645-x300R. If the AC drive requires a line reactor, the

regen should be connected to the utility grid side.

If an isolation transformer is to be used, the regen AC input MUST be

connected to the same point as the drive AC input. The transformer

should meet the ratings shown in Table 3-1.

Table 3-1: Transformer Ratings

Model

Minimum kVA

Maximum

Impedance

L30

13.5 kVA

5.0%

E30

23 kVA

2.9%

H30

26.5 kVA

2.5%

C30

33 kVA

2.0%

L50

22 kVA

6.0%

E50

38 kVA

3.4%

H50

44 kVA

3.0%

C50

55 kVA

2.4%

L100

44 kVA

6.3%

E100

75.5 kVA

3.6%

H100

87.5 kVA

3.1%

C100

109.5 kVA

2.5%

L300

131 kVA

4.4%

E300

226.5 kVA

2.5%

H300

262 kVA

2.2%

C300

327.5 kVA

1.7%

Do not connect to a generator. For further details, contact Bonitron.

The regen units are not phase sensitive.

The AC line connections should have short-circuit current protection.

Recommended fuses are listed in Section 6.5.

3.4.1.2. INTER-MODULE WIRING FOR 300A ONLY

For M3645 rated for 300A an individual line reactor must be used in

front of each M3645-x300T transistor module. See Figure 3-10 for

wiring diagram.

The user must wire both the control AC wiring from the M3645-x300R

line reactor to the M3645-x300T transistor module.

The control wiring must be connected to the utility side of the M3645-

x300R and is phase sensitive.

User’s Manual

19

DANGER!

The AC control wiring to the M3645-x300T is phase sensitive. If the AC

control wiring is not in phase with power wiring catastrophic damage to

equipment will result.

3.4.1.3. DC BUS INPUT

The DC bus input may be connected to the DC bus of an AC drive, the

DC output of a diode sharing unit, or to a common DC bus. If a reactor

or choke are being used in the bus, make sure the actual connection is in

parallel with filter capacitors of the drive/inverter.

DANGER!

Never attach the DC bus input of the M3645 to braking terminals on the AC

drive, commonly marked “BR”. These terminals are intended for use with an

external resistor, and are not directly connected to the bus filter capacitors of

the drive. Damage may occur if these terminals are used.

Please refer to your AC drive manual or AC drive technical support department

for assistance with this connection.

3.4.1.4. GROUNDING

Using the ground stud provided, ground the chassis in accordance with

local codes. Typically, the wire gauge will be the same as is used to

ground the attached drive.

Table 3-2: Power Terminal Specifications - 30 Amp Unit –M10 Chassis

TERMINALS

FUNCTION

ELECTRICAL

RATINGS

WIRE SIZE

MINIMUM

WIRE SIZE

MAXIMUM

TORQUE

L1, L2, L3

AC line outputs

30A

8 AWG

2 AWG

32 lb-in

DC+, DC-

DC bus inputs

30A

8 AWG

2 AWG

32 lb-in

GND

Ground

10 AWG

1/0

50 lb-in

Table 3-3: Power Terminal Specifications - 50 Amp Unit –M11 Chassis

TERMINALS

FUNCTION

ELECTRICAL

RATINGS

WIRE SIZE

MINIMUM

WIRE SIZE

MAXIMUM

TORQUE

L1, L2, L3

AC line outputs

50A

4 AWG

2/0

120 lb-in

DC+, DC-

DC bus inputs

50A

4 AWG

2/0

120 lb-in

GND

Ground

8 AWG

1/0

50 lb-in

Table 3-4: Power Terminal Specifications - 100 Amp Unit –M12 Chassis

TERMINALS

FUNCTION

ELECTRICAL

RATINGS

WIRE SIZE

MINIMUM

WIRE SIZE

MAXIMUM

TORQUE

L1, L2, L3

AC line outputs

100A

1 AWG

2/0

120 lb-in

DC+, DC-

DC bus inputs

100A

1 AWG

2/0

120 lb-in

GND

Ground

6 AWG

1/0

50 lb-in

Note: All power wire should be selected to match or exceed the voltage rating of the unit.

Field wiring for terminals will be copper 75°Cwire only.

M3645

20

Figure 3-2: 30A, 50A, 100A Power Connections

NO CONNECTION

L1 L2 L3 + - GND

3ØAC INPUT DC BUS

Figure 3-3: 30A, 50A, 100A Connection Locations

USER

I/0

POWER CONNECTIONS

AC

SENSE

Table of contents

Other bonitron Controllers manuals

Popular Controllers manuals by other brands

Micronix

Micronix MMC-110 Series Reference manual

Marathon

Marathon SE350E instruction manual

Johnson Controls

Johnson Controls M9204-B 2Z Series installation guide

HID

HID VertX EVO V1000 installation guide

Rail King

Rail King Z-750 manual

HP

HP VXI Pentium 75000 Series Hardware installation and configuration guide

Dontek

Dontek V2 Series Installation instructions manual

Resol

Resol DeltaSol C/1 manual

PIETRO FIORENTINI

PIETRO FIORENTINI CIRVAL Operation & maintenance manual

Hach

Hach SC1500 user manual

Lutron Electronics

Lutron Electronics Energi Savr Node QS QSNE-4S10-D Programming guide

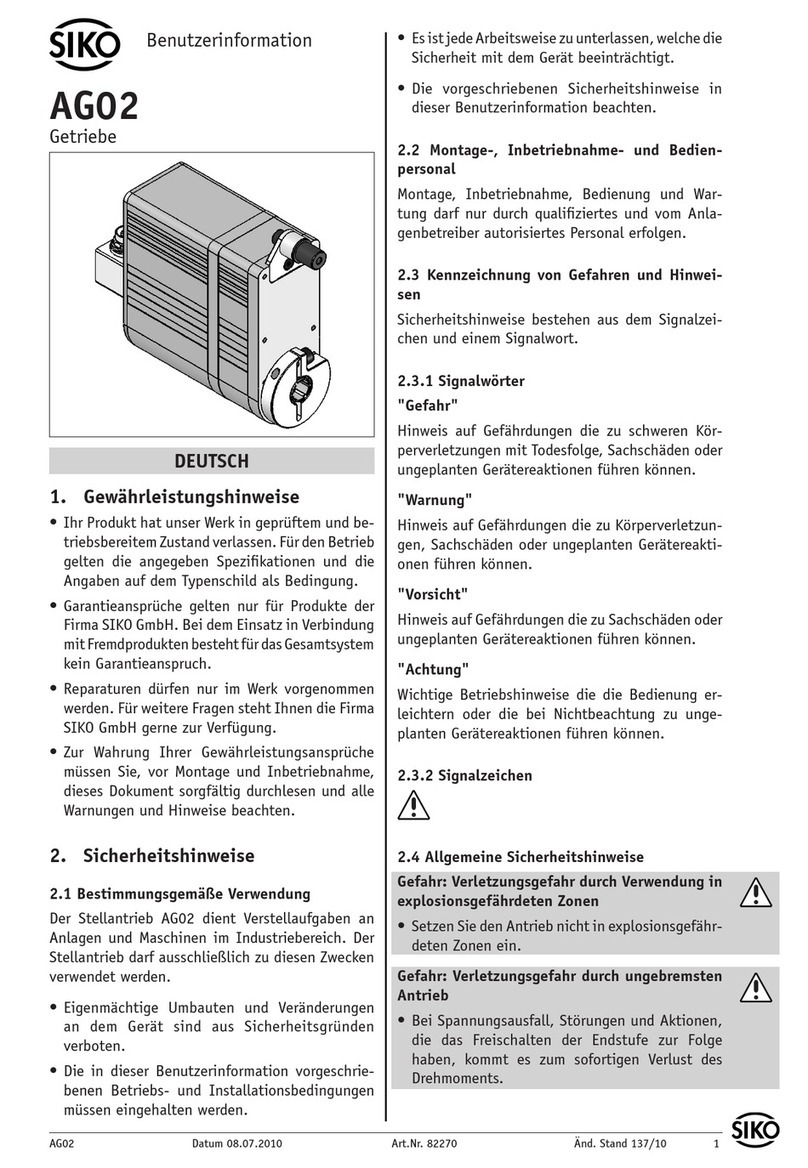

Siko

Siko AG02 User information