bonitron M3460 User manual

Model M3460

Ride-Thru

Voltage Regulator

Customer Reference Manual

Bonitron, Inc.

2

Bonitron, Inc.

Nashville, TN

An industry leader in providing solutions for AC drives.

ABOUT BONITRON

Bonitron designs and manufactures quality industrial electronics that improve the reliability of

processes and variable frequency drives worldwide. With products in numerous industries, and

an educated and experienced team of engineers, Bonitron has seen thousands of products

engineered since 1962 and welcomes custom applications.

With engineering, production, and testing all in the same facility, Bonitron is able to ensure its

products are of the utmost quality and ready to be applied to your application.

The Bonitron engineering team has the background and expertise necessary to design, develop,

and manufacture the quality industrial electronic systems demanded in today’s market. A strong

academic background supported by continuing education is complemented by many years of

hands-on field experience. A clear advantage Bonitron has over many competitors is combined

on-site engineering labs and manufacturing facilities, which allows the engineering team to have

immediate access to testing and manufacturing. This not only saves time during prototype

development, but also is essential to providing only the highest quality products.

The sales and marketing teams work closely with engineering to provide up-to-date information

and provide remarkable customer support to make sure you receive the best solution for your

application. Thanks to this combination of quality products and superior customer support,

Bonitron has products installed in critical applications worldwide.

Bonitron, Inc.

3

AC DRIVE OPTIONS

In 1975, Bonitron began working with AC inverter drive specialists at synthetic fiber plants to

develop speed control systems that could be interfaced with their plant process computers. Ever

since, Bonitron has developed AC drive options that solve application issues associated with

modern AC variable frequency drives and aid in reducing drive faults. Below is a sampling of

Bonitron’s current product offering.

WORLD CLASS PRODUCTS

Undervoltage Solutions

Overvoltage Solutions

Uninterruptible Power for Drives

(DC Bus Ride-Thru)

Voltage Regulators

Chargers and Dischargers

Energy Storage

Braking Transistors

Braking Resistors

Transistor/Resistor Combo

Line Regeneration

Dynamic Braking for Servo Drives

Common Bus Solutions

Portable Maintenance Solutions

Single Phase Power Supplies

3-Phase Power Supplies

Common Bus Diodes

Capacitor Formers

Capacitor Testers

Power Quality Solutions

Green Solutions

12 and 18 Pulse Kits

Line Regeneration

M3460

4

1. INTRODUCTION....................................................................................................................7

1.1. Who Should Use This Manual......................................................................................................7

1.2. Purpose and Scope........................................................................................................................7

1.3. Manual Revision...........................................................................................................................7

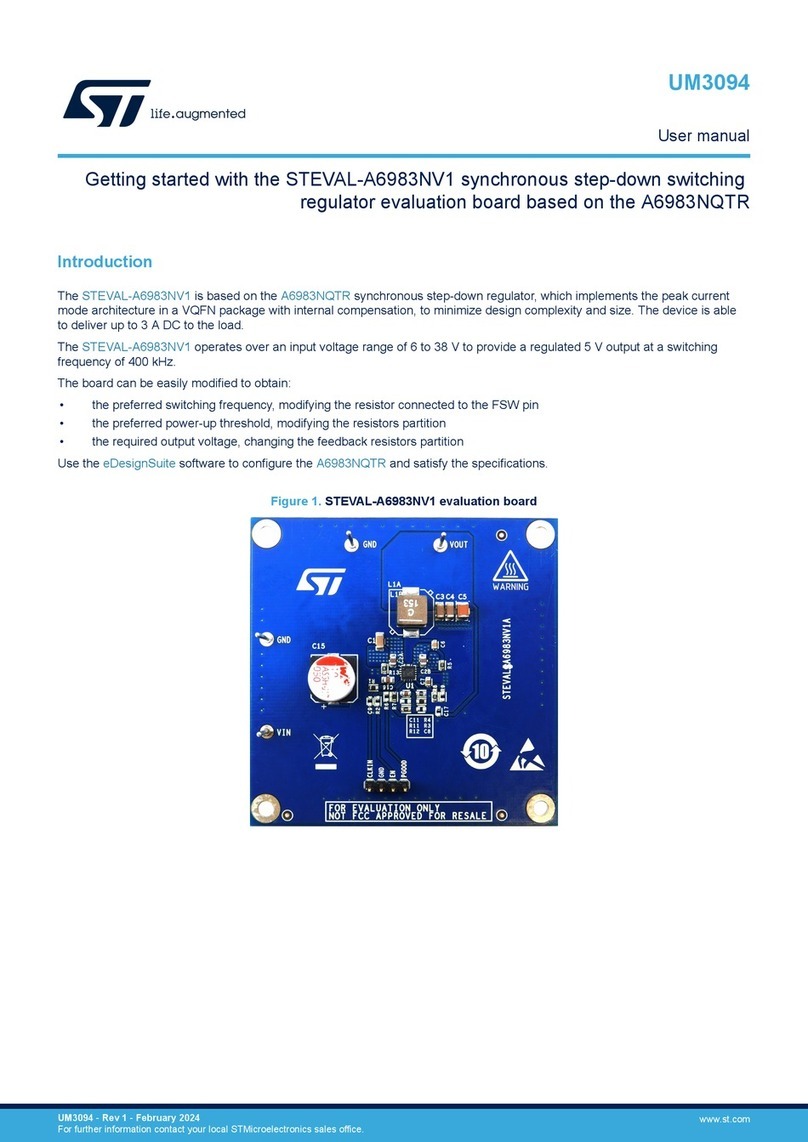

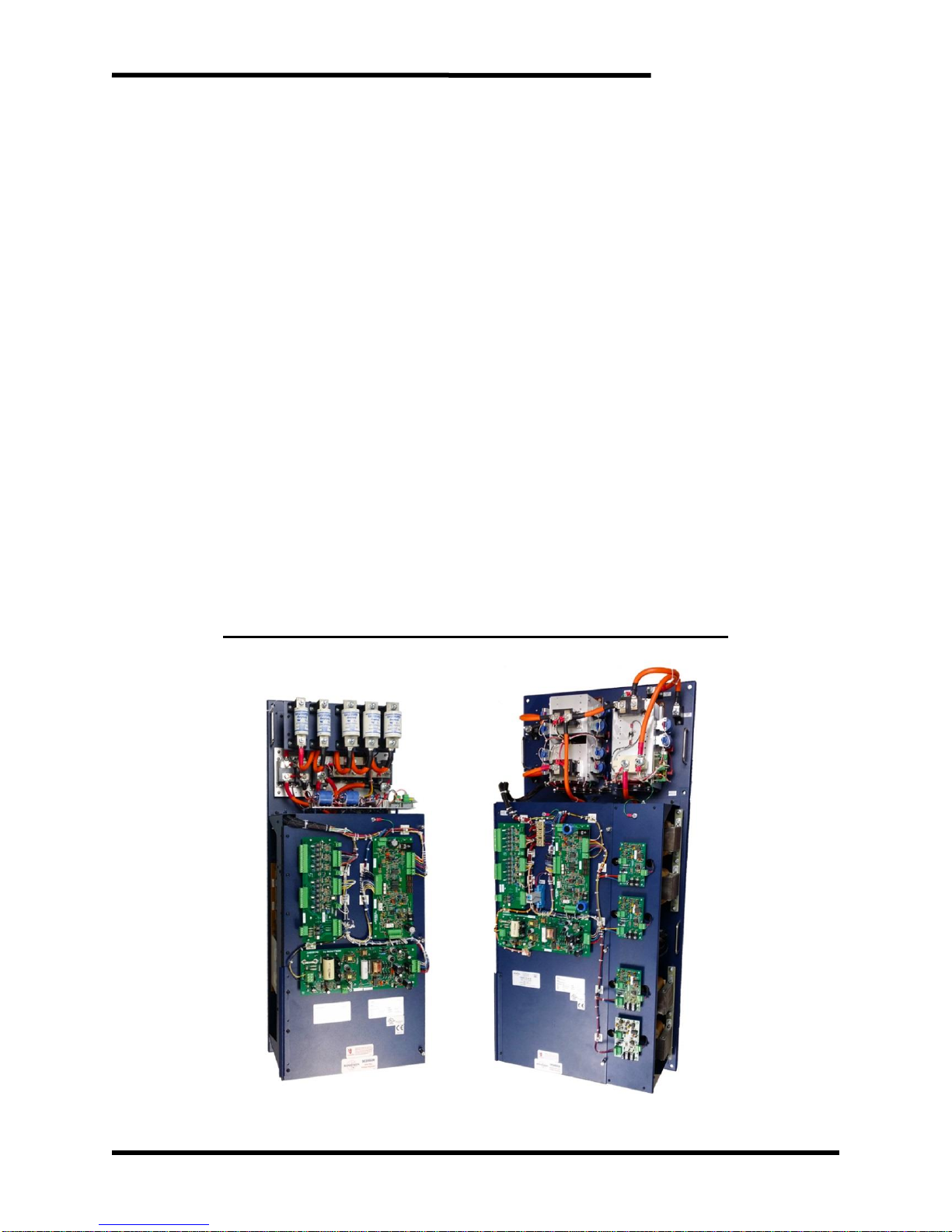

Figure 1-1: M3460R in R11 Chassis and M3460B in R2 Chassis...........................................................7

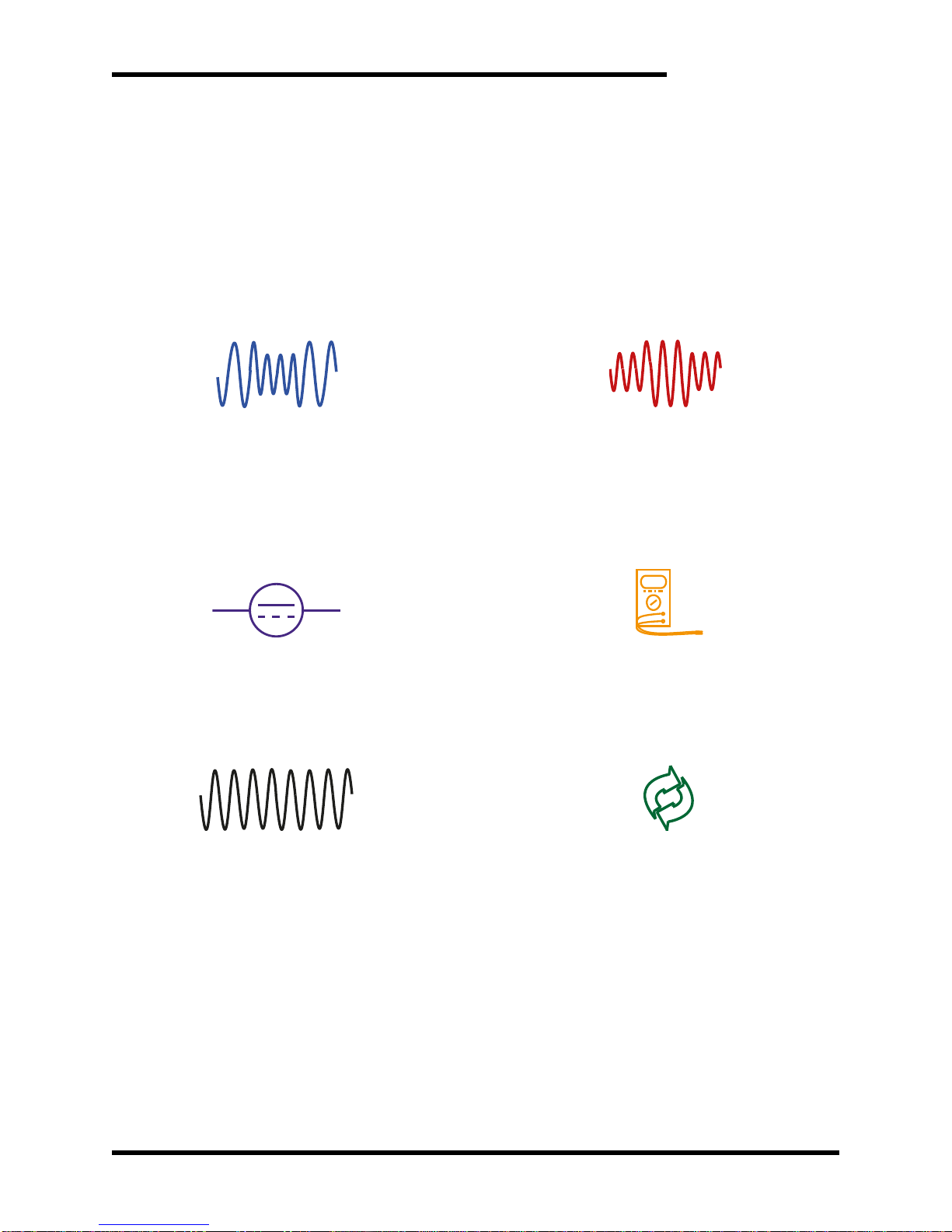

1.4. Symbol Conventions Used in this Manual and on Equipment.....................................................8

2. PRODUCT DESCRIPTION...................................................................................................9

2.1. Related Products and Documents.................................................................................................9

2.1.1. Products ............................................................................................................................................9

2.1.2. Documents ......................................................................................................................................10

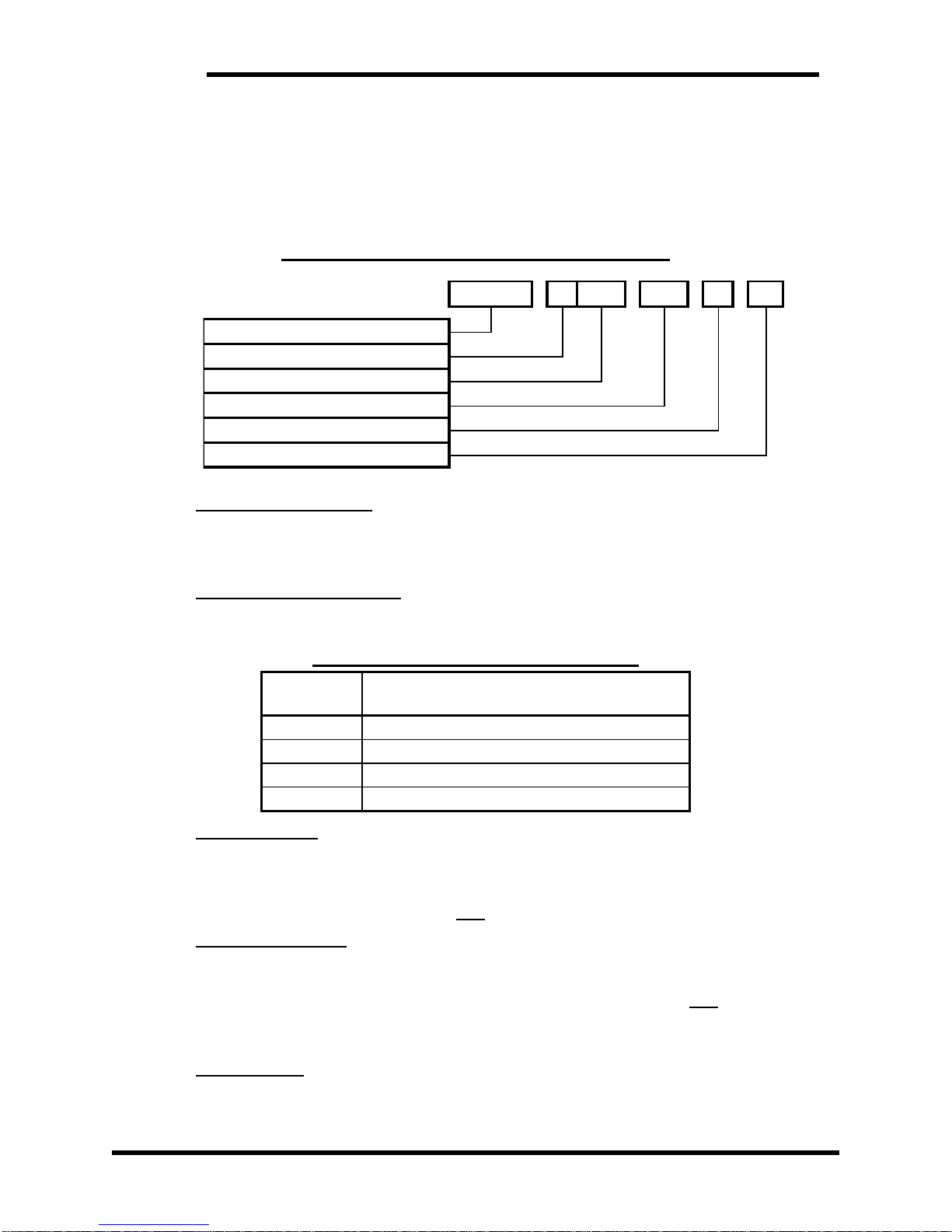

2.2. Part Number Breakdown ............................................................................................................10

Figure 2-1: Example of Part Number Breakdown..................................................................................10

Table 2-1: System Voltage Rating Codes ..............................................................................................10

Table 2-2: Chassis Size Codes ...............................................................................................................11

2.3. General Specifications................................................................................................................11

Table 2-3: M3460R General Specifications...........................................................................................11

Table 2-4: M3460B General Specifications...........................................................................................11

2.4. General Precautions and Safety Warnings .................................................................................12

3. INSTALLATION INSTRUCTIONS ...................................................................................13

3.1. Environment ...............................................................................................................................13

3.2. Unpacking................................................................................................................................... 13

3.3. Mounting ....................................................................................................................................13

3.4. Wiring and User Connections..................................................................................................... 13

3.4.1. Power Wiring..................................................................................................................................13

Table 3-1: M3460R Power Wiring Connections....................................................................................14

Table 3-2: M3460B Power Wiring Connections....................................................................................14

3.4.2. Control Interface and I/O Wiring....................................................................................................15

Table 3-3: User I/O Connections with 3460M6 Board ..........................................................................16

Table 3-4: User I/O Connections with 3660D1 Board...........................................................................17

Figure 3-1: M3460 Interconnections with DP10....................................................................................17

3.5. Typical Configurations...............................................................................................................18

Figure 3-2: M3460R Typical Configuration without Energy Storage....................................................18

Figure 3-3: M3460R Typical Configuration with Electrolytic Capacitor Storage Bank........................19

Figure 3-4: M3460R Typical Configuration with Ultracapacitor Storage Bank ....................................20

Figure 3-5: M3460B Typical Configuration with Battery Storage Bank ...............................................21

4. OPERATION .........................................................................................................................23

4.1. Functional Description ...............................................................................................................23

4.2. M3460R Operation for Full Outage Protection..........................................................................23

4.3. Operation Modes and Configuration..........................................................................................23

4.3.1. Normal Operation ...........................................................................................................................23

4.3.2. Test Mode .......................................................................................................................................23

4.4. I/O, Features, and Displays......................................................................................................... 24

Figure 4-1: 3460M6 Status Interface Board Layout...............................................................................24

Figure 4-2: 3460C1 Control Board Layout ............................................................................................24

Figure 4-3: 3460D5 Power Supply Board Layout (for 380V and 460V) ...............................................25

Figure 4-4: 3460D6 Power Supply Board Layout (for 575V)................................................................25

4.4.1. Input Terminals –3460M6 TB7 .....................................................................................................25

Table 4-1: 3460M6 Enable Input Logic Jumper Details........................................................................26

4.4.2. Output Terminals - 3460M6 TB5, TB6 ..........................................................................................26

Table 4-2: 3460M6 Status Output Signal Logic Jumper Details............................................................28

Table of Contents

5

4.4.3. Local I/O Power Supply - TB6 - 1, 9..............................................................................................28

4.4.4. Run Timeout Selection....................................................................................................................28

Table 4-3: Run Timeout Jumper Configurations....................................................................................28

4.4.5. Test Timer Selection.......................................................................................................................29

Table 4-4: Test Timer Jumper Configurations.......................................................................................29

4.4.6. Indicators.........................................................................................................................................29

4.4.7. Fan Timer........................................................................................................................................30

4.4.8. Display Options ..............................................................................................................................30

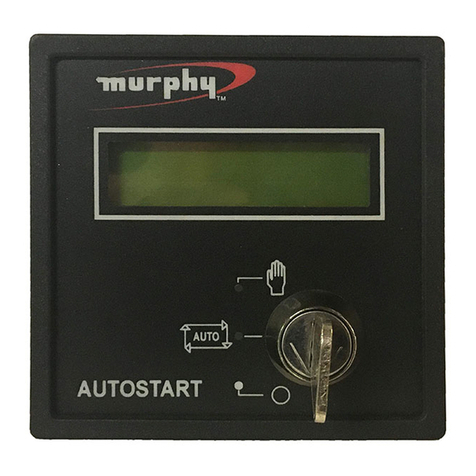

Table 4-5: Display Panel Configurations ...............................................................................................30

Figure 4-5: Display Panels.....................................................................................................................30

4.5. DC Bus Threshold Voltage Setting............................................................................................32

4.5.1. Determining the DC Bus Threshold Voltage Setting Directly (M3460R Models) .........................32

4.5.2. Determining the DC Bus Threshold Voltage Setting Directly (M3460B Models) .........................33

4.5.3. Determining the DC Bus Threshold Voltage Setting Using the Test Mode....................................33

4.5.4. Adjusting the DC Bus Threshold Voltage Setting ..........................................................................34

4.6. Input Undervoltage (IUV) Level Adjustment.............................................................................34

4.7. Output Undervoltage Level Adjustment.....................................................................................34

5. START-UP, MAINTENANCE AND TROUBLESHOOTING.........................................35

5.1. M3460R Start-up / Field Test Procedure....................................................................................35

5.2. M3460B Start-up / Field Test Procedure....................................................................................36

5.3. Maintenance Items......................................................................................................................37

5.3.1. Capacitor Replacement Recommendations.....................................................................................37

5.3.2. Capacitor Testing Procedure...........................................................................................................38

5.3.3. Cleaning..........................................................................................................................................38

5.3.4. Fans.................................................................................................................................................38

5.3.5. Heatsinks.........................................................................................................................................38

5.4. Troubleshooting..........................................................................................................................39

Table 5-1: Troubleshooting Guide .........................................................................................................39

5.5. Technical Help –Before You Call .............................................................................................40

6. ENGINEERING DATA ........................................................................................................41

6.1. Ratings........................................................................................................................................41

Table 6-1: M3460 kW Ratings...............................................................................................................41

Table 6-2: Factory Setpoints for DC Bus Threshold and Test Boost Voltages......................................41

Table 6-3: M3460R Minimum Input Voltages.......................................................................................41

Table 6-4: M3460B Battery Bank Typical Values.................................................................................41

Table 6-5: M3460R Model Specifications for 230 –480 VAC Systems...............................................42

Table 6-6: M3460B Model Specifications for 230 –480 VAC Systems...............................................42

Table 6-7: M3460R Model Specifications for 575 - 600 VAC Systems................................................43

Table 6-8: M3460B Model Specifications for 575 - 600 VAC Systems................................................43

6.2. Efficiency / Power Consumption................................................................................................43

6.3. Certifications ..............................................................................................................................44

6.3.1. Underwriters Laboratories Listing ..................................................................................................44

6.3.2. CE Conformity................................................................................................................................44

6.3.3. Third Party Certifications................................................................................................................44

6.4. Branch Circuit Protection and Wire Sizing................................................................................44

Table 6-9: M3460R Input Power Wiring Sizes and Fusing ...................................................................45

Table 6-10: M3460B Input Power Wiring Sizes and Fusing .................................................................45

6.5. Dimensions and Mechanical Drawings......................................................................................46

Figure 6-1: M3460-R10 Chassis Dimensional Outline..........................................................................46

Figure 6-2: M3460-R9 Chassis Dimensional Outline............................................................................47

Figure 6-3: M3460-R11 Chassis Dimensional Outline..........................................................................48

Figure 6-4: M3460-R2 Chassis Dimensional Outline............................................................................49

Figure 6-5: DD5 Digital Display Cutout and Mounting Dimensions.....................................................50

M3460

6

Figure 6-6: DP10 Display Cutout and Mounting Dimensions ...............................................................50

7. APPENDICES........................................................................................................................51

7.1. M3460 Installation Considerations.............................................................................................51

7.2. Specifying an Ultracapacitor Storage Bank for Full Outage Protection With M3460R Models 51

7.2.1. Energy Required for Outage ...........................................................................................................53

7.2.2. Minimum Capacitor Bank Voltage .................................................................................................53

7.2.3. Peak Current....................................................................................................................................53

7.2.4. Capacitor Specifications .................................................................................................................53

7.2.5. Minimum Series String ...................................................................................................................54

7.2.6. Available Joules..............................................................................................................................54

7.3. Steering Diode Sharing with a Bonitron M3460 Ride-Thru.......................................................55

Figure 7-1: Diode Sharing Example.......................................................................................................56

7.4. Sag Only Installations & Circulating Currents...........................................................................57

Figure 7-2: M3460R Typical Configuration without Energy Storage....................................................57

Figure 7-3: M3460R Typical Configuration with Current Flow............................................................58

Figure 7-3: M3460R Typical Configuration with Current Flow with affected SCR Highlighted..........59

Figure 7-4: M3460R Typical Configuration with Ultracapacitor Storage Bank ....................................60

User’s Manual

7

1. INTRODUCTION

1.1. WHO SHOULD USE THIS MANUAL

This manual is intendedfor use by anyone who is responsible for integrating, installing,

maintaining, troubleshooting, or using this equipment with any AC drive system.

Please keep this manual for future reference.

1.2. PURPOSE AND SCOPE

This manual is a user’s guide for the model M3460 ride-thru voltage regulator. It will

provide the user with the necessary information to successfully install, integrate, and

use this in a variable frequency AC drive system.

In the event of any conflict between this document and any publication and/or

documentation related to the AC drive system, the latter shall have precedence.

1.3. MANUAL REVISION

Figures 3-2, 3-3, 3-4, and 3-5 were updated in Rev 00d.

Manual template was updated in Rev 00e

Section 7.4 Application Note for Circulation Currents was added in Rev 00f.

Figure 6-5 was updated in Rev 00g

Updates to Section 5.4 and 7.2, and Figure 3-4 were made in Rev 00h.

The display options were updated in Rev 00i.

Updated tables 2-3, 2-4, 6-1, 6-2, 6-3, 6-4 and figures 6-1, 6-2, 6-3 in Rev 00j.

Update to include DD5 display in Rev 01a.

Figure 1-1: M3460R in R11 Chassis and M3460B in R2 Chassis

M3460

8

1.4. SYMBOL CONVENTIONS USED IN THIS MANUAL AND ON EQUIPMENT

Earth Ground or Protective Earth

AC Voltage

DC Voltage

DANGER!

DANGER: Electrical hazard - Identifies a statement that indicates

a shock or electrocution hazard that must be avoided.

DANGER!

DANGER: Identifies information about practices or circumstances

that can lead to personal injury or death, property damage, or

economic loss.

CAUTION!

CAUTION: Identifies information about practices or circumstances

that can lead to property damage, or economic loss. Attentions

help you identify a potential hazard, avoid a hazard, and

recognize the consequences.

CAUTION!

CAUTION: Heat or burn hazard - Identifies a statement regarding

heat production or a burn hazard that should be avoided.

User’s Manual

9

2. PRODUCT DESCRIPTION

Bonitron’s M3460 ride-thru voltage regulators provide protection from power quality events

for variable frequency drives (VFDs) that use a fixed rectifier and DC bus. The M3460R

provides sag protection for up to 2 seconds at 50% line sag on all 3 phases. It can also

provide protection from short term full outages of up to 2 seconds with the addition of

storage systems, such as capacitors. The M3460B, in conjunction with a battery bank,

provides full outage protection for up to 4 minutes at full power rating or 15 minutes at

50% power rating during a full outage.

Industries with continuous processes can suffer huge losses from equipment downtime,

loss of production, or damaged product when VFDs trip on under-voltage conditions.

Traditional UPS solutions are connected in series, which decreases the overall drive

system reliability. All Bonitron ride-thru products connect in parallel with the drive, thus

increasing system availability and reliability.

The M3460 regulates incoming voltage to the DC bus of the variable frequency drive. This

allows the drive to “ride through” these events while maintaining motor speed and torque

without experiencing drive shutdown.

ADVANTAGES

•Reliability

•Parallel connection to AC system

•M3460 maintenance can be done while normal process is on-line

•Works with almost any fixed bus, variable frequency, PWM drive

•Only 2-3 parallel connections

•Can use existing AC feed wiring and breakers

•Instant response

•Bumpless transfer

•Easy commissioning

2.1. RELATED PRODUCTS AND DOCUMENTS

2.1.1. PRODUCTS

S3460CR SERIES RIDE-THRU SYSTEMS

Complete systems that use electrolytic capacitor storage for short term power

outages.

S3460UR SERIES RIDE-THRU SYSTEMS

Complete systems that use ultracapacitor storage for short term power

outages.

S3460BR SERIES RIDE-THRU SYSTEMS

Complete systems that use batteries for longer term power outages.

M3534 SERIES RIDE-THRU MODULES

Voltage regulators used for sag or outage protection of lower power systems.

M3528 BATTERY AND ULTRACAPACITOR CHARGERS

Chargers for high voltage storage strings.

M3460

10

2.1.2. DOCUMENTS

Please refer to the KIT 3660DD5 manual when this unit is equipped with the

DD5 Digital Display option. This manual is available at www.bonitron.com or

by contacting Bonitron.

2.2. PART NUMBER BREAKDOWN

Figure 2-1: Example of Part Number Breakdown

- - - -

F

Fusing

SystemVoltage Rating

Power Rating

Outage Duration

Chassis Size

M3460R

H

100

240

R9

Base Model Number

BASE MODEL NUMBER

The base model number for all ride-thru modules in this series rated for 2 second

operation is M3460R. The base model number for all ride-thru modules in this series

rated for 4-15 minute operation is M3460B.

SYSTEM VOLTAGE RATING

The M3460 is available in several input voltage ratings. This rating is indicated by a

code as shown in Table 2-1.

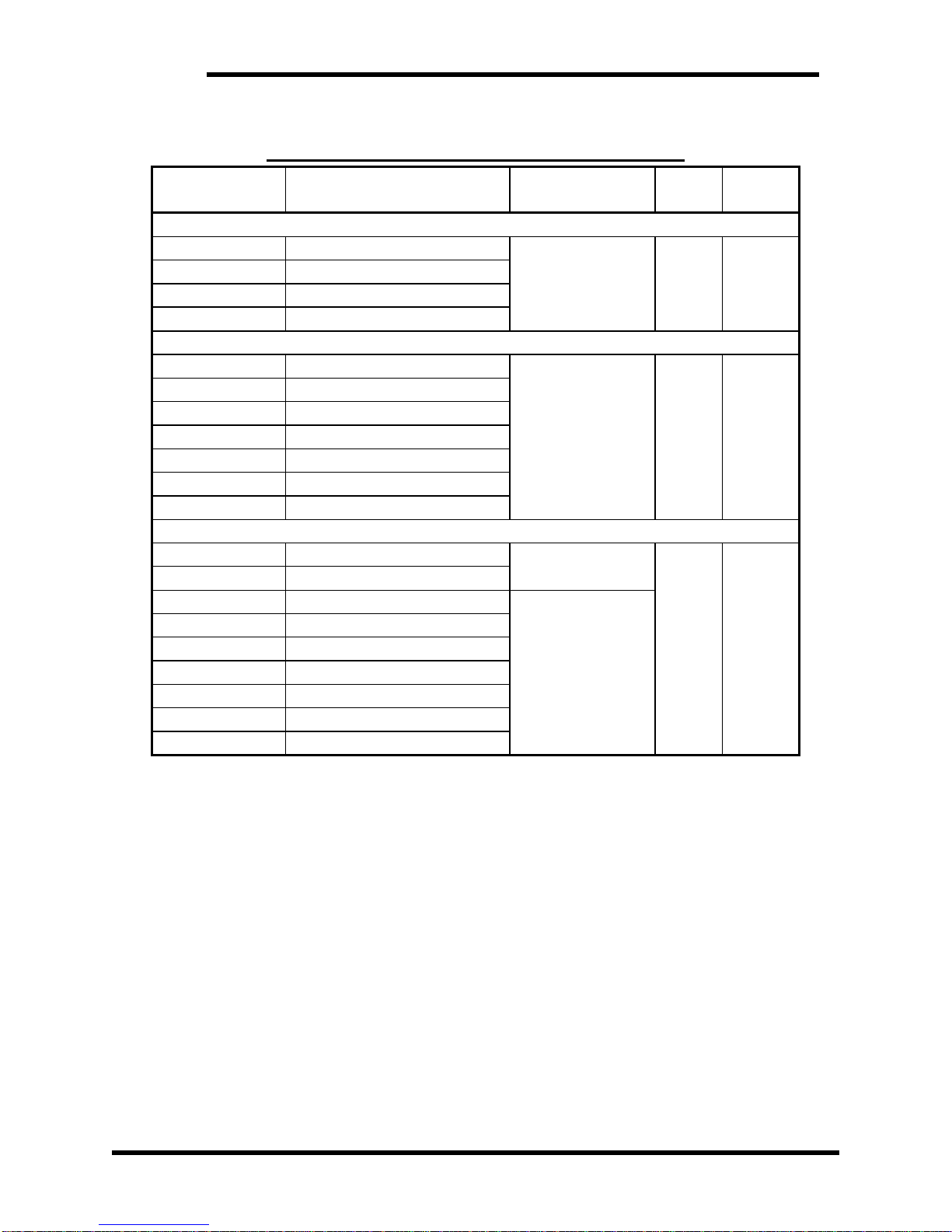

Table 2-1: System Voltage Rating Codes

RATING

CODE

NOMINAL VOLTAGE

(AC LINE /DRIVE BUS)

L

230 VAC / 325 VDC

E

380 - 415 VAC / 540 - 585 VDC

H

460 VAC / 650 VDC

C

575 - 600 VAC / 810VDC

POWER RATING

The power rating indicates the maximum power in kilowatts that can safely be handled

by the M3460 and is represented by a 3-digit value based on the nominal DC system

voltage rating and the maximum output current rating of the M3460. For instance, the

rating code for a 100kW M3460 is 100.

OUTAGE DURATION

The outage duration indicates the amount of time (in seconds) the M3460B module is

able to hold the DC bus at the threshold level while loaded to the rated current. This

duration is directly represented by a 3-digit value. For example, 240 in this position,

represents 240 seconds (4 minutes) of outage duration.

This code is omitted on M3460R models.

CHASSIS SIZE

Four open-backplate chassis sizes are indicated by a code as shown in Table 2-2.

This chassis size is determined by the current rating of the unit.

User’s Manual

11

Table 2-2: Chassis Size Codes

CHASSIS SIZE CODE

DIMENSIONS (H X WX D)

3460R

3460B

R10

28.00” x 16.00” x 13.50”

85-127 A

85 A

R9

34.00” x 16.00” x 13.50”

170 A

127-170 A

R11

44.00” x 15.25” x 13.50”

255-425 A

-

R2

52.00” x 24.00” x 12.50”

-

255-340 A

FUSING

The M3460R comes with internal fusing. This code is omitted on all M3460B models

and M3460R models if internal fusing is not desired.

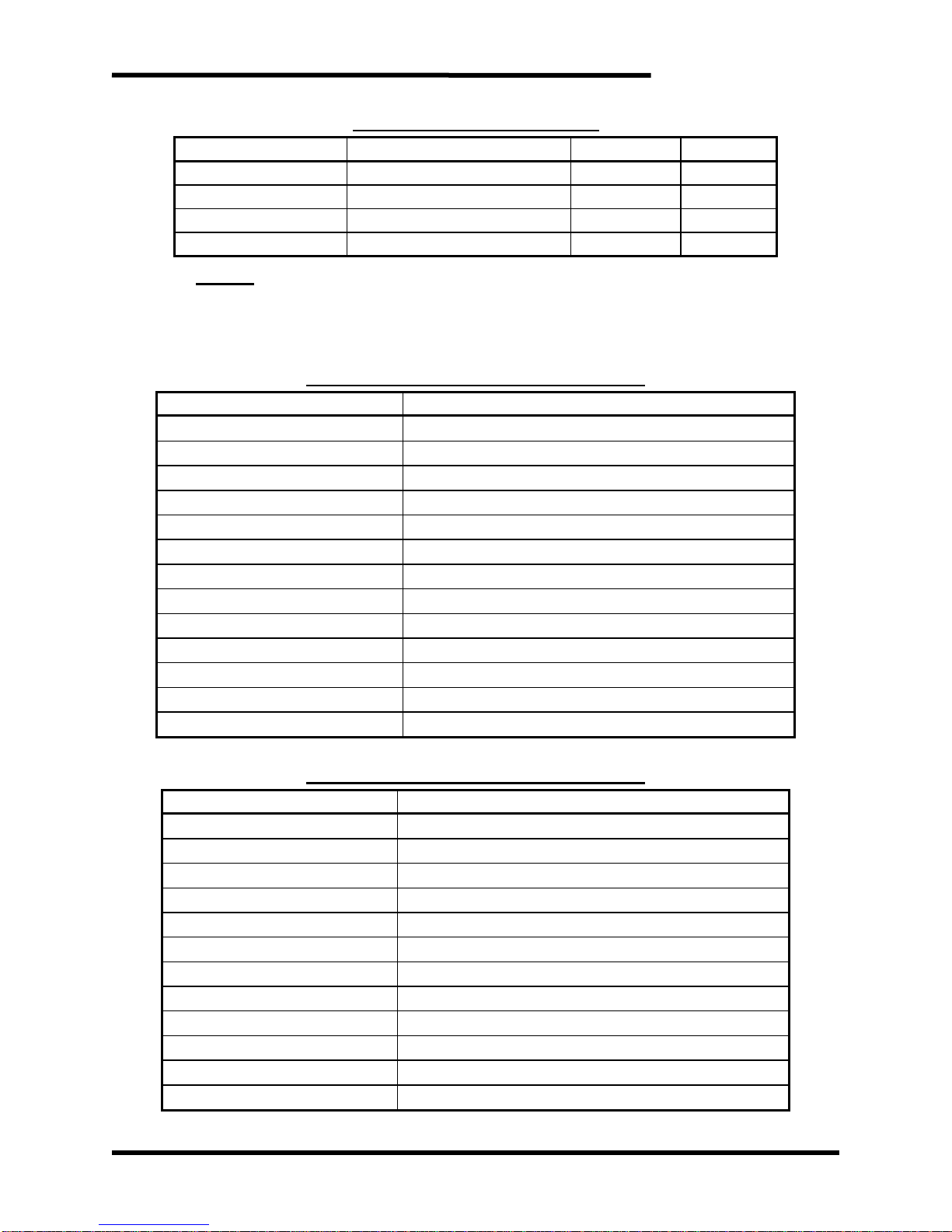

2.3. GENERAL SPECIFICATIONS

Table 2-3: M3460R General Specifications

PARAMETER

SPECIFICATION

Input AC Voltage

208 –575 VAC

Input DC Voltage

200 –675 VDC

Output DC Voltage

265 –810 VDC

DC Bus Current Rating

85 –425 ADC

Power Rating

25 –305 kW

Inactive Power Consumption

<200W

Duty Cycle (Full Load)

1%

Sag/Outage Duration

2 seconds

Enclosure Rating

Open

Operating Temperature

0 to +40ºC

Storage Temperature

-20 to +65 ºC

Humidity

Below 90% non-condensing

Atmosphere

Free of corrosive gas and conductive dust

Table 2-4: M3460B General Specifications

PARAMETER

SPECIFICATION

Input DC Voltage

200 –675 VDC

Output DC Voltage

265 –810 VDC

DC Bus Current Rating

85–340 ADC

Power Rating

25 –245 kW

Inactive Power Consumption

<200W

Duty Cycle (Full Load)

1%

Sag/Outage Duration

4 minutes at full power or 15 minutes at 50% power

Enclosure Rating

Open

Operating Temperature

0 to +40ºC

Storage Temperature

-20 to+ 65 ºC

Humidity

Below 90% non-condensing

Atmosphere

Free of corrosive gas and conductive dust

M3460

12

2.4. GENERAL PRECAUTIONS AND SAFETY WARNINGS

DANGER!

•HIGH VOLTAGES MAY BE PRESENT!

•NEVER ATTEMPT TO OPERATE THIS PRODUCT WITH THE

ENCLOSURE COVER REMOVED!

•NEVER ATTEMPT TO SERVICE THIS PRODUCT WITHOUT FIRST

DISCONNECTING POWER TO AND FROM THE UNIT.

•ALWAYS ALLOW ADEQUATE TIME FOR RESIDUAL VOLTAGES TO

DRAIN BEFORE OPENING THE ENCLOSURE.

•FAILURE TO HEED THESE WARNINGS MAY RESULT IN

SERIOUS INJURY OR DEATH!

CAUTION!

•CERTAIN COMPONENTS WITHIN THIS PRODUCT MAY GET HOT

DURING OPERATION.

•ALWAYS ALLOW AMPLE TIME FOR THE UNIT TO COOL BEFORE

ATTEMPTING SERVICE ON THIS PRODUCT.

•INSTALLATION AND/OR REMOVAL OF THIS PRODUCT SHOULD

ONLY BE ACCOMPLISHED BY A QUALIFIED ELECTRICIAN IN

ACCORDANCE WITH NATIONAL ELECTRICAL CODE OR

EQUIVALENT REGULATIONS.

•BEFORE ATTEMPTING INST ALLATION OR REMOVAL OF

THIS PRODUCT ,BE SURE TO REVIEW ALL SYSTEM

DOCUMENTATION FOR PE RTINENT SAFETY

PRECAUTIONS.

•NO USER-SERVICEABLE PARTS ARE CONT AINED

WITHIN THIS PRODUCT.INOPERABLE UNITS SHOU LD BE

REPLACED OR RETURNED F OR REPAIR.

•THIS PRODUCT DOES NOT PROVIDE MOTOR OVERLOAD

PROTECTION.

ANY QUESTIONS AS TO APPLICATION, INSTALLATION, OR SERVICE

SAFETY SHOULD BE DIRECTED TO THE EQUIPMENT SUPPLIER.

User’s Manual

13

3. INSTALLATION INSTRUCTIONS

The M3460 has an open frame construction. It is intended to be part of a larger variable

frequency drive system, and will require different hardware for interconnection based on

the installation. An appropriate enclosure may need to be provided to protect personnel

from contact and the system from damage. The enclosure may also need to protect the

equipment from the installation environment.

Please read this manual completely before designing the drive system or enclosure layout

to ensure all required elements are included.

3.1. ENVIRONMENT

The maximum ambient operating temperature of the M3460 should not exceed 40C.

Temperatures above this can cause overheating during operation.

The standby heat production of the M3460 is quite low, but can generate significant

heat during boosting. This is only of concern with the M3460B models because the

M3460R run time of 2 seconds will not allow the system to reach thermal equilibrium,

and should not cause thermal issues.

Non-condensing, filtered air may be required to cool the system if other components

cause excessive heat buildup in the enclosure.

3.2. UNPACKING

Inspect the shipping crate and M3460 for damage.

Notify the shipping carrier if damage is found.

3.3. MOUNTING

Mounting dimensions can be found in Section 6.5.

1. Lift M3460 backplate off the crate bottom using the 4 handles. Eyebolts

may be installed in the mounting holes for lifting with hooks or chains.

2. Install the module to the backplate. Secure the M3460 backplate to the

rack using the backplate’s ½” diameter mounting holes. Mounting

hardware is not supplied with the M3460. The power input terminals will

be at the top of the installation.

3. If supplied, install the display panel in an appropriate location.

3.4. WIRING AND USER CONNECTIONS

Review this entire section before attempting to wire the M3460.

3.4.1. POWER WIRING

DANGER!

THE M3460CAN HAVE MULTIPLE POWER SOURCES,INCLUDING THE MAIN AC INPUT,

ENERGY STORAGE SYSTEMS AND THE DC CONNECTION TO THE VFD.

ENSURE THAT ALL SOURCES ARE DISCONNECTED AND LOCKED OUT BEFORE

ATTEMPTING SERVICE OR INSTALLATION.

FAILURE TO HEED THESE WARNINGS MAY RESULT IN SERIOUS INJURY

OR DEATH!

This section provides information pertaining to the field wiring connections of

the M3460. Actual connection points and terminal numbers of the AC drive

system will be found in the documentation provided with the drive system.

Be sure to review all pertinent AC drive system documentation as well as the

connection details listed below before proceeding.

M3460

14

Table 3-1: M3460R Power Wiring Connections

TERMINAL

DESIGNATION

FUNCTION

WIRING

SPECIFICATION

CONNECTION

TORQUE

AC Line

L1, L2, L3

AC Input

600 VAC

3/8" stud

150 lb-in

Storage Bus

+ -

DC Input

600 VAC

Existing

Diode / SCR

Check Device

Datasheet

Drive Bus

+ -

DC Output

600 VAC

3/8" stud

150 lb-in

Ground

600 VAC

5/16" stud

75 lb-in

Table 3-2: M3460B Power Wiring Connections

TERMINAL

DESIGNATION

FUNCTION

WIRING

SPECIFICATION

CONNECTION

TORQUE

Storage Bus

+ -

DC Input

600 VAC

3/8" stud

150 lb-in

Drive Bus

+ -

DC Output

600 VAC

3/8" stud

150 lb-in

Ground

600 VAC

5/16" stud

75 lb-in

Main power connections should be made with copper wire; use compression

fitting lugs. Wire sizing should be appropriate for the current being carried.

System ratings are listed in Section 6.1.

M3460 ride-thru units only provide full currents for a limited amount of time.

Therefore, wire heating is not as much a concern as mechanical strength.

3.4.1.1. AC LINE (L1, L2, L3) CONNECTIONS

The AC input to the M3460R can temporarily reach up to 200% of the

normal input current during a power quality event. Size the upstream

current protection devices accordingly, so that the incoming AC will not

be interrupted by the temporary power draw.

During a power quality event, the AC input to the drive will not be drawing

current. Sizing the incoming AC feed to supply both the drive and the

M3460R simultaneously is not necessary. Even though the input current

during a power quality event may be higher than the normal input current,

this temporary overload is allowed by most codes without upsizing the

normal AC feed bus.

Due to the increasedcurrents in the ACfeed during apowerquality event,

the total voltage drop of the incoming AC feed should be considered to

make sure the voltage doesn't dip too low.

If line chokes are to be used in the system, the M3460R must be installed

on the load side of these chokes. This minimizes the possibility of

circulating currents through the M3460R and converter section of the

VFD.

There is no needto connect theAC line to theM3460R if an ultracapacitor

bank is being used.The DC connectionsfrom theultracapacitor bank can

be made to any two of the AC line connections so that the existing fuses

User’s Manual

15

can be used for protection. Please note that one terminal will not be

connected. See Figure 3-4.

3.4.1.2. STORAGE BUS (+ -) CONNECTIONS

If an electrolytic capacitor bank is used with the M3460R, the input can

be attached directly to the diode bus bars marked Storage Bus. External

fusing between the capacitor bank and the M3460R is recommended.

The M3460B battery bank connections are made at the Storage Bus

terminal blocks at the top of the module.

Make sure the polarity is correct for these connections, as failure to do

so can cause severe damage to the system.

DANGER!

FOR SYSTEMS THAT HAVE DC STORAGE,ALWAYS MEASURE DC VOLTAGES AND

FOLLOW PROPER PRECAUTIONS TO ENSURE THEY ARE AT SAFE LEVELS BEFORE

MAKING CONNECTIONS.

3.4.1.3. DRIVE BUS (+ -) CONNECTIONS

The M3460 must have a DC bus connection directly to the DC bus filter

capacitors within the drives. Connections cannot be made through the

braking terminals or with precharge resistors or DC link chokes between

the output of the M3460 and the DC bus capacitors in the drive. Consult

the manufacturers' documentation or contact Bonitron for further

assistance.

Make sure the polarity is correct for these connections, as failure to do

so can cause severe damage to the system.

DANGER!

FOR SYSTEMS THAT HAVE DC STORAGE,ALWAYS MEASURE DC VOLTAGES AND

FOLLOW PROPER PRECAUTIONS TO ENSURE THEY ARE AT SAFE LEVELS BEFORE

MAKING CONNECTIONS.

3.4.1.4. GROUNDING REQUIREMENTS

All units come equipped with a ground stud that is connected to the

module chassis. Ground the chassis in accordance with local codes.

Typically, the wire gauge will be the same as is used to ground the

attached drive.

3.4.2. CONTROL INTERFACE AND I/O WIRING

Control wiring allows for remote enabling, testing, and monitoring of the

M3460. Some I/O is duplicated to allow for isolated monitoring; some have a

mutual common.

When a display system is used, the system status outputs on 3460M6 TB6 are

connected to the display. This leaves the outputs on 3460M6 TB5 available for

remote monitoring.

M3460

16

3.4.2.1. CONNECTIONS FOR BASE CONFIGURATION

Table 3-3: User I/O Connections with 3460M6 Board

3460M6

TERMINAL

FUNCTION

ELECTRICAL

SPECIFICATIONS

WIRE

AWG

TORQUE

INPUTS

TB7 –1

Enable/Disable Input +

24VDC, 20mA

16-12

4.5 lb-in

TB7 –2

Enable/Disable Input -

TB7 –3

Test Input +

TB7 –4

Test Input -

ISOLATED OUTPUTS

TB5 –1 & 2

Ride-Thru Ready (RTR)

250V / 120mA

16-12

4.5 lb-in

TB5 –3 & 4

Overtemperature (OT)

TB5 –5 & 6

Voltage Fault (VF)

TB5 –7 & 8

Fault (FLT)

TB5 –9 & 10

Precharge Complete (PCC)

TB5 –11 & 12

Ride-Thru Active (RTA)

TB5 –13 & 14

Input Undervoltage (IUV)

COMMON OUTPUTS

TB6 –1

Local I/O Supply +

24 VDC, 500 mA

16-12

4.5 lb-in

TB6 –9

Local I/O Supply -

TB6 –2

Precharge Complete (PCC)

250 V / 120 mA

TB6 –3

Voltage Fault (VF)

TB6 –4

Overtemperature (OT)

TB6 –5

Ride-Thru Ready (RTR)

TB6 –6

Ride-Thru Active (RTA)

TB6 –7

Input Undervoltage (IUV)

TB6 –8

Output Common

3.4.2.2. CONNECTIONS WITH DD5DIGITAL DISPLAY

When the KIT 3660DD5 digital display is used, some user connections to

the digital display interface are made on a different module than the

M3460. They are made to the 3660I4 interface module.

Refer to the KIT 3660DD5 manual for operational and functional details.

3.4.2.3. CONNECTIONS WITH DP10 ANALOG DISPLAY

When the M3460 is used with the DP10 analog display, the

interconnections are made through TB6 and TB7 on the 3460M6 board

and TB1 on the 3660D1 board.

User’s Manual

17

Table 3-4: User I/O Connections with 3660D1 Board

3660D1

TERMINAL

FUNCTION

ELECTRICAL

SPECIFICATIONS

WIRE

AWG

TORQUE

TB1 –1

Overtemperature (OT)

15 VDC, 15 mA

16

2.1 lb-in

TB1 –2

Voltage Fault (VF)

TB1 –3

Ride-Thru Active (RTA)

TB1 –4

Ride-Thru Ready (RTR)

TB1 –5

Pre-Charge Complete (PCC)

TB1 –6

Test

TB1 –7

Local I/O Supply -

15 VDC, 50 mA

TB1 –8

Local I/O Supply +

Figure 3-1: M3460 Interconnections with DP10

3660D1

J1 BA

TB4

V+

TB1

3460M6

8

7

6

5

4

3

2

1

COM

TEST

PCC

RTR

RTA

VF

OT

12345678 TB6

910

1234 TB7

1

2

3

4

5

24V+

PCC

VF

OT

RTR

RTA

SIG COM

24V COM

+-+-

M3460

18

3.5. TYPICAL CONFIGURATIONS

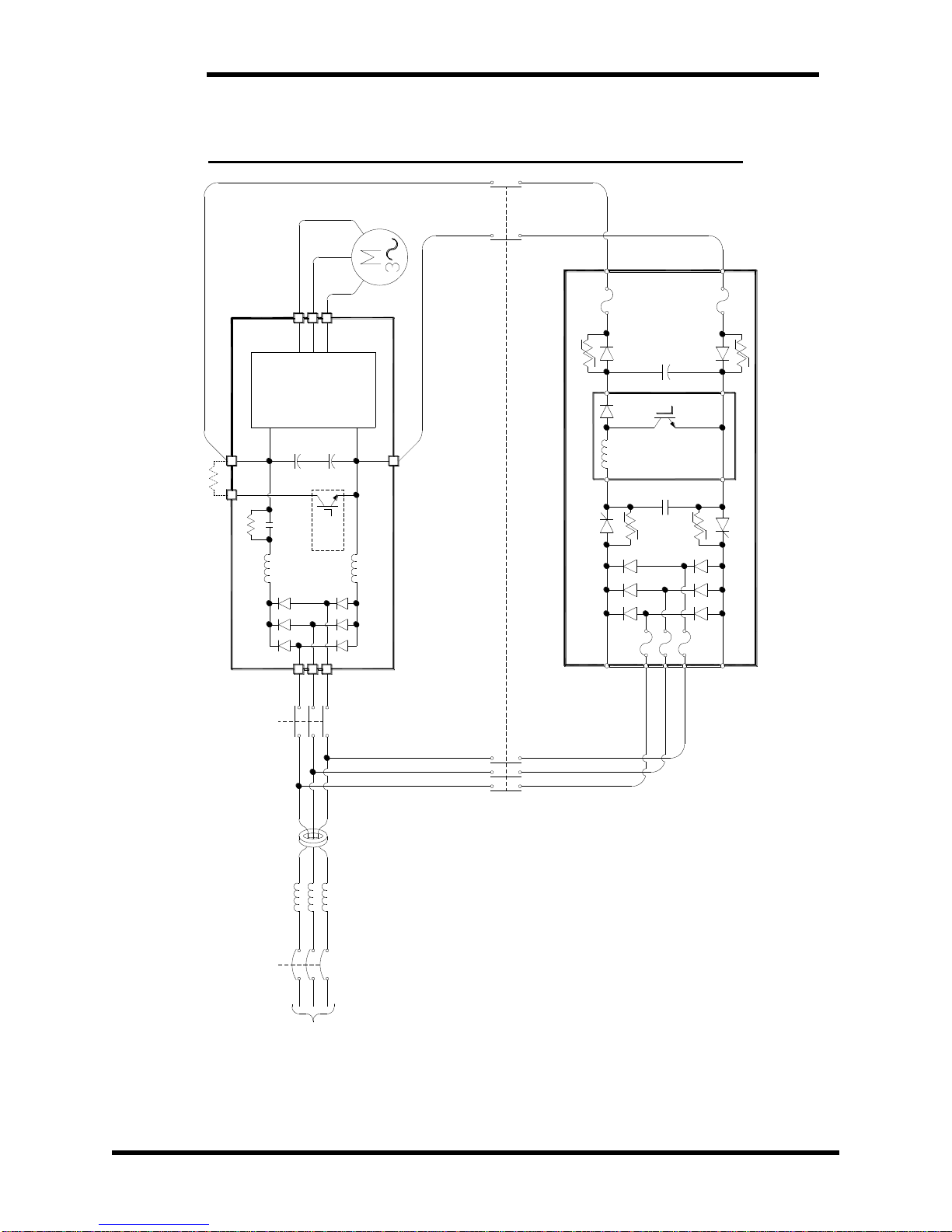

Figure 3-2: M3460R Typical Configuration without Energy Storage

FROM THE SAME FEED TRANSFORMER.

CONNECTED DOWNSTREAM.

2. IF LINE CHOKES ARE USED, RIDE-THRU MUST BE

1. INVERTER AND RIDE-THRU SHOULD BE POWERED

~NOTES~

CHOPPER

BRAKING

INTERNAL

VFD

INVERTER

BRAKING

RESISTOR

DISCONNECT

DRIVE

FEED

AC

CHOKES

LINE

GROUND

FAULT

SENSING

DISCONNECT

RIDE-THRU

M3460R

CHOPPER

+

-

+

-

DRIVE

BUS

STORAGE BUS

STORAGE BUS

User’s Manual

19

Figure 3-3: M3460R Typical Configuration with Electrolytic Capacitor Storage Bank

FROM THE SAME FEED TRANSFORMER.

CONNECTED DOWNSTREAM.

2. IF LINE CHOKES ARE USED, RIDE-THRU MUST BE

1. INVERTER AND RIDE-THRU SHOULD BE POWERED

~NOTES~

CHOPPER

BRAKING

INTERNAL

VFD

INVERTER

BRAKING

RESISTOR

DISCONNECT

DRIVE

FEED

AC

CHOKES

LINE

GROUND

FAULT

SENSING

DISCONNECT

RIDE-THRU

M3460R

CHOPPER

+

-

+

-

DRIVE

BUS

STORAGE BUS

STORAGE BUS

RESISTOR

DISCHARGE

ELECTROLYTIC

CAPACITORS

WITH PRECHARGE

ASM 3534EC

M3460

20

Figure 3-4: M3460R Typical Configuration with Ultracapacitor Storage Bank

KIT 3628T

DISCHARGER

M3628R

CHOPPER

BRAKING

INTERNAL

VFD

INVERTER

BRAKING

RESISTOR

DISCONNECT

DRIVE

FEED

AC

CHOKES

LINE

GROUND

FAULT

SENSING

M3528AC CHARGER

ULTRA CAP

ENERGY STORAGE

BANK

DISCONNECT

RIDE-THRU

M3460R

CHOPPER

+

-

+

-

+

-

DRIVE

RIDE-THRU

DISCONNECT

AUX. CONTACT

BUS

STORAGE BUS

STORAGE BUS

M

3

ISOLATION TRANSFORMER

FROM THE SAME FEED TRANSFORMER.

CONNECTED DOWNSTREAM.

2. IF LINE CHOKES ARE USED, RIDE-THRUMUSTBE

1. INVERTER AND RIDE-THRU SHOULD BE POWERED

~NOTES~

+

-

L1

L2

ASM 3460PS

IS LOWER THAN PCC VOLTAGE.

3. ASM 3460 PS WILL BE USED IF THE INPUT DC LEVEL

*OPTIONAL: SEE SECTION 7.2

Other manuals for M3460

1

Table of contents

Other bonitron Controllers manuals

Popular Controllers manuals by other brands

Fuji Electric

Fuji Electric CC-M instruction manual

RCTimer

RCTimer Ares F7 Quick reference manual

Rain Bird

Rain Bird ESP-Me user manual

United Technologies

United Technologies Carrier OPN-VAVB1 Installation and startup guide

Engineered air

Engineered air EngA M-TRAC4 User's operation manual

Chauvet

Chauvet Obey 6 user manual