20.6○C

19

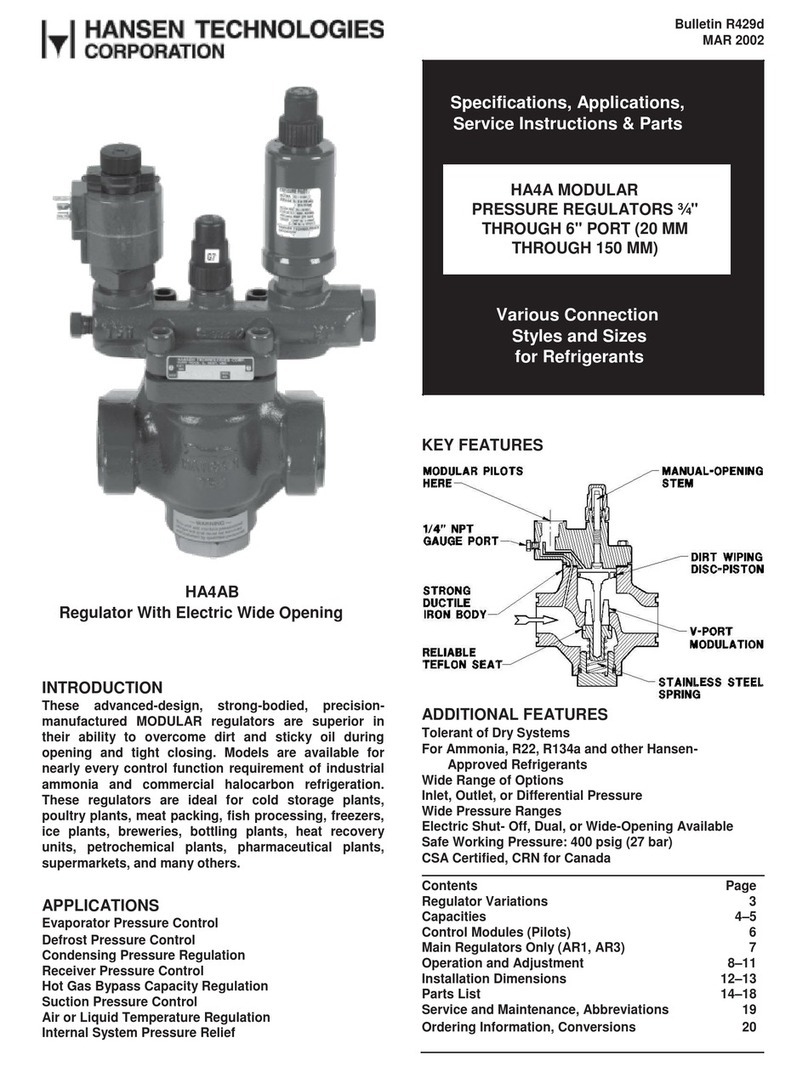

Screen Indication (PXVC-PT)

1 = Superheat/subcool value

2 = Actual pressure/temperature

Up

Increase SET POINT

(Parameter setting: SCROLL menu

options and parameters)

Center (POWER)

Press > 2 sec.: turn unit OFF.

(PXVC-PT default remote interlock ON

disables manual OFF)

(Parameter setting: ENTER to select

menu option, accept parameter change)

Large Digits

Display of

measured value

Small Digits

Display of set

point value

PI sequence

ramp-up delay

active

Indicators

Active alarm

Vertical Bar

Output Status

10% resolution

Left (ESC)

Select screen 1, 2 (PXVC-PT)

Parameter setting: Escape

menu, discard parameter value

Down

Decrease SET POINT

(Parameter setting: SCROLL menu

options and parameters)

Right (Option)

Instantaneous Press (< 2 seconds)

accept menu/parameter option (enter key)

Hold Button (> 2 seconds) clear

5PXVC

AUGUST 2018

MOUNTING CONSIDERATIONS:

Ensure the controller has adequate protective enclosure

for the environment, enclosure required for wet or

condensation prone environments. Ensure the controller

has adequate heating if the environment is below 32°F

(0°C). Controller may be surface mounted with two #4

screws or controller may be mounted to a DIN rail

SYSTEM STARTUP:

1. During operation the power button is not available

to be used to stop the system, so before starting the

controller connect a remote interlock and close the

circuit to disable the controller.

2. Power on the controller and verify the screen is

ashing to indicate the controller is not active. If the

interlock is not active, try operating the switch, if this

does not work power down the system and check the

controller jumpers, switch and wiring, contact Hansen

for further support.

3. Once interlock is disabled, verify the screen indicator

displays an underscore under the number “1,” as shown

in the user menus section. Screen #1, the default

screen, displays the measured value and the set point.

Screen two is available on all of the controllers, however

only the PXVC-PT offers additional information in the

form of temperature and pressure readings.

4. Pressing the up or down arrows will increase or

decrease the set point

5. Pressing the left arrow will either escape (go back)

from a menu or if at the main menu show the second

screen on PXVC-PT models. On other models Hansen

recommends only utilizing screen 1.

6. Set the controller to the desired set point, and wait

for the controller to approach the desired set point

(%, degrees, PSI).

7. Operating conditions should be monitored closely

during startup, and the interlock may be used if

necessary to stop the controller

8. The remote interlock should be connected to the

control system and used to disable the controller for

any applicable conditions, including but not limited

to: Defrost cycles, System Shutdown, etc.

USER MENUS

CHANGING PARAMETERS:

1. Press UP/DOWN buttons simultaneously for three

seconds. The display will show rmware version and

hardware revision number. Press the OPTION button

to start login.

2. CODE is shown in small digits display.

3. Select the relevant Parameter Access Code using UP/

DOWN (refer to controller subsections with parameter

listings)

4. Press OPTION button after selecting the correct code.

5. Select the parameter required with the UP/DOWN

buttons. Change a parameter value by pressing the

OPTION button. Three arrows are displayed to indicate

that the parameter may be modied. Use UP/DOWN

buttons to adjust the value.

6. Upon completion press the OPTION button to save the

new value and return to menu selections (three arrows

should disappear), pressing the POWER button will

discard changes without saving, press the esc button

to return to the next highest level menu

7. The POWER button may be used to exit the menu

as well, otherwise the unit will return to the default

screen when no button has been pressed for longer

than 5 minutes.

8. It is recommended that only personnel experienced

in control loops adjust control settings. There are

sets of control parameters (P and I values) for direct

acting and reverse acting controllers, if adjusting

the control parameters ensure you select the correct

parameter

PXVC UNIVERSAL CONTROLER

a. PXVC-(PT,DX,T) are direct acting controllers

meaning the output is directly related to the input

(temperature increases and valve opens)

b. PXVC-(P,L) are reverse acting controllers meaning

the output is inversely related to the input (level

or pressure drops and valve opens)